文章编号:1004-0609(2016)-11-2340-13

银元素对含银钎料性能的影响

王 禾,薛松柏,刘 霜

(南京航空航天大学 材料科学与技术学院,南京 210016)

摘 要:

分别选取3种典型的含银软钎料(Sn-Ag-Cu、Sn-Zn、Sn-Bi)和硬钎料(Ag-Cu-Zn、Cu-P、Zn-Al)作为代表进行阐述。综述了国内外含银钎料研究的最新研究成果,归纳分析银元素对软钎料与硬钎料的物理性能、显微组织和力学性能的影响规律,提出含银钎料在研究和应用过程中存在的问题及相应的解决措施,展望含银钎料的研究和发展趋势。

关键词:

中图分类号:TG425 文献标志码:A

随着电子工业和制冷技术的发展,越来越多的人开始关注钎料的使用安全,尤其是随着欧盟WEEE、RoHS两个指令和中国政府相关法令的颁布与实施,传统的含铅、镉钎料的使用受到很大限制,全球钎料工作者都在寻求合适的替代产品。其中,含银钎料由于具有优良的综合性能而受到广泛的关注。在软钎料中,Sn-Ag-Cu钎料具有良好的润湿性,Sn-Zn钎料的熔点最为接近Sn-Pb钎料,Sn-Bi钎料具有较低的熔点,因此,这3种钎料被认为是最合适的替代传统的Sn-Pb的钎料。在硬钎焊领域,无镉银钎料已广泛应用于航空航天、电力电子及家用电器等行业,其中最具代表性的有Ag-Cu-Zn和Ag-Cu-Zn-Sn钎料。然而,由于银资源的短缺,使用银基钎料的的成本很高,因此,目前更为便宜的Cu-P和Zn-Al钎料都是硬钎料研究的热点。

含银钎料是一类非常重要的钎焊材料,其固液相线温度范围易于调整,润湿性和导电性好、力学性能优良,可用来钎焊几乎所有的有色金属及黑色金属。经过合金化后的多种含银钎料还可用于钎焊碳化物、陶瓷、石墨、玻璃等材料[1]。此外,含银钎料还具有优良的加工性能,易于加工成丝、片、带、箔、环等形状,使用十分方便。含银钎料种类繁多,在制造业中是一类不可或缺、至关重要的连接材料[2],在钎焊技术的发展过程中起了十分重要的作用。

本文作者通过综述国内外含银钎料研究的最新研究成果,归纳分析银元素对软钎料与硬钎料的物理性

能、显微组织和力学性能的影响规律,提出含银钎料在研究和应用过程中存在的问题及相应的解决措施,展望含银钎料的研究、发展趋势,试图为现有银钎料的应用和新型含银钎料的研发提供有益的理论参考。

1 银含量对软钎料的影响规律

1.1 软钎料的熔化特性

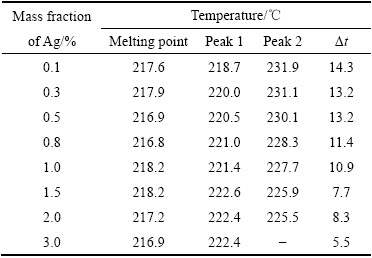

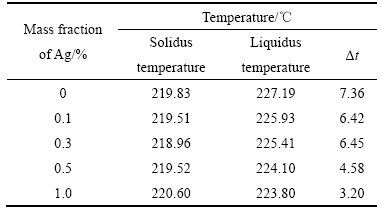

表1 Sn-xAg-0.5Cu钎料合金DSC曲线结果统计

Table 1 DSC statistical results of Sn-xAg-Cu solders

众所周知,钎焊温度低于450℃的钎料称为软钎料,目前SnAgCu系合金是应用最广泛的软钎料之一。表1所列为不同银含量Sn-Ag-Cu钎料的熔化特性[3],其最低熔化温度(固相线温度)约为217℃,其完全熔化温度(液相线温度)随着钎料中银元素含量的增大而有所降低,即钎料熔化起始温度至熔化结束温度之间的温度区间缩窄。

Sn-Zn钎料中添加银元素同样会提高钎料起始熔化温度,缩短熔化温度区间[4]。表2所列为Sn-9Zn-xAg的熔化温度。从表2可以看出,含银1%(质量分数)的和不含银钎料[5]相比,熔化温度区间降低幅度可达56.2%。当熔化温度区间变窄时,钎料在熔化时流动性更好,可避免部分钎焊接头组织的多孔性和不连续性。

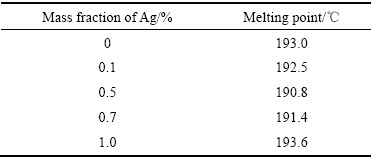

表3所列为Sn-Bi-xAg的熔化结果[6]。由表3可看出,Sn-Bi钎料中银元素的添加量从0增加到0.5%时,钎料的熔点从193.0 ℃降至190.8 ℃;继续添加银元素至1%,熔点升高到193.6 ℃。这种随着银含量的增加钎料熔点先下降后上升的现象,是由于加入银所形成的Ag3Sn相与钎料基体较为复杂的交互作用[7]而引起的。

表2 Sn-9Zn-xAg的熔化温度

Table 2 Melting temperature of Sn-9Zn-xAg solders

表3 Sn-Bi-xAg的熔化温度

Table 3 Melting temperature of Sn-Bi-xAg solders

1.2 软钎料的显微组织和界面结构

在钎焊过程中,钎料与基板在界面处形成IMC(金属间化合物)层,IMC层的形成一方面表明钎料与基板之间有良好的冶金结合;另一方面,若IMC层太厚,会降低焊点的可靠性。材料的组织决定了材料的性能和加工工艺,因此,有必要研究银元素加入软钎料中对基体和界面组织的影响。

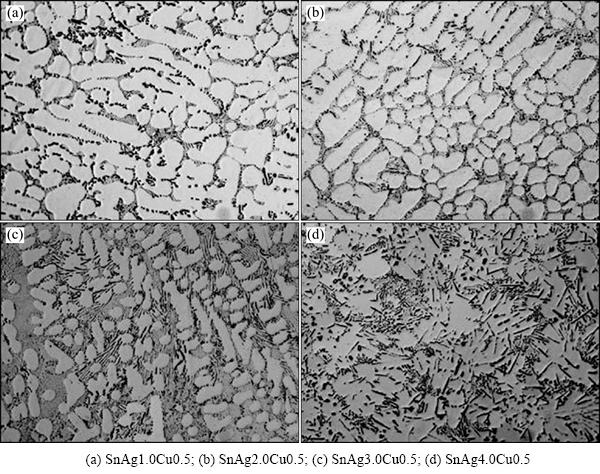

Sn-Ag-Cu钎料基体中主要由β-Sn相、Ag3Sn相和Cu6Sn5相组成,组织特征为树枝状初晶与二元、三元共晶组织。钎料中大块的Cu6Sn5相不仅是硬脆相,还可以作为β-Sn的异相形核点,使得钎料组织粗大。向钎料中添加银元素,钎料基体中Cu6Sn5相减少、Ag3Sn相增多。钎料中银元素含量高于1%时,Ag3Sn相呈网状分布于基体中,晶粒有所细化,如图1所示。由图1可看出,随着银的继续增加,β-Sn初晶晶粒尺寸变小,即银的加入有细化晶粒的作用;晶界处IMC尺寸也变细小、密度变大,包围β-Sn初晶的网状共晶结构的尺寸逐渐增大,即银的加入也可使基体晶格畸变增大[8]。一般认为,当银含量较低时,组织细化起主导作用,但随着银含量增加,固溶强化作用随之增强,IMC的数量也随之增加,合金元素强化作用占了主导地位,钎料强度也增加。

