DOI:10.19476/j.ysxb.1004.0609.2017.07.11

磁控溅射制备CrMoAlN梯度薄膜的抗高温氧化性能

王宇星,楼白杨,潘 健,张 侠

(浙江工业大学 材料科学与工程学院,杭州 310032)

摘 要:

摘 要:采用非平衡磁控溅射离子镀技术在M2工具钢和单晶Si表面沉积CrMoAlN梯度薄膜,并在静态空气中进行600、700、800、900 ℃的高温氧化实验。采用XRD、SEM、XPS、纳米压痕和划痕实验等研究,结果表明:CrMoAlN薄膜呈现与CrN相似的面心立方结构,主要以CrN、AlN和γ-Mo2N形态存在。经800 ℃氧化2 h后,CrMoAlN薄膜基本保持常温时的晶体结构与力学性能。随着氧化温度继续升高,薄膜表层的MoO3加速挥发,破坏由Cr2O3和Al2O3组成的致密氧化层,薄膜表面出现细小孔隙,薄膜氧化程度加剧。经900 ℃氧化2 h后,CrMoAlN薄膜的力学性能和膜/基结合强度均出现明显下降。

关键词:

文章编号:1004-0609(2017)-07-1403-08 中图分类号:TG174 文献标志码:A

磁控溅射沉积的CrN薄膜因具有较高的硬度、耐腐蚀和耐磨损性能,广泛地应用于加工制造业、汽车工业、生物医疗等领域[1-2]。近些年,随着现代加工技术的进步,对刀具和模具表面性能提出了更高的要求,原有单一的二元CrN薄膜已经无法满足不同工况环境下的使用要求。研究人员一方面通过优化薄膜结构,实现CrN薄膜向纳米多层化和梯度化发展[3-5];同时采用合金化的方法,在CrN薄膜基础上添加Y[6]、Zr[7]、Si[8]、Ti[9]、Al[10]、C[11]、Mo[12]等元素来进一步提高CrN薄膜的硬度、耐高温和耐磨损性能。CrN薄膜中由于Al的加入,可以将CrN薄膜的抗高温氧化温度提高约200 ℃[13],而Mo的氮化物由于在摩擦过程中能形成具有自润滑性能的氧化物[14-15],在CrN薄膜中添加Mo能显著提高薄膜的摩擦磨损性能。研究表 明[16-17]:将Mo和Al同时掺杂入CrN薄膜制备的四元CrMoAlN薄膜在室温下具有高的硬度和优越耐磨性能,且随着Mo含量的提高,薄膜耐磨性能越好。目前,关于CrMoAlN薄膜的研究主要集中在室温下的摩擦磨损性能方面,CrMoAlN薄膜在高温环境中的性能仍有待深入研究。

因此,本文作者采用非平衡磁控溅射技术制备CrMoAlN梯度薄膜,研究CrMoAlN梯度薄膜的微观结构和抗高温氧化性能,探讨Mo对CrMoAlN薄膜高

温氧化行为的影响机理。

1 实验

采用英国Teer公司生产的UDP650/4型闭合场非平衡磁控溅射仪制备CrMoAlN梯度薄膜。选用的靶材为:纯度(99.99%)的Cr靶材2个,纯度(99.99%)的Al和Mo靶材各1个。基体材料选用d 30 mm×2 mm的M2工具钢和单晶Si片,M2基体用砂纸打磨至2000号,并用金刚石抛光液抛光至Ra≤0.5 μm,然后依次用丙酮和无水乙醇超声波清洗15 min,用吹风机吹干后放入真空腔可旋转基架上,真空腔的真空度抽至5×10-4 Pa,镀膜前在-450 V的偏压下用Ar+清洗试样表面30 min,清除试样表面的杂质和氧化物,确保涂层有良好的结合强度。调整偏压为-75 V,增大Cr靶电流到4 A,沉积Cr打底层,5 min后通入纯度大于99.999%N2作为反应气体,沉积CrN过渡层,10 min后启动Mo靶和Al靶电流,Mo靶电流增到4 A,铝靶增大到8 A,沉积120 min,制备CrMoAlN薄膜。

