Trans. Nonferrous Met. Soc. China 25(2015) 732-737

Effects of grain size on shift of neutral layer of AZ31 magnesium alloy under warm condition

Guang-sheng HUANG1,2,3, Yan-xia WANG1,2, Li-fei WANG1,2, Ting-zhuang HAN1,2, Fu-sheng PAN1,2,3

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400045, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China;

3. Chongqing Research Center for Advanced Materials, Chongqing Academy of Science & Technology, Chongqing 401123, China

Received 28 April 2014; accepted 13 July 2014

Abstract:

The effects of grain size on the shift of neutral layer of AZ31 magnesium alloy sheets with different grain sizes ranging from 12.1 to 34.7 μm were investigated by the 90° V-bending tests at 150 °C. The results show that the neutral layer tends to shift to outer region of the sheets and the coefficient of neutral layer value (k-value) increases with the increasing grain size. This phenomenon is mainly owing to the enhanced asymmetry between the outer tension region and inner compression region with the increase of grain size. Twinning dominates the deformation in inner region while slips dominate the deformation in outer region.

Key words:

AZ31 magnesium alloy; grain size; V-bending; neutral layer; asymmetry;

1 Introduction

Due to the high specific strength, high stiffness and low density, magnesium alloy has been attracted by many industries, such as electron and automobile [1]. However, magnesium alloy has a hexagonal close- packed (HCP) crystal structure, so it performs a poor formability. According to von Mises criterion, it needs five independent slip systems to activate the deformation. Nevertheless, the basal plane is the main slip plane which can only provide two basal slips and the non-basal slip systems cannot be activated at low temperature [2]. So, there are few slip systems to coordinate the deformation along the c-axial direction, thus twins play an important role in the deformation. Recently researches have shown that high frequency of twinning is the reason for the tension–compression yield asymmetry of wrought magnesium alloys [3]. This limits the application of magnesium alloys. Many works were devoted to improve the property and weaken the tension-compression asymmetry of magnesium alloys. Texture, grain size and alloy element are mainly focused, especially the grain size [4]. WANG et al [5] found the tension–compression yield asymmetry originated from different twinned grain fractions at various grain sizes. BARBETT et al [6] suggested that the compression yield stress, strain hardening rate and twinned grain fraction changed remarkably with grain size. YIN et al [3] indicated that grain-coarsening promoted twinning in tension along extrusion axis and could not reduce the yield asymmetry. YIN et al [4] pointed out that the yield asymmetry of magnesium alloys could be alleviated by refining the grain size.

As well known, magnesium alloys express an asymmetry during bending process. The outer region is under tensile deformation while the inner region is under compressive deformation, which leads to the shift of neutral layer that is the zero strain layer. AVEDESIAN and BAKER [7] indicated that the neutral layer of magnesium alloy shifted to the tensile zone which was different from common metal material, such as aluminum alloy. The shift of neutral layer of magnesium alloy has a great influence on the springback during stamping process. Besides, it plays an important role in the punching accuracy. So, researching the shift of neutral layer of magnesium alloy is significant for controlling the working accuracy of magnesium alloy sheet.

To date, the effects of grain size on the tension- compression asymmetry of magnesium alloy were investigated by many researchers [3-8]. However, few reports that refer to the effect of grain size on the shift of neutral layer were found. Therefore, the present work aims to research the shift of neutral layer of magnesium alloy with different grain sizes during bending.

2 Experimental

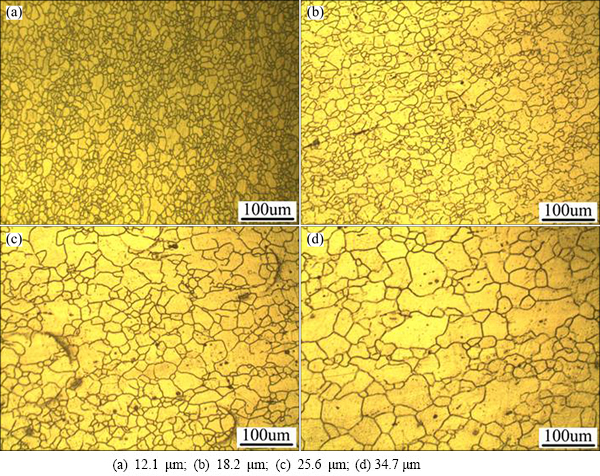

As-rolled AZ31B (Mg-3%Al-1%Zn) magnesium alloy sheet with a thickness of 3 mm was used in this work. Magnesium alloy sheets with different grain sizes were obtained by rolling and subsequent annealing. The microstructure evolution was measured with a metallographic microscope. The optical microstructures of the obtained magnesium alloy sheets are shown in Fig. 1. The average grain sizes of the obtained four kinds of sheets were 12.1, 18.2, 25.6 and 34.7 μm, respectively.