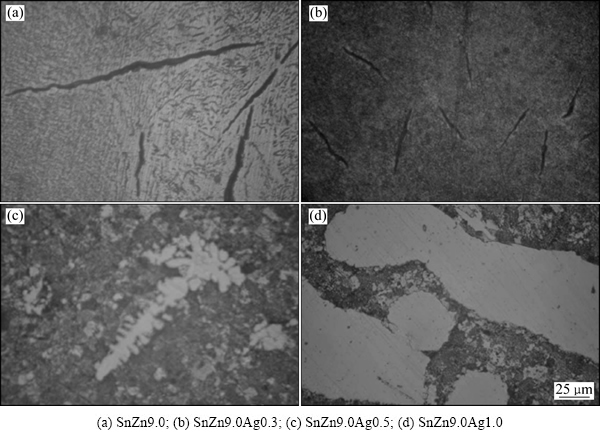

图2所示为Sn-9Zn-xAg的显微组织。Sn-Zn钎料由富锡相基体组织和富锌相的针状组织组成[9](见图2(a))。当向钎料中添加银元素时,不仅有细化组织的作用,而且能减少针状组织的数量,但添加过量,钎料中会形成颗粒状Ag3Sn化合物,甚至高熔点的银锌IMC相也明显增多,增加钎料的粘滞性,不利于润湿[10]。因此,Sn-Zn钎料中往往会有一个银的最佳添加量,例如在Sn-9Zn钎料中加入0.3%(质量分数)的银元素时,Sn-9Zn/Cu界面处平坦的Cu5Zn8化合物层会出现颗粒状的AgZn3相,组织最佳,然而,随着银含量的继续增加,颗粒状AgZn3会聚集并长大成扇贝状化合物层,使钎料性能降低。

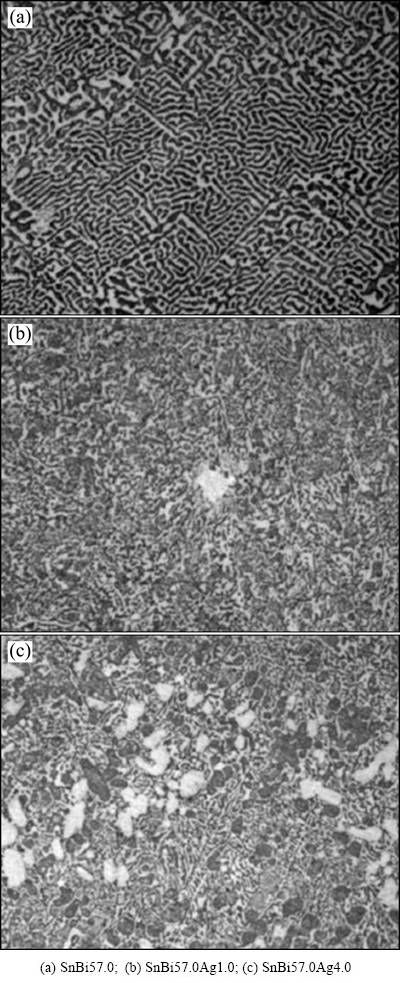

图3所示为Sn-57Bi-xAg的显微组织。从图3可以看出,Sn-57Bi钎料基体中Ag3Sn相会随着银含量的升高而增加[11]。当银含量在1%(质量分数)以下时,Ag3Sn相弥散分布使钎料组织细化,提高钎料强度;但银含量大于1%时,Ag3Sn相开始局部偏聚,降低钎料强度。文献[12]中提出这可能是由于在Sn-Bi钎料中加入的银抑制了富锡相的树枝晶粗化,使晶粒细化的同时也提高了钎料强度,但银过量时生成较多的IMC反而使组织恶化。

1.3 软钎料的润湿性

Sn-Ag-Cu钎料的铺展试验结果[13]表明,当银含量在1%(质量分数)以下时,随着银含量的增加,钎料在紫铜板上的铺展面积迅速增加;而当银含量在1%以上时,即使银含量增加,钎料铺展面积的变化也不大。

图1 Sn-xAg-0.5Cu的显微组织

Fig. 1 Microstructures of Sn-xAg-0.5Cu solders

图2 Sn-9Zn-xAg的显微组织

Fig. 2 Microstructures of Sn-9Zn-xAg solders

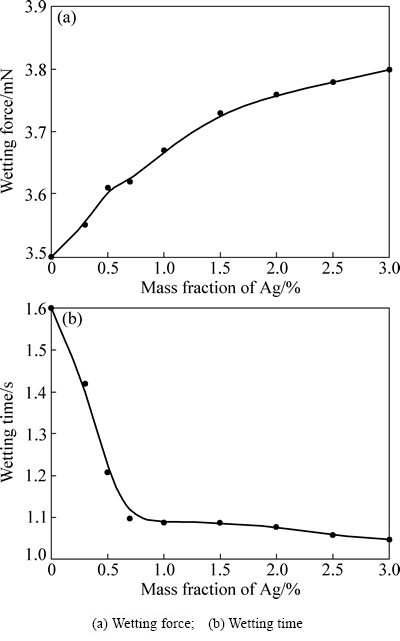

图4所示为Sn-xAg-Cu的润湿性能。由图4可以看出,钎料的润湿力和润湿时间也均是开始变化快而后逐渐趋于平缓的曲线。当银含量在小于1%的围内增加时,钎料合金的润湿性能得到显著改善。

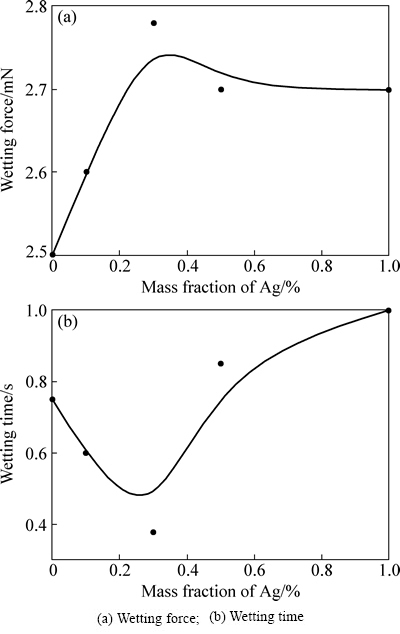

含银的Sn-Zn钎料润湿实验结果[14]如图5所示。由图5可以看出,当银含量为0.3%时,钎料具有最大的润湿力和最短的润湿时间,此时,钎料的润湿性能改善最为明显。WANG等[15]认为,钎焊时钎料表面氧化形成的氧化锌数量是影响Sn-9Zn钎料润湿性能的主要因素,而Sn-9Zn-0.3Ag钎料在钎焊时表面却基本保持光亮,说明添加0.3%(质量分数)的银,钎料抗氧化性增强,润湿性能明显提高。另一方面,当银含量大于0.5%(质量分数)时,钎料中会形成AgZn3金属间化合物,降低液态钎料流动性,进而降低了钎料的润湿性。

