网络首发时间: 2019-09-29 10:22

Mg-Y-Zn合金高应变率下LPSO结构的变形机制

摘 要:

长周期堆垛有序(long period stacking ordered,LPSO)结构是广泛存在于Mg-Y-Zn系镁合金中一种强化相。本文利用分离式霍普金森压杆(SHPB)和万能试验机测试了Mg-Y-Zn变形镁合金的动态压缩力学性能和准静态压缩力学性能,结果显示,Mg-Y-Zn变形镁合金存在一定的应变率强化效应;利用光学显微镜(OM)、扫描电子显微镜(SEM)、透射电子显微镜(TEM)和X射线衍射仪(XRD)分析实验材料的微观组织,通过比较LPSO结构在高应变率和准静态应变率下的变形机制,研究LPSO结构对材料应变率强化效应的作用:Mg-Y-Zn合金中有大量层状的LPSO结构在基体上随机分布;准静态条件下,在变形后的LPSO结构中发现<a>类位错,LPSO结构主要的变形方式是启动基面滑移系;动态条件下,变形后的LPSO结构中存在大量位于基面上的<a>类位错和少量位于柱面上的<c>类位错以及位于锥面上的<c+a>类位错,启动了临界切分应力更大的滑移系,LPSO结构的变形方式是层状结构厚度变薄,发生了聚集、扭折和断裂;LPSO结构附近的基体在变形过程产生了大量的位错缠结,产生大量的亚晶。

关键词:

长周期堆垛有序(LPSO)结构;高应变率;应变率效应;变形机制;

中图分类号: TG146.22

作者简介:何舒阳(1994-),男,吉林吉林人,硕士,研究方向:镁合金焊接,E-mail:heshuyang@live.com;*杨素媛,教授级高级工程师,电话:13910601206,E-mail:yangsuyuan@bit.edu.cn;

收稿日期:2019-07-01

基金:国家自然科学基金项目(51571031)资助;

LPSO in Mg-Y-Zn Alloy Deformation Mechanism under High Strain Rate

He Shuyang Yang Suyuan

School of Materials,Beijing Institute of Technology

Science and Technology on Materials impact Environment Laboratory

Abstract:

