Trans. Nonferrous Met. Soc. China 22(2012) s74-s78

Novel multilayer Mg-Al intermetallic coating for corrosion protection of magnesium alloy by molten salts treatment

HE Mei-feng1, HU Wen-bin2, ZHAO Su3, LIU Lei2, WU Ya-ting2

1. School of Materials Science and Engineering, University of Shanghai for Science and Technology, Shanghai 200093, China;

2. State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China;

3. School of Mechanical Engineering, Shanghai Dianji University, Shanghai 200240, China

Received 9 July 2012; accepted 10 August 2012

Abstract:

A novel multilayer Mg-Al intermetallic coating on the magnesium alloy was obtained by AlCl3-NaCl molten salt bath treatment. The molten salt was treated at 400 °C, which is lower than the treatment temperature of solid diffusion Al powder. The thick Al12Mg17, Al0.58Mg0.42 and Al3Mg2 multilayer Mg-Al intermetallic coating forms on the magnesium alloy. The corrosion resistance of AZ91D alloy with and without coating by multilayer of Mg-Al intermetallic compound was evaluated by electrochemical impedance spectroscopy measurements in 3.5% (mass fraction) NaCl solution. The polarization resistance value of the multilayer coating on the magnesium alloy by molten salt bath treatment is greater than that of the uncoated one, which is attributed to the homogenously distributed intermetallic phases.

Key words:

Mg-Al intermetallic coating; multilayer; diffusion; corrosion; magnesium alloy; molten salt treatment;

1 Introduction

In recent years, magnesium alloys, owing to their excellent combination of properties, have found numerous applications in the electronic, automobile and aerospace industries. However, these alloys suffer heavily from their poor corrosion resistance in many environments [1–3].

Surface alloying of magnesium alloy with Al has been considered an effective approach to improve the corrosion resistance. Al element was chosen for the protection layer on the Mg alloy due to three main factors as follows [4]: 1) Being a lightweight metal, Al does not increase the overall density significantly. Moreover, the corrosion resistance of Al and its alloys is satisfactory. 2) A coated Mg alloy can generate a continuous Mg–Al intermetallic compound near the surface. It has been confirmed that this compound possesses good corrosion resistance [5-8]. 3) Good recycling of materials can be maintained because Al is a primary alloy element for the AZ series Mg alloys. The Mg-Al intermetallic compounds including Al17Mg12 and Al3Mg2 have good corrosion resistance. Based on the understanding of the role of Al17Mg12 phase [6-9] in reducing the corrosion rate if the volume faction of the phase in the “skin” of a magnesium alloy is high enough, SONG [10] pointed out that an alloy would become very resistant to corrosion without sacrificing its mechanical properties if it was designed to have a skin mainly consisting of Al17Mg12 phase. SONG [10] further suggested that such a skin could be formed on the surfaces of magnesium alloys by dipping the magnesium alloys in molten aluminium.

In order to promote the diffusion of Al into the Mg substrate, the diffusion coating has to be carried out at temperatures over 450 °C [11-15]. Such temperatures are too high to be of practical use because they result in surface melting and cracking. Molten salts are completely ionized nonaqueous solvents having original and rich chemistry [16-18]. The molten salt surface treatment of a protective alloyed layer on the AZ91D alloy has been attempted in this study. Moreover, AlCl3- NaCl molten salt has a low melting point of 154 °C. The molten salt surface treatment is able to produce multilayer Mg-Al intermetallic compound coating on the AZ91D magnesium substrate at lower temperatures.

Previous work from our group [19] has prepared intermetallic coatings on the Mg alloys at a lower temperature of 380 °C through molten salt bath treatment. However, all the formed intermetallic compounds can not be roundly characterized. The present work aims to a novel effective process to produce continuous multilayer Mg-Al intermetallic compound coating on the AZ91D magnesium substrate at lower temperatures and improve the corrosion resistance of AZ91D alloy.

