文章编号:1004-0609(2016)-03-0544-07

300 ℃氮气中交变载荷条件下Inconel 690合金的微动磨损特性

张晓宇,任平弟,蔡振兵,彭金方,刘建华,朱旻昊

(西南交通大学 机械工程学院,成都 610031)

摘 要:

采用改进后的PLINT高温可控气氛的微动磨损试验机,研究Inconel 690合金在300 ℃氮气及法向交变载荷条件下的微动磨损机制和动力学特性。结果表明: 微动运行行为与激振频率密切相关,微动的Ft-D曲线呈现摩擦力周期波动的平行四边形型特征,微动运行于滑移区。在300 ℃氮气环境中,摩擦力的动态变化可以分为5个阶段,即跑合阶段、上升阶段、峰值阶段、下降阶段和稳定阶段。Inconel 690合金的微动损伤行为强烈地依赖于载荷、位移幅值、环境温度、气氛及激振频率等试验条件。从表面损伤形貌看,损伤微结构与试验参数密切相关;由于交变法向力和切向力共同作用,微动产生叠加效应,使剥层现象更加突出。在300 ℃氮气环境下,Inconel 690合金的损伤机理主要表现为磨粒磨损和剥层。

关键词:

Inconel 690合金;交变载荷;微动;高温;叠加效应;剥层;

中图分类号:TH117.1 文献标志码:A

在核电系统中,蒸汽发生器是关键设备之一,由于蒸汽发生器一回路和二回路热传导及高温高压介质流致振动,使传热管与支撑部件之间产生微动磨损[1-2],导致传热管局部损伤甚至破裂,使用寿命降低,危及核电安全。因此,防止蒸汽发生器传热管的破损,提高核电设备安全性和使用寿命,是核电工程的重大课题[3-4]。目前,对Inconel 690合金的研究主要集中在大气环境下恒定载荷微动磨损方面[4-14],而交变载荷条件下微动磨损的研究很少。开展高温氮气中法向交变载荷下微动磨损的试验研究,不仅对探索特殊工况下的复杂微动损伤机理具有实际指导意义,而且也能为核电设备抗微动损伤设计、运行安全性和使用寿命具有重要应用价值。

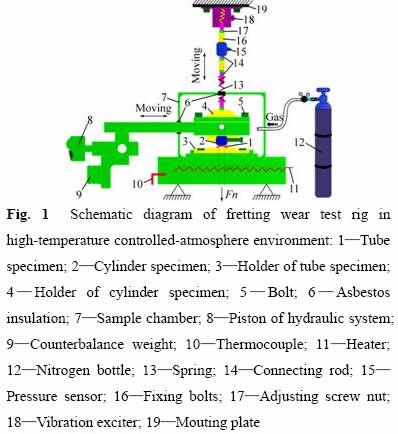

1 实验

在PLINT试验机法向上外加电磁激振器进行微动试验,试验机结构示意图如图1所示[7]。试验材料为直径19.05 mm、厚度1.09 mm的Inconel 690合金管,表面粗糙度 Ra=0.02 μm。对偶件为1Cr13不锈钢实心圆柱体(d=10 mm,Ra=0.02 μm)。微动磨损试验参数如下:法向恒定载荷(Fn)分别为20、50和100 N,位移幅值(D)分别为100、150和200 μm,试验温度为300 ℃,循环次数3×104次,切向频率为2 Hz,法向激振力Fn1=16 sin(ωt),法向激频率(fn)为10和50 Hz。在改进后PLINT高温氮气微动磨损试验机上,采用圆柱/圆柱水平“十”字交叉接触方式进行微动磨损试验。本试验中使用工业氮气纯度为98%,由气瓶(气压均为12 MPa,流速0.1 m3/min)向密封试验室输送氮气40 min,使试验室空气排出后开始试验,实验过程中用L型塑咀采样袋收集大量混合气体,通过Se-6000型气相色谱仪检测混合气体(氧含量占5%,氮含量占95%)。试验前用丙酮清洗试样表面。试验结束后用扫描电镜(SEM,FEI-S50型)、台阶仪(AMBIOS XP-2型)和X射线电子能谱仪(XPS,PHI-5702型)等对磨斑表面进行观测分析,利用Hysitron原位纳米力学测试系统(Ti-900 Triboludenter型)对磨痕剖面上微区的力学性能进行测试。

