文章编号:1004-0609(2015)-09-2517-06

Si3N4基微纳米复合陶瓷刀具的高速切削性能与磨损机理

吕志杰,杨广安,程凯强

(山东建筑大学 机电工程学院,济南 250101)

摘 要:

在亚微米Si3N4、TiC颗粒中添加纳米Si3N4、SiC颗粒,采用真空热压烧结工艺制备出STS微纳米复合陶瓷刀具,并对比STS刀具及FD-01刀具在PUMA200MA车削中心干切削淬硬40CrNiMo工件的切削性能。利用扫描电子显微镜(SEM)分析刀具前、后刀面的磨损形态,研究STS陶瓷刀具的磨损机理。结果表明:STS微纳米复合刀具材料具有较高的力学性能,抗弯强度达1000MPa,维氏硬度达19.5GPa。高速干切削40CrNiMo工件时,随着切削速度的增大,刀具后刀面磨损随之增大。切削速度越高,STS刀具优势越明显。两种刀具的磨损形态均主要为月牙洼磨损和后刀面磨损,磨损机制主要为磨粒磨损和粘结磨损。

关键词:

微纳米复合材料;陶瓷刀具;40CrNiMo;切削性能;磨粒磨损;

中国分类号:TG 711 文献标志码:A

Cutting performance and wear mechanism of Si3N4-based micro/nano composite ceramics tool in high speed cutting

Zhi-jie, YANG Guang-an, CHENG Kai-qiang

Zhi-jie, YANG Guang-an, CHENG Kai-qiang

(School of Mechanical and Electronic Engineering, Shandong Jianzhu University, Ji’nan 250101, China)

Abstract: Si3N4/TiC/SiC (STS) micro/nano composite ceramic tools were fabricated by vacuum hot pressing sintering technique using Si3N4 and TiC submicron particles by adding Si3N4 and SiC nanoparticles. The cutting performance of STS and FD-01 tools in dry high speed machining 40CrNiMo component was studied. The wear morphologies of rake and flank wear were observed by scanning electron microscopy (SEM). The wear characteristic and mechanism were discussed. The results show that STS micro/nano composite tool material has excellent mechanical properties. The flexural strength and hardness are 1000 MPa and 19.5 GPa, respectively. The flank wear increases with the increase of cutting speed in high speed dry machining 40CrNiMo workpiece. STS tool obtains smaller tool flank wear, longer tool life, and is more suitable for high speed cutting under the same cutting condition. The wear forms of both ceramic tools are crater and flank, and the wear mechanisms are mainly adhesive wear and abrasive wear.

Key words: micro/nano composite; ceramic tool; 40CrNiMo; cutting performance; adhesive wear

陶瓷刀具由于其独特的性能,在切削难加工材料方面显示出强大的优势。但陶瓷刀具材料硬脆性导致的低可靠性影响着陶瓷刀具的推广应用,高强度、高硬度和高韧性等一直是陶瓷刀具材料研究者追求的目标[1-3]。在微米粉体中加入适量纳米粉体,配以合理制备工艺,可获得较高力学性能的微纳米复合陶瓷刀具材料[4-5]。

Si3N4基陶瓷刀具热稳定性和抗热裂性高于Al2O3基陶瓷刀具,可用于加工各种淬硬钢和冷硬铸铁[6-7],具有较突出的断裂韧性, 切削时不易萌生裂纹。对于难加工材料,其切削性能明显优于传统硬质合金刀具的,在氧化皮切削、断续切削、湿式切削和端铣等场合,Si3N4基陶瓷刀具有稳定的切削性能[8-9]。Si3N4基陶瓷刀具材料可通过颗粒补强增韧、类晶须自增韧等方式获得较高的强度、硬度和抗热震性[10]。吕志杰等[11]通过在亚微米Si3N4中添加纳米TiC颗粒制备刀具材料,其维氏硬度16.9 GPa,抗弯强度900 MPa,断裂韧度7 M·Pam1/2。郑光明等[12]制备了Si3N4/Sialon梯度纳米复合刀具材料,维氏硬度16.9 GPa,抗弯强度900 MPa左右,断裂韧度达9 MPa·m1/2,并研究刀具在切削Inconel 718合金时的切削性能和磨损机理。比较而言,Si3N4基陶瓷刀具硬度普遍较Al2O3基陶瓷刀具低,耐磨性稍差[13]。