恒温氧化试验在箱式电阻炉中进行,试验在600、700、800和900 ℃的静态空气中氧化2 h,随炉冷却至室温。采用ΣIGMA型场发射扫描电镜(SEM)分析薄膜氧化前后的表面和截面形貌,并采用仪器附带的能谱仪(EDS)对薄膜成分进行分析。采用Axis Ultra X射线光电子能谱仪(XPS)分析薄膜中各元素的化学价态,X射线激发源为单色化Al靶,能量分辨率0.05 eV。采用Bruker D8 Advance X射线衍射仪(XRD)分析薄膜氧化前后的相结构变化。采用G200型纳米综合测试仪,选用测量薄膜的(G-Series CSM for Thin Films)模式研究薄膜在不同温度氧化后的硬度和弹性模量随压痕深度的变化规律,为减少测量误差,每个试样测量5次取平均值。采用HT-5001型划痕仪分析薄膜氧化前后的膜/基结合强度,加载范围在0~60 N之间。

2 结果与讨论

2.1 CrMoAlN梯度薄膜的成分、相结构和XPS谱

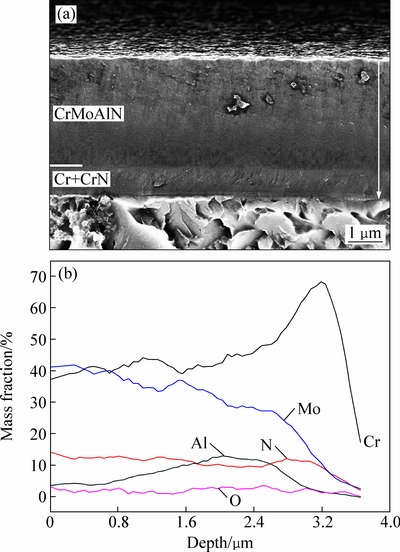

图1所示为CrMoAlN梯度薄膜的截面形貌和EDS线扫描曲线。由图1可以看出,CrMoAlN梯度薄膜由Cr打底层、CrN过渡层和CrMoAlN组成。梯度薄膜厚度约为3.6 μm,其中(Cr+CrN)的厚度约0.8 μm,CrMoAlN薄膜厚度约2.8 μm。薄膜表面的化学成分 (见表1)依次为Cr 34.66%、Mo 15.67%、Al 6.39%、N 42.78%和O 0.50%(摩尔分数),微量的O元素的存在可能与真空腔中残留的氧气有关。

图1 CrMoAlN梯度薄膜的截面形貌和EDS线扫描曲线

Fig. 1 Cross-section morphologies (a) and EDS line analysis (b) of CrMoAlN gradient coatings

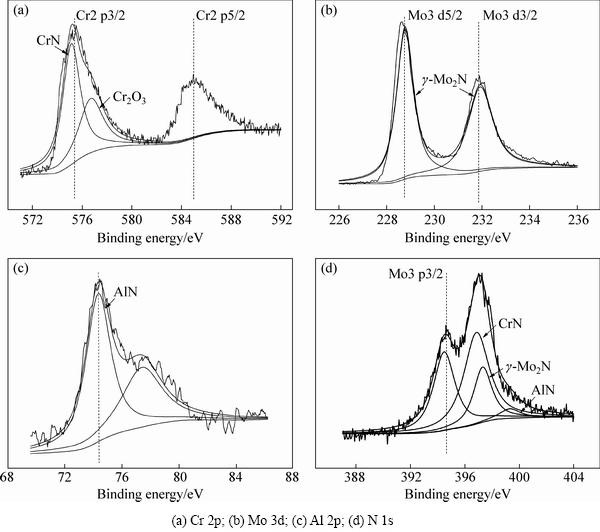

图2所示为CrMoAlN薄膜的Cr2p、Mo3d、Al2p和N1s的XPS谱,采用XPSPEAK4.1软件进行分峰处理。可以看出,Cr2p的两个峰位的结合能为575.3和585.4 eV,分别对应于Cr 2p3/2 和Cr 2p5/2(见图2(a))。采用Lorentzian-Gaussian迭代法对Cr2p3/2进行拟合,得到两个峰,分别为CrN(575.1 eV)和Cr2O3(577.4 eV)[18],单质Cr(574.3 eV) 和Cr2N (574.5 eV)没有发现。Mo3d在231.8和228.7 eV位置上的峰对应于Mo3d3/2和Mo3d5/2(见图2(b)),两个峰均为γ-Mo2N[19],由于Mo单质与γ-Mo2N结合能很接近,薄膜中可能存在少量的单质Mo。Al2p图谱出现了两个峰(见图2(c)),拟合得到结合能为74.1 eV对应的特征峰为AlN,另一个峰强较弱,可能是Al的氧化物[18]。图2(d)所示的两个峰为N1s峰和Mo3p峰[19],由于N1s的峰结合能一般都大于396 eV[20],因此结合能为397 eV对应的是N1s的衍射峰,主要是由CrN、AlN和γ-Mo2N的混合峰组成。