图3 Sn-57Bi-xAg的显微组织

Fig. 3 Microstructures of Sn-57Bi-xAg solders

Sn-Bi钎料中加入银元素能加快钎焊时钎料的扩散速度,改善润湿性能,然而银含量过高,会形成很多金属间化合物Ag3Sn相,对钎料的扩散形成阻碍,导致润湿性能降低[16]。文献[17]中报道了在Sn-Bi-Ag钎料中,最小的润湿角处对应的银含量是一个中间值。

图4 Sn-xAg-Cu的润湿性能

Fig. 4 Wettability of Sn-xAg-0.5Cu solders

图5 Sn-Zn-xAg的润湿性能

Fig. 5 Wettability of Sn-xAg-0.5Cu solders

1.4 软钎料的力学性能

在钎焊件使用中,钎焊处在服役期间必须具有较高的力学性能才能保证使用的可靠性。对钎料的力学性能测试主要集中在抗拉强度、抗剪强度上,试样有焊点和钎焊接头两种形式[18-19]。

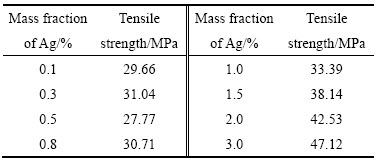

Sn-Ag-Cu钎料的BGA焊点剪切试验结果记录如表4所列。由表4可看出,当银含量低于0.5%时,随着银含量增加,钎料的抗拉强度先增加后下降,这一结果可能与接头组织中IMC相的分布情况有关[20]。而当银含量大于0.5%时,抗拉强度逐渐增加。高银钎料焊点的强度高、抵抗变形能力强,而低银钎料焊点的韧性优异,能吸收形变和热疲劳产生的能量,抗疲劳性能也较好。

表4 Sn-Ag-Cu钎料的拉伸数据

Table 4 Tensile strength of Sn-Ag-Cu solders

Sn-Zn钎料焊点的抗剪强度会随着银元素的加入先上升后下降[21]。如不含银元素Sn-9Zn钎料焊点[22]的抗剪强度为34.4 MPa,而银含量为0.3%的焊点,抗剪强度达到最大值35.4 MPa,当银元素含量继续增加到1%时,抗剪强度反而有所下降。

Sn-Bi钎料的钎焊接头不仅延展性差而且抗剪强度也比较低,加入银元素后可以明显弥补这些不足。添加2%银的Sn-57Bi钎料钎焊接头的抗剪强度比不含银接头的抗剪强度高很多[23-24],继续添加银,钎料的抗剪强度反而降低。这是由于银的加入一方面可以使硬脆的Bi相分散,另一方面Ag3Sn相弥散分布也具有强化效果,但含银量过多,Ag3Sn相长大会降低钎焊接头的抗剪强度。

1.5 银含量对钎焊接头可靠性的影响

在电子组装技术中,焊点同时承担着元器件与基板之间电气连接和机械连接的双重使命,随着电子器件向细间距高密度方向发展,元器件上需要钎焊的地方增多,某一个焊点出现问题,整个元器件都会遭到损坏。因此,研究焊点的可靠性是十分必要的,它关系到集成电路、元器件乃至整个电子产品的质量和寿命[25]。

研究[26]发现:Sn-Pb钎料的抗蠕变性能可以作为研究焊点可靠性的一个指标,钎料的抗蠕变性能越好,对应的焊点强度越高、使用寿命也越长。Sn-Pb钎料中加入银会明显地提高钎料的抗蠕变性能,由于Sn-Pb钎料失效时往往沿着富锡相和富铅相断裂,银的加入会在晶界处形成Ag3Sn相,对钎料基体具有明显的钉扎作用。然而,近年来,又有研究[27-28]指出,稀土元素甚至可以使软钎料的抗蠕变性能提高近9倍,远远大于添加银能提高的程度,另外,欧盟也在施行电子工业产品的无铅化,所以研究传统锡铅钎料的热度逐渐降低,更多的科研工作者开始关注银含量对新型无铅钎料抗蠕变性能的影响。

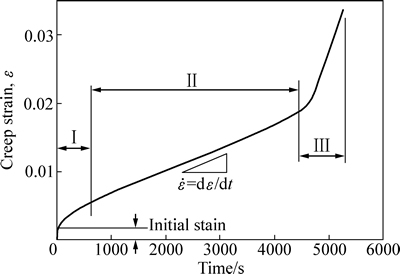

软钎料的熔点较低,在室温条件下工作温度也超过熔点的0.3倍,在该温度范围内,蠕变是最重要的变形机构之一,应力和应变中心必须是有效的蠕变松弛,以保证焊点的可靠性。无铅钎料典型的蠕变曲线如图6所示。描述了在恒载荷作用下蠕变随着时间的延续大致分3个阶段:初始蠕变、稳态蠕变和加速蠕变。蠕变过程的第二个阶段即稳态蠕变速率最小,其变形机制相对来说简单,有着很大的工程意义。因此,稳态蠕变速率常被用来衡量材料的抗蠕变变形的能力。描述蠕变第二阶段主要方程有Dorn方程、Wong模型、Garofalo-Arrheninus模型、Darveaux方程、Norton模型等[29]。

以较为简洁的Dorn方程为例:

(1)

(1)

式中:A1为材料参数;D0为自扩散系数;G为切变模量;b为布氏矢量;d为晶面间距;σ为屈服强度;n为应力指数;R为气体常数;T为绝度温度;Q为扩散激活能。

图6 无铅钎料的典型蠕变曲线

Fig. 6 Typical creep curve of solders

WIESE等[30]通过拉伸蠕变测试SnAg3.0Cu0.5钎料的Dorn方程,得到n=12.1,Q=61.1 kJ/mol;测试SnAg4.0Cu0.5钎料,得到n=18,Q=83.1 kJ/mol,可见银含量越高,蠕变速率越小,抗蠕变性能也越好。

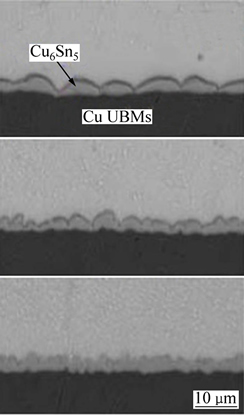

焊点在受到载荷时,断裂一般发生在脆性IMC层。图7所示为SnAgCu/Cu焊点的界面形貌。通过图7观察Sn-Ag-Cu钎料焊点的界面形貌,发现随着银含量的增加,焊点界面IMC层形貌有了较大的改变,变得相对光滑平坦[31]。这是由于Ag3Sn相的存在不仅可以细化Cu6Sn5相,使其密度增加,而且能抑制界面层的过度反应,从而改善了焊点界面形貌。IMC相越细小、数目越多,对晶界的移动可以产生更大的阻力,从而提高焊点的强度。