2 结果与分析

2.1 微动运行规律

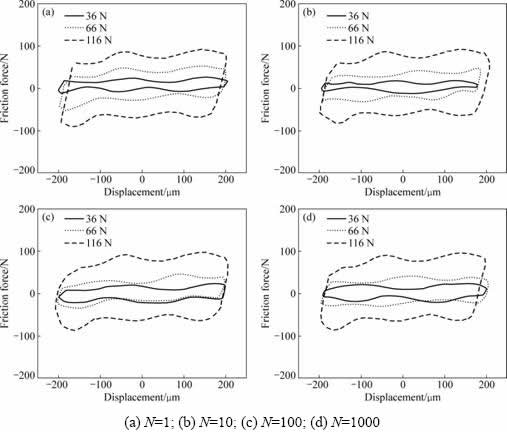

图2和图3所示分别为300 ℃氮气环境下最大载荷Fmax分别为36、66和116 N,位移幅值D为200 μm,激振频率fn分别为10和50 Hz时,Inconel 690合金在不同循环次数下微动的Ft-D曲线。微动运行行为与激振频率密切相关,Inconel 690合金从初始循环直至试验结束,微动的Ft-D曲线表现出在法向交变载荷作用下微动模式的叠加特征,摩擦力呈周期变化的平行四边形特征。根据微动图理论,微动运行状态均处于完全滑移状态。

图1 高温可控气氛环境中微动磨损试验机示意图

Fig. 1 Schematic diagram of fretting wear test rig in high-temperature controlled-atmosphere environment

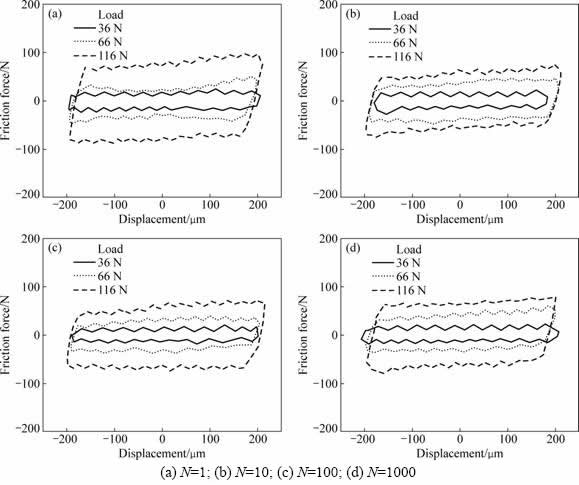

2.2 摩擦力

当最大载荷Fmax=66 N、位移幅值D=200 μm、径向频率分别为f=10 Hz和50 Hz时,摩擦力随循环次数演变曲线如图4所示。在高温氮气环境下,摩擦力的动态变化分为5个阶段,即跑合阶段、上升阶段、峰值阶段、下降阶段和稳定阶段。稳态摩擦力随激振频率增加而增加。

2.3 磨痕深度分析

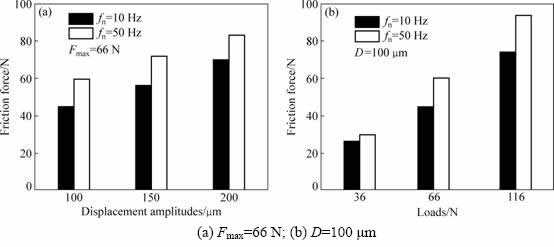

图5所示为300 ℃氮气环境中Inconel 690合金磨痕的截面轮廓最大深度分别与位移幅值或载荷的关系。由图5(a)可见,300 ℃氮气环境中,当激振频率为10 Hz或50 Hz、最大载荷为66 N时,随位移幅值增加,磨痕的最大深度增加,由于位移增加,磨屑容易被溢出、转移,材料表面磨损严重。当载荷和位移幅值不变,磨痕的最大深度和损伤程度随激振频率增加而增加。由图5(b)所示,当激振频率为10 Hz或50 Hz,位移幅值为100 μm时,磨痕的最大深度和损伤程度随载荷增加而增加。当载荷和位移幅值一定时,磨痕的最大深度随激振频率增加而增加,这是因为激振频率加快,交变法向力作用明显加强,材料表面磨损加剧。因此,在300 ℃氮气环境中,由于在高含量氮气作用下,氧化效应明显减弱,氧化反应速率显著降低,氧化物磨屑的生成受到抑制,磨屑极少,绝大部分裸露在磨痕表面,材料界面微凸体直接接触机会增加,磨损严重。