Long period stacking ordered(LPSO)structure is a kind of structure which widely present in Mg-Y-Zn magnesium alloys.LPSO is a structure formed by the orderly arrangement of two to twenty layers of atomic layers. The purpose of the article was to study the deformation mechanism of LPSO structure in magnesium alloy during dynamic compression and quasi-static compression and the strain rate strengthening effect of magnesium alloy containing LPSO structure. The test material was a deformed Mg-Y-Zn magnesium alloy plate,sampling along the RD(rolling direction)of the plate,according to GJB5365-2005 metal material dynamic compression test method and GBT7314-2017 metal material room temperature compression test method,dynamic compression and quasi-static compression samples were respectively taken Φ8 mm×8 mm and Φ6 mm×9 mm. Separate Hopkinson pressure bar and INSTRON5985 electronic universal material were used to test dynamic compression and quasi-static compression experiments on the sample;X-ray diffraction(XRD)analysis used BRUKER D8 ADVANCE SB001 type X for the X-ray diffractometer,a Cu target Kα ray source was used for X-rays,the wavelength was 0.15405 nm,the scanning angle was 10°-100°,and the scanning speed was 6(°)·min-1. The metallographic structure took the cross-section of the sample in the axial direction and polished it with sandpaper and velvet polishing cloth. It was corroded by the corrosive solution of 0.42 g picric acid+1 ml acetic acid+7 ml ethanol+1 ml water component. The samples were characterizal by 480 optical microscope(OM)and S-4800 field emission scanning electron microscope(SEM);transmission electron microscope(TEM)specimens were sampled along the cross-sectional direction of the specimen and ground to a thickness of 40 μm with sandpaper,and after ion thinning,they were subjected to Tencail G2 F20 field emission TEM observation. The metallographic structure of the deformed Mg-Y-Zn magnesium alloy was composed of crystal grains with a diameter of about 5 μm and an irregular second phase. The second phase structure was randomly distributed on the matrix and showed a certain directionality. The length of LPSO was 40~300 μm. The LPSO structure existed in the alloy in a layered form,and they were all 18-R structures. From the stress-strain curve,in the process of alloy deformation,when the strain was the same,the stress generated during dynamic compression of the alloy was higher than the stress generated during quasi-static compression,indicating that the magnesium alloy with LPSO structure had strain rate enhancement effect. Under the strain rate of dynamic compression,as the strain rate increases,when the strain was the same,the stress was also higher. After quasi-static and dynamic compression,the morphological changes of the LPSO structure inside the alloy were also different. Under the optical microscope,the morphology of LPSO after quasi-static compression did not change much from that before compression,but after dynamic compression,the structure was broken,and as the strain rate increased,the degree of fracture of the structure gradually increased. Under the field emission scanning electron microscope,it could be seen that after quasi-static compression,the layered LPSO structure in the alloy was slightly bent,and a small part of the layer was broken. After dynamic compression,the LPSO structure in the alloy was severely twisted and fractured,and the spacing of some layered structures widened. It was observed with a transmission electron microscope that after quasi-static compression,the LPSO structure was slightly bent,and there were some dislocations parallel to the base surface of the LPSO structure,and it was judged that this type of dislocation was an <a> type dislocation. It showed that during the process of quasi-static compression,the main morphological changes of the LPSO structure inside the alloy were slight bending and a small amount of layered structure fracture,and the main deformation mechanism was basal slip. After dynamic compression,a transmission electron microscope was used to find that the LPSO structure inside the alloy has undergone severe deformation. The layers of the layered LPSO structure were significantly thinner,and there were a lot of dislocations inside the LPSO structure,these dislocations were entangled with each other in different directions. The type of dislocation inside LPSO was judged by double beam diffraction. Select incident belt axis B=[11-20]. When the diffraction vector g={000,18},a large number of dislocations perpendicular to the basal plane of the LPSO structure were found in the double-beam imaging photos. According to the principle of double-beam diffraction imaging,these dislocations were <c>-type dislocations on the prism surface,which illustrated the active of the cylindrical slip system. When the diffraction vector g={11-20},a large number of dislocations paralleled to the base surface of the LPSO structure were found. It was observed that the base surface <a> type dislocations were activated during the dynamic compression process,and the number of basal <a> type dislocations was larger,indicating that the basal slip was the most active slip. When the diffraction vector g={10-19},a large number of <a+c> type dislocations were found,indicating that the pyramidal slip system was also activated at high strain rates. The deformed Mg-Y-Zn magnesium alloy had a quasi-static compressive strength of 408 MPa and a dynamic compressive strength of 456 MPa,with strain rate strengthening effect;the 18-R LPSO structure in the deformed Mg-Y-Zn magnesium alloy was a layered structure,which was randomly distributed on the matrix and had an irregular shape.The LPSO structure bent slightly during quasi-static deformation. The inpidual layers were discontinuously distributed,and the thickness of the layer did not change much. After dynamic compression,the LPSO structure layer got thinner,violent twisting and fracture,indicting that the deformation mechanism of the LPSO structure was affected by the strain rate. Under the quasi-static strain rate,only the base slip system was activated in the LPSO structure,and there were a large number of <a> type dislocations and a small amount of <c> type inside the LPSO structure at high variability. Dislocations like <c+a> and <c+a> indicated that in addition to the base slip system,the LPSO structure also activated the conical and cylindrical slip systems at high strain rates,resulting in the strain rate strengthening effect.