图7 SnAgCu/Cu焊点的界面形貌

Fig. 7 Interface morphologies of SnAgCu/Cu joints

2 银含量对硬钎料的影响规律

2.1 硬钎料的熔化特性

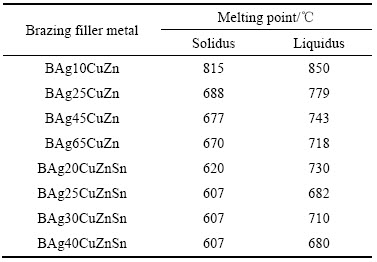

含银硬钎料的种类繁多、应用极广。常用的含银硬钎料几乎都含有铜,为降低熔点和减少银含量,通常还加入锌、镍、镉等合金元素,构成三元或多元合金。表5所列为国内市场上应用较多的几种Ag-Cu-Zn钎料的熔化温度。由表5可以看出,在Ag-Cu-Zn和Ag-Cu-Zn-Sn钎料中,随着银含量增加,钎料的固相线和液相线温度大体呈现下降趋势[1]。

Cu-P钎料由于具有较好的流动性以及钎焊温度接近银基钎料的特点,在500~800℃温度范围内,钎焊铜及铜合金的应用中被认为是取代高价银钎料的理想材料。表6所列为市场上应用较多的几种Cu-P-Ag钎料[1]。由表6可以看出,钎料由低银含量向高银含量变化,钎料的液相线下降,固相线基本不变,熔化温度区间变小。

Zn-Al钎料中添加银元素,钎料的液相线和固相线均会有所提高。FENG等[32]中提出,在85Zn-15Al钎料中添加4%的银,钎料固相线温度可达390 ℃,液相线达435 ℃,与不添加银时相比分别提高5 ℃和9 ℃。当熔点较高的银元素加入Zn-Al中时,银元素与钎料中的锌和铝都能形成固溶体,从而可以提高钎料熔点。

表5 Ag-Cu-Zn钎料的熔化温度

Table 5 Melting temperature of Ag-Cu-Zn(-Sn) brazing filler metals

2.2 硬钎料的显微组织

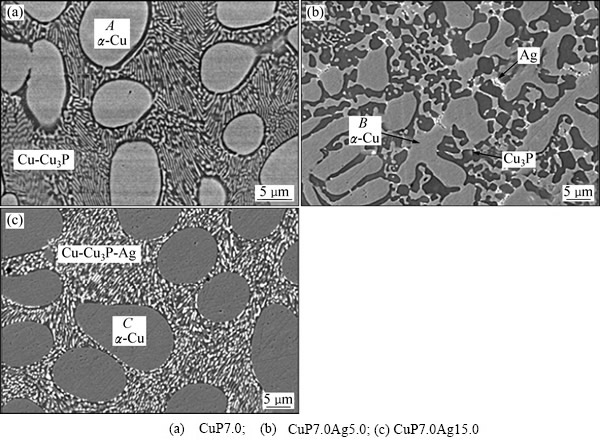

Ag-Cu-Zn钎料中有α-(Cu-Zn)、α-(Ag-Zn)、β、γ、δ、ε、η等相。α-Ag、α-Cu相为具有良好强度和塑性的相,β相是有高强度中等塑性的相,其余都为脆性相,因此,要获得优良性能的钎料,钎料的成分大都选择在未出现γ相的范围[33]。已被证实的是,当银含量在50%以上,钎料主要由α-Ag固溶体,α-Cu固溶体,Ag-Cu共晶和少量化合物相组成;当银含量在 50%以下时,化合物增多,α-Ag固溶体和Ag-Cu共晶减少,且此时钎料成分容易落在脆性的Ag5Zn8相区或Cu5Zn8相区,使合金很难加工(见图8)。因此,一般认为银的成分在40%~50%时,钎料的综合性能最佳,如型号为BAg45CuZn的钎料是一种被广泛使用、性能较优异的银钎料。

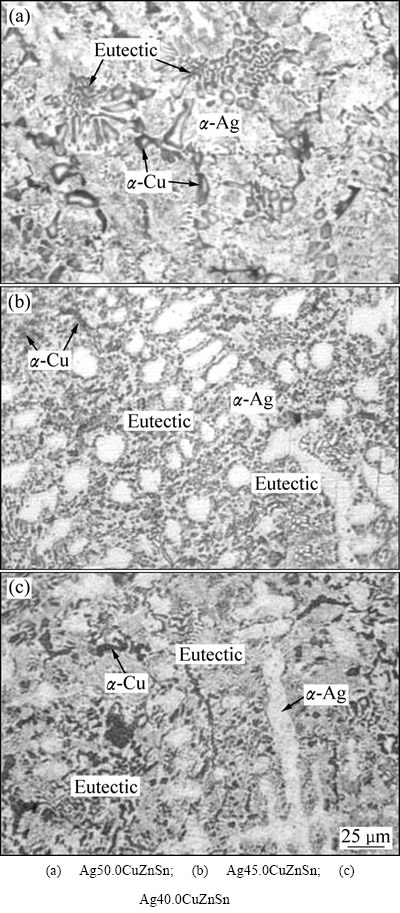

Ag-Cu-Zn-Cd钎料是银基钎料中性能最好的一种钎料。但随着2007年欧盟规定电子工业产品中不能含镉,学者们逐渐开始关注银基钎料中能替代镉的元素,发现只有锡元素可以替代镉[34]。适量的锡元素加入Ag-Cu-Zn钎料中可以改善钎料组织,这也掀起了对不同银含量的Ag-Cu-Zn-Sn钎料组织的研究热 潮[35],已知当银含量越多时,Ag-Cu-Zn-Sn钎料内也会有更多的韧性富银相和银铜共晶相区域(见图9),这会有利于提高钎料的加工性能和钎焊接头的导电性能及力学性能等。

目前,普遍认为Cu-P钎料中铜基体和Cu3P化合物的数量决定了其性能。研究发现[36],钎料中银含量越少,其显微组织中圆形的贫磷组织和树突状的富磷组织越多,而含银15%的钎料显微组织则由树枝状的铜基固溶体、银基固溶体及铜银磷共晶组织组成(见图10)。即银的添加不仅能减少钎料基体中脆性Cu3P相,同时使得塑性银基固溶体增多,改善了钎料的塑韧性和加工性能。

图9 Ag-Cu-15Zn-5Sn的显微组织

Fig. 9 Microstructures of Ag-Cu-15Zn-5Sn brazing filler metals

图10 Cu-P-xAg的显微组织

Fig. 10 Microstructures of Cu-P-xAg brazing filler metals

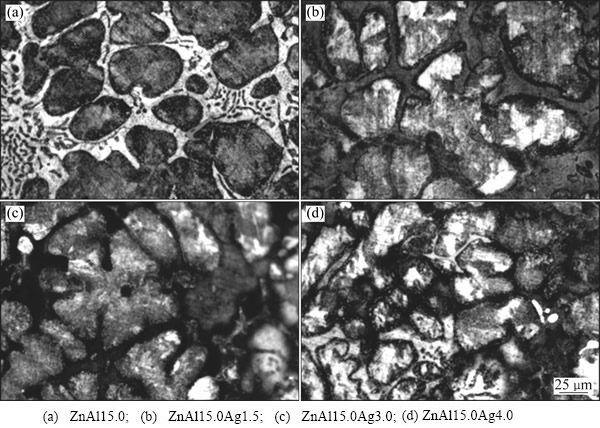

Zn-Al钎料组织如图11所示。银主要以固溶体形式存在,钎料组织是锌原子、铝原子和银原子互扩散的结果。且随着银含量的增加,Zn-Al钎料的组织更加细化,有利于钎料力学性能的提高。这是由于银元素的电负性与铝元素、锌元素的电负性差异较铝元素与锌元素的电负性差异大[32],因此,在Zn-Al钎料中添加银后,银原子与锌原子、铝原子的亲和力较大,减缓了锌原子与铝原子的互扩散速度,使得形成的固溶体相尺寸变小。

