BioMinE:An integrated project for developing biohydrometallurgy in Europe—Executive summary of its activities and outputs after three years

Dominique H. R. MORIN

BRGM-EPI/Eco, 3, Avenue C. Guillemin - BP 6009, 45060 Orléans Cedex 2, France

Received 20 September 2008; accepted 5 November 2008

Abstract:

Biohydrometallurgy is the offspring of the unexpected union of biotechnology and metallurgy. From specific properties of some extreme biotopes, active principles of interactions between microbial metabolisms and minerals have been extracted to be used as efficient metallurgical processes. Many profitable industrial operations based on these bioprocesses have been running to recover copper, gold, uranium or cobalt for instance and many other applications have been designed. Europe was quite active in this area in the past, but currently the leadership is in South Africa, America and Australia. BioMinE (Biotechnology of Metal-bearing material In Europe) is a large integrated project launched with the support of the European Commision. It is aimed at stimulating synergies between the most relevant universities, research and industrial organizations to develop new concepts in this technical field that allow a better exploitation of the mineral resources in the future. The European non-ferrous metals mining industry has initiated and developed the BioMinE project as they identified the need to find new processes for metal extraction from resources of today and of tomorrow.

Key words:

biohydrometallurgy; BioMinE project; biotechnology;

1 Introduction

Currently, the extracting and metallurgical industries can cope with the huge demands of the emerging countries but the prices of metals have soared at unexpected sky-high values. Many metal market analysts predict that a new area has begun and that the prices will remain high for an extended period. They will most probably not go down to levels before the hype.

Large orebodies of natural metal resources that can be processed easily with conventional techniques are becoming scarce. In addition, recently discovered deposits have a more complex mineralogy than before.

In the present context, some mining regions of the world are becoming wealthier as their resources are still relatively abundant and have the right characteristics to serve as feed for current metallurgical technologies. Chile is an example in case of copper. Others regions, like Europe, are (nowadays) poor in primary resources and have a growing economic dependence on substances that are absolutely necessary to their industry. From the point of view of the European extractive metallurgy, Europe has two converging ways to loosen the grip. One is to discover new resources on its own territory and the other is to develop its own technologies for its own resources. By the means of exploring all the options for a sustainable development and investing in research in innovative technologies able to deal with difficult-to- treat resources, Europe is getting ahead for the production of metals in the future.

Conventional technologies to extract base metals are mainly based on pyrometallurgy. This is, compared with hydrometallurgy, rather restricted with regard to ranges of metals grades and impurities it can process.

Hydrometallurgy has provided many alternatives that are more or less universally applicable at various costs and profits. The aim to keep elements in their aqueous phase reduces the risks of uncontrolled emissions. Many technologies have been developed to selectively recover impurities and valuable metals. However, the efficiency of these technologies has a cost in energy and in complexity.

Biohydrometallurgy results in lower energy expenses and simplifies the treatment of complex materials due to the catalytic effect exerted by the micro-

biological processes on the oxidizing reactions of the metal-bearing sulfides.

This initial picture of the base metal metallurgy sector guided the designers of the BioMinE project in the organisation of the project focused on the evaluation of processes to be applied in Europe to European resources.

BioMinE is an integrated project under the sixth framework programme of research supported by the European Commission, which started in November 2004 and will last until October 2008. At the end of 2007, the Consortium of BioMinE comprised 37 partners from industry (13 including 6 SMEs), research organisations (8), universities (15), and government (1). The participants are from 13 EU member states and from Serbia and South Africa (INCO Countries). For more details see http://biomine.brgm.fr. The names of the organizations partners of BioMinE, which are quoted in the text, are listed in Table 1.

