J. Cent. South Univ. (2020) 27: 1956-1964

DOI: https://doi.org/10.1007/s11771-020-4422-y

Settlement characteristics of bridge approach embankment based on scale model test

ZHANG Jiu-peng(张久鹏)1, LIU Tao(刘涛)1, PEI Jian-zhong(裴建中)1,

LI Rui(李蕊)1, ZOU Dao-guang(邹道光)2, ZHANG Yu-qing(张裕卿)3, 4

1. School of Highway, Chang’an University, Xi’an 710064, China;

2. China Railway Second Academy Engineering Group Co. Ltd., Chengdu 610036, China;

3. National Engineering Laboratory of Highway Maintenance Technology, Changsha University of Science & Technology, Changsha 410114, China;

4. Aston Institute of Materials Research, Engineering Systems & Management Group, Aston University,Birmingham B4 7ET, UK

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract:

In order to analyze the effects of backfill materials, geometries and slab setting on the settlement of bridge approach embankment, scale model was built based on the structural characteristics of bridge approach embankment, and scale model tests were carried out under different conditions. The results show that when graded gravels were selected as the backfill materials, the effect of setting approach slab to reduce the differential settlement is more prominent. When lime soils were selected as the backfill material, approach slab can moderate the longitudinal settlement slope. When using different backfill materials, the ultimate settlement of the positive trapezoidal backfill geometries is less than that of the inverted trapezoid, and the backfill geometries have little effect on the settlement slope.

Key words:

bridge approach; embankment; scale model; settlement; backfill;

Cite this article as:

ZHANG Jiu-peng, LIU Tao, PEI Jian-zhong, LI Rui, ZOU Dao-guang, ZHANG Yu-qing. Settlement characteristics of bridge approach embankment based on scale model test [J]. Journal of Central South University, 2020, 27(7): 1956-1964.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-020-4422-y1 Introduction

The bridge approach is the special section, which links the pavement and subgrade with the bridge abutment, culvert or other structures. Usually, the embankment is constructed for the bridge approach. However, differential settlements often occur in this section, resulting in pavement failure, uncomfortable and unsafe driving. At present, lots of studies have been reported on the characteristics, causes, controlling indexes and methods of differential settlement at bridge approach by using numerical simulations and field tests [1-7]. The causes mainly include bridge inclination, abutment types, backfilling height and materials, construction quality and natural condition [8-14]. The settlement modes of bridge approach embankment include three kinds of vertical slope change, slab staggering and subsidence [15]. Based on different settlement modes, different controlling indexes have been proposed, mainly including allowable post- construction settlement, allowable longitudinal differential slope and allowable height of slab staggering [16-18]. The commonly used controlling method for differential settlement of bridge approach embankment mainly includes foundation treatment, setting approach slab and backfilling treatment. When foundation treatment is adopted, different ground conditions need to be considered to adopt different treatment measures [19-21]. Setting an approach slab could provide a transition from the abutment to the embankment, and alleviate the driving discomfort caused by the differential settlement [22-24]. Using light engineering materials and geotextile to backfill the embankment could reduce the post-construction settlement of subgrade [25-28]. The effects of various disposal measures vary. In order to rationalize the construction of the transition section, it is necessary to analyze the influence of backfill materials and methods on the settlement of the transition section.

Experimental road paving is a common research method in the field of engineering. However, this method needs a lot of manpower and material resources, which is not conducive to extensive development. So, some researchers introduce the numerical simulation method into the engineering field. Numerical simulation can easily set up the required test conditions. The key point of this method lies in the premise assumption of simulation, the selection of parameters and the verification of results [29-31]. To analyze engineering problems more conveniently, an indoor scale model of bridge approach embankment was built in this paper. Scale model does not require a particularly large test site. And test conditions can be easily controlled compared with experimental roads.

The scale model tests were carried out under different conditions. Based on the scale model tests, the settlement laws of bridge approach embankment were revealed under different backfill materials and geometries. Further, the influence of different conditions on the differential settlement was also analyzed.

2 Materials and method

The objects whose physical properties have the same property can be considered similar, and the characteristics of similar objects are also of great similarity [6]. The core idea of similarity theory is to design model tests by applying physical similarity between objects. By using the similarity theory to build scale model, the dimension of engineering structure can be reduced at a certain proportion without neglecting the essential characteristics of actual structures, and then the simulation experiments could be carried out indoors. So, the huge engineering problem can be simplified with reliable mechanical responses.

