Trans. Nonferrous Met. Soc. China 27(2017) 429-439

Negative effects of dissolved organic compounds on settling performance of goethite in Bayer red mud

Meng WANG, Hui-ping HU, Jin-wei LIU

School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China

Received 22 July 2015; accepted 8 January 2016

Abstract:

Goethite, a typical iron-containing monomineral in red mud, was synthesized under the simulated Bayer digestion condition during the alumina production. The effects of dissolved organic compounds including sodium formate, sodium acetate, sodium oxalate, sodium salicylate and disodium phthalate on the settling performance of goethite slurries were studied. The settling performance of the slurries was also investigated with the addition of self-made hydroxamated polyacrylamide flocculant (HCPAM). The adsorption mechanism of dissolved organic compounds on the goethite surfaces was studied by FT-IR and XPS, respectively. The results show that the addition of organic compounds lowers the settling performance of the slurries and a deterioration in settling performance is observed in the order of sodium oxalate > sodium salicylate (~ disodium phthalate) > sodium formate > sodium acetate. Moreover, HCPAM can efficiently eliminate the negative effects of sodium formate, sodium acetate and sodium oxalate on the settling performance of the goethite slurries, but it can only partially improve the settling performance of the goethite slurries containing sodium salicylate or disodium phthalate. FT-IR and XPS results show that these organic compounds are chemically adsorbed on the goethite surface.

Key words:

goethite; dissolved organic compound; settling performance; adsorption mechanism;

1 Introduction

Bauxite mostly consists of different aluminum hydrate ores which are gibbsite Al(OH)3, boehmite γ-AlOOH and diaspore α-AlOOH. It is accumulated with a number of impurities, such as the two iron oxides (goethite and hematite), the clay mineral kaolinite and small amounts of anatase TiO2. The world’s productions of bauxite and metallurgical alumina are correspondingly more than 2×108 and 8×107 t/a, in which gibbsite, boehmite and diaspore ores share 62%, 22% and 16%, respectively [1]. The production of alumina from bauxite requires an effective solid-liquid separation in gravity thickeners to generate Bayer liquors containing low amount of suspended solids.

In general, the bauxite ores contain 0.1%-0.4% (mass fraction) organic compounds and occasionally as high as 0.6% [2]. The organic compounds are composed of a complex mixture of humates, lignin and cellulose [3]. On digestion of this bauxite in the Bayer process, 50%-90% of the organic compounds may be extracted into the Bayer liquor as dissolved organic compounds. The dissolved organic compounds may be classified into three distinct groups [2]: humic acids, freshly extracted high relative molecular mass material and its initial degradation products with relative molecular mass greater than 500 (e.g., fulvic acid); intermediate degradation products which constitute the building “blocks” of the large humic molecules (e.g., aromatic carboxylic acids and phenolic acids); and degradation products with lower relative molecular mass (sodium formate, sodium acetate, sodium oxalate and so on). Dissolved organic compounds build up in the recirculating process liquor to concentrations determined by a complex interaction of inputs, outputs and reactions in a dynamic steady state, and the organic concentrations range from 0 to 40 g/L [4].

SWINKELS and CHOUZADJIAN [2], MALITO and ROBERSON [5], SCHEPERS et al [6] and  et al [7-10] proposed that organic compounds dissolved in the Bayer process resulted in poorer settling performance of red mud.

et al [7-10] proposed that organic compounds dissolved in the Bayer process resulted in poorer settling performance of red mud.  et al [7-10] proposed that the order of the deterioration in the settling performance is humic acid (~fulvic acid)> disodium terephthalate > phenol > sodium oxalate > sodium formate (~sodium acetate). The negative effects of some organic compounds including fulvic or humic acids with the concentration below 1.0 g/L and the others including sodium formate, sodium acetate, sodium oxalate, phenol or disodium terephthalate can be mitigated by the addition of flocculants, and the deterioration of the settling performance of red mud cannot be apparently eliminated by flocculants when the concentration of fulvic or humic acid increased to 3.5 g/L. However, the wide variations in the species of red mud and dissolved organic compounds in Bayer liquors result in difficulties to identify the main influencing factors for settling performance of red mud.

et al [7-10] proposed that the order of the deterioration in the settling performance is humic acid (~fulvic acid)> disodium terephthalate > phenol > sodium oxalate > sodium formate (~sodium acetate). The negative effects of some organic compounds including fulvic or humic acids with the concentration below 1.0 g/L and the others including sodium formate, sodium acetate, sodium oxalate, phenol or disodium terephthalate can be mitigated by the addition of flocculants, and the deterioration of the settling performance of red mud cannot be apparently eliminated by flocculants when the concentration of fulvic or humic acid increased to 3.5 g/L. However, the wide variations in the species of red mud and dissolved organic compounds in Bayer liquors result in difficulties to identify the main influencing factors for settling performance of red mud.

Typically, the digestion temperature for gibbsitic bauxite by the Bayer process is in the range from 135 to 150 °C [11], which leaves behind red mud, containing predominant amount of hydration grossular, goethite and a bit of perovskite [12,13]. Generally, red mud with high content of goethite results in Bayer liquors with higher content of colloidal goethite and poorer settling performance [14,15]. Notwithstanding the wide variations in the species and amounts of dissolved organic compounds between different Bayer liquors, the fundamental organic compounds present in Bayer liquors are aliphatic and aromatic compounds with carboxylic groups and hydroxyl groups. On the other hand, LIU et al [16] found that an improvement in clarity of the supernatant in the goethite slurry using self-made hydroxamated polyacrylamide flocculant (HCPAM) was achieved by a chemisorption mechanism.

In this work, monocarboxylate (sodium formate and sodium acetate), dicarboxylate (sodium oxalate), phenol containing carboxylate groups (sodium salicylate) and aromatic carboxylate (disodium phthalate) were chosen as typical dissolved organic compounds in Bayer liquors. Goethite was synthesized as the typical iron-containing monomineral in red mud under the digestion condition of gibbsitic bauxite. The effects of dissolved organic compounds in Bayer liquors on the settling performance of the goethite slurries were studied. The settling performance of the goethite slurries in the presence or the absence of organic compounds was also investigated with the addition of HCPAM. The adsorption mechanism of dissolved organic compounds on the surfaces of goethite was studied by FT-IR and XPS, respectively.