2 Experimental

A die-cast AZ91D Mg alloy with a composition (mass fraction) of 9.1% Al, 0.64% Zn, 0.17% Mn, and balance Mg was used as the substrate. Before the molten salt treatment, the samples with size of d 20 mm×5 mm were ground successively by SiC emery paper with grits of 320, 500, 800, 1000, respectively, and then rinsed with acetone. A mixture salt with molar ratio of AlCl3 to NaCl of 1:1 was prepared. Anhydrous NaCl and anhydrous AlCl3 were melted at 400 °C under argon gas (99.999%) followed by HCl gas purification to remove oxide ions; argon was flushed again to remove dissolved HCl gas. The moisture and oxygen content were maintained in low level. Then the samples were dipped into the molten mixed salts bath for 6 h. The samples were cooled down until 100 °C in the furnace, then were taken out to the air.

After molten salt surface treatment, the samples were thoroughly cleaned using distilled water and then dried in air. The morphology of the sample was examined by scanning electron and back scattered electron microscopy (SEM/BSE, FEI SIRION-200) and X-ray diffractometry (XRD, D/max-2550). Deaerated 3.5% (mass fraction) NaCl testing solution was employed for corrosion resistance measurements. A high density graphite electrode and a saturated calomel electrode (SCE) were used as the counter electrode and the reference electrode, respectively. Electrochemical impedance spectroscopy (EIS) was carried out at the open circuit potential (OCP). The detected frequency was in the range of 1 MHz to 100 mHz, with a sinusoidal signal perturbation of 5 mV.

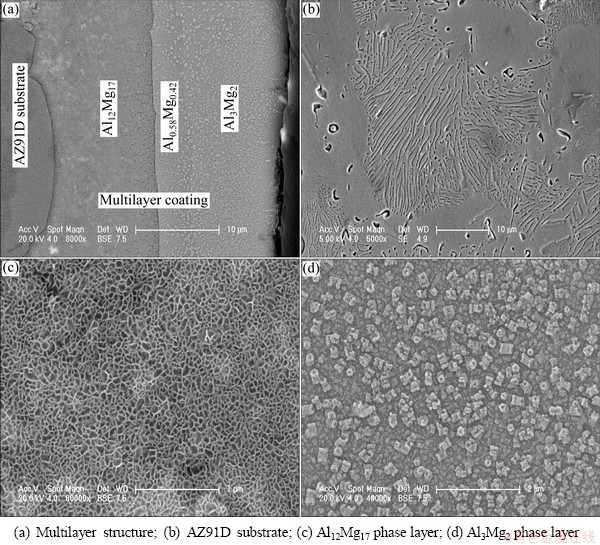

Fig. 1 SEM/BSE images of cross-section on molten salt surface treated sample

3 Results and discussion

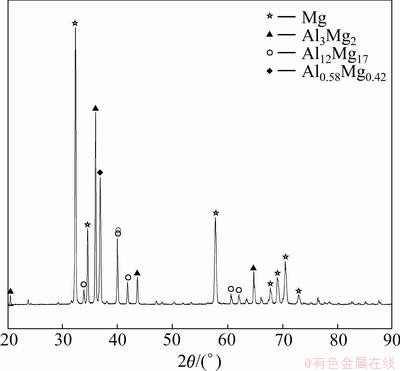

Reaction and diffusion between AZ91D alloy and AlCl3-NaCl molten salt bath with the formation of a multilayer structure was observed at 400 °C for 6 h. Representative microstructure of intermetallic layer is presented in Fig. 1(a). The intermetallic layers run parallel to the AZ91D substrate. As seen, the alloyed coating is multilayer and adherent to the surface. Figure 2 shows the XRD pattern of molten salt surface treated sample. It was confirmed that the alloyed coating consisted of Al12Mg17, Al3Mg2 and Al0.58Mg0.42. FUNAMIZU and WATANABE [20] found that the growth rate of the Al12Mg17 and Al3Mg2 phases follows a parabolic relationship typical of pseudo steady-state diffusion processes, increasing the heat treatment temperature from 340 to 425 °C for 20 h, and increasing the thickness of the Al3Mg2 layer by a factor of about 13, and the Al12Mg17 layer by a factor of about 1.7. The molten salt surface treatment can obtain fast layer growth at lower temperature. Figure 1(b) shows optical SEM (secondary electron image) photograph of cross-section of AZ91D substrate. The Al12Mg17 phase layer of alloyed coating presents network feature (Fig. 1(c)), while the Al3Mg2 phase layer of alloyed coating is composed of cubical shape particles (Fig. 1(d)).

