文章编号:1004-0609(2014)06-1422-06

电磁搅拌对等通道挤压前后Mg-Zn-Zr-Ca合金组织和性能的影响

于彦东,章 龙,李彩霞

(哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040)

摘 要:

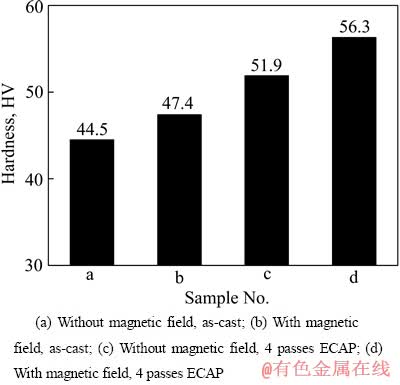

在合金熔炼过程中通过控制磁场的施加,分别制备无电磁搅拌和施加电磁搅拌的Mg-2.0Zn-0.7Zr-0.5Ca镁合金铸锭。采用等通道挤压(ECAP)工艺分别对这两种状态的合金进行挤压加工,研究电磁搅拌对ECAP前后合金组织和性能的影响。结果表明:与无磁场状态相比,施加电磁搅拌后,合金的显微组织和力学性能均得到很大改善。因电磁搅拌能细化铸态合金的原始晶粒,经1道次和2道次ECAP后合金的晶粒细化程度明显优于无磁场状态的铸态合金的。4道次ECAP后施加电磁搅拌合金的晶粒非常细小、均匀,且性能最佳,其硬度、屈服强度和伸长率分别达到56.3 HV、276 MPa和18.3%。

关键词:

Mg-Zn-Zr-Ca合金;电磁搅拌;等通道挤压;显微组织;力学性能;

中图分类号:TG146.2 文献标志码:A

Effects of electromagnetic stirring on microstructure and properties of Mg-Zn-Ca-Zr alloy before and after

equal channel angular pressing

YU Yan-dong, ZHANG Long, LI Cai-xia

(School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China)

Abstract: Mg-2.0Zn-0.7Zr-0.5Ca alloy ingots with and without electromagnetic stirring were fabricated separately by controlling the application of the magnetic field in the casting process, and then were processed by the equal channel angular pressing (ECAP) technology. The effects of electromagnetic stirring on the microstructure and properties of the alloys before and after ECAP were studied. The results show that the microstructure and mechanical properties of the alloy with electromagnetic stirring are improved greatly compared with those of the alloy without electromagnetic stirring. Because electromagnetic stirring can refine the initial grain of the as-cast alloy, the grain refinement is obviously better than that of the as-cast alloy without electromagnetic stirring after 1 pass and 2 passes of ECAP. After 4 passes of ECAP, the grain size of the alloy with electromagnetic stirring becomes very small and uniform. At this time, the alloy has the best mechanical properties, and the microhardness, yield strength and elongation of the alloy reach 56.3HV, 276 MPa and 18.3%, respectively.

Key words: Mg-Zn-Zr-Ca alloy; electromagnetic stirring; equal channel angular pressing; microstructure; mechanical property

镁合金具有密度低、比强度和比刚度高等优点,在航空航天、汽车等领域备受关注。但是,由于镁合金的强度较低和塑性成形性能较差,因此,在一定程度上限制了镁合金在工业上的广泛应用[1-2]。

近年来,材料电磁加工(EPM)已成为金属材料重要的研究方向[3]。在金属凝固过程中施加电磁搅拌可以细化晶粒、改善铸件质量、提高铸件的性能[4-5]。YU等[6-7]研究了低频交变磁场对ZK60凝固组织、固溶组织和力学性能的影响。结果表明:在磁场下凝固的组织其晶粒和晶界上的共晶网状结构变得细小且分布均匀;经固溶处理后,析出相溶解,晶粒边界变得明显且晶粒分布更加均匀;经电磁搅拌的ZK60铸态合金的力学性能得到显著改善。采用等通道挤压(ECAP)技术能使一些金属材料产生剧烈的塑性变形来获得细晶组织,从而提高材料的综合力学性能[8-13]。因此,本文作者对无磁场和施加磁场处理的Mg-2.0Zn-0.7Zr-0.5Ca合金进行ECAP处理,研究电磁搅拌对ECAP前后合金组织与性能的影响。