2 Experimental

2.1 Materials and reagents

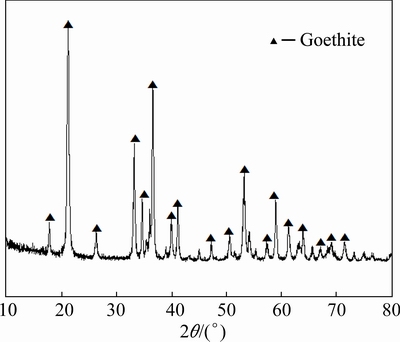

Goethite was prepared according to the procedure of CORNELL and SCHWERTMANN [17], then dried at 60 °C for 24 h and characterized by X-ray powder diffraction on X-ray diffractometer (XRD, D/max 2500, Rigaku Corporation, Cu Kα radiation, Japan). Industrial grade aluminum hydroxide (w(Al(OH)3)≥99.2%) was purchased from Zhengzhou Light Metals Institute of Aluminum Corporation of China. Other reagents were of analytical grade.

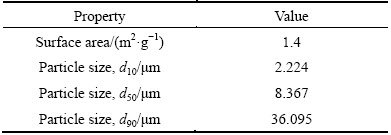

The synthetic goethite (α-FeOOH) was treated by a simulated Bayer digestion as follows: the simulative circulating mother liquor was prepared by NaOH and Al(OH)3, with alkali concentration (Nk) of 180 g/L and caustic ratio (ak, molar ratio of Na2O to Al2O3) of 1.5. The synthetic goethite suspension was prepared by digesting the mixture of 30 g synthetic goethite and 600 mL simulated circulating mother liquor (Nk≈180 g/L, ak≈1.50) in an autoclave at 145-150 °C for 60 min. The suspension was filtered, subsequently washed with 10% NaOH solution several times, and then dried in a vacuum oven at 60 °C for 24 h to obtain the dry mud. The main mineral of the dry mud was characterized by semi- quantitative analysis of XRD (Fig. 1). The dry mud was characterized by the surface area using nitrogen (Monosorb Autosorb, Quantachrome Instruments Ltd., USA) and the particle size distribution (Mastersizer2000, Malvern Instruments Ltd., UK), respectively. All the results are listed in Table 1.

Fig. 1 XRD pattern of dry mud from synthetic goethite (JCPDS-PDF of goethite is No. 29-0713)

Table 1 Properties of dry mud from synthetic goethite

Self-made hydroxamated flocculant HCPAM was prepared by a method described by Ref. [18] (HCPAM, with the intrinsic viscosity of 737 mL/g, 53% (mole fraction) hydroxamate groups and 15% (mole fraction) carboxyl groups, the contents of hydroxamate and carboxyl groups of HCPAM were measured by elemental analysis).

2.2 Settling tests

2.2.1 Preparation of flocculant solution

The flocculant solution of HCPAM was prepared as a solution of 0.5% (mass fraction) polymer solids in 10 g/L NaOH solution, and further diluted to a 0.1% flocculant solution with deionized water just before use.

2.2.2 Preparation of goethite slurry for settling tests

Several series of goethite slurries with dissolved organic compounds for settling tests were prepared as follows: the simulative circulating mother liquor (Nk≈240 g/L, ak≈1.5) was prepared with NaOH and Al(OH)3. 100 mL boiled simulative circulating mother liquor, 6 g synthetic goethite and suitable amount of deionized water along with varying amounts of the organic compound solution were added into a 250 mL graduated cylinder (d30 mm × 260 mm) to yield 200 mL suspensions. The addition of each organic compound to the suspension is based on a series of fixed molar ratios for carboxylate group of each organic compound to ferric ion of goethite, for example, the molar ratios for carboxylate group of each organic compound to ferric ion of goethite were correspondingly 0.29, 0.23, 0.17, 0.12 and 0.06. The suspensions were stirred at (95±1) °C to obtain goethite slurries with solid content of 30 g/L (Nk≈120 g/L, ak≈1.5) at different organic concentrations (g/L), respectively.

The goethite slurry in the absence of organic compounds was prepared similar to the slurries in the presence of organic compounds except that organic compounds were not added to the slurries.

2.2.3 Settling tests

200 mL boiled goethite slurry in the presence or absence of organic compounds was poured into a 250 mL graduated cylinder (d30 mm × 260 mm) which was placed into a glass water bath maintained at (95±1) °C. Then, the slurry was mixed using a hand-operated plunger for five strokes (a single stoke being considered as both down and up) to obtain well-mixed slurry. Timing was started immediately upon stopping mixing, and the height of the solid-liquid interface was recorded at a certain interval. The settling rates were calculated by timing the descent of the mud interface for the first 1 min and for the first 5 min, respectively. After the settling test lasted for 30 min, the clarity of the supernatant was determined by a WGZ-3 turbidimeter (China).

After finishing the settling tests described above, the settling tests of goethite slurries which were in the presence of organic compounds at a certain critical concentration with the lowest settling rate or in the absence of organic compounds were conducted similar to the operation described above except that 240 g/t HCPAM was added to the slurry. The amount of the flocculant was based on the ratio of mass of flocculant change to the mass of solids in the slurry (g/t).

2.3 Adsorption mechanism

The technique used for adsorbing sodium formate, sodium acetate, sodium oxalate, sodium salicylate or disodium phthalate on the goethite surface was modified from that developed by JONES et al [19]. 0.25 g synthetic goethite was placed in an airtight conical flask with 50 mL of 0.001 mol/L sodium hydroxide solution and sonicated at 60 °C for 10 h to obtain a suspension, and the suspension was centrifuged at 4000 r/min for 30 min to separate the supernatant and the solid. The supernatant was decanted to obtain a fresh, carbonate-free goethite solid placed in an airtight conical flask. 50 mL of a certain concentration of organic compounds in 2 mol/L sodium hydroxide solution was added to the conical flask with 0.25 g of carbonate-free goethite solid, and the molar ratio for carboxylate groups of organic compounds to ferric ion of goethite was 10:1. After the mixture was sonicated at 60 °C for 10 h and equilibrated for 24 h, the mixture was centrifuged at 4000 r/min to obtain a solid, and the solid was washed with deionized water once and dried in a vacuum oven at 60 °C for 24 h. The samples of goethite after the treatment of sodium formate, sodium acetate, sodium oxalate, sodium salicylate and disodium phthalate were obtained.