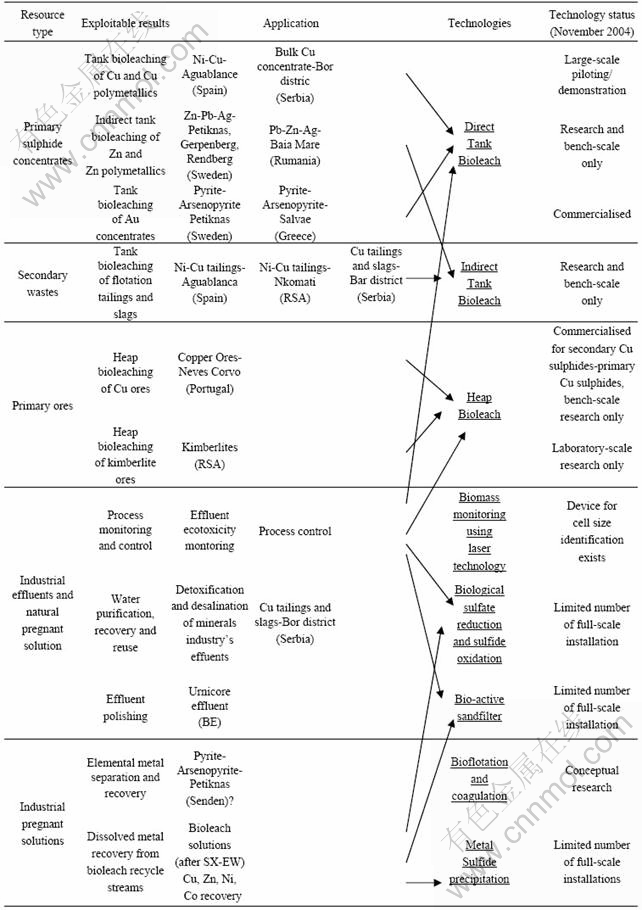

Table 1 Simplified diagram showing general work programme of project

After having described in a previous paper the context and the objectives of the project at its beginning [1], this one gives an overview of the progress of BioMinE after three years.

2 General scope of project

BioMinE is aimed at “the production of tomorrow” and encompasses biotechnological research to provide “radical changes in the Basic Materials industry for cleaner, safer and more eco-efficient production”.

The challenges of the BioMinE Integrated Project are to go beyond the limits of our fundamental understanding of bio-hydrometallurgy and to develop, improve, and/or better integrate biotechnological processes for recovery of metals from primary and secondary metal bearing materials. Technological breakthroughs will allow the integration of innovative biotechnology-based processes for recovery and/or removal of metals from primary materials such as ores and concentrates, secondary materials such as mining wastes, metallurgical slags, and combustion/power plant ashes. Processes will be developed, which give consideration for eco-design and a reduced impact on environment.

The biotechnologies to be investigated include bioleaching, biooxidation, biosorption, bioreduction, bioaccumulation, bioprecipitation, bioflotation, bioflocculation, and biosensors, as well as microbiological research. The ultimate objective was to determine the specifications of environmentally friendly biotechnologies that are economically attractive particularly at a small scale. They will provide an alternative to current technologies such as roasting and smelting.

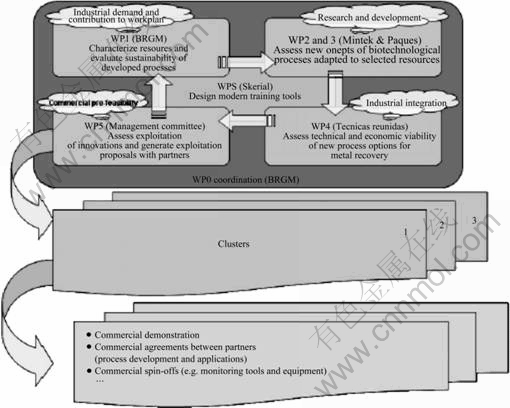

The anticipated breakthroughs under the RTD programme are currently commercially evaluated by integrated piloting of the new, or improved, processes together with preliminary economic assessments of European resources. This will provide a sound basis for decisions by industrial companies on whether to then proceed commercial demonstration. The competition of biohydrometallurgical treatments with conventional processes can only be successful if this would eventually lead to substantial improvements for metal production by increased recovery, reduced costs, reduced energy demands, increased revenue, access to new resources, better compliance with the environmental regulations and/or better acceptance from the public of the mining activities in Europe. The work is enhanced by Training and Educational activities. BioMinE has adopted a multi-discipline approach involving universities and research organisations, mining companies, waste treatment facilitators and equipment and instrument suppliers as shown in Fig.1.

Fig.1 A multidisciplinary partnership

3 Organization and work programme

Seven workpackages cover the technical rationale and the management of the project as illustrated Fig.2.

Fig.2 General structure of the organisation of BioMinE

3.1 Workpackage 1: Resources and sustainability assessment of new processes

It is firstly dedicated to the identification of the resources. This task has considered the mineralogical, economic, and infrastructure characterisation. Based on the needs of our economy and the obligation to minimise negative environmental and social impacts, an initial series of European metal bearing resources was listed. The listing was of course carried out in close interaction with the mining companies. The impact of the technologies has been monitored and directed by a continuous process of simultaneous decision support to the project partners at all stages of the project. This has integrated the assessment of the process-chain and the life cycle environmental information, costs, and work environment (i.e. accidents, labour, and health) within one consistent model.