2.1 Design of scale models

2.1.1 Determining model dimensions

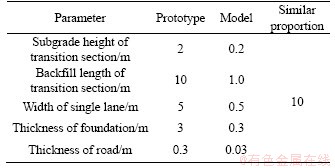

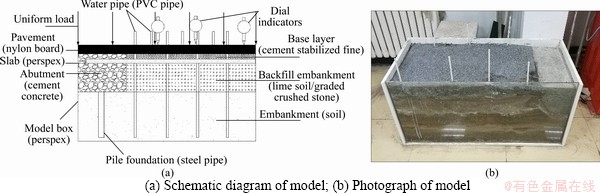

The dimension of the model box in test was determined by the actual dimension of the backfill structure according to a certain proportion. The model box was made of 3 cm thick board, in which one side was replaced by 2 cm thick perspex to observe the settlement of the model. In the model test, the width of a lane was studied. The specific dimensions are shown in Table 1.

Table 1 Geometric parameters of model test

2.1.2 Abutment simulation

The type of abutment’s foundation used in model test was steel pipe pile, and the abutment was made of reinforced concrete. The steel pipe pile was a hollow cylindrical structure with an outer diameter of 35 mm, a wall thickness of 3 mm and a height of 350 mm. Type Ф6 round steel was adopted in cushion cap welding with steel pipe piles to form a basic frame. The cement was 42.5R ordinary Portland cement. The mass ratio of water, cement, sand, and gravel was 0.39:1:1.032:1.519. The compactness and curing condition of concrete meet the requirement of the specification [32]. Finally, the dimensions of the formed abutment were with length of 45 cm, width of 20 cm, and height of 20 cm. The abutment model was divided into two cases: setting up approach slab and not setting up approach slab. The approach slab was made of a 1 cm thick perspex plate. The perspex was lapped on the abutment, and the joint position was 4 cm from the top of the abutment.

2.1.3 Simulation of pavement surface and base layers

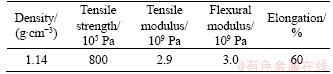

Because the difference between flexural modulus of nylon board and flexural modulus of asphalt mixture was slight [33], pavement material was replaced by nylon board (length of 95 cm, width of 45 cm, thickness of 3 cm) to test. Considering the requirement of smoothness, the base layer was replaced by 3 cm thick cement stabilized fine sand. The cement was 42.5R ordinary Portland cement, and the dosage was 4%. The surface layer and the base layer and the abutment were bonded using road binder. The material parameters of the nylon board are shown in Table 2.

Table 2 Material parameters of nylon board

2.1.4 Simulation of embankment and foundation

Backfilling geometries mainly include two kinds of positive trapezoidal and inverted trapezoidal. The simulation of embankment mainly used two backfill materials. The first was lime soil (LS), and the second was graded crushed stone (GCS). The height of embankment was 17 cm. The soil used in foundation was taken from the engineering site and the filling thickness was 30 cm in the model box. The moisture content of soil was maintained as natural moisture content. To improve the sensitivity of foundation soil to water, 1.5 kg soluble ammonium sulfate was added into the soil.

2.1.5 Selection of backfill materials

1) At present, LS is the most commonly used backfill material in bridge approach embankment. In this paper, the soil was fine-grained soil whose particle size was less than 2 mm. The lime dosage of LS was 7%, and the optimum water content was determined by proctor compaction test. The model test adopted layered compaction method to control the compaction degree of LS to 92%.

2) The content of flat and elongated particles crushed stone in the selected stones was not higher than 20%. The content of soft and friable crushed stones was not higher than 10%, and the content of clay group and organic matter was not higher than 2%. The maximum particle size was not more than 20 mm. Besides, crushed stone was stabilized by 42.5R ordinary Portland cement whose dosage was 4%. The compaction test of cement stabilized macadam was carried out, and finally, the maximum dry density of GCS was 2.39 g/cm3, and the optimum water content was 5.2%. The GCSs were layered and compacted, and the final degree of compaction was controlled at 92%.