Goethite before the treatment of organic compounds (abbreviated as untreated goethite) was prepared in the same manner except that dissolved organic compounds were not added to the carbonate-free goethite solid.

The infrared spectra of the samples were measured by a Nicolet-6700 FT-IR spectrometer. The samples were analyzed on X-ray photoelectron spectrometer (ESCALAB 250XI, Thermo Scientific Co., USA) utilizing a monochromatic Al Kα X-ray at 1486.6 eV. All measurements were carried out at the pressure below 1×10-8 Pa with a flood gun for charge neutralization. All spectra were charge-referenced so that the unfunctionalized aliphatic C 1s component occurred at 284.8 eV.

3 Results and discussion

3.1 Settling performance of goethite slurries without flocculants

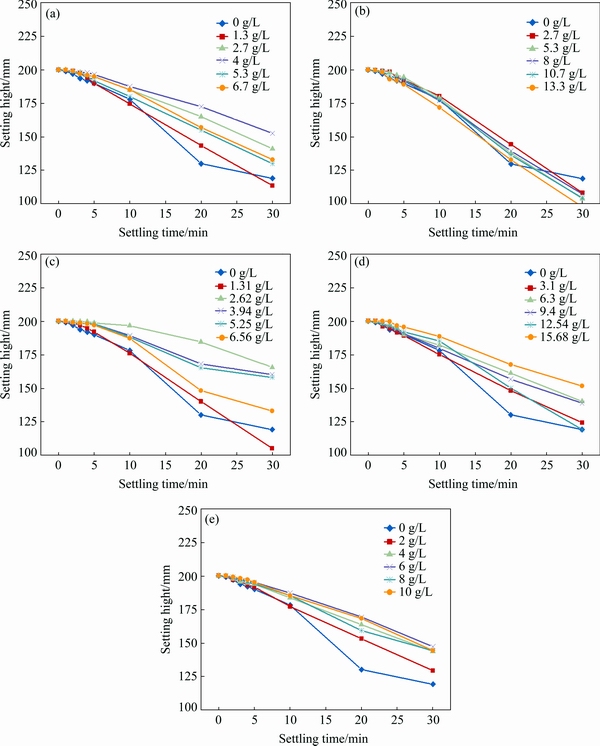

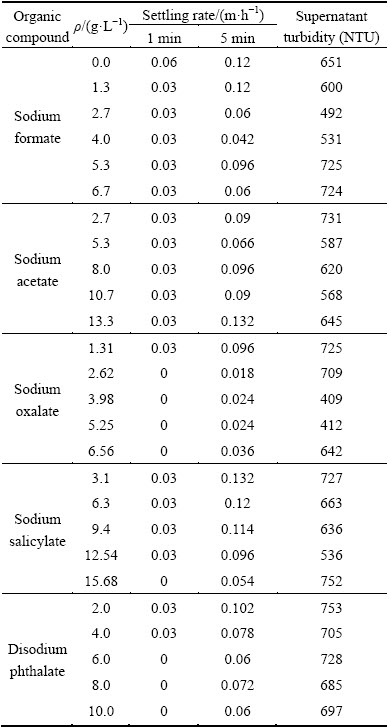

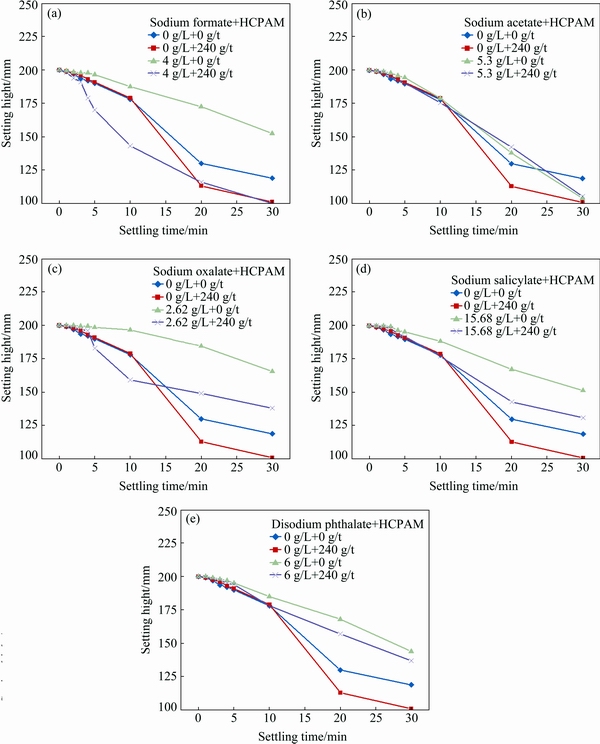

Settling tests were conducted on 30 g/L goethite slurries to illustrate the effects of dissolved organic compounds (including sodium formate, sodium acetate, sodium oxalate, sodium salicylate and disodium phthalate) on the settling performance without flocculants. The results (presented in Fig. 2 and Table 2) are generated by altering the organic species and increasing the concentration of organic compounds in the goethite slurries.