During the 90° V-bending test, magnesium alloy sheets with different grain sizes were cut into rectangular specimens with 80 mm in length and 30 mm in width. Due to the poor formability of magnesium alloy, the fracture will occur during V-bending at room temperature. Moreover, above 200 °C, DRX would appear which should have an impact on the twinning during bending. In order to avoid DRX and fracture, the V-bending test with an angle of 90° was carried out at 150 °C [9]. The initial punch speed was 3 mm/min. The coefficient of neutral layer (k) was the standard of offset of neutral layer. The bigger the k was, the further away shifting of neutral layer from geometrical middle layer. If k is less than 0.5, it means that the neutral layer shifts to compressive region during bending. If it exceeds 0.5, neutral layer shifts to the outer tensile region accordingly. For the calculation of k, the thickness at different locations in the fillet region of specimens after unloading was measured and the average value was used in calculation. The inside bending radius (Ri) was obtained by geometrical calculation. According to a theory of stamping process manual [10], the computational formula of the k is shown as follows:

k=0.5β2-(1-β)Ri/t (1)

where β, Ri and t are the coefficient of incrassation, the inside bending radius and the original thickness, respectively.

After the bending tests, the evolution of microstructure was measured by a metallographic microscope and optical micrographs.

To examine the relation between the shift of neutral layer of AZ31 magnesium alloy sheets with different grain sizes and tension-compression yield asymmetry, mechanical test specimens were machined from the treated AZ31B magnesium alloy sheets which are the same sheets in bending tests with four kinds of grain size. The tensile and compression specimens were in form of sheet with a gauge length of 37 mm and a gauge width of 12.5 mm. The uniaxial tensile and compression tests were also carried out at 150 °C. The specimens deformed to a true tensile and compression direction strain of 5%. The V-bending tests, tensile and compression tests were carried out on a CMT6305-300 kN electronic universal testing machine.

Fig. 1 Optical micrographs of rolled AZ31B alloy sheets with different grain sizes

3 Results and discussion

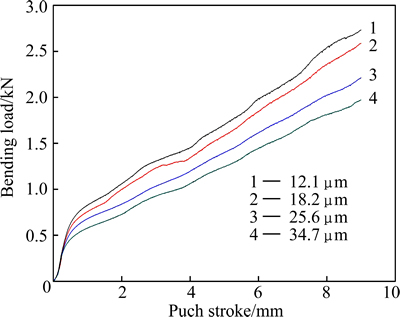

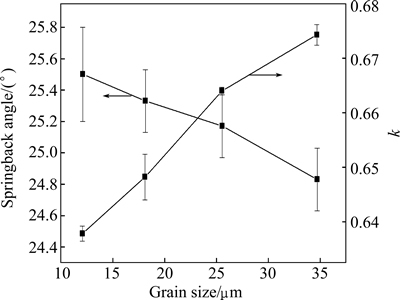

Figure 2 shows the load-stroke curves of magnesium alloy sheets with different grain sizes. It is obviously seen that the bending load decreases with the increasing grain size, which is due to the fine grain strengthening. The curves of springback angle and k of magnesium alloy sheets with different grain sizes are shown in Fig. 3. The springback angle slightly decreases with the increasing grain size. The springback angle is mainly attributed to the elastic anisotropy of surface grains and the reduction of grains along the thickness direction [11]. However, the grains in the edge of sheets are not evenly distributed, which leads to the small difference of the four grain sizes in the edge. So, the springback angle slightly decreases with larger grain size. The effect of grain size on the k is totally opposed to its effect on the springback angle. The result shows that the k exceeds 0.5 in magnesium alloy sheets with different grain sizes. The phenomenon indicates that the neutral layer shifts to the outer tension region and the magnesium alloy sheets become thicker after V-bending.