2.2 CrMoAlN薄膜的高温氧化行为

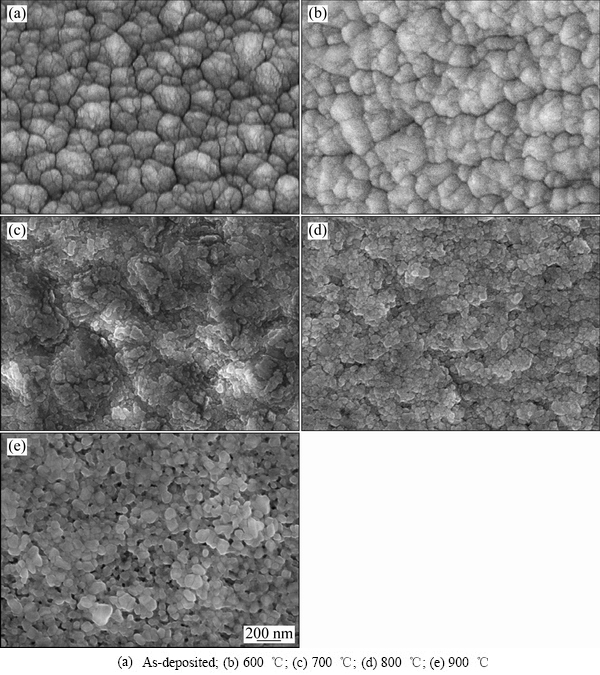

图3所示为CrMoAlN薄膜在不同温度氧化后的表面形貌,薄膜表面EDS面扫描结果见表1。可以看出,氧化前CrMoAlN薄膜表面呈不规则的颗粒状,颗粒间紧凑致密(见图3(a))。600 ℃氧化后,CrMoAlN薄膜基本保持了氧化前的表面形貌(见图3(b))和化学成分,少量的O说明薄膜表面开始出现轻微氧化现象。700和800 ℃氧化后,CrMoAlN薄膜表面O含量快速上升,N含量快速下降,薄膜表面开始快速氧化,形成细小致密的不规则形状的氧化物颗粒(见图3(c)和(d))。900 ℃氧化后,CrMoAlN薄膜表面的氧化物颗粒变大,氧化物颗粒之间出现了明显的孔隙(见图3(e)),薄膜表面Mo/(Cr+Al)的原子比与800 ℃氧化后相比大幅下降,说明900 ℃氧化后薄膜表面的Mo元素出现了快速流失的现象。极低的N含量表明薄膜表面已经基本被氧化,氧化产物主要由Cr和少量Al的氧化物组成。

图2 CrMoAlN薄膜的XPS结果

Fig. 2 XPS results of CrMoAlN coatings

图3 CrMoAlN薄膜在不同温度氧化后的表面形貌

Fig. 3 Surface morphologies of CrMoAlN coatings after oxidation at different temperatures for 2 h

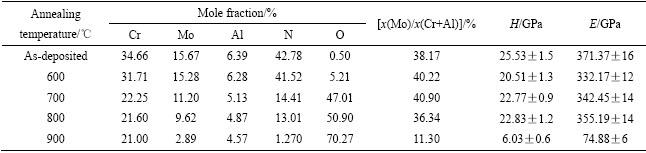

表1 CrMoAlN薄膜在不同温度氧化后的成分、硬度和弹性模量

Table 1 Elemental compositions, nanohardness (H) and elastic modulus (E) of CrMoAlN coatings after oxidation at different temperatures for 2 h

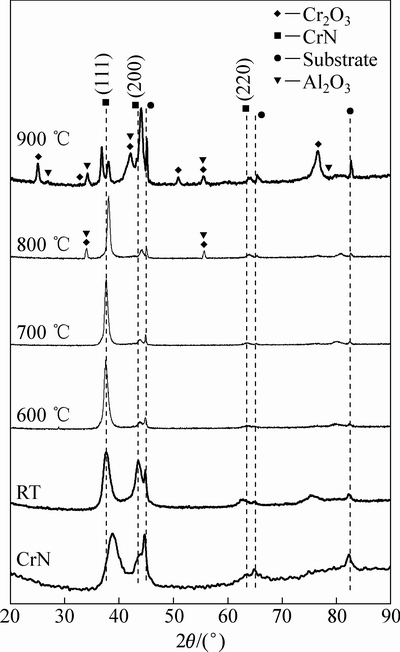

图4 CrMoAlN薄膜在不同温度氧化后的XRD谱

Fig. 4 XRD patterns of CrMoAlN coatings before and after heat treatment at different temperatures for 2 h