本文作者在亚微米Si3N4、TiC粉体中混合纳米Si3N4、SiC粉体,通过合理的分散和烧结工艺,制备出STS微纳米复合陶瓷刀具。相比Si3N4/TiC复合陶瓷刀具材料[11],STS复合陶瓷刀具材料利用颗粒增韧、Si3N4类晶须增韧及裂纹偏转等多种方式协同补强增韧,综合力学性能得到明显提高。对比STS陶瓷刀具与商品化刀具FD-01(Si3N4/TiC)加工淬硬40CrNiMo时的切削性能和磨损机理。

1 实验

1.1 刀具材料制备

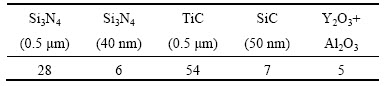

切削实验用STS陶瓷刀具材料采用0.5 μm Si3N4(纯度>99%,N含量≥37.5%,氧含量≤1.5%(质量分数))和0.5 μm TiC 粉末(纯度>99%,C含量≥19.5%,氧含量≤1.0%(质量分数))作为基体材料,添加40 nmSi3N4粉末(纯度>99.0%,总氧含量<0.62%(质量分数),非晶态,比表面积>115 m2/g)和50 nm SiC粉末(纯度>99.9%,非晶态,氧含量<1.0%(质量分数),比表面积>120 m2/g)。刀具材料组分配比如表1所示。

表1 STS刀具材料配比

Table 1 Constituents of STS micro/nano composite (mass fraction, %)

采用聚乙二醇PEG作为分散剂,辅以SB5200型超声波清洗器超声搅拌,对纳米粉末进行分散,制得均匀悬浮液并静置12 h。然后同亚微米粉末混合,装入滚筒搅拌8 h,真空干燥、过筛。将适量粉末装入涂抹BN的石墨模具,置于真空热压炉中在1750 ℃、30 MPa下进行热压烧结。取出圆饼,切割,在工具磨床上加工成所要求刀片。

1.2 实验过程

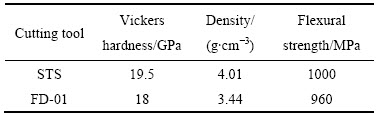

干切削实验在PUMA200MA车削中心进行。工件材料为40CrNiMo高强度淬硬钢(HRC58),棒料尺寸100 mm×400 mm。刀具材料的性能见表2。刀具的几何参数为前角γ0=-5°,后角α0=5°,主偏角κr=45°,刃倾角λs=-5°,刀尖圆弧半径rε=0.8 mm。

表2 陶瓷刀具STS与FD-01的性能

Table 2 Performances of STS and FD-01

实验中陶瓷刀具设定的切削参数分别为:v为200 m/min、250 m/min、300 m/min, f = 0. 1 mm/r,ap= 0.15 mm。

取后刀面磨损量为0.3 mm作为磨钝标准,以此时的切削时间作为刀具寿命。采用工具显微镜下测量刀具后刀面的磨损量值,用扫描电镜(SEM)观察刀具前、后刀面的磨损形态。

2 结果与分析

2.1 STS刀具的显微组织与力学性能

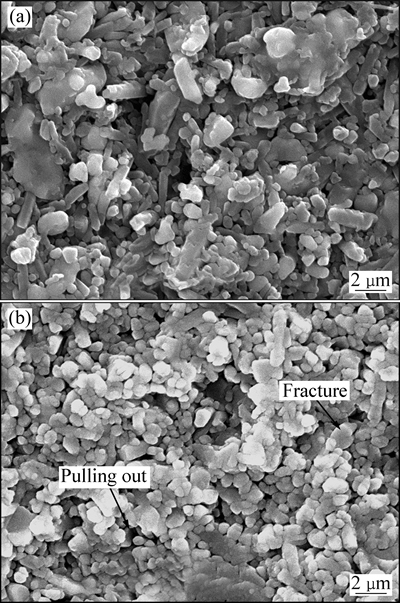

图1(a)所示为STS微纳米复合陶瓷刀具材料表面经400 ℃熔融NaOH腐蚀60 s后的SEM像。由图1(a)可见,β-Si3N4柱状晶发育较好,晶粒大小不一,呈现出明显纵横交错、相互嵌套的互锁结构。这种长柱状类晶须颗粒,可诱发原位自增韧机制[14]。不同直径和长径比的类晶须β-Si3N4晶粒可构成双峰分布。基体相的晶粒尺寸为0.2~1.2 μm,长径比为2~5。较粗大晶粒均匀地分布在细小的针状晶粒之间,晶粒结构比较规整,表面缺陷少。这样的结构晶粒堆积密实、孔隙少,容易产生裂纹的偏转、桥联与柱状晶粒的拔出效应,导致材料力学性能提高[15]。