Fig. 2 Load-stroke curves of magnesium alloy sheets with different grain sizes

Fig. 3 Springback angles and k of magnesium alloy sheets with different grain sizes

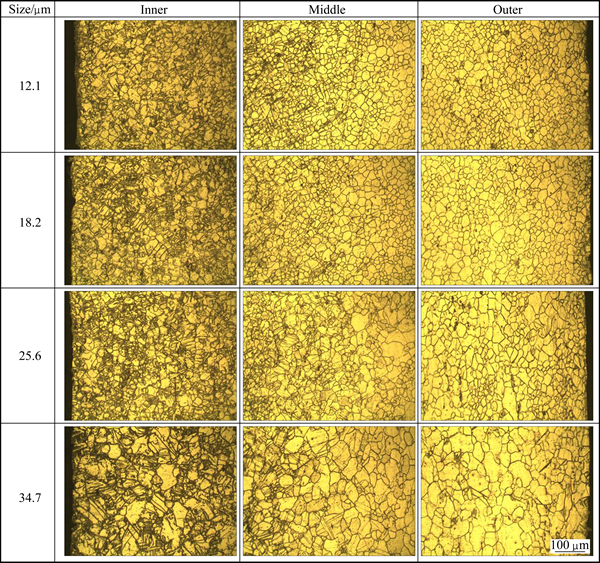

Figure 4 shows the optical micrographs of V-bended specimens with different grain sizes in the filet regions. It can be seen that there are a large amount of twins appearing in the inner region, while fewer twins in the outer region. And a clear twinning dividing is found in the middle region. This is because the grains in the outer region are subjected to tensile stress, while the grains in inner region are subjected to compressive stress during bending. The operating deformation mechanism between the outer region and the inner region is different. LVet al [8] proposed that {1, 0, -1, 2} extension twinning is easily activated by a compressive stress perpendicular to the c-axis of grains or a tensile stress parallel to the c-axis when the axial ratio is less than 1.732:1, while the magnesium alloys have an axial ratio (c/a) of around 1.633:1. Our research group verified that the twins formed in the inner region during bending were {1, 0, -1, 2} extension twins by EBSD data [12]. Therefore, the {1, 0, -1, 2} twinning is the main reason leading to the tension-compression asymmetry. WANG and HUANG [13] showed that {1, 0, -1, 2} twinning could be activated rather easily when compression was perpendicular to c-axis or tension was along c-axis. Hence, the twinning contributes to large plastic deformation in the inner region of specimen under compression. But the c-axis of some grains tended to rotate toward the directions perpendicular to the tensile direction during tensile deformation [14]. YIN et al [4] indicated that tensile deformation was dominated by slip under tensile load along c-axis. So, dislocation slips dominated the larger plastic deformation in the outer region of specimen during bending. A strong basal texture in rolled magnesium alloys can provide a preferred loading condition for the {1, 0, -1, 2} extension twins in the compression region. The texture also results in tension-compression yield asymmetry, making the compression yield stress only 1/2 or 3/4 of the tension yield stress along the rolling direction [3,15]. Consequently, the tension-compression asymmetry of magnesium alloy sheet during bending results in the neutral layer shifting to the tension region.

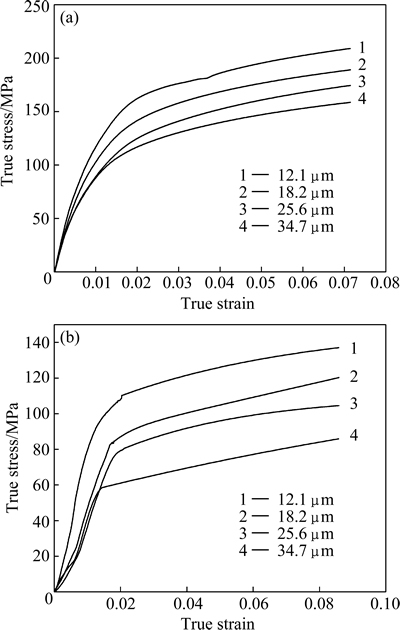

Fig. 4 Optical micrographs of V-bended specimens with different grain sizes in filet regions

The k increases with the increasing grain size, which means that the tension-compression asymmetry increases. MEYERS et al [16] suggested that the twinning has larger grain size dependence than slip and the Hall-Petch slope for twinning dominates the flow stress compared with that for slip. In other words, the yield strength increases with the decrease of grain size, and the increasing rate of twinning stress is larger than that of slip. This makes it more difficult for twinning to activate than slip in smaller grain size range. In order to investigate the grain size effect on the tension- compression asymmetry, tension and compression tests were carried out along rolled direction. The curves of tension and compression of magnesium alloy sheets with different grain sizes are shown in Fig. 5. It is found that both tension and compression true stresses increase with the decrease of grain size, showing obvious fine-grain strengthening. The yield stress of tension is significantly greater than that of compression. The decreasing rate of compression yield stress with increasing grain size is faster than that of tension yield stress. Consequently, the tension-compression asymmetry becomes weaker with the decrease of grain size. YIN et al [3] also obtained the same result, which was, the tension-compression asymmetry of magnesium alloy increased with the increase of grain size.