3.2 Workpackage 2: Bioleaching

It is focused on bioleaching and the technical assessment of new ways of processing applied to new resources including bioleaching of ores, concentrates and wastes and the study of the fundamental mechanisms of bioleaching. This part of the project is supported by the largest technical and financial effort. The primary objectives and focus of the RTD activities in this work- package have been to provide solutions to the technical constraints that are currently limiting the broader commercial applications of bioleaching technologies. Thus, the RTD activities has addressed improvements in the performance and cost effectiveness of bioleaching processes, the wider application of the technologies to low-grade, complex and waste metal resources and process innovations that will minimise environmental impact and enhance sustainability. This has been achieved through the combined and integrated application of advanced biotechnological and engineering sciences. Bioleaching microorganisms that may exhibit improved bioleaching capabilities have been prospected in extreme environments characterised by high metal ion concentrations, salinity and temperature, and improved. Molecular biology techniques have been developed to identify and monitor the microorganisms of interest. Other aspects of molecular biology have been used to improve understanding of how bioleaching microorganisms survive and interact under the extreme conditions encountered in bioleaching processes, and to assess how this knowledge can be applied to achieve better process control and operation. Important metal-containing resources have been subjected to bench-scale bioleaching testing using conditions that simulate near industrial-scale process conditions for further optimisation and to obtain the engineering data required for process scale-up.

3.3 Workpackage 3: Metal recovery and other bio- treatments

It is s mainly about the technical investigation of the biological applications to recover metals from liquor and effluents and other original biological applications like bioflocculation and bioflotation.

In WP3 of the BioMinE project, we have been looking into the application of biotechnology to recover as much as possible of the valuable metals. Technology has been developed or improved to remove remaining metals and, when required, sulphate from the bleeds from the processes. The final goal is to obtain as much as possible socio-economic benefits.

In summary, the drivers of WP3 are as follows:

1) Eco-efficient and economic production;

2) Highly efficient and selective metal recovery;

3) Economic benefits;

4) Reduction of wastes;

5) Reduction of toxicity of unavoidable wastes;

6) Reduction of potential future liabilities; and

7) Fulfillment of high effluent standards, both chemically and (eco)toxicologically.

To fulfil these drivers the following main topics will be investigated:

1) Metal recovery and sulphate removal;

2) Biological separation processes; and

3) Monitoring and quality assessment.

3.4 Workpackage 4: Process integration

WP4 aims at the integration of the new bioprocesses applied to new resources in consistent chains of treatments from the resources to the final products from the technical, economic, and environmental points of view. This includes pilotscale operations on selected subjects favourably evaluated at smaller scale.

The key to success in biotechnology is the process of translating the basic laboratory achievements into a cost-effective, reliable and robust plant-scale operation. Thus it is crucial to consider the engineering aspects of any biometallurgical project at an early stage and identifying where the cost bottlenecks are likely to be.

Engineering should be undertaken from initial stages and alongside the biological developments.

WP4 objectives include:

1) Integration of innovative biotechnological processes for valuable metals recovery from primary and secondary sources, e.g. ores and concentrates, mining wastes, secondary materials such as slags, scraps, dusts and ashes, mining and industrial effluents;

2) Development of biometallurgical processes at three levels: laboratory, bench scale, and pilot plant;

3) Definition, design and evaluation of developed biometallurgical technologies aiming to get a reliable “product” for potential industrial applications; and

4) To establish procedures for biometallurgical processes assessment, and setting criteria for bioreactors and bioprocesses design and scale-up.

3.5 Workpackage 5: Exploitation

It is the frame to design the plan for the use and dissemination of the new information and knowledge arising from the project. A technology implementation plan should be the main deliverable of this workpackage. Although the dominant activity in BioMinE is research driven, a major objective is to promote opportunities for the exploitation of the research results in terms of industrial applications. This will be particularly done through the provision of market analyses and support. Also, the guidance to the Consortium partners in terms of development of plans for use and dissemination of the knowledge arising from the project will be supported. To maximise the number of commercial opportunities that will result from RTD products, the prospective market needs will be analysed. The market analysis will give an overview of the European market, and indicate its size and identify potential opportunities for the results.