2.2 Testing methods

2.2.1 Simulation of loading methods

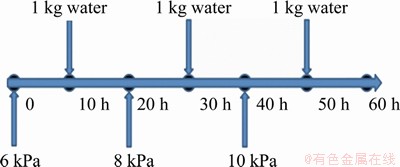

To simplify the calculation process, the equivalent uniform load was usually used instead of the traffic load in the traditional design of the road structure. In this model test, we used uniform static load to simulate the load and the load was divided into three grades of 6, 8 and 10 kPa.

2.2.2 Simulation of influence of water on subgrade and foundation

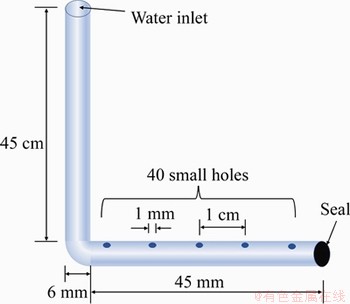

The simulation of water was achieved by seepage. Water here referred to groundwater wicking up into embankment [34]. When the model box was backfilled, water seepage pipe was embedded at the bottom 20 cm of the foundation soil. The water pipe was composed of two PVC tubes (inner diameter of 6 mm, length of 45 cm), and was connected with “L” through the internal connection. In one section of PVC pipes, holes with a diameter of 1 mm were drilled at intervals of 1 cm. A total of 7 were buried and were alternately arranged along the sides of the model. The PVC pipe connection and opening style are shown in Figure 1.

2.2.3 Process of gradual loading and seepage

During the model test, three times of loading and infiltrating water were carried out alternately, by the specific process shown in Figure 2.

2.2.4 Data acquisition

In this paper, the main data were observed and collected by using dial indicators and TDS-530 static data acquisition instrument.

Figure 1 Schematic graph of PVC pipes

Figure 2 Gradual loading and water injection process

The three-dial indicators were fixed after abutment by using a special bracket. The dial indicators were located at 5, 35 and 70 cm abutment. The dial indicators were connected to the static data acquisition instrument through the data cables. The settlement variations can be directly obtained by the acquisition instrument.

Figure 3 shows a schematic diagram and a photograph of the model.

There are there steps of data collection. First, zero the static data collector at the beginning of the test. Then, the settlement data at three acquisition points are recorded every 10 h. Finally, observation time of each different backfill condition lasts for 60 h.

3 Effect of approach slab and backfilling materials on settlements

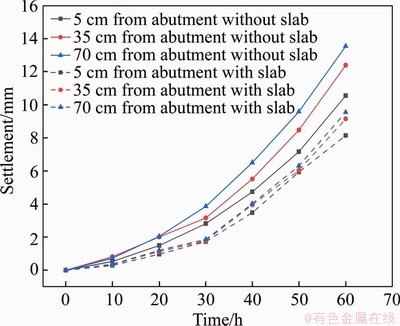

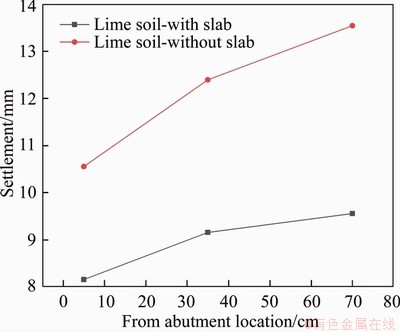

3.1 Settlement of LS embankment

Based on the test method designed in the first section, when the subgrade was filled with LS, the settlement deformation regular of two cases, namely, embankment with slab and embankment without slab, were studied. The test results are shown in Figure 4.

As shown in Figure 4, as the test progresses, settlement at the rear three positions of the bridge abutment increased under each condition. Within the first 30 h of the test, the increase of the settlement was small, and the trend of differential settlement over time was relatively stable. After 30 h, as the amount of water seepage increased and the load level increased, the influence of moisture on LS increased, and the range of change in settlement began to increase. Observing the settlement curve and setting the slab could significantly reduce the settlement after the abutment. Also, the three settlement curves with slab were relatively tighter than without slab. This indicated that the differential settlement at different locations behind the abutment was smaller due to the upper load blocking effect of the slab. Under the combined effect of water and load, the settlement gradient after the abutment was relatively gentle. This changing trend was conducive to alleviating the irregularity of the route and reducing the harm caused by “bridge jump”.