图2 300 ℃氮气环境中不同荷载下Ft-D曲线随循环次数的变化(fn=10 Hz,D=200 μm)

Fig. 2 Variation of Ft-D curves as function of number of cycle with different normal loads at 300 ℃ in nitrogen environment (fn=10 Hz, D=200 μm)

图3 300 ℃氮气环境中不同荷载下Ft-D曲线随循环次数的变化(fn=50 Hz,D=200 μm)

Fig. 3 Variation of Ft-D curves as function of number of cycle with different normal loads at 300 ℃ in nitrogen environment (fn=50 Hz, D=200 μm)

图4 300 ℃氮气环境中摩擦力与循环次数的关系(Fmax=66 N,D=200 μm)

Fig. 4 Relationship between friction force and cycle numbers at 300 ℃ in nitrogen environment (Fmax=66 N, D=200 μm)

2.4 磨痕形貌分析

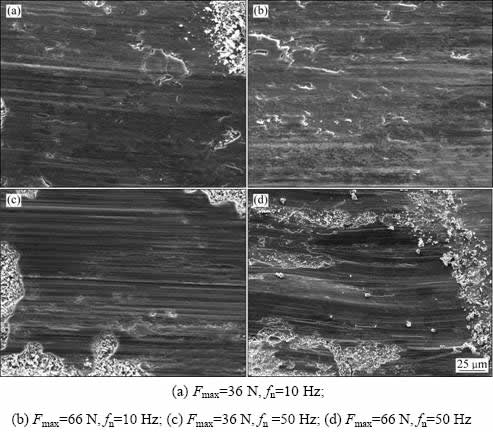

图6所示为300 ℃氮气环境下Inconel 690合金磨痕的SEM像。当最大载荷为36 N、激振频率为10 Hz时,由图6(a)可以看出,磨痕的整个表面较平整,在磨痕中心,可以观察到厚厚的磨屑层覆盖于接触区,同时可以观察到平行于摩擦方向的较浅犁沟痕迹;随最大载荷增加到66 N时,磨痕整个接触区域表面平整,磨痕中心区域几乎没有细小磨屑,仅观察到少量剥落坑和大量较深的犁沟痕迹(见图6(b)),这是因为载荷增加,相应切向力分量增加,切向力起到主导作用,同时在300 ℃氮气环境下,由于高含量氮作用,降低了氧含量,氧化磨损轻微,形成的氧化磨屑较少且薄,导致材料表面两体直接接触,磨痕表面损伤严重。

图5 300 ℃氮气环境下Inconel 690合金磨痕的最大深度与位移幅值或载荷的关系

Fig. 5 Relationship between depth maximum depth of wear traces of Inconel 690 alloy and displacement amplitudes or normal loads at 300 ℃ in nitrogen environment

图6 300 ℃氮气中Inconel 690合金磨痕的SEM像(D=100 μm)

Fig. 6 SEM images of worn scars of Inconel 690 alloy at 300 ℃ in nitrogen environment (D=100 μm)

当最大载荷为36 N、位移幅值为100 μm、激振频率为50 Hz时,可以观察到较深平行于摩擦方向的犁沟痕迹、剥落坑以及少量的细小磨屑散布在剥落坑区域(见如图6(c));随最大载荷增加,磨痕中心区域可以观察到较大尺寸的剥落坑、犁沟痕迹以及塑性流动特征,材料表面损伤严重(见图6(d));当载荷一定时,随激振频率增加,剥落坑的数量、尺寸以及塑性流变现象特别明显(见图6(b)和(d)),这可能是因为载荷和激振频率较大,在法向交变载荷作用下产生叠加效应特性显著增强。因此,300 ℃氮气环境下Inconel 690合金的磨损机制是以磨粒磨损与剥层为主[15]。