2.3 硬钎料的润湿性能

图11 Zn-Al-xAg的显微组织

Fig. 11 Microstructures of Zn-Al-xAg brazing filler metals

Ag-Cu-Zn钎料的润湿性和钎料中的银含量存在较为明显的线性关系。根据钎焊手册[1],BAgl0CuZn主要用于钎焊铜及铜合金、钢及硬质合金等,其含银量低、铺展性差,故应用不够广泛;BAg25CuZn与前者相比,银的含量提高了15%,所带来的效果是使其铺展性能得到了改善,钎缝也比较光洁。这种钎料常用于钎焊铜及铜合金、钢及不锈钢等;BAg45CuZn是最常用的银钎料之一,具有良好的铺展性能和填缝能力,整个钎缝的表面光洁;BAg50CuZn也具有良好的铺展能力和填缝能力,这种钎料常制成箔片状使用,可用于铜及其合金和钢等的钎焊;BAg70CuZn的含银量较高,铺展性较好,钎缝光洁,经常用于导电性要求高的产品的钎焊。类似地,在Ag-Cu-Zn-Sn钎料中[37],随着银含量的增加,钎料在铜基板上铺展面积逐渐增加,表明钎料的流动性增加,润湿性能增强。

银含量的提高改善了Cu-P钎料的润湿铺展性能,原因是由于银能够加快母材铜在液态钎料中溶解反应速度。然而,文献[38]中在对几种典型的Cu-P钎料润湿性能进行了测试与研究之后,提出了银含量不是影响润湿性能的主要因素,而磷含量才是主要影响因素。目前,Cu-P钎料中铜元素、磷元素含量不变时,仅增加银元素含量,是否可以改善钎料润湿性能的研究较少。

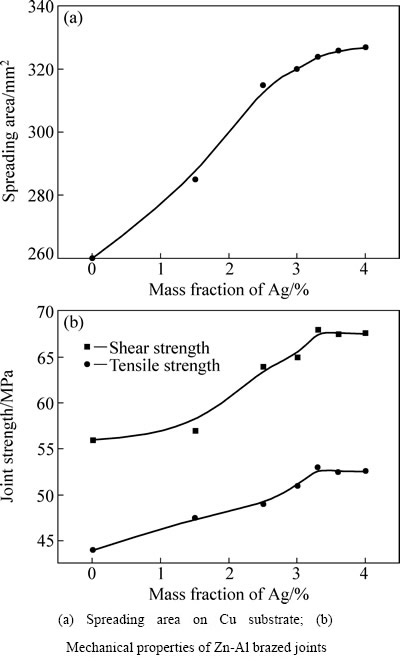

用于铝和铜钎焊的Zn-Al钎料是近年来迅速发展起来的一种新型钎料[39]。在Zn-Al钎料中加入银元素能够显著提高其钎焊接头的润湿性能和力学性能(见图12)。图12(a)显示了在Zn-15Al钎料中加入银元素之后,Zn-Al钎料铺展性能的变化。试验[32]表明,不含银的钎料铺展面积较小的原因是由于锌元素向铜板和铝板等母材晶间渗透的速度相当快,阻碍钎料的铺展;而加入银后,铺展面积增加是由于银元素与锌元素亲和力大,减弱了钎料中锌向母材的扩散速度,故而铺展性能得到提高。同时,钎料润湿性能的改善也可以促进力学性能的提高。

2.4 硬钎料钎焊接头的力学性能

Ag-Cu-Zn和Ag-Cu-Zn-Sn钎料钎焊不锈钢接头的抗拉强度均高于300 MPa,已经满足大部分情况下的使用要求[40],且随着钎料中银含量的增加,抗拉强度降低,韧性有所提高。但此时若钎料中银含量过低,就会导致接头的脆性增大,使得接头更加容易断裂,接头的使用寿命也随之降低。

Cu-P钎料钎焊接头的切面中Cu3P化合物及银基固溶体的数量与分布情况是决定其力学性能的主要因素。试验表明[38]:BCuPAg5钎料钎焊接头的塑韧性、抗拉强度均强于无银Cu-P钎料的,但接头的硬度却不如前者,进一步试验发现,钎焊接头的硬度主要取决于填充金属的成分,银含量越高,接头的韧性越好。同时,在有些高磷含量的Cu-P钎料中,加入银元素组成Cu-P-Ag钎料时,钎料和钎焊接头的塑性并未显著改善[41]。这也促使研究者们对Cu-P-Ag钎料中银的作用需要进行更加深入地分析。

图12 银添加对Zn-Al钎料性能的影响

Fig. 12 Effect of Ag addition on properties of Zn-Al brazing filler metals

Zn-Al钎料接头力学性能参见图12(b)[42]。钎料中银含量增加,会使钎料组织中含银固溶体数量增加,固溶强化不断增强,铜-铝接头的抗拉强度和抗剪强度均呈上升趋势,当添加银元素到一定含量时,固溶强化作用已经饱和,接头强度达到最高,再添加银,钎焊接头的力学性能趋于稳定。

2.5 银含量对钎焊接头导电性能的影响

电机是一种应用广泛、技术要求高的动力设备, 它的许多构件采用钎焊结构,如水力、火力发电设备定子线圈上下层、转子磁极线圈、笼型转子导条与端环、直流电机电枢绕组升高片与换向片的连接等。不同含银量钎料对电机钎焊接头电阻值的影响早已有详尽的研究报道[43-45] 。而电机钎焊所用钎料则主要以Ag-Cu-Zn钎料和Cu-P-Ag钎料为主[46-47]。发电设备中钎焊接头的导电性能稍有提高,电能的损耗将大大降低,接头的使用寿命也随之提高。因此,研究含银钎料钎焊接头的导电性能是至关重要的。对于电机中铜导线的钎焊接头来说,由于合金总是比金属单质的电阻率高很多,因此,钎缝处电阻值对整个导线圈的导电性能有十分重要的影响。而银是已知的电阻率最小的金属,钎料中的银含量越高,电阻值一般也越低(见表6),其钎焊接头的导电性能也越好,这也是导致高银含量钎料一直很难被取代的原因之一。