A parallel structure of the partnership in clusters aims at focusing the efforts of the Consortium on the technical results that have the highest potential of exploitation after the project.

3.6 Workpackage 6: Training

It is dedicated to training with the introduction of the concept of case-based learning objects and education via Internet.

“Training” has worked at the production of new web-based learning materials and tools, aimed at flexible use both in distance education, residential education and continuing training at the workplace. This has been achieved by making “Learning objects”, which is a kind of digital content modules for learning, that can easily be reused and repurposed for different kinds of training and education.

Biohydrometallurgy is a cross-disciplinary field of knowledge, where mainly microbiology meets mineral engineering, but other disciplines are involved also as process and environmental engineering, geology, metallurgy, etc. The objects produced are mainly at master’s level. A test course using a first version of the objects was run in the project, and the objects have been made available on open-source-basis in global repositories of learning objects. Education solutions will be essential in the exploitation process also – if the project succeeds, there will be a growing demand for education and training in the field for implementing new technology in Europe.

The overall co-ordination and secretariat are ensured in the frame of a specific workpackage; Workpackage 0.

4 Main results after three years of project

From a general point of view, two dominant aspects characterized the third year of the project are

1) The achievement of a large bulk of preliminary assessments of resources and technologies screened and selected during the first two years of the project (in WP1, 2 and 3).

2) The focus on bench scale experiments towards pilot-scale demonstration operations on the selected resources as defined in the Description of Work planning after two years.

The selected categories of resources and technologies to be evaluated are listed in Table 1 (next page). This table is an illustration of the work plan for the technologies to be assessed on selected resources covering activities from WP1 at the beginning of the project to WP4 at its end. Additionally, this set of test work and the objectives of the entire evaluation up to the sustainable assessment (back to WP1) are structured in accordance with the screening of the exploitable results as defined in WP5.

In the background of this major stream of development activities, research work has been continued on specific subjects of interest mainly in the area of bioleaching and for the benefit of a better understanding and control of the processes.

Test work on the application of bioleaching has been carried out in the frame of WP2 for quite a large range of European resources with the various techniques previously selected for their presumed appropriateness. Direct or indirect bioleaching were assessed on Ni-Cu, Cu, Zn, Pb and Zn/Pb concentrates and wastes (tailings and slags). The technical results of the bench-scale studies are satisfactory and generally confirm the validity of undertaking operations at pilot scale and subsequent calculation of costs at a pre-feasibility level for the technologies applied to the benchmark resources selected.

Fundamental issues about bioleaching which have been addressed for their pertinence in the case of European context have significantly progressed towards a better efficiency and sustainability of the applications of the processes. A non-exhaustive selection of these technical studies is as follows:

1) Use of wastes as reagents;

2) Enhancement of bioreactors for regenerating ferric as oxidant;

3) Prevention of passivation of chalcopyrite during bioleaching;

4) Biostabilisation of arsenic in solid bioresidues;

5) Reduction of elemental sulfur in the solid residues of bioleached refractory gold ores to lower the consumption of cyanide required for the recovery of the precious metal;

6) Determination of the operating conditions of bioleaching of slags and tailings;

7) Identification and characterisation of low-temperature micro-organisms;

8) Understanding of the biochemical mechanisms of tolerance to high concentrations of inhibiting elements; and

9) Selection of bacterial cultures able to tolerate high Zn concentrations in solution (up to 75 g/L).

A major driver for WP2 is to reduce the environmental impact of the mineral industry.

However, that cannot be completely prevented. The aim of WP3 is to develop technologies that can tackle environmental issues that remain despite these efforts. The technologies (like treatment or polishing of the final effluents) should fill the gaps or interact with existing treatment technologies to ensure that the overall metal extraction process is environmentally benign. But, WP3 goes further than just a developing treatment technique. The aim is also to integrate treatment and metal recovery. This can be especially attractive for metal of secondary importance in concentrates; metals that are often wasted to the tailings dam.

In the past year of the project, the work in WP3 became more focused and was more targeted towards the problem areas of the related technologies. The work on the sulfate reduction focused on (semi) extremophilic micro-organisms to extend the range under which this technology is applicable and to open new opportunities. The main work was on acidotolerant bacteria, direct conversion of (waste) metal sulfates and on psychrophillic bacteria. Membrane technology for the separation of biologically produced sulfur was developed and tested on bench scale. Membrane technology as a final treatment was also investigated. Work was started to develop more know-how on the special conditions that occur when metals are precipitated with biologically produced sulfide. The work on the bioflotation continued and more information on the attachment of minerals to flotation products was obtained.