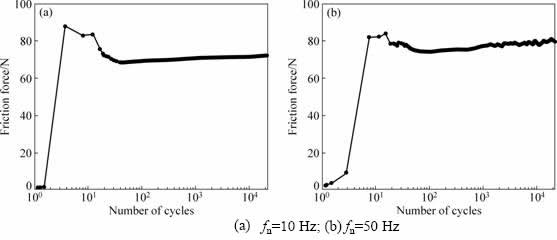

2.5 剖面损伤形貌分析

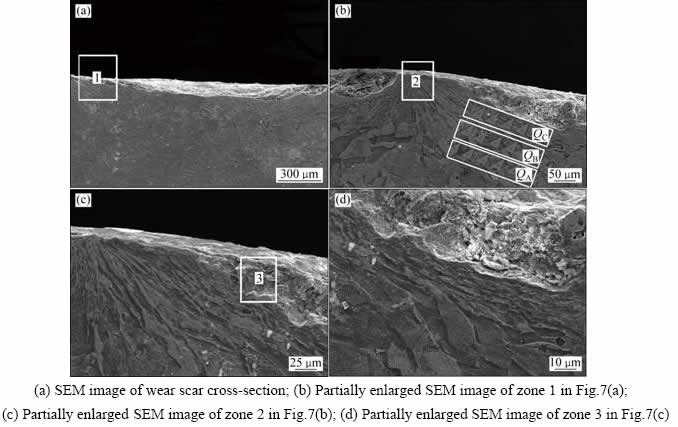

图7所示为Inconel 690合金在300 ℃氮气环境中磨痕横截面的SEM像。在磨损区由上到下分别为呈疏松态细小磨屑的磨屑层、在交变载荷作用下晶粒结构发生显著变化(产生塑性变形)形成塑变层以及基体层[16-17]。

图7 Inconel 690合金在300 ℃氮气环境下磨痕剖面的SEM像(Fmax=116 N,fn=50 Hz,D=200 μm)

Fig. 7 SEM images of wear scar cross-section of Inconel 690 alloy at 300 ℃ in nitrogen environment (Fmax=116 N, fn=50 Hz, D=200 μm)

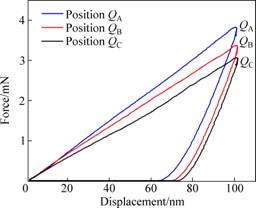

图8 纳米压痕试验典型的力-位移曲线

Fig. 8 Typical force-displacement curve on nano-indentation test

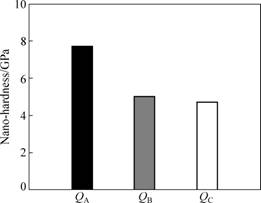

图9 纳米压痕硬度测试

Fig. 9 Nano-indentation hardness tests

图8所示为磨痕横截面上距上表面不同深度区域进行纳米压痕测试获得的力-位移曲线(测试区域见图7(b)中QA、QB以及QC区域)。当测试深度相同时(100 nm),QA区域需要施加的载荷最大,QB区域相对较小,而QC区域最小。图9所示为图8中不同力-位移曲线计算获得的纳米压痕硬度值。QA区域附近的纳米压痕硬度明显比QB区域和QC区域(基体层)高。因此,通过对磨痕横截面(QA区域)的晶粒结构形貌观察以及该区域的较高纳米压痕硬度值[18],发现材料在交变载荷条件下的摩擦过程中,由于加工硬化作用更容易形成塑性变形层。

3 结论

1) 微动的Ft-D曲线表现出在法向交变载荷作用下微动模式的叠加特征,摩擦力呈周期变化的平行四边形特征,微动运行于完全滑移状态。

2) 在300 ℃氮气环境中,摩擦力的动态变化可以分为5个阶段,即跑合阶段、上升阶段、峰值阶段、下降阶段和稳定阶段。

3) 在300 ℃氮气环境中,Inconel 690合金微动行为运行于滑移区时,试验参数对微动损伤行为产生重要影响。在磨痕表面呈现较大尺寸的剥落坑、犁沟痕迹以及塑性变形特征,材料表面损伤严重,这是因为在法向交变载荷作用下叠加效应特性显著增强。Inconel 690合金的磨损机制主要表现为磨粒磨损与剥层。

REFERENCES

[1] 周仲荣, 朱旻昊. 复合微动磨损[M]. 上海: 上海交通大学出版社, 2004.

ZHOU Zhong-rong, ZHU Min-hao. Composite fretting[M]. Shanghai: Shanghai Jiao Tong University Press, 2004.

[2] ZHU M H, Zhou Z R. Composite fretting wear of aluminum alloy[J]. Key Engineering Materials, 2007, 353/358(6): 868-873.

[3] LOW M B J. Fretting problems and some solutions in power plant machinery[J]. Wear, 1985, 106(3): 315-336.