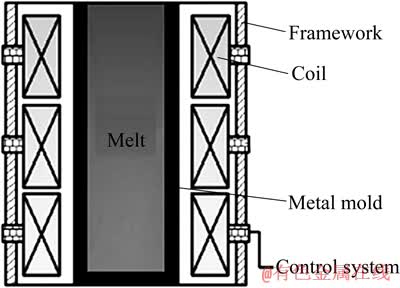

1 实验

实验所用Mg-2.0Zn-0.7Zr-0.5Ca镁合金为自行制备,首先向石墨坩埚中加入纯Mg,放入电阻炉中加热,Mg熔化后依次向坩埚中加入纯Zn、纯Ca和Mg-Zr中间合金,全部熔化后浇铸至预热到350 ℃的d 45 mm×200 mm的金属模中。在浇铸时施加电磁搅拌的合金在金属模外持续施加电压为110 V的磁场进行电磁搅拌直至金属液完全凝固,电磁搅拌示意图如图1所示,熔炼和浇注过程使用高纯Ar进行保护。将所得铸锭切割成d 24.5 mm×90 mm的圆棒,在275 ℃下用Bc路径(相邻道次顺时针旋转90°)对圆棒进行4道次ECAP,ECAP模具的内、外交角Φ和Ψ均为90°。

对合金进行取样,将所取试样的一面进行打磨抛光并用苦味酸腐蚀,采用光学显微镜对腐蚀后的试样进行金相组织观察。采用X射线衍射仪对合金的物相进行分析。采用HX-1000显微硬度计(载荷1 N,加载时间15 s)测定试样的维氏硬度。采用CSS-44300拉伸试验机进行室温拉伸实验,拉伸试样的标距部分尺寸为10 mm×5 mm×1 mm,应变速率为8.3×10-4 s-1。最后利用扫描电镜对拉伸试样的断口形貌进行分析。

图1 电磁搅拌示意图

Fig. 1 Schematic diagram of electromagnetic stirring

2 结果与讨论

2.1 Mg-2.0Zn-0.7Zr-0.5Ca合金铸态组织

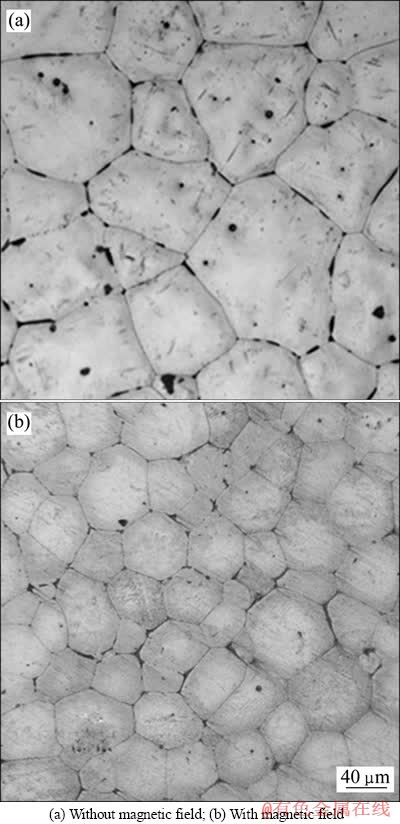

图2所示为铸态Mg-2.0Zn-0.7Zr-0.5Ca合金的显微组织。由图2(a)可以看出,合金的晶界及基体中存在一些析出相,晶粒的形状不规则,大小不均匀,平均晶粒尺寸约为109 μm;由图2(b)可以看出,合金的晶界及晶粒内部析出相很少,晶粒圆整且大小趋于均匀,平均晶粒尺寸约为58 μm。由此可知,磁场搅拌可以很好地改善铸态组织,使铸态组织成分变得均匀,晶粒变得细小。