Fig. 2 Settlement curves of 30 g/L goethite slurries as function of different concentrations of sodium formate (a), sodium acetate (b), sodium oxalate (c), sodium salicylate (d) and disodium phthalate (e)

As shown in Fig. 2 and Table 2, organic compounds have notable effects on the settling performance of the goethite slurries. This is accompanied by a remarkable decrease of the settling rates for the first 1 min and the first 5 min compared with those in the absence of organic compounds. The settling rates for the first 1 min and the first 5 min of the goethite slurry in the absence of organic compounds are 0.06 and 0.12 m/h, respectively. In general, when the concentrations of sodium formate, sodium acetate and sodium oxalate in the goethite slurries increase, the settling rate decreases at first, and then increases. The lowest settling rates for the first 1 min and the first 5 min are respectively 0.03 and 0.042 m/h at 4 g/L of the critical concentration of sodium formate. At the critical concentration of 5.3 g/L of sodium acetate, the lowest settling rates for the first 1 min and the first 5 min are 0.03 and 0.066 m/h, respectively. And the lowest settling rates for the first 1 min and the first 5 min are 0 and 0.018 m/h, respectively at the critical concentration of 2.62 g/L in the presence of sodium oxalate. As the concentration of sodium salicylate in the goethite slurries ranged from 3.1 to 15.68 g/L, a gradual decrease of the settling rate occurred. When the concentration of sodium salicylate increased to 15.68 g/L, the lowest settling rates for the first 1 min and the first 5 min are correspondingly 0 and 0.054 m/h, respectively. When the concentration of disodium phthalate in the goethite slurry ranged from 2 to 10 g/L, the lowest settling rates for the first 1 min and the first 5 min are respectively 0 and 0.06 m/h at the critical concentration of 6.0 g/L of disodium phthalate. The lowest settling rate for the first 1 min decreased to 0 in presence of sodium oxalate, sodium salicylate or disodium phthalate. Meanwhile, the clarity of the supernatant in the presence of organic compounds (especially sodium oxalate, sodium salicylate and disodium phthalate) is poorer than that in the absence of organic compounds. These results indicate that the deterioration in settling performance is observed in the presence of organic compounds. The order of the deterioration in settling performance is sodium oxalate > sodium salicylate (~ disodium phthalate) > sodium formate >sodium acetate.

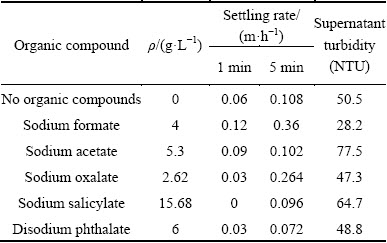

Table 2 Settling rate and supernatant turbidity of 30 g/L goethite slurries at different concentrations of organic compounds

3.2 Settling performance of goethite slurries with HCPAM

Focused on 30 g/L goethite slurries in the presence of organic compounds at the critical concentration (i.e., the lowest settling rate occurred at this critical concentration of organic compounds without flocculants) or in the absence of organic compounds, HCPAM at the dosage of 240 g/t was introduced in order to improve the settling performance of the slurries. The results are present in Fig. 3 and Table 3.

As shown in Fig. 3 and Table 3, with the addition of HCPAM, the settling rates of the goethite slurries in the presence of sodium formate, sodium acetate and sodium oxalate are observed to equal or even surpass that in the absence of organic compounds. The addition of HCPAM can improve the settling performance of the goethite slurries in the presence of sodium salicylate or disodium phthalate. Whereas with the addition of HCPAM to the slurries, the settling rate of the goethite slurries in the presence of sodium salicylate or disodium phthalate is still smaller than that in the absence of organic compounds. With the addition of HCPAM, the clarity of the supernatant of goethite slurries in the presence of organic compounds at a critical concentration or in the absence of organic compounds is significantly improved. Therefore, the negative effects of sodium formate, sodium acetate and sodium oxalate on the settling performance of the goethite slurries can be efficiently eliminated by HCPAM, and HCPAM just partially improves the settling performance of the goethite slurries in the presence of sodium salicylate or disodium phthalate.

3.3 Adsorption mechanism of dissolved organic compounds on goethite surface

The structural changes of goethite before and after the treatment of organic compounds were investigated by FT-IR and XPS, respectively.

3.3.1 FT-IR analysis

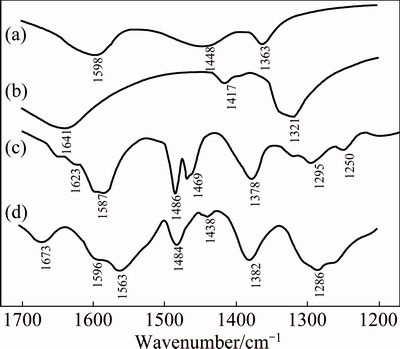

FT-IR spectra of unadsorbed sodium formate, sodium oxalate, sodium salicylate and disodium phthalate are depicted in Fig. 4. FT-IR spectra of goethite before and after the treatment of sodium formate, sodium oxalate, sodium salicylate and disodium phthalate are depicted in Fig. 5.

Fig. 3 Settlement curves of 30 g/L goethite slurries in presence of organic compounds at critical concentration or in absence of organic compounds with or without addition of HCPAM

In the FT-IR spectrum of unadsorbed sodium formate (Fig. 4(a)), the asymmetric (νasym) and symmetric (νsym) stretches of the carboxylate group in unadsorbed sodium formate are located at 1598 and 1363 cm-1, respectively. Furthermore, the weak band at 1448 cm-1 is assigned to the C—H bending vibration of sodium formate.

In the FT-IR spectrum of unadsorbed sodium oxalate (Fig. 4(b)), the asymmetric (νasym) and symmetric (νsym) stretches of the carboxylate group in sodium oxalate are located at 1641 and 1321 cm-1, respectively. Furthermore, the weak band at 1417 cm-1 is assigned to the δ(O—C=O) vibration of sodium oxalate [20].

In the FT-IR spectrum of unadsorbed sodium salicylate (Fig. 4(c)), the asymmetric (νasym) and symmetric (νsym) stretches of the carboxylate group can be identified as the bands at 1587 and 1378 cm-1, respectively. The bands at 1623, 1486 and 1469 cm-1 are assigned to the C—C ring stretching modes of benzene. The band at 1295 cm-1 is assigned to the bending mode of the phenolic (Ph—O—H) group. The phenolic Ph—O stretching vibration is represented by the band at 1250 cm-1 in sodium salicylate [21].

Table 3 Settling rate and supernatant turbidity of 30 g/L goethite slurries in presence of organic compounds at critical concentration or in absence of organic compounds with addition of 240 g/t HCPAM

Fig. 4 FT-IR spectra of sodium formate (a), sodium oxalate (b), sodium salicylate (c) and disodium phthalate (d)

In the FT-IR spectrum of unadsorbed disodium phthalate (Fig. 4(d)), the asymmetric (νasym) and symmetric (νsym) stretches of the carboxylate group can be identified as the bands at 1563 and 1382 cm-1, respectively. The band corresponding to C=O stretching vibration in carboxylate group is located at 1673 cm-1. And the C—C ring stretching mode of benzene occurs at 1484 cm-1 [22].