3 含银钎料的发展趋势

无论是含银的软钎料还是硬钎料,都是使用量极其广泛的钎料。尽管它具有优良的工艺性能、适宜的熔点、良好的润湿铺展性能,且钎料和钎缝的强度、导电性和耐蚀性优良等系列优点,但含银钎料的研究和发展依然有很长的路要走[48-49]。含银钎料的研究方向一方面是人们迫切的需要开发出更多的低银钎料,以降低成本和增加经济性;另一方面,含银钎料已经突破了传统的三元、四元合金,很多的研究者们已经开始转向研究五元含银钎料甚至更多元含银钎料,无论如何,含银钎料研究的出发点总是既要想方设法降低银含量又要获得更加优良的润湿性能和力学性能。因此,未来银钎料可能的研究趋势如下。

1) 降低成本的研究:银是一种贵金属,不但价格昂贵,而且资源有限。一直以来研究者都是在保证钎料性能的前提下,降低银元素含量,开发以经济性为目的的低银软钎料,以替代部分Sn-Pb钎料和高银含量的钎料,目前,国内外对低银Sn-Ag-Cu钎料的研究是一大热点。同样,对于含银硬钎料,以Ag-Cu-Zn钎料来说,配方中的银含量能节省10%,成本费就能省约40%,具有十分可观的经济效益。

2) 随着钎料中禁止使用铅镉等6种有害物质,银对钎料性能的改善作用重新得到重视。另外,含银钎料性能的改进也是目前研究的热点,而添加部分稀有元素或稀土元素是最为有效的办法之一,例如在SnAgCu钎料中添加铈和镧能很好的抑制Cu6Sn5相的产生[50-51],且能提高润湿性。在硬钎料如银基钎料中添加镓和铟也可显著改善钎料组织[52],甚至部分含镓银钎料整体性能超过了传统含镉银钎料,往含银钎料的添加稀土元素的研究仍将是重点发展方向之一。银与钎料、含银钎料与稀土元素之间相互作用机理研究的迫切性更加突出。

4 结论

1) 通过总结归纳银含量对含银钎料合金的熔化温度、润湿性能、组织和力学性能等行为的影响,发现银元素的含量一定时,可以明显改善钎料的润湿性能,细化钎料组织和减小金属间化合物颗粒尺寸,添加适量的银可以提高钎料的综合性能。

2) 随着钎料中银含量增加,钎料性能反而下降的现象,这往往和钎料的组织结构有关。

3) 银的昂贵价格制约着高银含量钎料的研究和推广,因此,学者更多地把目光放在能替代其性能的低银钎料,从而发展出添加稀土元素的四元含银钎料,甚至更多元含银钎料。

4) 分析含银钎料的研究和发展趋势,提出含银钎料在研究和应用过程中存在的问题及相应的解决措施,为进一步研究提供基础支撑。

REFERENCES

[1] 庄鸿寿, 张启运. 钎焊手册[M]. 北京: 机械工业出版社, 1998.

ZHUANG Hong-shou, ZHANG Qi-yun. Manual for brazing and soldering[J]. Beijing: China Machine Press, 1998.

[2] HANDBOOK A S M. Welding, brazing and soldering[J]. ASM International, 1993, 6: 416-418.

[3] SHNAWAH D A A, SABRI M F B M, BADRYDDIN I A, SAID S. A review on effect of minor alloying elements on thermal cycling and drop impact reliability of low-Ag Sn-Ag-Cu solder joints[J]. Microelectronics International, 2012, 29(1): 47-57.

[4] HUNG Fei-yi, WANG Chih-jung, HUANG Sung-min, CHEN Li-hui, LUI Truan-sheng. Thermoelectric characteristics and tensile properties of Sn-9Zn-xAg lead-free solders[J]. Journal of Alloys and Compounds, 2006, 420(1): 193-198.

[5] LIN Kwang-lung, SHIH Chia-ling. Microstructure and thermal behavior of Sn-Zn-Ag solders[J]. Journal of Electronic Materials, 2003, 32(12): 1496-1500.

[6] MIAO Hui-wei, DUH Jenq-gong, CHIOU Bi-shiou. Thermal cycling test in Sn-Bi and Sn-Bi-Cu solder joints[J]. Journal of Materials Science: Materials in Electronics, 2000, 11(8): 609-618.

[7] VIANCO P T, REJENT J A. Properties of ternary Sn-Ag-Bi solder alloys: Part I—Thermal properties and microstructural analysis[J]. Journal of Electronic Materials, 1999, 28(10): 1127-1137.

[8] REID M, PUNCH J, COLLINS M, RYAN C. Effect of Ag content on the microstructure of Sn-Ag-Cu based solder alloys[J]. Soldering & Surface Mount Technology, 2008, 20(4): 3-8.

[9] SONG J M, LAN G F, LUI T S, CHEN L H. Microstructure and tensile properties of Sn-9Zn-xAg lead-free solder alloys[J]. Scripta Materialia, 2003, 48(8): 1047-1051.

[10] 吴文云, 邱小明, 殷世强, 孙大谦, 李明高. Bi, Ag 对 Sn-Zn 无铅钎料性能与组织的影响[J]. 中国有色金属学报, 2006, 16(1): 158-163.

WU Wen-yun, QIU Xiao-ming, YIN Shi-qiang, SUN Da-qian, LI Ming-gao. Influence of Bi, Ag on microstructure and properties of Sn-Zn lead-free solder[J]. The Chinese Journal of Nonferrous Metals,2006, 16(1): 158-163.

[11] 何 鹏, 吕晓春, 张斌斌, 马 鑫, 钱乙余. 合金元素对 Sn-57Bi 无铅钎料组织及韧性的影响[J]. 材料工程, 2010, 10(5): 13-17.

HE Peng, LU Xiao-chun, ZHANG Bin-bin, MA Xin, QIAN Yi-yu. Effect of alloy element on microstructure and impact toughness of Sn-57Bi led-free solders[J]. Journal of Materials Engineering,2010, 10(5): 13-17.

[12] CHEN Chih-ming, HUANG Chih-chieh. Effects of silver doping on electromigration of eutectic SnBi solder[J]. Journal of Alloys and Compounds, 2008, 461(1): 235-241.

[13] BURKE C, PUNCH J. A Comparison of the creep behavior of joint-scale SAC105 and SAC305 solder alloys[J]. IEEE Transactions on Components Packaging and Manufacturing Technology, 2014, 4(3): 516-527.

[14] LIN Kwang-lung, SHIH Chia-ling. Wetting interaction between Sn-Zn-Ag solders and Cu[J]. Journal of Electronic Materials, 2003, 32(2): 95-100.

[15] WANG Hui, XUE Song-bai, ZHAO Feng, CHEN Wen-xue. Effects of Ga, Al, Ag, and Ce multi-additions on the properties of Sn-9Zn lead-free solder[J]. Journal of Materials Science Materials in Electronics, 2010, 21(2): 111-119.

[16] SHIUE Ren-kae, TSAY Leu-wen, LIN Chun-lun, OU Jia-lin. A study of Sn-Bi-Ag-(In) lead-free solders[J]. Journal of Materials Science, 2003, 38(6): 1269-1279.

[17] VIANCO P T, REJENT J A. Properties of ternary Sn-Ag-Bi solder alloys: Part II—Wettability and mechanical properties analysis[J]. Journal of Electronic Materials, 1999, 28(10): 1138-1143.

[18] MA Hong-tao, SUHLING Jeffrey-C. A review of mechanical properties of lead-free solders for electronic packaging[J]. Journal of Materials Science, 2009, 44(5): 1141-1158.