Keyword:

long period stacking ordered(LPSO); high strain rate; strain rate effect; deformation mechanism;

Received: 2019-07-01

镁合金是最轻的结构金属材料,具有较强的比特性,在航空、汽车及电子产品等领域获得了广泛的应用。稀土镁合金因为其优于传统镁合金的常温和高温力学性能,引起了研究者们的关注,关于稀土元素在镁合金中的强化机制已经做了很多研究

Hagihara等

1 实验

实验材料为变形Mg-Y-Zn镁合金板,沿着板材RD(轧制方向)取样,根据GJB5365-2005金属材料动态压缩试验方法和GBT7314-2017金属材料室温压缩试验方法,动态压缩和准静态压缩试样分别取Φ8 mm×8 mm和Φ6 mm×9 mm,用分离式霍普金森压杆和INSTRON5985电子万能材料试验机对试样进行动态压缩和准静态压缩实验;X射线衍射(XRD)分析使用BRUKER D8 ADVANCE SB001型X射线衍射仪,X射线采用Cu靶Kα射线源,波长为0.15405 nm,扫描角度为10°~100°,扫描速度为6(°)·min-1。金相组织取试样轴线方向的剖面,用砂纸磨平、丝绒抛光布抛光后,经0.42 g苦味酸+1 ml乙酸+7 ml乙醇+1 ml水组分的腐蚀液腐蚀,用LECO系列Olympus PM-3S-480光学显微镜(OM)、S-4800场发射扫描电镜(SEM)观察;透射电镜(TEM)试样沿试样剖面方向取样,用砂纸磨至40μm厚,经离子减薄后用Tencai G2 F20场发射透射电子显微镜(TEM)观察。

2 结果与讨论

2.1 力学性能

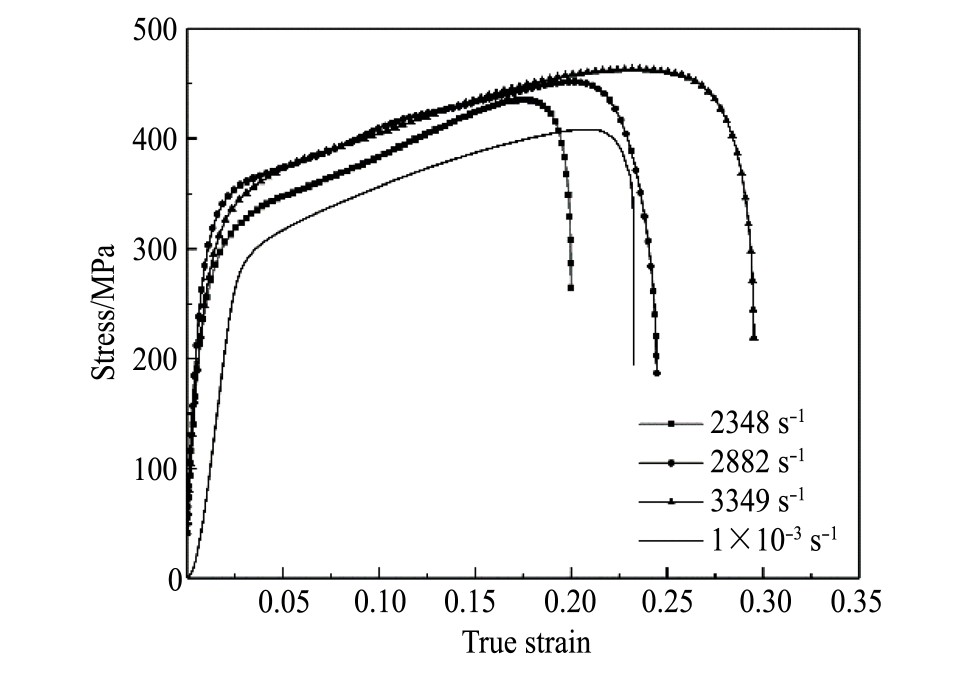

试样的准静态和动态压缩的真应力应变曲线如图1所示。分别在2348,2882和3349 s-1的应变率下对试样进行动态压缩,最终在3349 s-1的应变率下断裂,强度是456 MPa。动态压缩的真应力应变曲线均高于准静态压缩曲线,且动态压缩强度大于准静态压缩强度,准静态压缩强度408 MPa,说明Mg97Y2Zn镁合金存在一定的应变率强化效应。