图2 铸态Mg-2.0Zn-0.7Zr-0.5Ca合金的显微组织

Fig. 2 Microstructures of as-cast Mg-2.0Zn-0.7Zr-0.5Ca alloys

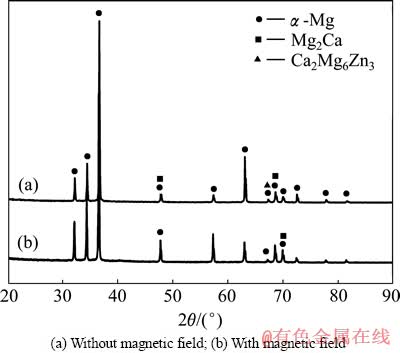

铸态Mg-2.0Zn-0.7Zr-0.5Ca合金的XRD谱如图3所示。由于添加的合金元素较少,合金基体以α-Mg相为主,铸态未施加磁场的合金中还含有少量的Ca2Mg6Zn3相和Mg2Ca相,而施加磁场的铸态合金中Ca2Mg6Zn3相的衍射峰消失,仅存在极少量Mg2Ca相的衍射峰。含钙量高(0.5%~0.7%,质量分数)的合金在凝固过程中容易在晶界上形成Ca2Mg6Zn3相,铸锭在凝固和冷却过程中可能存在时效过程,此时过饱和的钙从基体中以Mg2Ca稳定相形式析出,电磁搅拌能改善成分偏析,导致Ca2Mg6Zn3相量减少,所以其衍射峰消失。

图3 铸态Mg-2.0Zn-0.7Zr-0.5Ca合金的XRD谱

Fig. 3 XRD patterns of as-cast Mg-2.0Zn-0.7Zr-0.5Ca alloys: (a) Without magnetic field; (b) With magnetic field

2.2 经ECAP后Mg-2.0Zn-0.7Zr-0.5Ca合金的组织

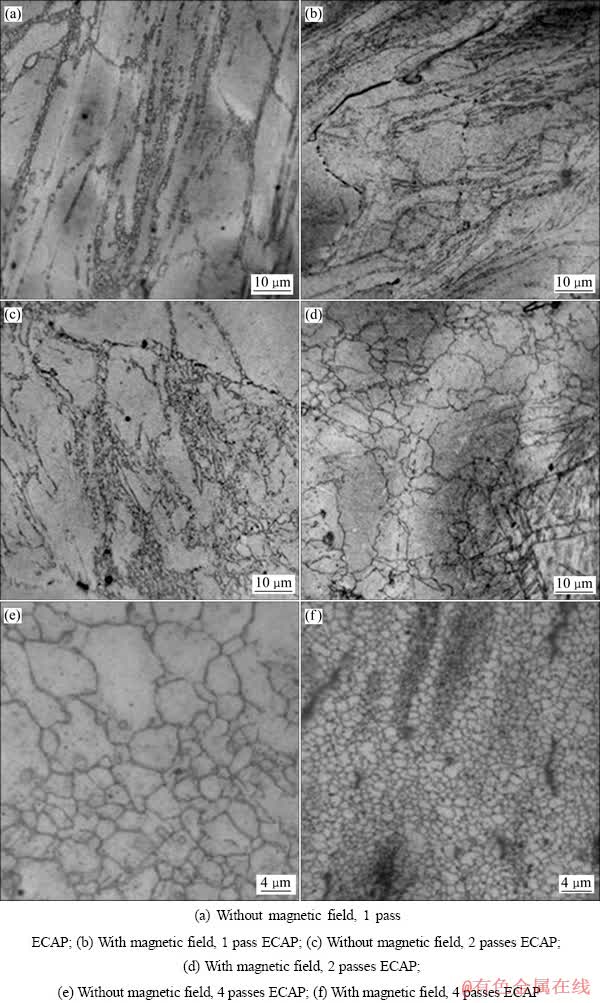

图4所示为经ECAP后合金的显微组织。图4(a)和(b)所示分别为无电磁和有电磁搅拌的热处理态合金经1道次ECAP的显微组织。从图4(a)中可以看出,两种状态合金晶粒在剧烈的剪切变形下发生破碎且沿剪切方向被拉长,合金显微组织中出现许多细小的再结晶晶粒,这些小晶粒包裹着未细化的组织呈项链状分布,施加磁场的合金显微组织中发生再结晶的区域较多,再结晶晶粒比较细小。镁为密排六方结构金属,在275 ℃下进行ECAP变形时滑移系少,位错滑移不能完全协调大变形,只能通过孪生改变晶体的位向,激发滑移,促使大剪切变形顺利进行[14]。孪生变形和滑移会产生大量的位错,当位错密度很高时,位错通过攀移和重新分布,形成位错密度较低的亚晶。这些亚晶向周围位错密度较高的区域生长,相应亚晶界的位错密度逐渐增大,亚晶与周围基体的取向差逐渐变大,最终由小角度晶界演变为大角度晶界。大角度晶界形成之后,可突然弓出,迁移蚕食途中所遇位错,留下无畸变的再结晶核心。变形过程中产生的储存能则驱动再结晶核心长大,最终形成细小的无畸变的晶粒,所以经1道次ECAP后合金的显微组织中出现了很多细小的再结晶晶粒。由于施加磁场的合金初始晶粒较小,变形过程中能提供较多的形核位置和产生较多的位错,相应地,形成的再结晶晶粒会变得更多更细小,所以,经1道次ECAP后施加磁场合金的细化效果优于未施加磁场合金的。