图4所示为不同温度氧化后CrMoAlN薄膜的XRD谱,可以看出,600和700 ℃氧化后的XRD谱与常温下的CrMoAlN薄膜的XRD图基本一致,未发现明显的氧化物的衍射峰,说明CrMoAlN薄膜在700 ℃以下氧化2 h后仍保持氧化前的晶体结构。800 ℃氧化后的XRD谱开始出现少量的Cr2O3和Al2O3的衍射峰,但仍能检测到很强的CrMoAlN薄膜的衍射峰,说明800 ℃氧化后薄膜仍具有较好的保护作用。当氧化温度升高到900 ℃时,XRD谱中出现了多处的Cr2O3和Al2O3的衍射峰,同时属于CrMoAlN薄膜的衍射峰强度变小,这表明薄膜900 ℃时氧化程度明显增大,结合表1的EDS分析结果,可以推断薄膜表层氧化产物主要由Cr2O3和少量Al2O3组成。CrMoAlN薄膜呈现与CrN相似的面心立方结构,出现了(111)、(200)和(220)衍射峰,薄膜的晶体结构没有随着Mo和Al元素的加入而改变。

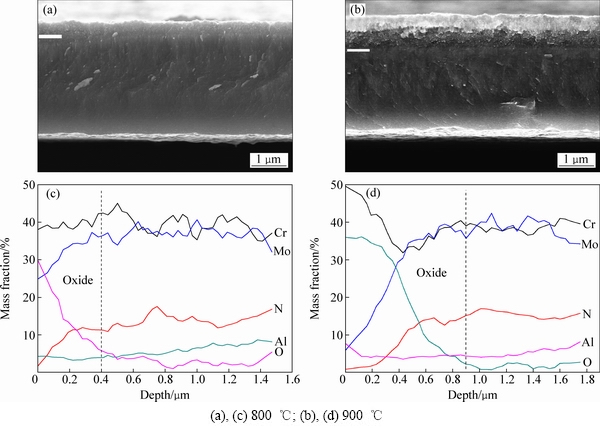

图5所示为CrMoAlN薄膜800和900 ℃氧化后的截面形貌和EDS线扫描曲线。由图5可以看出,CrMoAlN薄膜800 ℃氧化后出现了深度约为0.4 μm氧化层(见图5(a)),氧化层深度与图5(c)中富O区的深度基本一致,氧化层表面Mo元素有少量流失,深度超过0.4 μm后,各元素的含量趋于稳定。CrMoAlN薄膜900 ℃氧化后的氧化层深度约为0.9 μm,氧化层结构疏松,出现针孔和分层的现象(见图5(b))。外层(0~0.4 μm)氧化层主要由Cr和少量Al的氧化物组成,Mo元素大量流失,氧原子快速向内扩散,同时Cr和Al离子加速向表面扩散。内层(0.4~0.9 μm)氧化层中Mo的流失速度减慢,N含量快速上升,氧化层中未被氧化的CrMoAlN薄膜逐渐增多(见图5(d))。

综上可见, CrMoAlN薄膜表层在600~700 ℃时已经开始氧化,900 ℃氧化2 h后的氧化层深度约为0.9 μm。文献[6]中报道CrAlN薄膜在1100 ℃下高温氧化2 h后,氧化层的厚度仅为0.3 μm。说明在高温环境下,Mo的掺杂会加速CrAlN薄膜的氧化进程,降低CrAlN薄膜抗高温氧化性能。

为了进一步理解Mo对CrMoAlN薄膜高温氧化行为的影响,由图2的XPS分析可知,CrMoAlN薄膜中Mo主要以Mo2N形态存在,氧化过程中可能发生的反应如下所示[21]:

Mo2N+2O2=2MoO2+1/2N2 (1)

MoO2+1/2O2=MoO3 (2)

MoO3(s)=MoO3(g) (3)