2.2 微观组织

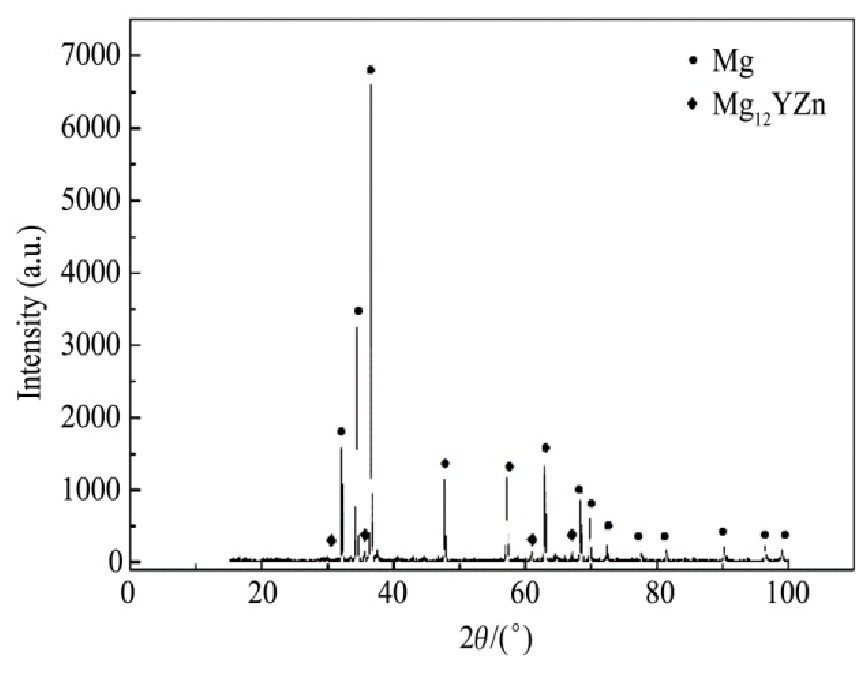

图2是变形Mg-Y-Zn镁合金的XRD图谱。可见其在室温条件下包含Mg和Mg12YZn两相,从衍射峰的强度判断,主要的相是Mg,Mg12YZn含量相对较少。

图1 试样在不同应变速率下的真应力应变曲线

Fig.1 True stress-strain curves of sample at different strain rates

图2 Mg-Y-Zn合金的XRD图谱

Fig.2 XRD pattern of Mg-Y-Zn alloy

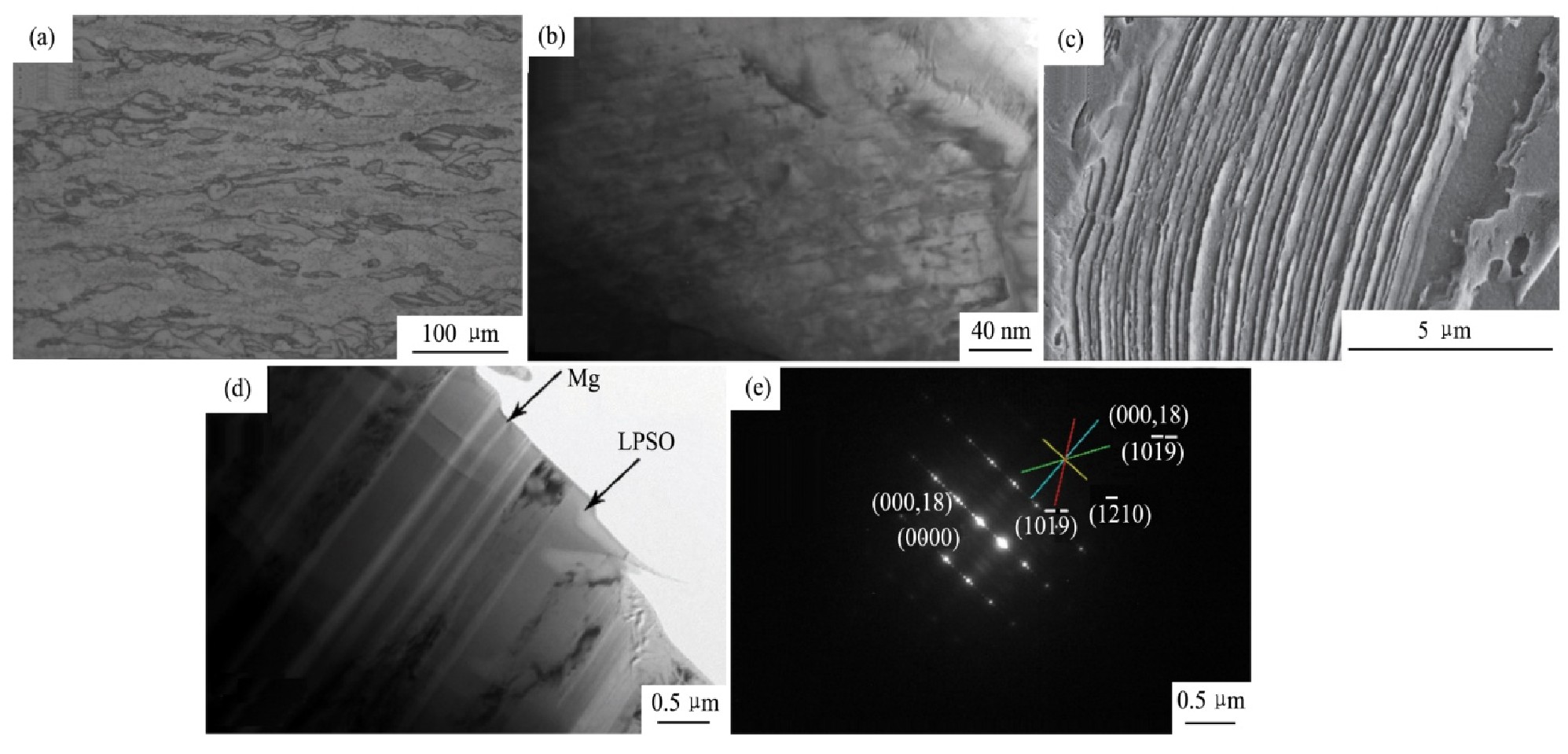

图3是实验材料的微观组织,图3(a)是OM照片,变形Mg-Y-Zn镁合金中的金相组织由直径约为5μm的晶粒和形状不规则的第二相构成,第二相结构在基体上随机分布,有一定的方向性,长度40~300μm之间,文献