Fig.5 Effect of grain size on tension (a) and compression (b) of magnesium alloy sheets

As mentioned, the shift of neutral layer was closely related to the twins. Twinning was easy to occur in large grains as a complementary deformation mechanism [17,18]. This is because the dislocation glide stroke is larger in coarse-grain. The stress concentration at the grain boundaries is serious, which is conducive to twin nucleation. Because of the short dislocation glide stroke and the release of stress concentration by cross-slip, non- basal slip, grain boundary sliding and dynamic recovery in fine grain, the strain cannot meet the requirements of twinning nucleation [16-19]. So, the nucleation and growth of twins are limited by the grain size. It has been reported that the volume fraction of twins increased with the increase of grain size in annealed AZ31 sheet [20]. When the grain size is refined to some extent, the stress required for activating the twins is larger than that for activating the slip according to the Hall-Petch law [4], which means that the slip will dominate the deformation and the yield asymmetry will disappear. BARBETT et al [6] also suggested that a transition from twinning to slip dominated flow occurs with the decrease of grain size and is accompanied by lowering the Hall-Petch slope for the yield stress. As shown in Fig. 3, the k gradually approaches 0.5 with the decrease of grain size. But maybe the increased degree of twinning stress is not enough for the transition from twinning to slip in the grain size range of 12.1-34.7 μm for the present experimental results. Many twins are still found in the inner region of sample with the grain size of 12.1 μm during bending. Therefore, the effects of grain size on the shift of neutral layer of magnesium alloy are not ignored.

4 Conclusions

1) The shift of neutral layer of AZ31B alloy sheets with different grain sizes was analyzed by 90° V-bending tests at 150 °C. The results show that the neutral layer tends to shift to the outer region with the increase of grain size. This is mainly owing to the asymmetry of tension and compression.

2) The

References

[1] KIM D G, LEE K M, LEE J S, YOON Y O, SON H T . Evolution of microstructures and textures in magnesium AZ31 alloys deformed by normal and cross-roll rolling [J]. Materials Letters, 2012, 75: 122-125.

[2] YASI J A, HECTOR JR L G, TRINKLE D R. First-principles data for solid-solution strengthening of magnesium: From geometry and chemistry to properties [J]. Acta Materialia, 2010, 58(17): 5704-5713.

[3] YIN De-liang, WANG Jing-tao, LIU Jin-qiang, ZHAO Xiang. On tension-compression yield asymmetry in an extruded Mg-3Al-1Zn alloy [J]. Journal of Alloys and Compounds, 2009, 478(1): 789-795.

[4] YIN S M, WANG C H, DIAO Y D, WU S D, LI S X. Influence of grain size and texture on the yield asymmetry of Mg-3Al-1Zn alloy [J]. Journal of Materials Science & Technology, 2011, 27(1): 29-34.

[5] WANG Jing-tao, YIN De-liang, LIU Jin-qiang, TAO Jun, SU Yan-ling, ZHAO Xiang. Effect of grain size on mechanical property of Mg-3Al-1Zn alloy [J]. Scripta Materialia, 2008, 59(1): 63-66.

[6] BARBETT M R, KESHAVARZ Z, BEER A G, ATWELL D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn [J]. Acta Materialia, 2004, 52(17): 5093-5103.

[7] AVEDESIAN M M, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys [M] Ohio: ASM International, 1999.

[8] LV C, LIU T, LIU D, JIANG S, ZENG W. Effect of heat treatment on tension–compression yield asymmetry of AZ80 magnesium alloy [J]. Materials & Design, 2012, 33: 529-533.

[9] WANG Li-fei, HUANG Guang-sheng, ZHANG Hua, WANG Yan-xia, YIN Liang. Evolution of springback and neutral layer of AZ31B magnesium alloy V-bending under warm forming conditions [J]. Journal of Materials Processing Technology, 2013, 213(6): 844-850.