Many of the activities in W2 and WP3 have an environmental aim either indirectly in using wastes of other industrial activities (slags, slimes, tailings) or directly in the reduction of the impact of developed processes (polishing of the final effluent in metals, measurement of the environmental characteristics and assessment of the use of the solid residues). This work wants to contribute not only to the justification of a better sustainability of the bioprocesses investigated, but also to their possible integration in the current context of the metal extractive industry.

Within the third year of the project, WP4 has been much dedicated to the determination of the specifications of the operating conditions and of the equipment of the applications that include a processing step with the use of the bioleach technologies to be technoeconomically evaluated.

A focus on indirect bioleaching of zinc/lead bulk and polymetallic concentrates has demonstrated very attractive results and the combination of expertises in WP2 on microbial aspects and in WP4 on the process side have had a synergetic effect on the development studies.

Work on the optimisation of the metal recovery from the pregnant solutions (Zn/Cu/Ni) or from the solid residues (Pb/Ag) according to the resources treated has progressed towards a reliable knowledge of the performances of the technologies used.

The exploitation of the data obtained at bench scale has allowed establishing the design of process flowsheets from the attack of the mineral resources by bioleaching to the recovery of pure metals and water recycling.

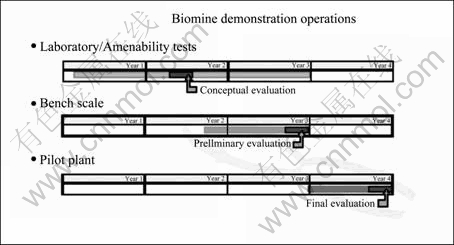

The time schedule of this workpackage aiming at the demonstration operations during the fourth year of the project is quite respectful of the planning as shown in Fig.3.

Fig.3 Time schedule from amenability test work to pilot-scale operations

More details about the scientific and technical outputs of the project are available on the web site of the project (http://biomine.brgm.fr) through the list of the recent publications released by the participants about their work in this project and a paper published in Hydrometallurgy recently[2].

5 Conclusions

No doubt that the market pull becomes more and more visible with the high price levels of the non-ferrous metals whereas the technology push as developed in BioMinE is more and more self-assured. During the third year of the project, WP5 has given more opportunity to the partners to focus their involvement and their efforts on targets that represent a true European challenge as pointed out from the screening of the resources in WP1. The clusters of partners around a limited number of exploitable results targeting real evaluation of processing routes have allowed rationalizing the work and reinforcing the motivation about the success in terms of applicability of the process developed. The cluster meetings constitute techno-economic workshops where the researchers enter the real world.

The work in WP6 has now a closer and more direct contact with the R&D activities, since this work has been more accepted among the partners and is used by them. Many other partners than WP6 partners are now contributing to the work as extra services. This is especially true for the BioMineWiki (http://wiki.biomine. skelleftea.se/wiki), which was launched during the spring of 2007. The Wiki is also on good way to develop into a ‘living’ instrument, a network community tool and a reference tool to be presented as a service for people starting a professional career in biohydrometallurgy. The Wiki is expected to play a vital role in the dissemination and exploitation work also.

Acknowledgement

The work described in this paper was carried out in the frame of BioMinE (European project contract NMP1-CT-500329-1). The authors acknowledge the financial support given to this project by the European Commission under the Sixth Framework Programme for Research and Development. We also wish to thank our various partners on the project for their contributions to the work reported in this paper.

References

[1] MORIN D, LIPS A, PINCHES T, HUISMAN J, FRIAS C, NORBERG A, FORSSBERG E. BioMinE—Integrated project for the development of biotechnology for metal-bearing materials in Europe [J]. Hydrometallurgy, 2006, 83: 69-76.

[2] MORIN D, PINCHES T, HUISMAN J, FRIAS C, NORBERG A, FORSSBERG E. Progress after three years of BioMinE—Research and Technological Development project for a global assessment of biohydrometallurgical processes applied to European non-ferrous metal resources [EB/OL]. Hydrometallurgy, 2008, doi:10.1016/ j.hydromet.2008.05.050

Corresponding author: Dominique H. R. MORIN; Tel: +33.2.38.64.32.00; Fax: +33.2.38.64.36.80; E-mail: biomine@brgm.fr

(Edited by YANG Bing)