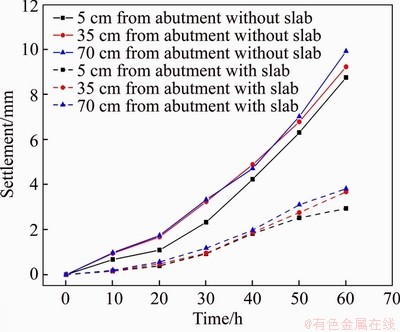

3.2 Settlements of GCS embankment

Based on the model test method designed in the first section, the settlement regular of GCS backfill material was analyzed. Similarly, setting up the slab and not setting up slab were studied. The test results are shown in Figure 5.

Figure 3 Bridge abutment model:

Figure 4 Relationship between settlement and time of LS embankment

As shown in Figure 5, the settlement of 5, 35 and 70 cm behind abutment had little difference with or without the slab, and the settlement curves of the three were relatively close. Over time, the trend of settlement changes was relatively flat. In other words, when backfilling embankment with graded gravel, the differential settlement behind the abutment in different locations was very small, and the settlement gradient was gentle. In addition, compared to the ultimate settlement, the settlement of with slab was significantly smaller than that of without slab, whether it was close to the abutment or away from the abutment.

Figure 5 Relationship between settlement and time of GCS embankment

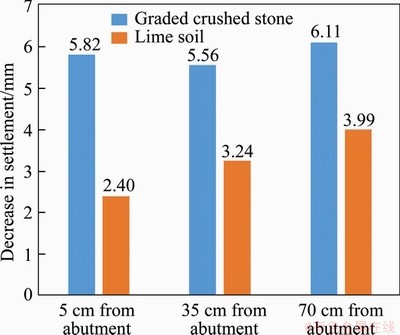

3.3 Settlements comparison under different conditions

The efficiency of approach slab setting was analyzed in Figure 6. When different backfill materials were used, the effect of slab was different. The effect of GCS with slab was greater than that of LS with slab.

Figure 6 Decrease in settlement behind abutment with slab (mm)

It can be seen from the analysis of model test results, whether LS or gravel crushed stone was adopted as backfill material, settlement had been reduced in the setting of slab. As shown in Figure 7, when the LS was used as backfill material, the settlement slope line of not setting slab was larger than that of setting slab. This shows that the approach slab had a significant moderating effect on the settlement gradient of bridge approach embankment. For the using of GCS, as shown in Figure 8, when the slab was not settled, the ultimate settlement curve at three locations behind the abutment was almost in a straight line. The linear trend of the settlement of the slab and without slab was very similar. This suggested when the stiffness of backfill material was lager, the setting slab had little influence on the settlement gradient behind abutment.

Figure 7 Ultimate settlement at different positions of LS embankment

Figure 8 Ultimate settlement at different positions of GCS embankment

4 Effect of backfill geometry on settlements

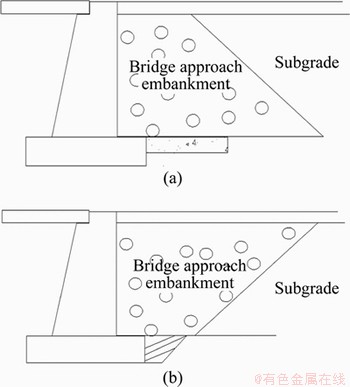

4.1 Backfill geometry selection

In the process of bridge approach embankment model test, the following two circumstances of backfill geometry were analyzed:

1) The backfill geometry was a positive trapezoid. As shown in Figure 9(a), the upper width of the structure was 20 cm, and bottom width was 70 cm.

2) The backfill structure was an inverted trapezoid. As shown in Figure 9(b), the upper width of the structure was 70 cm, bottom width was 20 cm.