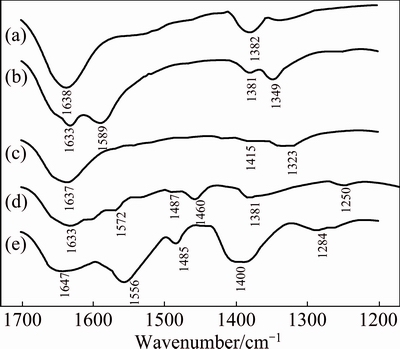

The FT-IR spectrum of goethite before the treatment of organic compounds is depicted in Fig. 5(a). There are no characteristic vibrational bands in the zone between 1200 and 1700 cm-1, and the bands at 1638 and 1382 cm-1 are respectively assigned to the vibration of adsorbed and constitutional water.

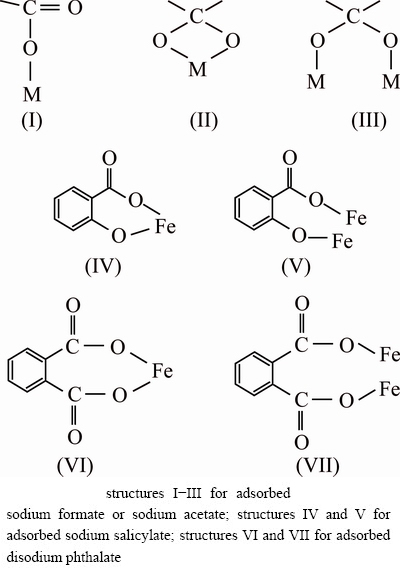

Several studies [19,21] have demonstrated that the expected frequency shifts occurred when carboxylic acids or their salts were adsorbed as carboxylates on inorganic (oxide) surfaces. When the carboxyl groups of carboxylic acids or their salts are directly involved in the adsorption, it is possible to identify the structures on the basis of the carboxylate asymmetric (νasym) and symmetric (νsym) stretches, and their separation (Δν=νasym-νsym). Δν(adsorbed) and Δν(salt) are the separations of the symmetric and asymmetric stretches of the carboxylate groups of the adsorbed carboxylate salt and the unadsorbed carboxylate salt, respectively. They can be used to identify the adsorbed structures: when the value of Δν(adsorbed) is smaller than Δν(salt), a bidentate chelating complex (II) is observed (two oxygen atoms of the carboxylate group form two bonds with one metal atom on the solid surface). However, when Δν(adsorbed) is greater than Δν(salt), a monodentate mononuclear complex (I) is seen (only one oxygen atom of the carboxylate group binds with one metal atom on the solid surface). In binuclear bridging complex (III) (two oxygen atoms of the carboxylate group bind with two metal atoms on the solid surface), Δν(adsorbed) is almost equal to Δν(salt).

Fig. 5 FT-IR spectra of untreated goethite (a) and goethite after treatment of sodium formate (b), sodium oxalate (c), sodium salicylate (d) and disodium phthalate (e)

Figure 6 shows the possible surface complex of goethite after the treatment of organic compounds. Sodium formate and sodium oxalate may form surface complex on goethite surface as complexes (I), (II) and (III). Sodium salicylate may be adsorbed on goethite surface with a bidentate chelating complex (IV) or a bidentate bridging complex (V). In the bidentate chelating complex (IV), one oxygen atom of the carboxylate group and the oxygen atom of phenolic group bind with one surface iron atom of goethite. Whereas, one oxygen atom of the carboxylate group and the oxygen atom of phenolic group bind with two adjacent surface iron atoms of goethite to form a bidentate bridging complex (V). Disodium phthalate may have the similar adsorption manner in which two oxygen atoms of carboxylate group bind with surface iron atoms of goethite as a complex (VI) or (VII).

Fig. 6 Possible surface structures for organic compounds adsorbed on goethite surface

For goethite after the treatment of sodium formate, spectral bands at 1589 and 1349 cm-1 are indicative of the asymmetric (νasym) and symmetric (νsym) stretches of carboxylate group (Fig. 5(b)), respectively. The asymmetric (νasym) and symmetric (νsym) stretches of carboxylate group of adsorbed sodium oxalate are correspondingly at 1637 and 1323 cm-1 (Fig. 5(c)). Δν(salt) values for unadsorbed sodium formate and sodium oxalate are respectively 235 and 320 cm-1, while Δν(adsorbed) values of adsorbed sodium formate and sodium oxalate are respectively 240 and 314 cm-1. This suggests that a bidentate chelating complex (II) (Fig. 6) may be formed between two oxygen atoms of carboxylate group in sodium formate or sodium oxalate and one surface iron atom of goethite.

FT-IR spectrum of goethite after the treatment of sodium salicylate (Fig. 5(d)) shows that the asymmetric (νasym) and symmetric (νsym) stretches frequencies of carboxylate group of adsorbed sodium salicylate are at 1572 and 1381 cm-1, respectively. There is only a slight decrease in the Δν(adsorbed) value (191 cm-1) of adsorbed sodium salicylate compared with the Δν(salt) value (208 cm-1) of unadsorbed sodium salicylate. Besides, the C—C stretching of benzene ring undergoes significant shifts upon forming a complex with goethite surface because the substituent of the benzene ring affects the charge density and the charge distribution on the benzene ring. In addition, the absence of the bending frequency of the Ph—O—H in adsorbed sodium salicylate indicates the deprotonation and the coordination of the phenolic group with the surface iron atom of goethite. This suggests that adsorbed sodium salicylate may form a binuclear chelating complex (IV) or a binuclear bridging complex (V) (Fig. 6) on the goethite surface.