SOLAK等[21]发现MoN薄膜氧化后形成的MoO3在600 ℃就有明显挥发的迹象,而CrMoAlN薄膜在900 ℃高温氧化后Mo元素才开始快速流失。这是因为与Mo相比,Cr和Al与O有更强的化学亲和力和更低的生成自由能[22],CrMoAlN薄膜在氧化过程中,Cr和Al会优先被氧化,形成由Cr2O3和Al2O3组成的致密的氧化层,研究[6-7, 13]表明由Cr2O3和Al2O3组成的致密氧化层可以有效阻止氧原子向内扩散,从而减缓表层Mo的氧化物的形成和挥发。随着氧化温度升高到900 ℃,薄膜表面氧化形成的MoO3加速挥发,破坏了CrMoAlN薄膜表面致密的氧化层,薄膜表面开始出现细小孔隙,为氧原子向内扩散和金属离子向外扩散提供了快速通道,薄膜在加速氧化过程中形成了连续的MoO3层,这些MoO3层之间以较低的范德华力结合在一起[23],很容易在高温环境中挥发流失,从而进一步破坏了氧化层的致密结构, 加速薄膜的氧化进程。

图5 CrMoAlN薄膜800和900 ℃氧化后的截面形貌和EDS线扫描曲线

Fig. 5 Cross-section morphologies ((a),(b)) and EDS line analysis ((c), (d)) of CrMoAlN after oxidation at different temperatures for 2 h

2.3 CrMoAlN薄膜不同温度氧化后的力学性能

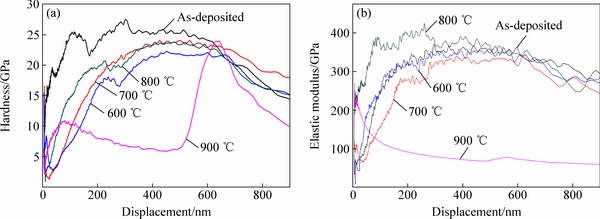

图6所示为CrMoAlN薄膜在不同温度氧化后的硬度和弹性模量随压入深度的变化曲线。根据薄膜的厚度,选取342~378 nm之间的平均值来表征薄膜氧化后的硬度和弹性模量(见表1)。可以看出:由于高温氧化后薄膜的残余应力和晶格畸变减少、晶粒尺寸变大等原因[24],CrMoAlN薄膜在不同温度氧化后的硬度和弹性模量均小于沉积态的薄膜,薄膜在700和800 ℃氧化后的硬度和弹性模量高于600 ℃氧化后的数值,这可能与薄膜在高温氧化过程中生成的Cr2O3氧化物有关,研究表明[25]:PVD制备的Cr2O3涂层硬度能达到30 GPa。900 ℃氧化后,薄膜硬度和弹性模量均出现大幅度的下降,结合900 ℃的硬度-位移曲线可以发现,在距离表面0~500 nm之间,薄膜硬度仅为6~10 GPa左右,由2.2的分析可知,薄膜900 ℃氧化后,氧化层表面和内部均出现了大量的孔隙,疏松的结构势必造成薄膜外层氧化层的力学性能大幅度的下降。压入深度超过500 nm后,薄膜硬度突然变大,这可能是由于550~650 nm之间刚好位于内层氧化层的区域,该区域Mo的挥发速度明显下降,氧化层能保持较为致密的结构,氧化层中主要是由硬度较高的Cr2O3和未氧化的CrMoAlN薄膜组成,从而导致薄膜在550~650 nm之间出现了硬度突然变大的现象。