275 ℃下经2道次ECAP后无磁场和有磁场处理合金的显微组织分别如图4(c)和(d)所示。相比经1道次ECAP后合金的显微组织,图4(c)中再结晶晶粒所占的比例增加,图4(d)中合金的显微组织已基本被再结晶晶粒所取代,但晶粒大小极不均匀。经4道次ECAP后,无磁场和有磁场处理合金的显微组织都被细小的等轴晶取代,分别如图4(e)和(f)所示,但图4(f)中的显微组织非常均匀,晶粒尺寸更加细小,达到了微米级,实验结果与FIGUEIREDO等[15]建立的ECAP过程中镁合金晶粒细化模型相吻合。综上所述,细小、均匀的原始晶粒能使合金在ECAP过程中组织细化速度加快,从而一定程度上减少ECAP道次。

2.3 Mg-2.0Zn-0.7Zr-0.5Ca合金的力学性能和断口形貌

图5所示为铸态和经4道次ECAP后合金的硬度变化。从图5中可以看出,电磁搅拌和ECAP都能使合金的硬度得到提高,且施加电磁搅拌且经4道次ECAP后合金的硬度最高,达到56.3HV。

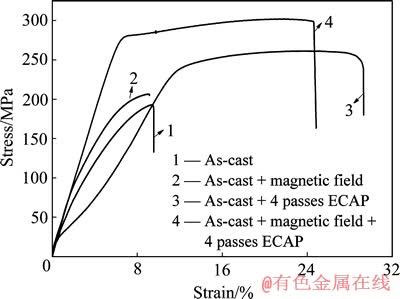

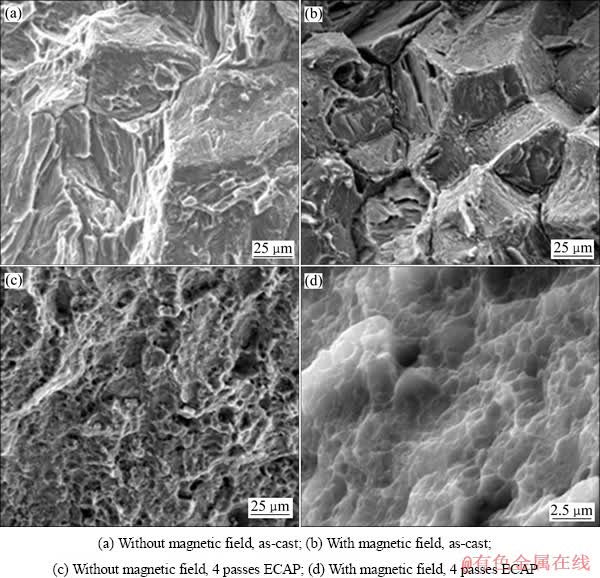

图6所示为ECAP前后合金的应力-应变曲线。其拉伸性能如表1所列。与无磁场状态相比,施加电磁搅拌的铸态合金的力学性能有所提高。4道次 ECAP使得两种状态合金的力学性能均得到了明显的改善,且施加电磁搅拌的合金在经4道次ECAP后其室温力学性能最佳。

一般情况下,合金的强度与晶粒的大小有关[16],电磁搅拌和ECAP都能细化晶粒,所以,经过两种工艺处理后Mg-2.0Zn-0.7Zr-0.5Ca合金的硬度、抗拉强度、屈服强度和伸长率均得到不同程度的提高。由于ECAP工艺对合金显微组织的细化效果优于电磁搅拌工艺的细化效果,所以,经4道次ECAP后合金的力学性能提高较为显著。施加电磁搅拌合金经4道次ECAP后,由于其显微组织更加均匀和细小,所以其硬度和室温拉伸性能都最佳。此外,电磁搅拌和ECAP都能改善合金的内部缺陷,能很好地消除显微组织的成分偏析,这些对合金性能的改善也有一定的影响。

图4 不同条件下Mg-2.0Zn-0.7Zr-0.5Ca合金的显微组织

Fig. 4 Microstructures of Mg-2.0Zn-0.7Zr-0.5Ca alloys prepared under different conditions