Fig. 2 XRD pattern of surface of molten salt surface treated sample.

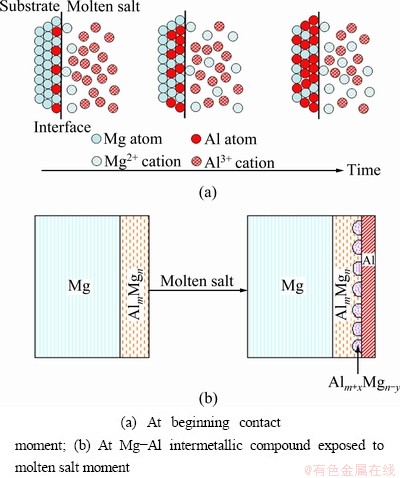

Fig. 3 Sketch diagram of substitution reaction related Al deposition at interface between molten salt and AZ91D substrate at different moments

ROLLAND and MAMANTOV [21] proposed that AlCl3 species formed a complex ion, AlCl4-, in AlCl3- NaCl molten salt system:

AlCl3+NaCl→NaAlCl4 (1)

Substitution reaction-related Al deposition which is shown in Fig. 3(a) occurs during dipping the substrates in molten NaAlCl4 at the beginning contact moment.

3Mg+2NaAlCl4→2Al+3MgCl2+2NaCl (2)

The Gibbs free energy of reaction (2) will follow with the formula of △G=-461997+5.071T which was calculated using thermodynamic data. When the value of △G is negative, reaction (2) might occur. The temperature range is determined by the above limiting condition:

△G=-461997+5.071T <0,

Then,

T<91105.7 K (viz. θ<90832.7 °C)

The Gibbs free energy of reaction (2) at the temperature of 400°C is negative, which indicates that the reaction (2) might occur at the temperature of 400 °C. Merge the reactions (1) and (2), the equivalent reaction can be obtained.

3Mg+2Al3+→2Al+3Mg2+ (3)

The formation of the alloying coating may contain the following steps. At the beginning, the diffusion occurs in the contact interface between the magnesium surface and aluminum particles. Once the aluminum atoms cross the interfacial barriers, it initially exists in the form of Mg-Al solid solution and Al continuously diffuses inward into the substrate due to the existence of a concentration gradient. With increasing concentration of aluminum elements, aluminum would react with magnesium on the surface to form Mg-Al intermetallic compounds at high temperature for long time. When the Mg-Al intermetallic compound coating is exposed to the molten salt, the substitution reaction related Al deposition and new Mg-Al intermetallic compound formation would occur. The reaction occurs between the Mg-Al intermetallic compound and molten salt, which is shown in Fig. 3(b).

AlmMgn+(x-1)Al3+→Al+Alm+xMgn-y+yMg2+ (4)

The processes of reaction, diffusion, and solid solution reaction to form Mg-Al intermetallics compound continue during the treatment process.

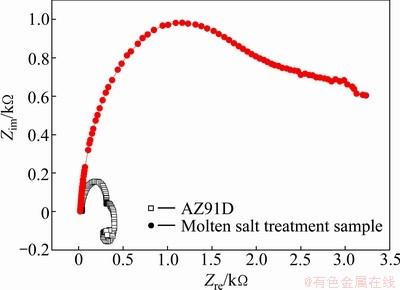

The EIS data of the samples were collected at the OCPs to evaluate the corrosion resistance. Figure 4 demonstrates the Nyquist plot of the AZ91D and molten salt treated samples. The single semicircle of each spectrum characterized a one time constant equivalent circuit. The simulation values obtained by ZSimpWin software revealed that the polarization resistances (Rp) of the AZ91D Mg alloy and molten salt surface treated samples were 329 and 1870 Ω/cm2, respectively. As compared to that of AZ91D Mg alloy, the Rp value of the coated sample is six times greater; this clearly indicates that the alloyed coating leads to an improvement in corrosion resistance.