For goethite after the treatment of disodium phthalate, the bands at 1556 and 1400 cm-1 are correspondingly the asymmetric (νasym) and symmetric (νsym) stretches of carboxylate group of adsorbed disodium phthalate. There is a slight decrease of Δν(adsorbed) value (156 cm-1) of adsorbed disodium phthalate compared with the Δν(salt) value (181 cm-1) of unadsorbed disodium phthalate. And the band corresponding to the C=O stretching vibration in carboxylate group located at 1673 cm-1 disappears after adsorption (Fig. 5(e)). The results indicate that the adsorbed disodium phthalate may form a binuclear chelating complex (VI) or a binuclear bridging complex (VII) (Fig. 6) involving two carboxylate groups on the goethite surface.

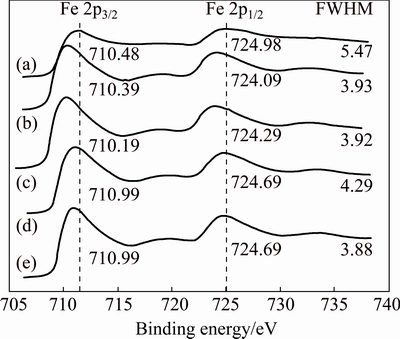

3.3.2 XPS analysis

Figure 7 shows the binding energies and full widths at half maximum (FWHM) of Fe 2p of goethite before and after the treatment of dissolved organic compounds. As shown in Fig. 7, in comparison with the untreated goethite, the binding energies of Fe 2p3/2 for goethite after the treatment of sodium formate, sodium oxalate, sodium salicylate and disodium phthalate were correspondingly decreased by 1.1, 1.3, 0.5 and 0.5 eV, and those of Fe 2p1/2 were correspondingly decreased by 0.9, 0.7, 0.3 and 0.3 eV, respectively. The change of chemical shift can be explained by the atomic potential model [23]. The atomic potential model assumes that the atomic core potential varies linearly with the valence charge of atoms, and the oxidation of one atom results in the increase of the atomic binding energy of the inner electron, whereas the reduction of one atom results in the decrease of the atomic binding energy of the inner electron. This indicates that partial reduction of surface iron atoms after the treatment of organic compounds may happen due to the coordination of Fe(III) of goethite surfaces with oxygen atoms of organic compounds.

Fig. 7 XPS spectra of untreated goethite (a) and goethite after treatment of sodium formate (b), sodium oxalate (c), sodium salicylate (d) and disodium phthalate (e)

Figure 6 presents the possible surface complex of goethite after the treatment of organic compounds. This indicates that the adsorbed iron atoms on the goethite surfaces can partially accept electron clouds from oxygen atom. The electronic charge densities of the adsorbed iron atoms with bidentate chelating complexes (II), (IV) and (VI) would have been higher than those in a monodentate mononuclear complex (I) or bidentate bridging complexes (III), (V) and (VII). According to the above mentioned relationship between the change of the binding energies and electronic charge densities of adsorbed atoms on solid surfaces, the decrease of the binding energy of Fe 2p spectra in XPS for goethite after the treatment of organic compounds with bidentate chelating complexes (II), (IV) and (VI) would have been more apparent than that with a monodentate mononuclear complex (I) or bidentate bridging complex (III), (V) and (VII). In fact, it can be noted that a corresponding decrease in the binding energies of Fe 2p3/2 and Fe 2p1/2 of goethite after the treatment of sodium formate (by 1.1 and 0.8 eV, respectively) or sodium oxalate (by 1.3 and 0.7 eV, respectively) was observed compared with the untreated goethite, while the corresponding decrease values of 0.5 and 0.3 eV in the binding energies of Fe 2p3/2 and Fe 2p1/2 of goethite after the treatment of sodium salicylate or disodium phthalate were observed in comparison with the untreated goethite. This shows that the decrease of Fe 2p binding energies for goethite after the treatment of sodium formate or sodium oxalate is almost two times larger than that of goethite after the treatment of sodium salicylate or sodium phthalate. Therefore, all the results indicate that adsorbed sodium formate or sodium oxalate may form a bidentate chelating complex (II) on the goethite surface after the treatment of sodium formate or sodium oxalate. And the adsorbed sodium salicylate or disodium phthalate may correspondingly form a bidentate bridging complex (V) or (VII) on the goethite surface.

On the other hand, FWHM of the peaks of Fe 2p for goethite after the treatment of organic compounds is slightly smaller than that of untreated goethite, which also indicates that the partial reduction of the iron atoms may occur on the goethite surface. This opinion is also supported by TORU and PETER [24]: FWHM was inversely proportional to the lifetime of ion state remaining after photoemission, the electronic configuration of Fe2+ was 3d6 whilst that of Fe3+ was 3d5, and Fe2+ would have a longer lifetime than Fe3+, and then FWHM of Fe(II) 2p peaks was expected to be slightly smaller than that of Fe(III) 2p peaks. This proved that chemisorptions of organic compounds on the goethite surface in a bidentate chelating complex took place.

All the results showed that organic compounds were chemically adsorbed on the goethite surface. This accounts for the notable effects of organic compounds on the settling performance of the goethite slurries.

The goethite slurries in the presence of sodium salicylate or disodium phthalate own poorer settling performance than those in the presence of sodium formate or sodium acetate, which might be due to the stronger hydrophobicity of sodium salicylate or disodium phthalate than that of sodium formate or sodium acetate. The octanol-water partition coefficient (KOW) is a coefficient representing the ratio of the solubility of an organic compound in octanol to its solubility in water, and is generally used as a relative indicator of the tendency of an organic compound to adsorb to soil [25]. The higher the KOW is, the more the non-polar and the more likely to adsorb on soil the organic compound is. KOW values for salicylic acid and phthalic acid are 102.26 and 100.73, respectively, which are higher than those for formic acid (10-0.54) and acetic acid (10-0.17). This means that the adsorption of sodium salicylate or disodium phthalate on the goethite surface increases the hydrophobicity of the goethite surface and causes the goethite particles easier to float at the air-water interface. This accounts for the lower settling rate and poorer clarity of the supernatant in the presence of sodium salicylate or disodium phthalate than that in the presence of sodium formate or sodium acetate. The presence of additional carboxylate groups enhances the adsorption of sodium oxalate on the goethite surface [26], and lower solubility of sodium oxalate makes it easier to precipitate as a fine needle shaped crystals [1]. Hence, the cataclastic fine grain of these fragile crystals further reduces the settling rate and results in the worst settling performance [5].