图1(b)所示为STS材料横断面的SEM像。由图1(b)可见,熔融NaOH腐蚀后STS微纳米复合陶瓷材料的断裂方式为沿晶断裂和穿晶断裂的混合型。断口可观察到明显的Si3N4类晶须晶粒断裂、桥接、拔出留下的孔洞等,提供了额外的能量耗散途径,导致类晶须原位自增韧效果,相比外部施加增韧相的制备方法,原位自增韧方式具有制备成本低和材料热稳定性好的特点。

图1 STS微纳米复合表面和材料横断面的SEM像

Fig. 1 SEM images of surface (a) and crack section (b) of STS micro/nano composite material

亚微米Si3N4和TiC粉体中添加纳米Si3N4、SiC颗粒,在真空热压烧结过程中,充分弥散的纳米颗粒,可以抑制基体晶粒的异常长大,使复合材料组织结构均匀细化,也可在基体形成晶内型结构,改善基体内的应力状态,提高陶瓷材料的力学性能。类晶须增韧、颗粒弥散强化、裂纹偏转等机制协同作用,使STS微纳米复合材料的综合力学性能得到了明显提高。

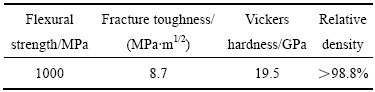

制备材料的力学性能如表3所示。由表3可见,STS微纳米复合陶瓷刀具材料的性能比微米Si3N4添加纳米TiC颗粒烧结制备的刀具材料综合力学性能有较大提高[16]。

表3 STS微纳米复合刀具材料的力学性能

Table 3 Mechanical properties of STS micro/nano composite

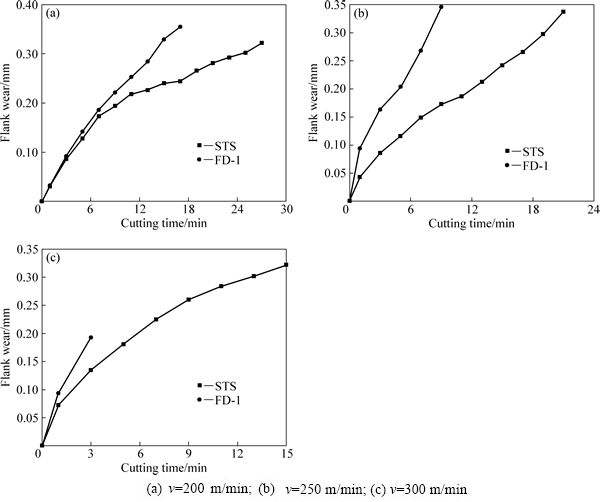

图2 f=0.1 mm/r和ap=0.15 mm时后刀面磨损与切削时间的关系

Fig. 2 Relationship between flank wear evolution and cutting time on flank at f=0.1 mm/r, ap=0.15 mm and different velocities

2.2 刀具的切削性能

40CrNiMo钢的强度高、韧性大,切削刀具易产生磨损,使刀具的使用寿命大为缩短。当切削速度提高时,刀具-切屑的接触长度变短,刀尖接触面的压强较大,切削温度较高,工件与刀具间发生元素的扩散、粘结现象,导致部分刀具材料从基体剥落,进而产生磨损和破损。

图2所示为后刀面磨损与切削时间的关系。由图2(a)可看出,在v=200 m/min,f=0. 1 mm/r,ap=0.15 mm 条件下,陶瓷刀具达到后刀面磨损量为0.3 mm时,STS陶瓷刀片切削时间为FD-01陶瓷刀片的两倍。随着切削时间的增加,STS的磨损曲线斜率在12 min时变缓到最后近似呈一条30°的直线,而FD-01的整个磨损曲线近似直线。

从图2(b)可见,在v=250 m/min,f=0.1 mm/r,ap=0.15 mm条件下,刀具达到磨损标准时,STS陶瓷刀具的切削时间比FD-01陶瓷刀具的增加到近3倍。