Fig. 4 EIS plots of uncoated AZ91D alloy and molten salt surface treatment sample after being immersed in 3.5% NaCl solution

4 Conclusions

1) The multilayer structure was observed in the alloyed coating. The molten salt was treated at 400 °C, which is lower than the treatment temperature of the solid diffusion Al powder. This results in the formation of thick Al12Mg17, Al0.58Mg0.42 and Al3Mg2 multilayer Mg-Al intermetallic coating.

2) The corrosion behavior of AZ91D alloy without and with coating by multilayer Mg-Al intermetallic compound was examined in 3.5% NaCl solutions. As compared to that of AZ91D Mg alloy, the polarization resistance (Rp) value of the coated sample is six times greater. Continuous Mg-Al intermetallic compounds act as corrosion barrier.

References

[1] HILLIS J E. The effect of heavy metal contamination on magnesium corrosion performance [R]. 1983.

[2] GHALI E, REVIE R W. Uhlig’s corrosion handbook [M]. New York: John Wiley, 2000: 793-830.

[3] SONG G L, ATRENS A. Corrosion mechanisms of magnesium alloys [J]. Advanced Engineering Materials, 1999, 1(1): 11-33.

[4] CHANG J K, CHEN S Y, TSAI W T, DENG M J, SUN I W. Electrodeposition of aluminum on magnesium alloy in aluminum chloride (AlCl3)-1-ethyl-3-methylimidazolium chloride (EMIC) ionic liquid and its corrosion behavior [J]. Electrochemistry Communications, 2007, 9(7): 1602-1606.

[5] GRAY J E, LUAN B. Protective coatings on magnesium and its alloys—A critical review [J]. Journal of Alloys and Compounds, 2002, 336(1-2): 88-113.

[6] SONG G, ATRENS A, DARGUSCH M. Influence of microstructure on the corrosion of die cast AZ91D [J]. Corrosion Science, 1999, 41(2): 249-273.

[7] SONG G, ATRENS A. Magnesium alloys and applications [C]// International Conference on Magnesium Alloys and Their Application. Wolfsburgy, German, 1998: 415.

[8] SONG G, ATRENS A, STJOHN D, ZHENG L. Magnesium alloys and their applications [C]// International Conference on Magnesium Alloys and Their Application. Munich, Germany, 2000: 425.

[9] SONG G, ATRENS A, WU X, ZHANG B. Corrosion behaviour of AZ21, AZ501 and AZ91 in sodium chloride [J]. Corrosion Science, 1998, 40: 1769-1791.

[10] SONG G. Corrosion of magnesium alloy [D]. The University of Queensland, 1997: 176.

[11] SHIGEMATSU I, NAKAMURA M, SAITOU N, SHIMOJIMA K. Surface treatment of AZ91D magnesium alloy by aluminum diffusion coating [J]. Journal of Materials Science Letters, 2000, 19(6): 473-475.

[12] HUO Hong-wei, WANG Fu-hui, LI Ying, XU Jia-yin. Effect of aluminum diffusion coating on corrosion resistance of AZ91D magnesium alloy [J]. Corrosion Science Protection Technology, 2001, 13(z1): 484-486.

[13] LIU F, LIANG W, LI X, ZHAO X, ZHANG Y, WANG H. Improvement of corrosion resistance of pure magnesium via vacuum pack treatment [J]. Journal of Alloys and Compounds, 2008, 461(1/2): 399-403.

[14] MA You-ping, XU Ke-wei, WEN Wei-xin, HE Xi-peng, LIU Peng-fei. The effect of solid diffusion surface alloying on properties of ZM5 magnesium alloy [J]. Surface Coating and Technology, 2005, 190: 165-170.