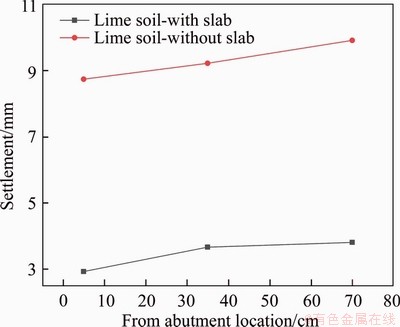

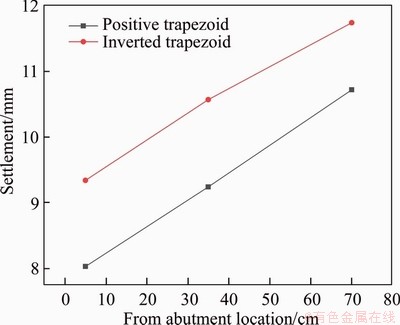

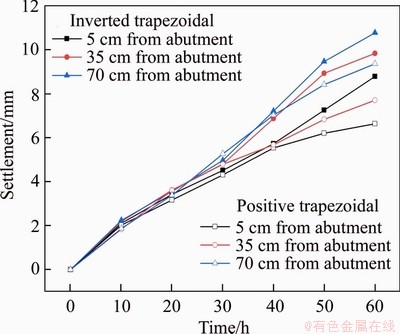

4.2 Settlement of LS embankment with different backfill geometries

The influence of different backfill geometry was studied as the emphasis in this section, without progressive loading and successive seepage. The final test result is shown in Figure 10.

Relationship diagrams of two different backfill geometries between settlement and time were very similar as shown in Figure 10. However, backfill geometries settlement of the positive trapezoidal at 5, 35 and 70 cm from the abutment was less than that of the inverted trapezoidal backfill. After 40 h of trial, the settlement curve of different positions behind the abutment was further stable, which showed that when the positive trapezoidal backfill used, the time to stabilize the settlement of the bridge approach embankment using positive trapezoidal backfill geometries was relatively short compared with the inverted trapezoidal backfill geometries.

Figure 9 Positive trapezoidal backfill geometry (a) and inverted trapezoidal backfill geometry (b)

Figure 10 Settlement regular of LS embankment

Figure 11 shows that when backfill materials were LS, the settlement at different positions behind abutment was almost straight along with the longitudinal direction of the route and the slope was roughly the same. When two different backfill geometries for the different of route vertical position behind abutment were used, the impact of degree of settlement slope was very small.

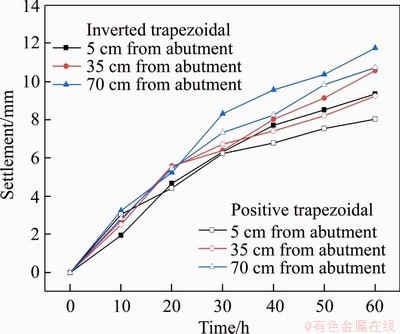

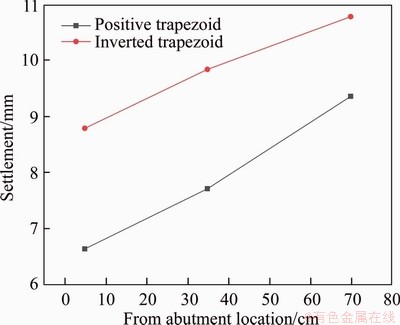

4.3 Settlement of GSC embankment with different backfill geometries

When backfill materials were GCS, the sizes of the two backfill geometries were the same as the LS. The experimental results are shown in Figure 12.

Figure 11 Ultimate settlement of LS embankment

Figure 12 Settlement regular of GCS embankment

As shown in Figure 12, in the first 20 h of test process, the difference of settlement change at different positions at 5, 35 and 70 cm behind the abutment in bridge approach embankment of GCS was small in inverted trapezoidal. In the last 20 h of test process, settlement gradually increased with the time increasing, but the amount of increase had changed. In addition, the amount of settlement at 70 cm behind abutment was rapidly increased. It can be shown that the greater the distance from the abutment is the settlement can be larger.

On the other side, in the first 30 h of the test process, the difference of settlement change at three different positions behind the abutment in bridge approach embankment of GCS was small in positive trapezoidal. In general, if the road uses inverted trapezoidal backfill geometry, the uneven settlement of the longitudinal slope would appear later behind the abutment along the longitudinal direction of the route.