由图2(c)可见,在v=300 m/min,f=0.1 mm/r,ap=0.15 mm条件下,STS陶瓷刀具切削时间达15 min时,后刀面磨损量为0.322 mm。而FD-01陶瓷刀片在切削3 min后即出现崩刃,无法继续切削。

2.3 刀具磨损机理

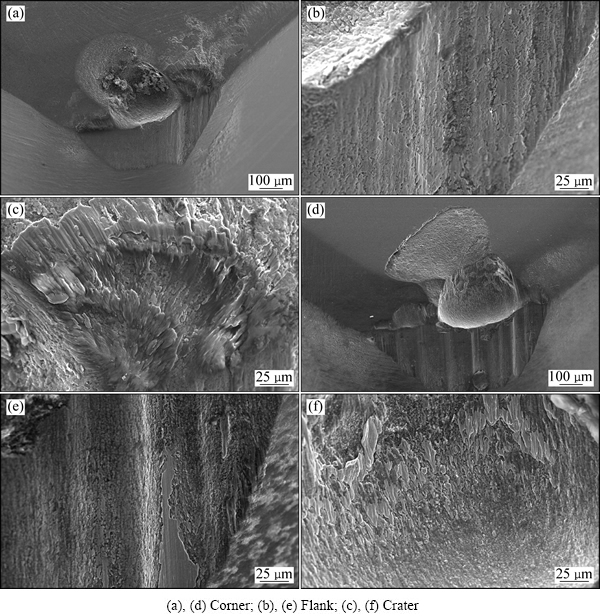

图3所示为STS刀具及FD-01刀具在v=200 m/min、f=0.1 mm/r、ap=0.15 mm条件下干切削淬硬40CrNiMo工件时刀尖磨损的SEM像。

对比图3(a)和(d)可看出,STS刀具和FD-01刀具都有明显月牙洼磨损及后刀面磨损。STS刀具产生了轻微的边界磨损,这是由于工件表面硬皮或加工硬化层等的影响,使得磨损加剧,产生较大的磨损沟纹。FD-01刀具在机械和热冲击作用下有微崩刃,在前刀面内侧有小块碎断和剥落。

对比图3(b)和(e)可见,FD-01刀具比STS刀具后刀面磨损严重,且有遍布整个磨损区的多条耕犁沟槽。这主要是由于淬硬工件中高硬度颗粒杂质在法向载荷作用下被压入刀-屑接触区, 在切削过程中,通过高硬度颗粒的犁沟作用使刀具表面产生沟槽。对于陶瓷这种脆性材料而言,犁沟则是由晶粒的脆断或脱落形成。STS刀具材料具有较高的强度和硬度,犁沟现象不明显。

图3 v=200 m/min时STS和FD-01陶瓷刀具的磨损形貌

Fig. 3 Wear morphologies of STS ((a)-(c)) and FD-1 ((d)-(f)) inserts at v=200 m/min

对比图3(c)和(f)可见,刀具前刀面都存在粘结现象。高速切削时,刀具和工件的摩擦面的实际接触面上,在足够大的压力和温度作用下,产生塑性变形而发生冷焊现象[17]。随着切削的深入,粘着部分一层层被挤出或被高温高速切削流带走,逐渐形成粘结磨损。

3 结论

1) 在亚微米Si3N4和TiC粉体中加入纳米Si3N4和SiC颗粒,真空热压烧结制备STS微纳米复合陶瓷刀具。多种补强增韧机制协同作用使刀具材料获得优良的力学性能,材料抗弯强度1000 MPa,维氏硬度达到19.5 GPa。

2) 对比STS陶瓷刀具和FD-01陶瓷刀具在不同切削速度下干切削淬硬40CrNiMo工件的实验结果,当v=200 m/min时,STS陶瓷刀具的切削时间是FD-01陶瓷刀具的一倍;当v=250 m/min时,STS陶瓷刀具切削时间FD-1陶瓷刀片的2.5倍;而v=300 m/min时,FD-1陶瓷刀片在切削3 min后出现崩刃现象。可见,随着切削速度的增加,STS陶瓷刀具的耐用度明显优于FD-01陶瓷刀具的。

3) 当v=200 m/min时,STS陶瓷刀具和FD-01陶瓷刀具磨损形态主要是月牙洼磨损和后刀面磨损。STS陶瓷刀具有轻微的边界磨损,而FD-01陶瓷刀具则产生微崩刃和片状剥落;STS陶瓷刀具和FD-01陶瓷刀具的磨损机制主要是磨粒磨损和粘结磨损。

REFERENCES

[1] 李鹏南, 唐思文, 张厚安, 张永忠. Ti (C, N) 基金属陶瓷刀具的高速切削性能与磨损机理[J]. 中国有色金属学报, 2008, 18(7): 1286-1291.