Furthermore, due to the difference in hydrophobicity of organic compounds, the hydrophilicity of HCPAM may weaken its adsorption on the goethite surface in the presence of sodium salicylate or disodium phthalate compared with that in the presence of sodium formate or sodium acetate. On the other hand, MANASH et al [27] studied the adsorption of benzoate and salicylate onto the natural hematite surfaces, and found that unlike benzoate, salicylate was not only chemically adsorbed at one-surface iron site but also covered around three or more surface iron sites of the hematite surface. The FT-IR and XPS analyses show that sodium formate, sodium acetate or sodium oxalate may just adsorb at one- surface iron site of the goethite surface, and sodium salicylate or disodium phthalate may chemically adsorb at two-surface iron sites of the goethite surface. This indicates less amount of active iron sites on the goethite surface, which makes HCPAM more difficult to be adsorbed on the goethite surface in the presence of sodium salicylate or disodium phthalate than in the presence of sodium formate, sodium acetate or sodium oxalate. Thus, HCPAM can efficiently eliminate the negative effects of sodium formate, sodium acetate or sodium oxalate on the settling performance of the goethite slurries, but only partial improvement in settling performance of the goethite slurries in the presence of sodium salicylate or disodium phthalate can be achieved by HCPAM.

4 Conclusions

1) The deterioration in settling performance of the goethite slurries in the presence of dissolved organic compounds occurred compared with that in the absence of organic compounds. The order of the deterioration in settling performance of the slurries is sodium oxalate > sodium salicylate (~disodium phthalate) > sodium formate >sodium acetate.

2) HCPAM can efficiently eliminate the negative effects of sodium formate, sodium acetate or sodium oxalate on the settling performance of the goethite slurry. But only partial improvement in settling performance of the goethite slurries in the presence of sodium salicylate or disodium phthalate can be achieved by HCPAM.

3) The analyses of FT-IR and XPS show that the dissolved organic compounds are chemically adsorbed on the goethite surface. A bidentate chelating complex (II) may be formed between oxygen atoms of carboxylate group of sodium formate, sodium acetate or sodium oxalate and one-surface iron atom of goethite. A bidentate bridging complex (V), in which one oxygen atom of the carboxylate group and the oxygen atom of the phenolic group of adsorbed sodium salicylate bind with two-adjacent surface iron atoms, may be formed. And the formation of a bidentate bridging complex (VII) between two carboxylate groups of disodium phthalate and two adjacent surface iron atoms of goethite may take place.

References

[1] FARROKH M. Thermodynamic process modeling and simulation of a diaspore bauxite digestion process [D].  University Press, 2013: 64.

University Press, 2013: 64.

[2] SWINKELS D A, CHOUZADJIAN K. Removal of organics from Bayer process streams: US patent, 4836990 [P]. 1989-01-06.

[3] POWER G, LOH J S C. Organic compounds in the processing of lateritic bauxites to alumina. Part 1: Origins and chemistry of organics in the Bayer process [J]. Hydrometallurgy, 2010, 105: 1-29.

[4] POWER G, LOH J S C, VERNON C. Organic compounds in the processing of lateritic bauxites to alumina. Part 2: Effects of organics in the Bayer process [J]. Hydrometallurgy, 2012, 127-128: 125-149.

[5] MALITO J T, ROBERSON M L. Removal of high molecular weight organic compounds from Bayer process caustic liquor: US patent, 4663133 [P]. 1987-05-05.

[6] SCHEPERS B, BAYER G, URMANN E, SCHANZ K. Method for removing harmful organic compounds from aluminate liquors of the Bayer process: US patent, 4046855 [P]. 1977-09-06.

[7]  Zi-jian, BI Shi-wen, XIE Yan-li, YANG Yi-hong. Effect of sodium oxalate on processes of red mud sedimentation [J]. Journal of Materials and Metallurgy, 2006, 5(2): 105-108. (in Chinese)

Zi-jian, BI Shi-wen, XIE Yan-li, YANG Yi-hong. Effect of sodium oxalate on processes of red mud sedimentation [J]. Journal of Materials and Metallurgy, 2006, 5(2): 105-108. (in Chinese)

[8]  Zi-jian, BI Shi-wen, XIE Yan-li. Effects of para-phthatlic sodium on sedimentation of red mud [J]. Journal of Northeastern University (Natural Science), 2007, 28(1): 83-86. (in Chinese)

Zi-jian, BI Shi-wen, XIE Yan-li. Effects of para-phthatlic sodium on sedimentation of red mud [J]. Journal of Northeastern University (Natural Science), 2007, 28(1): 83-86. (in Chinese)

[9]  Zi-jian, BI Shi-wen, XIE Yan-li, YANG Yi-hong. The effects of the fulvic acid on properties of mud sedimentation [J]. Light Metal of China, 2007(4): 13-15. (in Chinese)

Zi-jian, BI Shi-wen, XIE Yan-li, YANG Yi-hong. The effects of the fulvic acid on properties of mud sedimentation [J]. Light Metal of China, 2007(4): 13-15. (in Chinese)

[10]  Zi-jian, BI Shi-wen, XIE Yan-li, YANG Yi-hong. The effects of the humic acid on properties of mud sedimentation [J]. Journal of Molecular Science, 2006, 22(6): 413-415. (in Chinese)

Zi-jian, BI Shi-wen, XIE Yan-li, YANG Yi-hong. The effects of the humic acid on properties of mud sedimentation [J]. Journal of Molecular Science, 2006, 22(6): 413-415. (in Chinese)

[11] HOND R D, HIRALAL I, RIJKEBOER A. Alumina yield in the bayer process past, present and prospects [C]//Light Metals: Alumina and Bauxite. New York: Springer International Publishing, 2007: 528-533.

[12] LIU Jin-wei, HU Hui-ping, WANG Meng, CHEN Qi-yuan. Main components of red mud from simulative Bayer process in China and the adsorption mechanisms [J]. Light Metal of China, 2015(4): 1-12. (in Chinese)

[13] PAWLEK F, KHEIRI M J, KAMMEL H C R. The leaching behavior of bauxite during mechanochemical treatment [C]//Proceedings of the 125th TMS Annual Meeting. San Diego, 1996: 91.