[15] MA You-ping, WEN Wei-xin, LIU Peng-fei, XU Ke-wei. Effects of treatment parameters on microstructure of diffusion alloyed coatings on pure magnesium [J]. Surface Engineer, 2004, 20: 108-112.

[16] KANATZIDIS M G, SUTOURIK A G. The application of polychalcogenide salts to the exploratory synthesis of solid state multinary chalcogenides at intermediate temperatures [J]. Prog Inorg Chem, 1995, 43: 151-265.

[17] KERRIDGE D H, LAGOVSKI J J. The chemistry of nonaqueous solvents [M]. New York: Ed. Academic Press, 1978: 270.

[18] AFANASIEV P, GEANTET C. Synthesis of solid materials in molten nitrates [J]. Coordination Chemistry Reviews, 1998, 178-180: 1725-1752.

[19] ZHONG Cheng, HE Mei-feng, LIU Lei, WU Ya-ting, CHEN Yu-juan, DENG Yi-da, SHEN Bin, HU Wen-bin. Lower temperature fabrication of continuous intermetallic coatings on AZ91D magnesium alloy in molten salt [J]. Journal of Alloys and Compounds, 2010, 504(2): 377-381.

[20] FUNAMIZU Y, WATANABEK. Interdiffusion in the Al-Mg system [J]. Trans Jap Inst Met, 1972, 13(4): 278-283.

[21] ROLLAND P, MAMANTOV G. Electrochemical reduction of. Al2Cl7- ions in chloroaluminate molts [J]. Journal of Electrochemistry Society, 1976, 123: 1299-1303.

镁合金表面新颖多层的耐腐蚀Mg-Al金属间化合物涂层

何美凤1,胡文彬1, 2,赵 素3,刘 磊2,仵亚婷2

1. 上海理工大学 材料科学与工程实验室,上海 200093;

2. 上海交通大学 复合材料国家重点实验室,上海 200240;

3. 上海电机学院 机械工程学院,上海 200240

摘 要:通过AlCl3-NaCl熔盐扩散表面改性,在镁合金表面制备多层的Mg-Al金属间化合物层。熔盐扩散的处理温度为400 °C,此温度低于纯铝粉扩散的处理温度。熔盐扩散处理后,在镁合金表面形成Al12Mg17、Al0.58Mg0.42和Al3Mg2 多相层的金属间化合物涂层。通过电化学阻抗实验将表面改性和未经表面改性的镁合金的耐蚀性进行比较,发现镁合金表面经过熔盐扩散处理的极化电阻远大于未经表面改性镁合金的。这是因为在镁合金表面形成均匀的多相金属间化合物层。

关键词:Mg-Al金属间化合物涂层;多相层;扩散;腐蚀;镁合金;熔盐处理

(Edited by LONG Hui-zhong)

Foundation item: Project (11R21414700) supported by Shanghai Postdoctoral Sustentation Fund, China; Project (20110490715) supported by the National Science Foundation for Post-doctoral Scientists of China; Projects (50974088, 51004070) supported by the National Natural Science Foundation of China; Project (10QA1403400) supported by Shanghai Rising-Star Program; Project (10540500900) supported by the Shanghai Municipal Education Commission

Corresponding author: WU Ya-ting; Tel: +86-21-34202981; Fax: +86-21-34202749; E-mail: hmf752@usst.edu.cn

Abstract: A novel multilayer Mg-Al intermetallic coating on the magnesium alloy was obtained by AlCl3-NaCl molten salt bath treatment. The molten salt was treated at 400 °C, which is lower than the treatment temperature of solid diffusion Al powder. The thick Al12Mg17, Al0.58Mg0.42 and Al3Mg2 multilayer Mg-Al intermetallic coating forms on the magnesium alloy. The corrosion resistance of AZ91D alloy with and without coating by multilayer of Mg-Al intermetallic compound was evaluated by electrochemical impedance spectroscopy measurements in 3.5% (mass fraction) NaCl solution. The polarization resistance value of the multilayer coating on the magnesium alloy by molten salt bath treatment is greater than that of the uncoated one, which is attributed to the homogenously distributed intermetallic phases.