[19] 王凤江, 钱乙余, 马 鑫. 微观压痕法测量 Sn-Ag-Cu 系无铅钎料的力学性能[J]. 中国有色金属学报, 2005, 15(5): 688-693.

WANG Feng-Jiang, QIAN Yi-Yu, MA Xin. Measurement of mechanical properties of Sn-Ag-Cu series lead-free solder alloy by using micro-indentation[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 688-693.

[20] ZENG Guang, XUE Song-bai, ZHANG Liang, GAO Li-li, DAI Wei, LUO Jia-dong. A review on the interfacial intermetallic compounds between Sn-Ag-Cu based solders and substrates[J]. Journal of Materials Science (Materials in Electronics), 2010, 21(5): 421-440.

[21] SONG J M, LUI T S, LAN G F, CHEN L H. Resonant vibration behavior of Sn-Zn-Ag solder alloys[J]. Journal of Alloys and Compounds, 2004, 379(1): 233-239.

[22] CHEN Wen-xue, XUE Song-bai, WANG Hui, WANG Jian-xin, HAN Zong-jie. Effects of Ag on microstructures, wettabilities of Sn-9Zn-xAg solders as well as mechanical properties of soldered joints[J]. Journal of Materials Science (Materials in Electronics), 2010, 21(5): 461-467.

[23] SHALABY R M. Effect of silver and indium addition on mechanical properties and indentation creep behavior of rapidly solidified Bi-Sn based lead-free solder alloys[J]. Materials Science and Engineering A, 2013, 560: 86-95.

[24] 何 鹏, 赵智力, 钱乙余. Sn-Bi-Ag-Cu 钎料波峰焊焊点的剥离现象[J]. 中国有色金属学报, 2005, 15(7): 993-999.

HE Peng, ZHAO Zhi-li, QIAN Yi-yu. Fillet-lifting phenomenon of wave soldering with Sn-Bi-Ag-Cu solder[J]. The Chinese Journal of Nonferrous Metals,2005, 15(7): 993-999.

[25] RIDOUT S, BAILEY C. Review of methods to predict solder joint reliability under thermo-mechanical cycling[J]. Fatigue & Fracture of Engineering Materials & Structures, 2007, 30(5): 400-412.

[26] KANCHANOMAI C, MIYASHITA Y, MUTOH Y. Low cycle fatigue behavior and mechanisms of a eutectic Sn-Pb solder 63Sn/37Pb[J]. International Journal of Fatigue, 2002, 24(6): 671-683.

[27] ZHANG Liang, XUE Song-bai, GAO Li-li, ZENG Guang, SHENG Zhong, CHEN Yan, YU Sheng-lin. Effects of rare earths on properties and microstructures of lead-free solder alloys[J]. Journal of Materials Science (Materials in Electronics), 2009, 20(8): 685-694.

[28] 张 亮, 韩继光, 何成文, 郭永环, 薛松柏, 皋利利, 叶 焕. 稀土元素对无铅钎料组织和性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1680-1696.

ZHANG Liang, HAN Ji-guang, HE Cheng-wen. GUO Yong-huan, XUE Song-bai, GAO Li-li, YE Huan. Effects of rare earths on properties and microstructures of lead-free solder alloys[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1680-1696.

[29] LALL P, GUPTE S, CHOUDHARY P, SUHLING J. Solder-joint reliability in electronics under shock and vibration using explicit finite-element sub-modeling[C]//Electronic Components and Technology Conference, 2006. Proceedings. 56th. IEEE, 2006: 8.

[30] WIESE S, SCHUBERT A, WALTER H, DUKEK R, FEUSTEL F, MEUSEL E, MICHEL B. Constitutive behavior of lead-free solders vs lead-containing solders-experiments on bulk specimens and flip-chip joints[C]//Electronic Components and Technology Conference, 2001. IEEE, 2001: 890-902.

[31] CHO M G, PARK Y S, SEO S K, PAIK K W LEE H M. Effect of Ag addition on the ripening growth of grains at the Interface of Sn-xAg-0.5 Cu/Cu during a reflow[J]. Components, Packaging and Manufacturing Technology, IEEE Transactions on Components, 2011, 1(12): 1939-1946.

[32] FENG Ji, XUE Song-bai, LOU Ji-yuan, LOU Yin-bin, WANG Shui-qing. Microstructure and properties of Cu/Al joints brazed with Zn-Al filler metals[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 281-287.

[33] MURAKAMI Y, NAKANISHI N, KACHI S. Superlattice formation in the ternary β phase alloys—I. AuxCu55-xZn and AgxCu53-xZn alloys[J]. Acta Metallurgica, 1971, 19(2): 93-96.

[34] XUE Song-bai. Effect of tin and indmium in silver filler metal and its mechanism[J]. Welding & Joining, 1998, 11(12): 28-31.

[35] LI Zhou-ran, JIAO Ning, FENG Ji-cai, LU Cheng-hong. Effect of alloying elements on microstructure and property of AgCuZuSn brazing alloy[J]. Transactions of the China Welding Institution, 2008, 29(3): 65-68.

[36] LI Yi-nan, WANG Chang-wen, PENG Zi-long, YAN Jiu-chun, LIU Xue-song. Dissolution behavior of Cu in Cu-Ag and Cu-P brazing alloys using weld brazing[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 394-399.

[37] SHIUE R K, WU S K, CHAN C H. The interfacial reactions of infrared brazing Cu and Ti with two silver-based braze alloys[J]. Journal of Alloys and Compounds, 2004, 372(1): 148-157.

[38] KARAMIS M B, TASDEMIRCI A, NAIR F. Microstructural analysis and discontinuities in the brazed zone of copper tubes[J]. Journal of Materials Processing Technology, 2003, 141(3): 302-312.

[39] NAKA M, HAFEZ K M. Applying of ultrasonic waves on brazing of alumina to copper using Zn-Al filler alloy[J]. Journal of Materials Science, 2003, 38(16): 3491-3494.

[40] ARENAS M F, ACOFF V L, REDDY R G. Physical properties of selected brazing filler metals[J]. Science and Technology of Welding & Joining, 2004, 9(5): 423-429.

[41] HASAP A, NORAPHAIPHIPAKSA N, KANCHANOMAI C. The microstructure and strength of copper alloy brazing[J]. Welding Journal, 2014, 93(4): 116-123.

[42] 张 满, 薛松柏, 戴 玮, 娄银斌, 王水庆. Ag元素对Zn-Al钎料性能的影响[J]. 焊接学报, 2010, 21(10): 73-76.

ZHANG Man, XUE Song-bai, DAI Wei, LOU Yin-bin, WANG Shui-qing. Effect of Ag on properties of Zn-Al brazing filler metal[J]. Transactions of the China Welding Institution, 2010, 21(10): 73-76.

[43] 刘永安. 不同含银量钎料对电机钎焊接头电阻值的影响[J]. 大电机技术, 1997(3): 30-32.

LIU Yong-an. The influence on soldering connection resistance of solder with different silver content in electric machined[J]. Large Electric Machine and Hydraulic Turbine, 1997(3): 30-32.