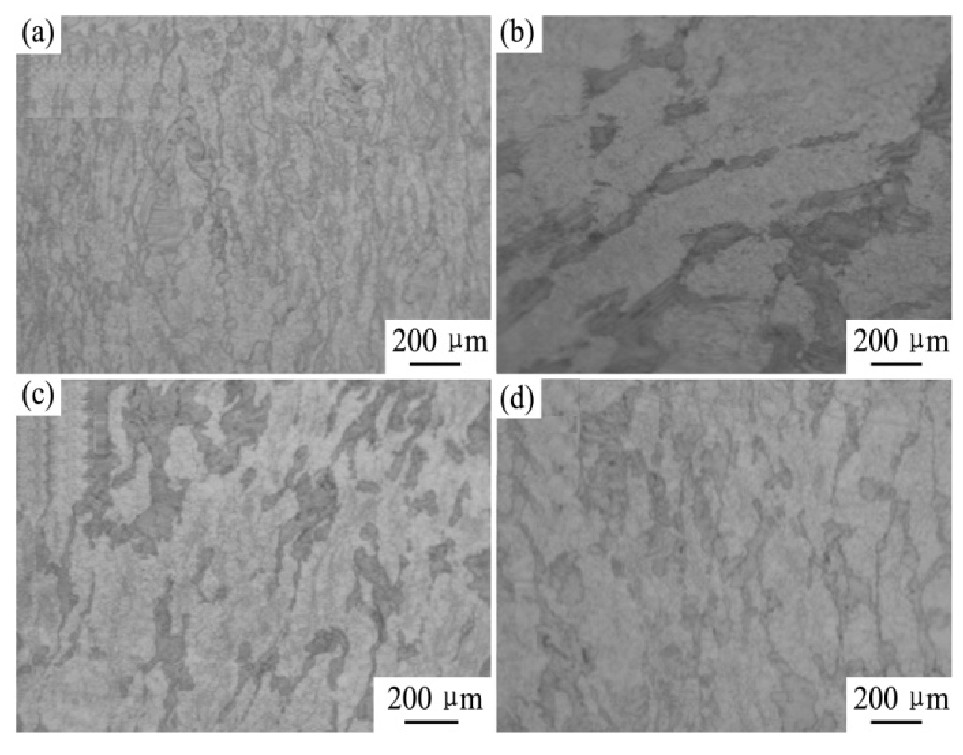

图4(a-d)是实验材料经过1×10-3,2348,2828,3349 s-1压缩后试样剖面的OM组织,准静态压缩后的LPSO形态上与压缩前变化不大,但动态压缩的LPSO结构发生断裂和破碎。在图4(b-d)中可以看到有数微米的LPSO碎块连成流线型,这可能因为其塑性变形过程中不断被剥落,产生的碎块随着材料整体的流变而发生线性排列。在动态压缩的应变率范围内,随着应变率的增加LPSO碎块也逐渐增多。