From Figure 13, after 60 h of text, according to the slope of the ultimate settlement curve at different positions behind the abutment, the ultimate settlement curve difference of the positive trapezoidal and inverted trapezoidal was very small. This phenomenon was similar to bridge approach embankment of LS, so the writer indicated regardless of the choice of high stiffness of GCS or the use of less rigidity of the bridge approach embankment of LS. When two different backfill geometries for the different of the route vertical position behind abutment were used, the impact of the degree of settlement slope was very small.

Figure 13 Ultimate settlement of GCS embankment

5 Conclusions

In this study, the settlement data of bridge approach of different backfilling forms were collected by establishing a scale model. The effects of backfill materials, methods and slab settings on the settlement law were further analyzed. The main conclusions are as follows:

1) The slab can reduce the settlement of the bridge approach embankment. And when GCS is used as the backfill material, the effect is even more significant.

2) Compared with the inverted trapezoidal backfill structure, the positive trapezoid can reduce the settlement. However, the contribution of the two to the uneven settlement behind the abutment is not much different.

3) When GCS, trapezoid backfill and approach slab are used, differential settlement can be minimized.

References

[1] LACO K, BORZOVIA V. Reliability of approach slabs and modelling of transition zones of bridges [J]. Applied Mechanics & Materials, 2016, 821: 741-746. DOI: 10.4028/www.scientific.net/ AMM.821.741.

[2] NIU Fu-jun, LIN Zhan-ju, LU Jia-hao, LIU Hua, XU Zhi-ying. Characteristics of roadbed settlement in embankment-bridge transition section along the Qinghai- Tibet Railway in permafrost regions [J]. Cold Regions Science and Technology, 2011, 65(3): 437-445. DOI: 10.1016/j.coldregions.2010.10.014.

[3] ZHOU Juan-lan, ZHENG Mu-lian, WANG Chong-tao, JING Wei, MENG Jian-dang, CHEN Jing-xing. Dynamic response analysis of road-bridge transition section without slab [J]. International Journal of Pavement Research and Technology, 2017, 10(6): 526-535. DOI: 10.1016/j.ijprt.2017.04.004.

[4] IKEMOTO H, TAKASAKI H. Experimental study on method for controlling settlement of backfill of abutment [J]. Japanese Geotechnical Society Special Publication, 2016, 2(61): 2096-2100. DOI: 10.3208/jgssp.JPN-092.

[5] MUHO E V, BESKOU N D. Dynamic response of an infinite beam resting on a Winkler foundation to a load moving on its surface with variable speed [J]. Soil Dynamics and Earthquake Engineering, 2018, 109: 150-153. DOI: 10.1016/ j.soildyn.2018.02.034.

[6] YU Yong-hua, XIE Yong-li, YANG Xiao-hua, LI Xin-wei. Three-dimensional numerical analysis of geocell flexible approach slab for treating differential settlement at bridge- subgrade transition section [J]. China Journal of Highway & Transport, 2006, 20(4): 12-18. (in Chinese)

[7] ZHANG Jun-hui, PENG Jun-hui, ZENG Ling, LI Jue, LI Feng. Rapid estimation of resilient modulus of subgrade soils using performance-related soil properties [J]. International Journal of Pavement Engineering, 2019, 1: 1-8. DOI: 10.1080/ 10298436.2019.1643022.

[8] JAYAWICKRAMA P, NASH P, LEAVERTON M, MISHRA D. Water intrusion in base/subgrade materials at bridge ends [R]. Center for Multidisciplinary Research in Transportation, 2004. DOI: hdl.handle.net/2346/22808.

[9] MOUSAVI S E, KARAMVAND A. Assessment of strength development in stabilized soil with GBR PLUS and silica sand [J]. Journal of Traffic and Transportation Engineering (English Edition), 2017, 4(4): 412-421. DOI: CNKI:SUN: JTTE.0.2017-04-011.

[10] WHITE D J, MEKKAWY M M, SRITHARAN S, SULEIMAN M T. “Underlying” causes for settlement of bridge approach pavement systems [J]. Journal of Performance of Constructed Facilities, 2007, 21(4): 273-282. DOI: 10.1061/(asce)0887-3828(2007)21:4(273).

[11] ZHANG Jun-hui, PENG Jun-hui, ZHENG Jian-long, DAI Liang-liang, YAO Yong-sheng. Prediction of resilient modulus of compacted cohesive soils in south China [J]. International Journal of Geomechanics, 2019, 19(7): 04019068.