2.4 CrMoAlN薄膜氧化前后的膜/基结合强度

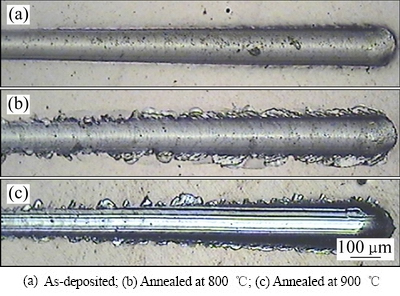

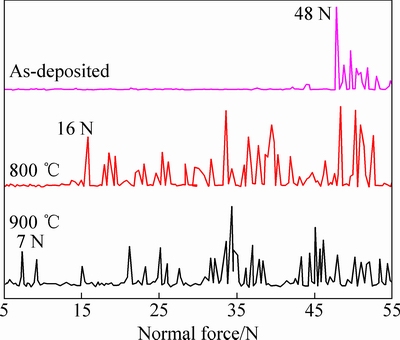

图7所示为CrMoAlN薄膜高温氧化前后的划痕形貌,图8所示为CrMoAlN薄膜划痕的声发射曲线。可以看出,氧化前的CrMoAlN薄膜划痕形貌完整,划痕周边没有明显的裂纹和剥落现象(见图7(a)),薄膜的膜/基结合力在48 N左右。800 ℃氧化后CrMoAlN薄膜划痕周边出现大片的剥落(见图7(b)),薄膜与基体的结合力出现明显下降,约为16 N。图7(c)所示为CrMoAlN薄膜900 ℃氧化后的划痕形貌,与800 ℃氧化后比较,划痕变宽变深,基体暴露在划痕尾部,出现膜层被划穿现象,薄膜基本失效,结合力仅为7 N左右。薄膜高温氧化后膜/基结合强度下降主要是因为在高温环境中基体开始变软,在相同加载力作用下,基体塑性变形增大,使薄膜和基体结合部位保持很高的应力状态,导致薄膜过早的出现剥落。同时高温氧化过程中薄膜软化、残余应力减少等因素也会导致薄膜结合力变小[8]。

图6 不同温度氧化后CrMoAlN薄膜纳米硬度和弹性模量随压入深度的变化曲线

Fig. 6 Hardness-displacement (a) and elastic modulus-displacement (b) curves of CrMoAlN coatings before and after annealing at different temperatures

图7 CrMoAlN薄膜不同温度氧化后的划痕形貌

Fig. 7 Typical scratch track morphologies of CrMoAlN

图8 CrMoAlN薄膜划痕的声发射谱

Fig. 8 Acoustic emission spectra of CrMoAlN coatings before and after heat treatment at 800 and 900 ℃ for 2 h

3 结论

1) CrMoAlN薄膜呈现与CrN相似的面心立方结构,主要以CrN、AlN和γ-Mo2N形态存在。

2) CrMoAlN薄膜在低于800 ℃高温环境中具有一定的抗高温氧化性能。900 ℃氧化后,薄膜氧化程度加剧,硬度、弹性模量和膜/基结合强度均出现大幅度下降,薄膜基本失效。

3) Mo的氮化物高温氧化形成的MoO3会破坏CrMoAlN薄膜表面致密氧化层,加速CrMoAlN薄膜的氧化进程,降低CrMoAlN薄膜抗高温氧化性能。

REFERENCES

[1] LORENZO-MARTIN C, AJAYI O, ERDEMIR A, FENSKE G R, WEI R. Effect of microstructure and thickness on the friction and wear behavior of CrN coatings[J]. Wear, 2013, 302: 963-971.

[2] PETROGALLI C, MONTESANO L, GELFI M, LA VECCHIA G M, SOLAZZI L. Tribological and corrosion behavior of CrN coatings: Roles of substrate and deposition defects[J]. Surface and Coatings Technology, 2014, 258: 878-885.

[3] 陈 灵, 曾德长, 邱万奇, 董小红, 李炳雄, 黄拿灿. TiAlCrN和TiAlCrN/CrN复合膜的微观组织与力学性能[J]. 中国有色金属学报, 2009, 19(9): 1608-1612.

CHEN Ling, ZENG De-chang, QIU Wan-qi, DONG Xiao-hong, LI Bing-xiong, HUANG Na-can. Microstructure and mechanical properties of TiAICrN and TiAICrN/CrN composite coatings by arc ion plating[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1608-1612.

[4] SONG Gui-hong, LUO Zhuo, LI Feng, CHEN Li-jia, HE Chun-lin. Microstructure and indentation toughness of Cr/CrN multilayer coatings by arc ion plating[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 811-816.

[5] 牛仕超, 余志明, 代明江, 林松盛, 侯慧君, 李洪武. 中频磁控溅射沉积梯度过渡C/CrN/CrNC/CrC膜的附着性能[J]. 中国有色金属学报, 2007, 17(8): 1307-1312.

NIU Shi-chao, YU Zhi-ming, DAI Ming-jiang, LIN Song-sheng, HOU Hui-jun, LI Hong-wu. Adhesion of Cr/CrN/CrNC/CrC graded interlayer deposited by MF-magnetron sputtering[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1307-1312.

[6] QI Z B, WU Z T, WANG Z C. Improved hardness and oxidation resistance for CrAlN hard coatings with Y addition by magnetron co-sputtering[J]. Surface and Coatings Technology, 2014, 259: 146-151.