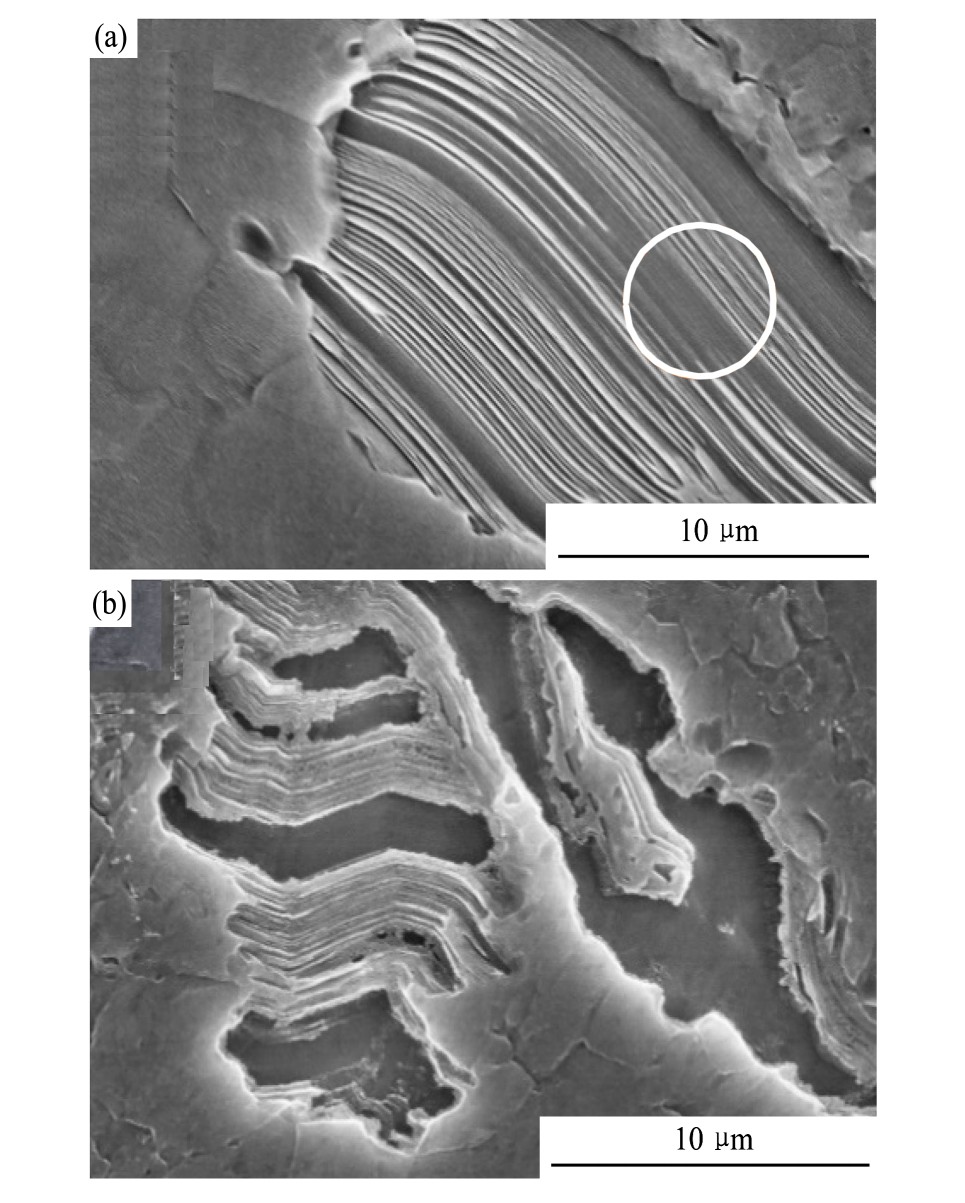

图5(a,b)分别是经过准静态和动态压缩后LPSO结构的SEM照片,可以看到准静态压缩的层状LPSO结构有个别层呈不连续分布,有轻微的弯曲,如图中白色圆圈位置。动态压缩后,层状的LPSO结构发生了聚集、剧烈扭折和断裂现象。

图3 Mg-Y-Zn的微观组织

Fig.3 Microstructure of Mg-Y-Zn

(a)OM image and(b)TEM image of internal grain dislocation;(c)SEM image;(d)TEM bright field image;(e)SAED patterns of LPSO

图4 不同应变率下的压缩试样OM照片

Fig.4 OM images of compressed sample at different strain rates(a)1×10-3s-1;(b)2348 s-1;(c)2828 s-1;(d)3349 s-1