LI Peng-nan, TANG Si-wen, ZHANG Hou-an, ZHANG Yong-zhong. Cutting performance and wear mechanism of Ti(C, N)-based cermets tools in high speed cutting[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1286-1291.

[2] 刘维民, 赵 军, 艾 兴, 周咏辉. 高速车削 300M 超高强度钢时的 Al2O3基陶瓷刀具磨损机理研究[J]. 摩擦学学报, 2012, 31(6): 564-568.

LIU Wei-min, ZHAO Jun, AI Xing, ZHOU Yong-hui. Wear mechanisms of Al2O3-based ceramic cutting tool in high speed cutting turning of 300M ultra high strength steel[J]. Tribology, 2012, 31(6): 564-568.

[3] 苗赫濯. 新型陶瓷刀具的发展与应用[J]. 中国有色金属学报, 2004, 14(5): 237-242.

MIAO He-zuo. Development and applications of new types of ceramic cutting tools[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 237-242.

[4]  Z J, DING M F, ZHAO J. Wear mechanism of Si3N4/TiC micro-nano-composite ceramic tool in dry machining of nodular cast iron[J]. Applied Mechanics and Materials, 2013, 319: 79-83.

Z J, DING M F, ZHAO J. Wear mechanism of Si3N4/TiC micro-nano-composite ceramic tool in dry machining of nodular cast iron[J]. Applied Mechanics and Materials, 2013, 319: 79-83.

[5] 邢佑强, 邓建新, 冯秀亭, 闫光远, 程宏伟. 微纳复合织构自润滑陶瓷刀具的制备及切削性能[J]. 航空制造技术, 2013(6): 42-46.

XING You-qiang, DENG Jian-xin, FENG Xiu-ting, YAN Guang-yuan, CHENG Hong-wei. Fabrication and properties of micro/nano-textured self-lubricated ceramic tool in dry cutting[J]. Aeronautical Manufacturing Technology, 2013(6): 42-46.

[6] 罗 虹, 刘家浚, 朱宝亮, 罗振壁, 黄仕平, 苗赫濯. Si3N4陶瓷刀具在切削淬硬钢时的磨损行为[J]. 硅酸盐学报, 1996, 24(6): 641-647.

LUO Hong, LIU Jia-jun, ZHU Bao-liang, LUO Zhen-bi, HUANG Shi-ping, MIAO He-zhuo. Wear mechanism of silicon nitride ceramic tool in cutting quenched steel[J]. Journal of the Chinese Ceramic Society, 1996, 24(6): 641-647.

[7] KOWALCZYK D, KISZKA P. Wear behaviour of nitride ceramic cutting tools in the machining of nodular cast iron[J]. Advances in Manufacturing Science and Technology, 2011, 35(2): 5-16.

[8] 艾 兴, 刘战强, 赵 军, 邓建新, 宋世学. 高速切削刀具材料的进展和未来[J]. 制造技术与机床, 2001(8): 21-25.

AI Xing, LIU Zhan-qiang, ZHAO Jun, DENG Jian-xin, SONG Shi-xue. Progress and prospect of high-speed cutting tool material[J]. Manufacturing Technology & Machine Tool, 2001(8): 21-25.

[9] 郑光明. Sialon-Si3N4 梯度纳米复合陶瓷刀具的研制及高速切削性能研究[D]. 济南:山东大学, 2012: 94-105.

ZHENG Guang-ming. Fabrication and high speed cutting performance of Sialon-Si3N4 graded nano-composite ceramic tools[D]. Jinan: Shandong University, 2012: 94-105.

[10] BLUGAN G, HADAD M, GRAULE T, KUEBLER J. Si3N4-TiN-SiC three particle phase composites for wear applications[J]. Ceramics International, 2014, 40(1): 1439-1446.

[11] LV Z J, SONG X C, DING M F, ZHOU Y H. Cutting force, temperature and wear behavior in dry machining of nodular cast iron with Si3N4/TiC micro-nano-composite ceramic tool[J]. Advanced Materials Research, 2013, 711: 267-271.