[44] 高显志. 对电动机绕组接头焊接法的改进研究[J]. 黑龙江科学, 2014, 5(6): 227.

GAO Xian-zhi. Improvement on the welding method of motor winding joints[J]. Heilongjiang Science, 2004, 5(6): 227.

[45] MAMUNYA Ye P, ZOIS H, APEKIS L, LEBEDEV E V. Influence of pressure on the electrical conductivity of metal powders used as fillers in polymer composites[J]. Powder Technology, 2004, 140(1): 49-55.

[46] 汪永东, 史文卿, 呼义通, 徐 波. 交直流电机转子铜条与端环中频感应钎焊工艺方法的研究[J]. 大电机技术, 2003, 1(1): 5-7.

WANG Yong-dong, SHI Wen-qing,HU Yi-tong, XU Bo. Making an investigation in the technological method of the medium-frequency induction braze welding of the rotor copper bar and end-ring for the AC and DC motor[J]. Large Electric Machine and Hydraulic Turbine, 2003, 1(1): 5-7.

[47] MORSE R S. Electronic circuit package and method of brazing: US Patent 3941916[P]. 1976-03-02.

[48] RANJIT P T. Effect of silver in common lead-free alloy[C]//Proceedings of the SMTA International Conference. Florida: IEEE, 2008.

[49] 韩宪鹏, 薛松柏, 赖忠民, 顾文华, 顾立勇. 无镉银钎料研究现状与发展趋势[J]. 焊接, 2007(6): 19-23.

HAN Xian-peng, XUE Song-bai, LAI Zhong-min, GU Wen-hua, GU Li-yong. Research progress and development of cadmium-free silver brazing solder[J]. Weiding & Joining, 2007(6): 19-23.

[50] ZHANG Liang, XUE Song-bai, GAO Li-li, YU Sheng-lin, SHENG Zhong, ZENG Guang. Microstructure and creep properties of Sn-Ag-Cu lead-free solders bearing minor amounts of the rare earth cerium[J]. Soldering & Surface Mount Technology, 2010, 22(2): 30-36.

[51] YU D Q, ZHAO J, WANG L. Improvement on the microstructure stability, mechanical and wetting properties of Sn-Ag-Cu lead-free solder with the addition of rare earth elements[J]. Journal of Alloys and Compounds, 2004, 376(1): 170-175.

[52] LAI Zhong-min, XUE Song-bai, HAN Xian-peng, GU Li-yong, GU Wen-hua. Study on microstructure and property of brazed joint of AgCuZn-X (Ga, Sn, In, Ni) brazing alloy[J]. Rare Metal Materials and Engineering, 2010, 39(3): 397-400.

Effect of Ag on properties of Ag-contained filler metals

WANG He, XUE Song-bai, LIU Shuang

(College of Materials Science and Technology,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: Ag is used as a beneficial alloy element in no matter solders or brazing filler metals. Obviously, the addition of Ag has a positive function on melting temperature, wettability, mechanical property and conductivity of filler metals. Therefore, Ag is still widely used in many researches and production in spite that Ag is very expensive. Respectively, three kinds of typical solders (Sn-Zn, Sn-Bi, Zn-Al) and brazing filler metals (Ag-Cu-Zn, Cu-P, Zn-Al) were selected as the representative. The research status on the Ag-contained filler metals and the influence rules of Ag addition on the change of filler metals physical property and microstructure as well as mechanical property were reviewed. Moreover, the problems and difficulties in the process of studying Ag-contained solders and brazing filler metals were presented. Synchronously, some suggestions were put forward to solve the problems and difficulties mentioned above, which provides theory guide for the follow-up study of Ag-contained solders and brazing filler metals, and their prospects were also prospected.

Key words: Ag; Ag-contained alloy; wettability; solder joint; solder; brazing filler metal

Foundation item: Project(kfjj20150604) supported by Foundation of Graduated Innovation Center in NUAA, China; Project supported by Priority Academic Program Development of Jiangsu Higher Education Institutions, China

Received date: 2015-07-22; Accepted date: 2016-02-28

Corresponding author: XUE Song-bai; Tel: +86-25-84896070; E-mail: xuesb@nuaa.edu.cn

(编辑 李艳红)

基金项目:南航研究生创新基地开放基金资助项目(kfjj20150604);江苏高校优势学科建设工程资助项目

收稿日期:2015-07-22;修订日期:2016-02-28

通信作者:薛松柏,教授,博士;电话:025-84896070;E-mail:xuesb@nuaa.edu.cn

摘 要:分别选取3种典型的含银软钎料(Sn-Ag-Cu、Sn-Zn、Sn-Bi)和硬钎料(Ag-Cu-Zn、Cu-P、Zn-Al)作为代表进行阐述。综述了国内外含银钎料研究的最新研究成果,归纳分析银元素对软钎料与硬钎料的物理性能、显微组织和力学性能的影响规律,提出含银钎料在研究和应用过程中存在的问题及相应的解决措施,展望含银钎料的研究和发展趋势。

[1] 庄鸿寿, 张启运. 钎焊手册[M]. 北京: 机械工业出版社, 1998.

[2] HANDBOOK A S M. Welding, brazing and soldering[J]. ASM International, 1993, 6: 416-418.

[10] 吴文云, 邱小明, 殷世强, 孙大谦, 李明高. Bi, Ag 对 Sn-Zn 无铅钎料性能与组织的影响[J]. 中国有色金属学报, 2006, 16(1): 158-163.

[11] 何 鹏, 吕晓春, 张斌斌, 马 鑫, 钱乙余. 合金元素对 Sn-57Bi 无铅钎料组织及韧性的影响[J]. 材料工程, 2010, 10(5): 13-17.

[19] 王凤江, 钱乙余, 马 鑫. 微观压痕法测量 Sn-Ag-Cu 系无铅钎料的力学性能[J]. 中国有色金属学报, 2005, 15(5): 688-693.

[24] 何 鹏, 赵智力, 钱乙余. Sn-Bi-Ag-Cu 钎料波峰焊焊点的剥离现象[J]. 中国有色金属学报, 2005, 15(7): 993-999.

[28] 张 亮, 韩继光, 何成文, 郭永环, 薛松柏, 皋利利, 叶 焕. 稀土元素对无铅钎料组织和性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1680-1696.

[42] 张 满, 薛松柏, 戴 玮, 娄银斌, 王水庆. Ag元素对Zn-Al钎料性能的影响[J]. 焊接学报, 2010, 21(10): 73-76.

[43] 刘永安. 不同含银量钎料对电机钎焊接头电阻值的影响[J]. 大电机技术, 1997(3): 30-32.

[44] 高显志. 对电动机绕组接头焊接法的改进研究[J]. 黑龙江科学, 2014, 5(6): 227.

[46] 汪永东, 史文卿, 呼义通, 徐 波. 交直流电机转子铜条与端环中频感应钎焊工艺方法的研究[J]. 大电机技术, 2003, 1(1): 5-7.

[47] MORSE R S. Electronic circuit package and method of brazing: US Patent 3941916[P]. 1976-03-02.

[49] 韩宪鹏, 薛松柏, 赖忠民, 顾文华, 顾立勇. 无镉银钎料研究现状与发展趋势[J]. 焊接, 2007(6): 19-23.