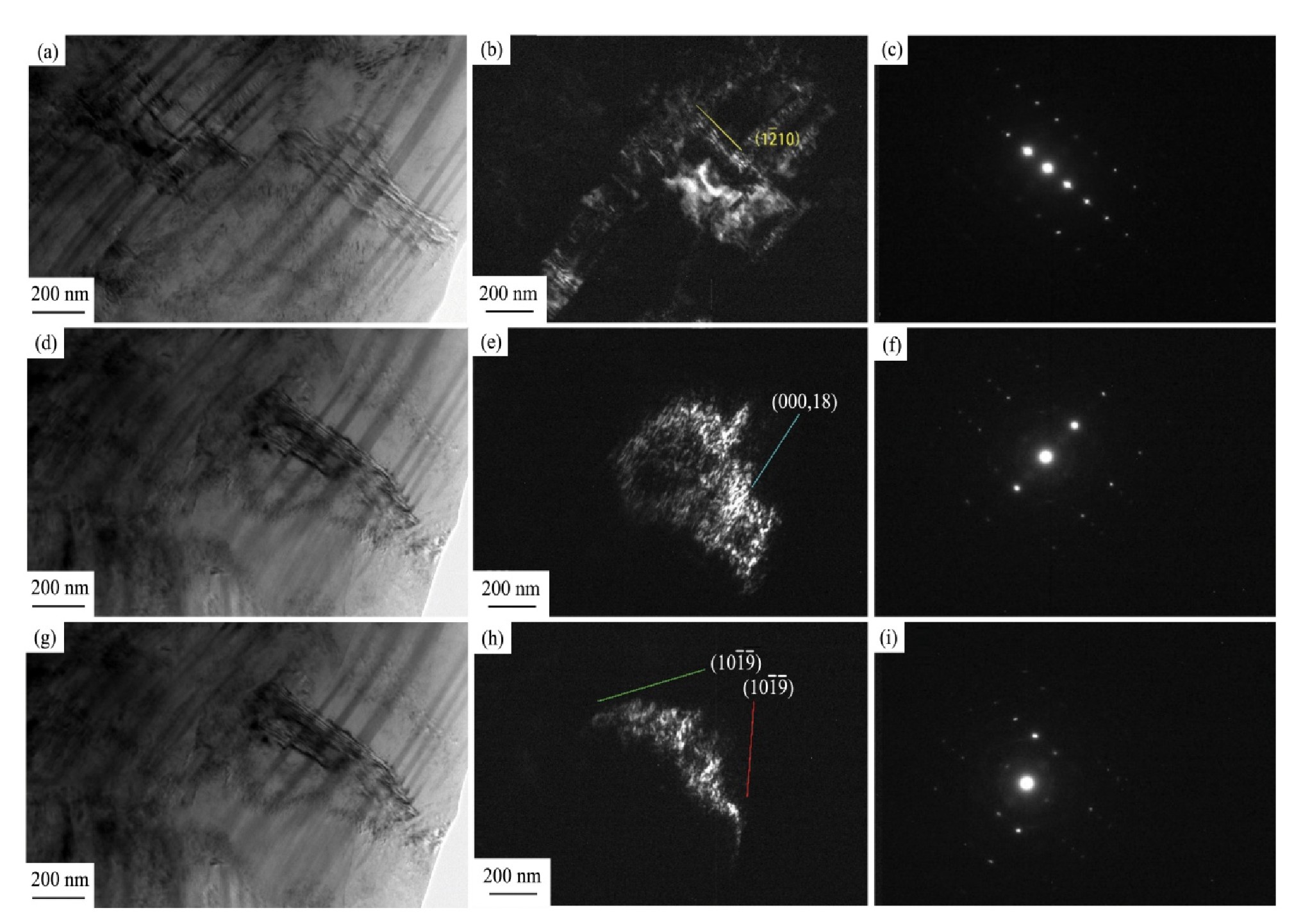

图6(a)是准静态压缩试样的TEM照片,LPSO结构中位错线都平行于基面方向,说明准静态压缩后LPSO中产生的位错都是<a>类型位错。LPSO结构层的厚度在100~600 nm之间,与变形前相比变化不大。图6(b)是动态压缩试样的TEM照片,LPSO结构层的厚度在50~100 nm之间,LPSO结构的层变薄,动态压缩后的LPSO结构内的位错有多个方向,需要通过TEM双束衍射对位错情况做进一步的分析。

图5 不同应变率变形后的LPSO结构SEM照片

Fig.5 SEM images of LPSO structure after deformation at dif-ferent strain rates

(a)1×10-3s-1;(b)3349 s-1

图6 准静态和动态压缩试样TEM照片

Fig.6 TEM images of quasi-static and dynamic compression sample(a)Quasi-static;(b)Dynamic

图7 动态压缩试样TEM照片

Fig.7 TEM images of dynamic compression sample

(a-c)TEM bright field,weak beam dark field images and diffraction pattern under g={000,18};(d-f)TEM bright field,weak beam dark field images and diffraction pattern under g={112-0};(g-i)TEM bright field,weak beam dark field images and diffraction pattern under