[4] 唐 辉. 世界核电设备与结构将长期面临的一个问题—微动磨损[J]. 核动力工程, 2000, 21(3): 222-231.

TANG Hui. Fretting damage, one of world wide difficulties in the field of nuclear power equipment and structures for a long term[J]. Nuclear Power Engineering, 2000, 21(3): 222-231.

[5] 叶 毅, 任平弟, 张晓宇, 郭 洪, 李长香. 高温大气和N2中Inconel690/1Cr13不锈钢的微动磨损特性[J]. 中国有色金属学报, 2013, 7(23): 1900-1906.

YE Yi, REN Ping-di, ZHANG Xiao-yu, GUO Hong, LI Chang-xiang. Fretting wear behavior of Inconel690/1Cr13 stainless steel in high-temperature air and nitrogen[J]. The Chinese Journal of Nonferrous Metals Society, 2013, 7(23): 1900-1906.

[6] 张晓宇, 任平弟, 张亚非, 朱旻昊, 周仲荣. Incoloy800合金的高温微动磨损特性研究[J]. 中国有色金属学报, 2010, 20(8): 1545-1551.

ZHANG Xiao-yu, REN Ping-di, ZHANG Ya-fei, ZHU Min-hao, ZHOU Zhong-rong. Fretting wear behavior of Incoloy800 alloy at high temperature[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(8): 1545-1551.

[7] 向红先, 任平弟, 张晓宇, 刘建涛, 李 放. 交变载荷条件下NC30Fe合金微动损伤特性研究[J]. 摩擦学学报, 2014, 34(4): 437-445.

XIANG Hong-xian, REN Ping-di, ZHANG Xiao-yu, LIU Jian-tao, LI Fang. Fretting damage behavior of NC30Fe nickel-based alloy under alternating load conditions[J]. Tribology, 2014, 34(4): 437-445.

[8] HONG J K, KIM I S. Environment effects on the reciprocating wear of Inconel690 steam generator tubes[J]. Wear, 2003, 255(9): 1174-1182.

[9] CHUNGA I, LEE M. An experimental study on fretting wear behavior of cross-contacting Inconel 690 tubes[J]. Nuclear Engineering and Design, 2011, 241(5): 4103-4110.

[10] SUNG H J, CHUN W C, LEE Y Z. Fretting and wear of Inconel 690 for steam generator tube in elevated temperature water under fretting condition[J]. Tribology Internation, 2005, 38(4): 283-288.

[11] YUN J Y, PARK M C, SHIN, G S, HEO J H, KIM D I, KIM S J. Effects of amplitude and frequency on the wear mode change of Inconel 690 SG tube mated with SUS 409[J]. Wear, 2014, 313: 83-88.

[12] LI J, LU Y H. Effects of displacement amplitude on fretting wear behaviors and mechanism of Inconel 600 alloy[J]. Wear, 2013, 304(1/2): 223-230.

[13] MI X, WANG W X, XIONG X M, QIAN H, TANG LC, XIE Y C, PENG J F , CAI Z B, ZHU M H. Investigation of fretting wear behavior of Inconel 690 alloy in tube/plate contact configuration[J]. Wear, 2015, 328/329: 582-590.

[14] ZHANG Xiao-yu, REN Ping-di, ZHONG Fa-chun, ZHU Min-hao, ZHOU Zhong-rong. Fretting wear and friction oxidation behavior of 0Cr20Ni32AlTi alloy at high temperature[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 825-830.

[15] JAE Y Y, GYEONG S S, DAE I K, HO S L, WOONG S K, SEON J K. Effect of carbide size and spacing on the fretting wear behavior of Inconel 690 SG tube mated with SUS 409[J]. Wear, 2015, 338/339: 252-257

[16] 辛 龙, 李 杰, 陆永浩. Inconel 690合金高温微动磨损特性研究[J]. 摩擦学学报, 2015, 35(4): 470-476.

XIN Long, LI Jie, LU Yong-hao. Fretting wear properties of inconel 690 alloy at elevated temperature[J]. Tribology, 2015, 35(4): 470-476.

[17] 王文秀, 蔡振兵, 钱 浩, 李 晨, 谢永诚, 米 雪, 彭金方, 朱旻昊. 不同温度下 690合金传热管与抗振条的微动磨损特性[J]. 中国有色金属学报, 2014, 24(11): 2777-2783.