[12] ZHENG G M, ZHAO J, GAO Z J, CAO Q. Cutting performance and wear mechanisms of Sialon-Si3N4 graded nano-composite ceramic cutting tools[J]. The International Journal of Advanced Manufacturing Technology, 2012, 58(1/4): 19-28.

[13] AI X, LI Z Q, DENG J X. Development and perspective of advanced ceramic cutting tool materials[J]. Key Engineering Materials, 1995, 108: 53-66.

[14] YAN J W, ZHOU J C, LU S Q, LI W C, ZHANG Z H. Mechanism of toughening and strengthening of Si3N4/SiC/ZrO2 nanocomposites[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(3): 430-435.

[15] LIANG Z H, ZHANG H L, GUI L C, LI J, PENG G H, JIANG G J. Effects of whisker-like β-Si3N4 seeds on phase transformation and mechanical properties of α/β Si3N4 composites using MgSiN2 as additives[J]. Ceramics International, 2013, 39(3): 2743-2751.

[16]  Z J, AI X, ZHAO J. Mechanical properties and microstructure of Si3N4/TiC nanocomposites[J]. Journal of Materials Science & Technology, 2005, 21(6): 899-902.

Z J, AI X, ZHAO J. Mechanical properties and microstructure of Si3N4/TiC nanocomposites[J]. Journal of Materials Science & Technology, 2005, 21(6): 899-902.

[17] 艾 兴. 高速切削加工技术[M]. 北京: 国防工业出版社, 2003: 63.

AI Xing. High speed machining technology[M]. Beijing: National Defense Industry Press, 2003: 63.

(编辑 李艳红)

基金项目:国家自然科学基金面上资助项目(51375281)

收稿日期:2015-01-06;修订日期:2015-06-16

通信作者:吕志杰,副教授,博士;电话:0531-86361369;E-mail:zhijie@sdjzu.edu.cn

摘 要:在亚微米Si3N4、TiC颗粒中添加纳米Si3N4、SiC颗粒,采用真空热压烧结工艺制备出STS微纳米复合陶瓷刀具,并对比STS刀具及FD-01刀具在PUMA200MA车削中心干切削淬硬40CrNiMo工件的切削性能。利用扫描电子显微镜(SEM)分析刀具前、后刀面的磨损形态,研究STS陶瓷刀具的磨损机理。结果表明:STS微纳米复合刀具材料具有较高的力学性能,抗弯强度达1000MPa,维氏硬度达19.5GPa。高速干切削40CrNiMo工件时,随着切削速度的增大,刀具后刀面磨损随之增大。切削速度越高,STS刀具优势越明显。两种刀具的磨损形态均主要为月牙洼磨损和后刀面磨损,磨损机制主要为磨粒磨损和粘结磨损。

[1] 李鹏南, 唐思文, 张厚安, 张永忠. Ti (C, N) 基金属陶瓷刀具的高速切削性能与磨损机理[J]. 中国有色金属学报, 2008, 18(7): 1286-1291.

[2] 刘维民, 赵 军, 艾 兴, 周咏辉. 高速车削 300M 超高强度钢时的 Al2O3基陶瓷刀具磨损机理研究[J]. 摩擦学学报, 2012, 31(6): 564-568.

[3] 苗赫濯. 新型陶瓷刀具的发展与应用[J]. 中国有色金属学报, 2004, 14(5): 237-242.

[5] 邢佑强, 邓建新, 冯秀亭, 闫光远, 程宏伟. 微纳复合织构自润滑陶瓷刀具的制备及切削性能[J]. 航空制造技术, 2013(6): 42-46.

[6] 罗 虹, 刘家浚, 朱宝亮, 罗振壁, 黄仕平, 苗赫濯. Si3N4陶瓷刀具在切削淬硬钢时的磨损行为[J]. 硅酸盐学报, 1996, 24(6): 641-647.

[8] 艾 兴, 刘战强, 赵 军, 邓建新, 宋世学. 高速切削刀具材料的进展和未来[J]. 制造技术与机床, 2001(8): 21-25.

[9] 郑光明. Sialon-Si3N4 梯度纳米复合陶瓷刀具的研制及高速切削性能研究[D]. 济南:山东大学, 2012: 94-105.

[17] 艾 兴. 高速切削加工技术[M]. 北京: 国防工业出版社, 2003: 63.

AI Xing. High speed machining technology[M]. Beijing: National Defense Industry Press, 2003: 63.