[7] LI W Z, LIU H W, EVARITO M, POLCAR T, CAVALEIRO A. Influence of Al content on the mechanical properties and thermal stability in protective and oxidation atmospheres of Zr-Cr-Al-N coatings[J]. Surface and Coatings Technology, 2013, 236: 239-245.

[8] LEE D B, NGUYEN T D, KIM S K. Air-oxidation of nano-multilayered CrAlSiN thin films between 800 and 1000℃[J]. Surface and Coatings Technology, 2009, 203(9): 1199-1204.

[9] 石永敬, 潘复生, 王维青, 杨世才, 龙思远, 朱光俊. 溅射沉积铝合金基CrTiAlN涂层的结构、力学以及摩擦学特性[J]. 中国有色金属学报, 2011, 21(9): 2099-2104.

SHI Yong-jing, PAN Fu-sheng, WANG Wei-qing, YANG Shi-cai, LONG Si-yuan, ZHU Guang-jun. Structural, mechanical and tribological properties of CrTiAlN coatings on Al alloy deposited by sputtering[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2099-2104.

[10] ZHOU Z F, TAM P L, SHUM P W, LI K Y. High temperature oxidation of CrTiAlN hard coatings prepared by unbalanced magnetron sputtering[J]. Thin Solid Films, 2009, 517(17): 5243-5247.

[11] 陈 颢, 叶育伟, 王永欣, 李金龙, 杨建高. 多弧离子镀制备的CrCN涂层组织及摩擦磨损性能[J]. 中国有色金属学报, 2015, 25(2): 423-429.

CHEN Hao, YE Yu-wei, WANG Yong-xin, LI Jing-long, YANG Jian-gao. Microstructure and tribological properties of CrCN coating prepared by arc ion plating[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 423-429.

[12] HO K K, YOUNG C E, GYUN H S, GYU P B, HONG Y J, HAE Y J. Syntheses and mechanical properties of Cr-Mo-N coatings by a hybrid coating system[J]. Surface and Coatings Technology, 2006, 201(7): 4068-4072.

[13] 余春燕, 王社斌, 尹小定, 许并社. CrAlN薄膜高温抗氧化性的研究[J]. 稀有金属材料与工程, 2009, 38(6): 1015-1018.

YU Chun-yan, WANG She-bin, YIN Xiao-ding, XU Bing-she. Study on high-temperature oxidation resistance of CrAlN coatings[J]. Rare Metal Materials and Engineering, 2009, 38(6): 1015-1018.

[14] YANG Ke, XIAN Guang, ZHAO Hai-bo, FAN Hong-yuan, WANG Jun, WANG Hui, DU Hao. Effect of Mo content on the structure and mechanical properties of TiAlMoN films deposited on WC-Co cemented carbide substrate by magnetron sputtering[J]. International Journal of Refractory Metals and Hard Materials, 2015, 52: 29-35.

[15] 许俊华, 鞠洪博, 喻利花. Mo含量对TiMoN薄膜微观组织和摩擦磨损性能的影响[J]. 金属学报, 2012, 48(9): 1132-1135.

XU Jun-hua, JU Hong-bo, YU Li-hua. Effects of Mo content on the microstructure and friction and wear properties of TiMoN films[J]. Acta Metallurgica Sinca, 2012, 48(9): 1132-1135.

[16] 楼白杨, 王宇星. Mo含量对CrMoAlN薄膜微观结构和摩擦磨损性能的影响[J]. 金属学报, 2016, 52(6): 727-733.

LOU Bai-yang, WANG Yu-xing. Effects of Mo content on the micro-structure and tribological properties of CrMoAlN films[J]. Acta Metallurgica Sinca, 2016, 52(6): 727-733.

[17] CHANG S Y, KIM K H, KWON S H, PARK I W. Syntheses and properties of Cr-Al-Mo-N coatings fabricated by using a hybrid coating system[J]. Journal of the Korean Physical Society, 2009, 54: 1237-1241.

[18] WANG Li-ping, ZHANG Guan-gan, WOOD R J K, WANG S C, XUE Qun-ji. Fabrication of CrAlN nanocomposite films with high hardness and excellent anti-wear performance for gear application[J]. Surface and Coatings Technology, 2010, 204(21/22): 3517-3524.