图8(a,b)分别是准静态和动态压缩后LPSO结构附近晶粒TEM明场像和衍射花样,可以看到有大量的位错缠结,选区衍射花样是由很多衍射斑点连成的衍射环,说明形成了很多亚晶。LPSO是合金中的硬质相,在与镁的晶粒一起塑性变形时会在交界处产生应力集中,所以在镁的晶粒中产生的位错多数会堆积在晶粒组织和LPSO结构的交界处,高密度的位错会发生缠结成位错胞。高应变率下的变形在单位时间内产生的位错密度更大,所以临界切分应力更大这是产生应变率强化效应的另一个原因。

图8 不同应变率变形后晶粒动态压缩后的微观组织明场像

Fig.8 Bright field image of microstructure after dynamic grain compression at different strain rates(a)1×10-3s-1;(b)3348 s-1

3 结论

1.变形态Mg-Y-Zn镁合金准静态压缩强度408MPa,应变率1×10-3s,动态压缩强度456 MPa,应变率3349 s-1,有应变率强化效应。

2.变形态Mg-Y-Zn镁合金中的18-R LPSO结构是层状组织,在基体上随机分布,形状不规则。LP-SO结构在准静态变形时,发生轻微的弯曲,个别层呈不连续分布,层的厚度变化不大,在动态压缩时,LPSO结构层变薄,发生了聚集、剧烈扭折和断裂。

3.LPSO结构的变形机制受到应变率的影响,准静态应变率下LPSO结构内只开动基面滑移系,高变率下LPSO结构内部存在大量的<a>类位错和少量的<c>类和<c+a>类位错,说明在高应变率下LPSO结构除了基面滑移系外还启动了锥面和柱面滑移系,导致了应变率强化效应。

参考文献