WANG Wen-xiu, CAI Zhen-bing, QIAN Hao, LI Chen, XIE Yong-chen, MI Xue, PENG Jin-fang, ZHU Min-hao. Fretting wear behavior of alloy 690 heat transfer tubes against anti-vibration strip at different temperatures[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2777-2783.

[18] QIAN L M, LI M, ZHOU Z R, YANG H, SHI X Y. Comparison of nanoindentation hardness to microhardness[J]. Surface Coating Technology, 2005, 195(4): 264-271.

Fretting wear behavior of Inconel 690 alloy under alternating load conditions at 300 ℃ in nitrogen environment

ZHANG Xiao-yu, REN Ping-di, CAI Zhen-bing, PENG Jin-fang, LIU Jian-hua, ZHU Min-hao

(School of Mechanical Engineering, Southwest Jiaotong University, Chengdu 610031, China)

Abstract: The fretting wear mechanisms and kinetic behaviours of Inconel690 alloy were investigated on the improved PLINT fretting rig under alternating loads conditions in high-temperature controlled-atmosphere environments. The results show that the fretting running behaviors are closely related to the normal excitation frequency. In parallelogram shaped Ft-D curves, the friction fluctuates periodically, and accordingly the fretting runs in the slip regime (SR). Five stages of friction force curves can be observed at 300 ℃ in nitrogen environment, including initial stage, ascending stage, peak value stage descending stage and steady stage. The fretting wear behaviors for Inconel 690 alloy strongly depend on the normal load, displacement amplitude, temperature, atmosphere, excitation frequency and other test conditions. The super position effect of fretting wear behavior due to the combined effect of alternating normal force and tangential force is produced, so that delamination phenomenon becomes much more prominent. The abrasive wear and delamination are the major mechanisms of Inconel 690 at 300 ℃ in nitrogen environment.

Key words: alternating load; fretting wear; high temperature; superposition effect; delamination

Foundation item: Projects (51075324, 51305364) supported by the National Natural Science Foundation of China; Project (2682014CX03) supported by the 2014 Scientific and Technological Innovation Funds of the Central Universities

Received date: 2015-05-29; Accepted date: 2015-10-28

Corresponding author: REN Ping-di; Tel: +86-28-87603924; E-mail: rpd@swjtu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51075324,51305364);中央高校基本科研业务费专项资金科技创新项目(2682014CX037)

收稿日期:2015-05-29;修订日期:2015-10-28

通信作者:任平弟,教授,博士;电话:028-87603924;E-mail:rpd@swjtu.edu.cn

摘 要:采用改进后的PLINT高温可控气氛的微动磨损试验机,研究Inconel 690合金在300 ℃氮气及法向交变载荷条件下的微动磨损机制和动力学特性。结果表明: 微动运行行为与激振频率密切相关,微动的Ft-D曲线呈现摩擦力周期波动的平行四边形型特征,微动运行于滑移区。在300 ℃氮气环境中,摩擦力的动态变化可以分为5个阶段,即跑合阶段、上升阶段、峰值阶段、下降阶段和稳定阶段。Inconel 690合金的微动损伤行为强烈地依赖于载荷、位移幅值、环境温度、气氛及激振频率等试验条件。从表面损伤形貌看,损伤微结构与试验参数密切相关;由于交变法向力和切向力共同作用,微动产生叠加效应,使剥层现象更加突出。在300 ℃氮气环境下,Inconel 690合金的损伤机理主要表现为磨粒磨损和剥层。

[1] 周仲荣, 朱旻昊. 复合微动磨损[M]. 上海: 上海交通大学出版社, 2004.

[4] 唐 辉. 世界核电设备与结构将长期面临的一个问题—微动磨损[J]. 核动力工程, 2000, 21(3): 222-231.

[6] 张晓宇, 任平弟, 张亚非, 朱旻昊, 周仲荣. Incoloy800合金的高温微动磨损特性研究[J]. 中国有色金属学报, 2010, 20(8): 1545-1551.

[7] 向红先, 任平弟, 张晓宇, 刘建涛, 李 放. 交变载荷条件下NC30Fe合金微动损伤特性研究[J]. 摩擦学学报, 2014, 34(4): 437-445.

[16] 辛 龙, 李 杰, 陆永浩. Inconel 690合金高温微动磨损特性研究[J]. 摩擦学学报, 2015, 35(4): 470-476.