[19] QI Dong-li, HAO Lei, WANG Tie-gang, PEI Zhi-liang, GONG Jun, SUN Chao. Mechanical, microstructural and tribological properties of reactive magnetron sputtered Cr-Mo-N films[J]. Journal of Materials Science & Technology, 2015, 31(1): 55-64.

[20] MOULDER J F, STICKE W F, SOBOL P E. Handbook of X-ray photoelectron spectroscopy[M]. Minnesota: Perkin Elmer Corporation, 1992: 227-228.

[21] SOLAK N, USTEL F, URGEN M, AYDIN S, CAKIR A F. Oxidation behavior of molybdenum nitride coatings[J]. Surface and Coatings Technology, 2003, 174: 713-719.

[22] 叶大伦. 实用无机物热力学数据手册[M]. 北京: 冶金工业出版社, 2005: 72-73.

YE Da-lun. Handbook of thermodynamic data for applied inorganic material[M]. Beijing: Metallurgical Industry Press, 2005: 72-73.

[23] XUN Jun-hua, JU Hong-bo, YU Li-hua. Microstructure, oxidation resistance, mechanical and tribological properties of Mo-Al-N films by reactive magnetron sputtering[J]. Vacuum, 2014, 103: 21-27.

[24] LI W Z, POLAR T, EVARISTO M, CAVALEIRO A. High temperature properties of the CrNbAlN coatings with increasing Al contents[J]. Surface and Coatings Technology, 2013, 228: 187-194.

[25] LUO Fei, PANG Xiao-lu, GAO Ke-wei, YANG Hui-sheng, WANG Yan-bin. Role of deposition parameters on microstructure and mechanical properties of chromium oxide coatings[J]. Surface and Coatings Technology, 2007, 202: 58-62.

High temperature oxidation resistance of CrMoAlN gradient coatings prepared by unbalanced magnetron sputtering

WANG Yu-xing, LOU Bai-yang, PAN Jian, ZHANG Xia

(Faculty of Materials Science and Engineering, Zhejiang University of Technology, Hangzhou 310032, China)

Abstract: CrMoAlN gradient coatings were deposited on M2 and silicon wafers by closed-field unbalanced magnetron sputtering ion plating(CFUMSIP)technique, and their high-temperature oxidation behaviours were studied after static oxidation tests in air at different temperatures (600, 700, 800, 900 ℃) for 2h. The chemical composition, structural, hardness and adhesive/cohesive strength of the coatings were characterized by EDS, XRD, XPS, SEM, nanoindentation and scratch test. The experimental results show that CrMoAlN coatings exhibit a single phase cubic structure. After oxidation at 800 ℃ for 2 h, the CrMoAlN coatings still retain basically their crystalline structure and mechanical properties. The volatilization reaction rate of MoO3 increases, the dense and protective oxide layer consisting of Cr2O3 and Al2O3 is broken. The porous become clearly observable on the surface of the coating, which provides fast diffusion paths for oxygen and cations, and thus promotes the growth rates of oxide scales. After oxidation at 900 ℃ for 2 h, the mechanical properties and adhesive strength decrease drastically.

Key words: CrMoAlN gradient coating; magnetron sputtering; microstructure; high temperature oxidation

Foundation item: Project (LY15E050017) supported by Zhejiang Natural Science Foundation, China

Received date: 2016-03-11; Accepted date: 2016-10-16

Corresponding author: LOU Bai-yang; Tel: +86-13355810002; E-mail: 1597000573@qq.com

(编辑 王 超)

基金项目:浙江省自然基金资助项目(LY15E050017)

收稿日期:2016-03-11;修订日期:2016-10-16

通信作者:楼白杨,教授,博士;电话:13355810002;E-mail:1597000573@qq.com

[11] 陈 颢, 叶育伟, 王永欣, 李金龙, 杨建高. 多弧离子镀制备的CrCN涂层组织及摩擦磨损性能[J]. 中国有色金属学报, 2015, 25(2): 423-429.

[13] 余春燕, 王社斌, 尹小定, 许并社. CrAlN薄膜高温抗氧化性的研究[J]. 稀有金属材料与工程, 2009, 38(6): 1015-1018.

[15] 许俊华, 鞠洪博, 喻利花. Mo含量对TiMoN薄膜微观组织和摩擦磨损性能的影响[J]. 金属学报, 2012, 48(9): 1132-1135.

[16] 楼白杨, 王宇星. Mo含量对CrMoAlN薄膜微观结构和摩擦磨损性能的影响[J]. 金属学报, 2016, 52(6): 727-733.