[14] CANG Xiang-hui. Study on the microstructure and reaction properties of iron mineral in Lao bauxite [J]. Metallurgical Analysis, 2010, 30(7): 16-19. (in Chinese)

[15] BASU P. Reactions of iron minerals in sodium aluminate solution [C]//Light Metals. New York: The Metallurgical Society of AIME. 1983: 176-183.

[16] LIU Jin-wei, HU Hui-ping, WANG Meng, CHEN Qi-yuan, DAI Kuan. Adsorption mechanism of the simulated red mud from diaspore with high levels of silicon and iron [J]. The Canadian Journal of Chemical Engineering, 2016, 94(9): 1700-1709.

[17] CORNELL R M, SCHWERTMANN U. The iron oxides: Structure, properties, reactions, occurrences and uses [M]. New York: VCH Publishers, 2003: 175.

[18] LIU Jin-wei, HU Hui-ping, WANG Meng, CHEN Xiang-pan, CHEN Qi-yuan, DING Zhi-ying. Synthesis of modified polyacrylamide with high content of hydroxamate groups and the settling performance of red mud [J]. Journal of Central South University, 2015, 22(1): 1-10.

[19] JONES F, FARROW J B, BRONSWIJK W V. An infrared study of a polyacrylate flocculant adsorbed on hematite [J]. Langmuir: ACS Journal of Surfaces and Colloids, 1998, 14(22): 6512-6517.

[20] LI Qiao-yun, WANG Xue-lin, SUN Shu-ping. Infrared spectroscopic qualitative study of carboxylic acid and carboxylate structure [J]. Journal of Harbin Normal University (Natural Sciences), 1996, 12(1): 67-70. (in Chinese)

[21] ERLC C Y, ISABEL M T, MARC A A. In-situ CIR-FTIR characterization of salicylate complexes goethite/aqueous interface [J]. Environ Sci Technol, 1990, 24(6): 822-826.

[22] BOILY J F, PERSSON P, SJOBERG S. Benzenecarboxylate surface complexation at the goethite (α-FeOOH)/water interface. II: Linking IR spectroscopic observations to mechanistic surface complexation models for phthalate, trimellitate, and pyromellitate [J]. Geochimica et Cosmochimica Acta, 2000, 64(20): 3453-3470.

[23] COLE R J, GREGORY D A C, WEIGHTMAN P. Analysis of Auger-parameter and XPS shifts: Application of potential models [J]. Physical Review B, 1994, 49(8): 5657-5661.

[24] TORU Y, PETER H. Analysis of XPS spectra of Fe2+ and Fe3+ ions in oxide materials [J]. Applied Surface Science, 2008, 254: 2441-2449.

[25] LYMAN W J, REEHL W F, ROSENBLATT D H. Handbook of chemical property estimation methods: Environmental behavior of organic compounds [M]. New York: McGraw-Hill, 1990: 960.

[26] CYNTHIA R E, DAVID A D. Influence of structural features on sorption of NOM-analogue organic acids to goethite [J]. Environ Sci Technol, 1998, 32(19): 2846-2855.

[27] MANASH R D, DIPAK B, PRAKASH C B, SEKH M. Kinetics and adsorption of benzoate and salicylate at the natural hematite-water interface [J]. Colloids and Surfaces A, 2005, 254: 49-55.

可溶性有机物对拜耳法赤泥中针铁矿沉降性能的负作用

王 梦,胡慧萍,刘锦伟

中南大学 化学化工学院,长沙 410083

摘 要:在模拟拜耳法氧化铝生产溶出条件下合成赤泥中主要含铁组分针铁矿,研究可溶性有机物包括甲酸钠、乙酸钠、草酸钠、水杨酸钠和邻苯二甲酸钠对针铁矿悬浮液沉降性能的影响,考察添加自制聚丙烯酰胺改性氧肟酸型絮凝剂(HCPAM)时针铁矿悬浮液的沉降性能,分别采用傅里叶红外光谱(FT-IR)和X射线光电子能谱(XPS)研究可溶性有机物在针铁矿表面上的吸附机理。结果表明:有机物使针铁矿悬浮液的沉降性能恶化,恶化程度由大到小顺序如下:草酸钠、水杨酸钠(邻苯二甲酸钠)、甲酸钠、乙酸钠。此外,絮凝剂HCPAM能够有效消除甲酸钠、乙酸钠和草酸钠对针铁矿悬浮液沉降的负作用,但只能部分消除水杨酸钠和邻苯二甲酸二钠对针铁矿悬浮液沉降的负作用。FT-IR和XPS光谱分析结果表明:上述有机物在针铁矿表面上的吸附机理为化学吸附。

关键词:针铁矿;可溶性有机物;沉降性能;吸附机理

(Edited by Wei-ping CHEN)

Foundation item: Projects (51174231, 51134007) supported by the National Natural Science Foundation of China

Corresponding author: Hui-ping HU; Tel: +86-731-88879616; E-mail: phuhuiping@126.com

DOI: 10.1016/S1003-6326(17)60049-9

Abstract: Goethite, a typical iron-containing monomineral in red mud, was synthesized under the simulated Bayer digestion condition during the alumina production. The effects of dissolved organic compounds including sodium formate, sodium acetate, sodium oxalate, sodium salicylate and disodium phthalate on the settling performance of goethite slurries were studied. The settling performance of the slurries was also investigated with the addition of self-made hydroxamated polyacrylamide flocculant (HCPAM). The adsorption mechanism of dissolved organic compounds on the goethite surfaces was studied by FT-IR and XPS, respectively. The results show that the addition of organic compounds lowers the settling performance of the slurries and a deterioration in settling performance is observed in the order of sodium oxalate > sodium salicylate (~ disodium phthalate) > sodium formate > sodium acetate. Moreover, HCPAM can efficiently eliminate the negative effects of sodium formate, sodium acetate and sodium oxalate on the settling performance of the goethite slurries, but it can only partially improve the settling performance of the goethite slurries containing sodium salicylate or disodium phthalate. FT-IR and XPS results show that these organic compounds are chemically adsorbed on the goethite surface.