[12] BAI Tao, HU Xiao-di, GU Fan. Practice of searching a noncircular critical slip surface in a slope with soil variability [J]. International Journal of Geomechanics, 2019, 19(3): 04018199. DOI: 10.1061/(ASCE)GM.1943-5622.0001350.

[13] REZAEI M, BINDIGANAVILE V. Application of cement-based foams for narrow-trench backfilling [J]. Road Materials and Pavement Design, 2020(11): 1-25. DOI: 10.1080/14680629.2020.1722206.

[14] ZHOU Nan, OUYANG Shen-yang, CHENG Qiang-qiang, JU Feng. Experimental study on mechanical behavior of a new backfilling material: Cement-treated marine clay [J]. Advances in Materials Science and Engineering, 2019, 2019: 1-8. DOI: 10.1155/2019/1261694.

[15] ZHANG Kai-peng, JIANG Li-min, WANG Zhi-de. Research of the settlement of bridge approach slab's impact on bump at bridgehead [C]// 2011 International Conference on Electric Technology and Civil Engineering (ICETCE). Lushan: IEEE, 2011: 589-592. DOI: 10.1109/ICETCE.2011.5775451.

[16] PARKS S, YANG M, GAJAN S, PEI Qing. Strength-based differential tolerable settlement limits of bridges [J]. Advances in Structural Engineering, 2018, 21(1): 46-58. DOI: 10.1177/1369433217706779.

[17] WAHLS H E. Tolerable deformations [C]// Vertical & Horizontal Deformations of Foundations & Embankments. ASCE, 2015.

[18] PECNIK M, BORZOVI V, LACO K. Non-linear FEM analysis of integral bridges transition area [J]. Solid State Phenomena, 2017, 259: 152-157. DOI: 10.4028/ www.scientific.net/ssp.259.152.

[19] RAMALAKSHMI M, DODAGOUDAR G R. Passive force-displacement behaviour of GRS bridge abutments [J]. International Journal of Geosynthetics and Ground Engineering, 2018, 4(4): 28-38. DOI: 10.1007/s40891- 018-0145-7.

[20] LI Xi-an, WANG Li, HONG Bo, LI Lin-cui, LIU Jia, LEI Hao-nan. Erosion characteristics of loess tunnels on the Loess Plateau: A field investigation and experimental study [J]. Earth Surface Processes and Landforms, 2020. DOI: 10.1002/esp.4857.

[21] RAJA P S K, THYAGARAJ T. Effect of compaction time delay on compaction and strength behavior of lime-treated expansive soil contacted with sulfate [J]. Innovative Infrastructure Solution, 2020, 5(14). DOI: 10.1007/s41062- 020-0268-2.

[22] CAI C S, SHI X M, VOYIADJIS G Z, ZHANG Z J. Structural performance of bridge approach slabs under given embankment settlement [J]. Journal of Bridge Engineering, 2005, 10(4): 482-489. DOI: 10.1061/(asce)1084-0702(2005) 10:4(482).

[23] CHEN Dar-hao, YI Wen. Performance of settled bridge-approach slabs with polyurethane-foam injection [J]. Journal of Testing and Evaluation, 2015, 43(6): 20140431. DOI: 10.1520/JTE20140431.

[24] WANG Zhi-yuan, ZHANG Hong, WANG Ya-jun. Method of determining the length of approach slab for highway bridge [J]. Advanced Materials Research, 2014, 953-954: 1657- 1662. DOI: 10.4028/www.scientific.net/amr.953-954. 1657.

[25] SUN Wen-bin, HE Wei-zhong, JIANG Yang, CHEN Bao-hai. Distresses and countermeasures of the abutment displacsments on the soft clay ground [C]// 2012 2nd International Conference on Consumer Electronics, Communications and Networks (CECNet). Yichang, 2012: 288-291. DOI: 10.1109/CECNet.2012.6201379.

[26] JIN Xiao-qin, SHAO Xu-dong, YAN Ban-fu, PENG Wang-hu. New technologies in China’s first jointless integral-abutment bridge [J]. IABSE Symposium Report, 2004, 88(6): 84-89. DOI: 10.2749/222137804796 291331.