[10] WANG Xiao-pei. Practical stamping handbook [M]. Beijing: China Machine Press, 2000. (in Chinese)

[11] LIU J G, FU M W, LU J, CHAN W L. Influence of size effect on the springback of sheet metal foils in micro-bending [J]. Computational Materials Science, 2011, 50(9): 2604-2614.

[12] HUANG Guang-sheng, WANG Li-fei, ZHANG Hua, WANG Yan-xia, SHI Zhao-yang, PAN Fu-sheng. Evolution of neutral layer and microstructure of AZ31B magnesium alloy sheet during bending [J]. Materials Letters, 2013, 98: 47-50.

[13] WANG Y N, HUANG J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy [J]. Acta Materialia, 2007, 55(3): 897-905.

[14] HUANG Guang-sheng, LI Hong-cheng, SONG Bo, ZHANG Lei. Tensile properties and microstructure of AZ31B magnesium alloy sheet processed by repeated unidirectional bending [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 28-33.

[15] BAIRD J C, LI B, PARAST S Y, HORSTEMEYER S J, HECTOR L G, WANG P T, HORSTEMEYER M F. Localized twin bands in sheet bending of a magnesium alloy [J]. Scripta Materialia, 2012, 67(5): 471-474.

[16] MEYERS M A, HRINGER O V O, LUBARDA V A. The onset of twinning in metals: A constitutive description [J]. Acta Materialia, 2001, 49(19): 4025-4039.

[17] KOIKE J. Dislocation plasticity and complementary deformation mechanisms in polycrystalline Mg alloys [J]. Materials Science Forum, 2004, 449-452: 665-668.

[18] ZHANG Hua, HUANG Guang-sheng, SONG Bo, ZHANG Lei, KONG De-qiang. Influence of microstructure and texture on formability of AZ31 magnesium alloy sheets [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 844-850.

[19] PEREZ-PRADO M T, del VALLE J A, RUANO O A. Effect of sheet thickness on the microstructural evolution of an Mg AZ61 alloy during large strain hot rolling [J]. Scripta Materialia, 2004, 50(5): 667-671.

[20] JAIN A, DUYGULU O, BROWN D W,  C N, AGNEW S R. Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy, AZ31B, sheet [J]. Materials Science and Engineering A, 2008, 486(1): 545-555.

C N, AGNEW S R. Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy, AZ31B, sheet [J]. Materials Science and Engineering A, 2008, 486(1): 545-555.

晶粒尺寸对AZ31镁合金温成形条件下中性层偏移的影响

黄光胜1,2,3,王艳霞1,2,王利飞1,2,韩廷状1,2,潘复生1,2,3

1. 重庆大学 材料科学与工程学院,重庆 400045;

2. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044;

3. 重庆科学技术研究院 重庆先进材料研究中心,重庆 401123

摘 要:通过在150 °C下90° V形弯曲实验研究范围为12.1~34.7 μm的不同晶粒尺寸对AZ31镁合金板材中性层偏移的影响。结果表明,随着晶粒尺寸的增大,镁合金中性层偏移系数(k值)逐渐增大,中性层向弯曲外层偏移量增加。这种现象主要是由于随着晶粒尺寸的增加,在外部拉伸区域和内部压缩区域之间的拉压不对称性的增强。孪生主导内部区域的塑性变形,而滑移支配着外部区域的变形。

关键词:AZ31镁合金;晶粒尺寸;V形弯曲;中性层;不对称性

(Edited by Xiang-qun LI)

Foundation item: Project (CSTC2012GGB50003) supported by Scientific and Technological Project of Chongqing Science and Technology Commission, China; Project (CDJZR13130081) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: Guang-sheng HUANG; Tel: +86-23-65112239; E-mail: gshuang@cqu.edu.cn

DOI: 10.1016/S1003-6326(15)63658-5

Abstract: The effects of grain size on the shift of neutral layer of AZ31 magnesium alloy sheets with different grain sizes ranging from 12.1 to 34.7 μm were investigated by the 90° V-bending tests at 150 °C. The results show that the neutral layer tends to shift to outer region of the sheets and the coefficient of neutral layer value (k-value) increases with the increasing grain size. This phenomenon is mainly owing to the enhanced asymmetry between the outer tension region and inner compression region with the increase of grain size. Twinning dominates the deformation in inner region while slips dominate the deformation in outer region.