[27] TAFRESHI S N M, NOROUZI A. Application of waste rubber to reduce the settlement of road embankment [J]. Geomechanics & Engineering, 2015, 9(2): 219-241. DOI: 10.12989/gae.2015.9.2.219.

[28] ZHANG Jun-hui, GU Fan, ZHANG Yu-qing. Use of building-related construction and demolition wastes in highway embankment: Laboratory and field evaluations [J]. Journal of Cleaner Production, 2019, 230: 1051-1060. DOI: 10.1016/j.jclepro.2019.05.182.

[29] ZHANG Jun-hui, DING Le, LI Feng, PENG Jun-hui. Recycled aggregates from construction and demolition wastes as alternative filling materials for highway subgrades in China [J]. Journal of Cleaner Production, 2020, 255: 120223.

[30] ZHANG Jun-hui, PENG Jun-hui, LIU Wei-zheng, LU Wei-hua. Predicting resilient modulus of fine-grained subgrade soils considering relative compaction and matric suction [J]. Road Materials and Pavement Design, 2019: 1-13. DOI: 10.1080/14680629.2019.1651756.

[31] ZHANG Jiu-peng, TAN Hao-qi, PEI Jian-zhong, QU Tian, LIU Wo-long. Evaluating crack resistance of asphalt mixture based on essential fracture energy and fracture toughness [J]. International Journal of Geomechanics, 2019, 19(4): 06019005. DOI: 10.1061/(ASCE)GM.1943-5622.0001390.

[32] GB 506666-2011. Code for construction of concrete structures [S]. Beijing: China Architecture & Building Press, 2012. (in Chinese)

[33] LV Song-tao, LIU Chao-chao, YAO Hui, ZHENG Jian-long. Comparisons of synchronous measurement methods on various moduli of asphalt mixtures [J]. Construction and Building Materials, 2018, 158: 1035-1045. DOI: 10.1016/ j.conbuildmat.2017.09.193.

[34] PENG Jun-hui, ZHANG Jun-hui, LI Jue, YAO Yong-sheng, ZHANG An-shun. Modeling humidity and stress-dependent subgrade soils in flexible pavements [J]. Computers and Geotechnics, 2020, 120: 103413. DOI: 10.1016/j.compgeo. 2019.103413

(Edited by ZHENG Yu-tong)

中文导读

基于缩尺模型试验的路桥过渡段沉降特性

摘要:为了研究不同回填材料、回填结构及桥头搭板的设置对路桥过渡段沉降的影响,本文根据路桥过渡段的结构特性,进行了不同条件下的路桥过渡段缩尺模型试验。结果表明,使用级配碎石作为回填材料进行路桥过渡段路基回填时,设置搭板对减小路桥过渡段差异沉降的效果更为明显;使用石灰土时,设置搭板可以缓和桥台后路线纵向不同位置的沉降坡度。使用不同回填材料时,正梯形回填结构最终沉降量均小于倒梯形,且回填结构对沉降坡度的影响不大。

关键词:路桥过渡段;桥台;缩尺模型;沉降;回填材料

Foundation item: Project(51978068) supported by the National Natural Science Foundation of China; Project(2018YFE0103800) supported by the National Key R&D Program of China; Project(2017M620434) supported by the China Postdoctoral Science Foundation; Project(310821173501) support by the Special Fund for Basic Scientific Research of Central College of Chang’an University, China

Received date: 2020-03-26; Accepted date: 2020-05-11

Corresponding author: ZHANG Jiu-peng, PhD, Professor; Tel: +86-13720410029; E-mail: zhjiupeng@chd.edu.cn; ORCID: 0000-0002- 9627-4836

Abstract: In order to analyze the effects of backfill materials, geometries and slab setting on the settlement of bridge approach embankment, scale model was built based on the structural characteristics of bridge approach embankment, and scale model tests were carried out under different conditions. The results show that when graded gravels were selected as the backfill materials, the effect of setting approach slab to reduce the differential settlement is more prominent. When lime soils were selected as the backfill material, approach slab can moderate the longitudinal settlement slope. When using different backfill materials, the ultimate settlement of the positive trapezoidal backfill geometries is less than that of the inverted trapezoid, and the backfill geometries have little effect on the settlement slope.