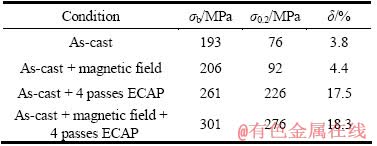

图7所示为拉伸试样的断口形貌。由图7可知,未加磁场的Mg-2.0Zn-0.7Zr-0.5Ca铸态合金断口呈现“河流花样”,其断裂形式为典型的解理断裂。经电磁搅拌后其断口形貌部分呈现“河流状”,其断裂形式为解理和沿晶的混合断裂,施加电磁搅拌使得合金元素在基体中大量固溶,晶界上有利的相较少,加上一些杂质和硬脆相Mg2Ca的影响,导致晶界对裂纹扩展的阻碍作用降低,合金的塑性下降,从而发生解理和沿晶断裂的混合断裂特征。有、无磁场的两种状态合金经4道次ECAP后,其断口形貌变为细小的孔坑,断裂形式为典型的微孔聚集型断裂,但是施加电磁搅拌合金的韧窝非常细小、均匀,所以,其强度和塑性都得到最大程度的提高。

图5 铸态和经4道次ECAP后合金的硬度

Fig. 5 Hardness of as-cast alloy and alloy after 4 passes ECAP

图6 不同条件下合金的室温应力-应变曲线

Fig. 6 Stress-strain curves of alloys at room temperature under different conditions

表1 不同条件下合金的室温拉伸力学性能

Table 1 Mechanical properties of alloys under different conditions

图7 ECAP前后合金的断口形貌

Fig. 7 Fracture morphologies of alloys before and after ECAP

3 结论

1) 施加电磁搅拌后Mg-2.0Zn-0.7Zr-0.5Ca合金在凝固过程中的显微组织得到改善,合金的硬度和室温拉伸性能相对于铸态未加磁场的合金得到改善,但是,受晶界析出相的影响,其断裂形式呈现出解理断裂和沿晶断裂的混合断裂特征。

2) Mg-2.0Zn-0.7Zr-0.5Ca合金在275 ℃经4道次ECAP后,粗大的显微组织得到很好的细化,硬度和室温拉伸性能相对于挤压前得到显著的提高,其断裂由原先的脆性断裂变为韧性断裂。

3) 施加电磁搅拌的Mg-2.0Zn-0.7Zr-0.5Ca合金、初始晶粒较为细小,在一定ECAP道次内晶粒细化程度明显好于未施加电磁搅拌的合金的,经4道次ECAP后其显微组织比未施加磁场的更加细小、均匀,力学性能也得到很好的改善。

REFERENCES

[1] KUBOTA K, MABUCHI M, HIGASHI K. Review processing and mechanical properties of fine-grained magnesium alloys[J]. Journal of Materials Science, 1999, 34(10): 2255-2262.

[2] MIYAHARA Y, MATSUBARA K, HORITA Z, LANGDON T. Grain refinement and superplasticity in a magnesium alloy processed by equal-channel angular pressing[J]. Metallurgical and Materials Transactions A, 2005, 36(7): 1705-1711.

[3] 李延举, 温 斌, 张志峰, 金俊泽. 电磁场作用下材料加工新技术[J]. 大连理工大学学报, 2000, 40(S1): 61-64.

LI Ting-ju, WEN Bin, ZHANG Zhi-feng, JIN Jun-ze. New technology of processing of materials under electromagnetic field[J]. Journal of Dalian University of Technology, 2000, 40(S1): 61-64.

[4] 韩富银, 杨巧莲, 高义斌, 张金山, 池承忠. 电磁搅拌对镁合金半固态组织的影响及机理[J]. 铸造设备研究, 2005(3): 13-15.

HAN Fu-yin, YANG Qiao-lian, GAO Yi-bin, ZHANG Jin-shan, CHI Cheng-zhong. Effect of the electromagnetic agitation on semi-solid microstructure of AZ91D alloy and mechanism[J]. Research Studies on Foundry Equipment, 2005(3): 13-15.

[5] 张小立, 凌向军, 李廷举, 谢水生, 金云学. 电磁搅拌过程中镁合金半固态浆料初生相颗粒的团簇行为[J]. 中国有色金属学报, 2012, 22(9): 2448-2453.

ZHANG Xiao-li, LING Xiang-jun, LI Ting-ju, XIE Shui-sheng, JIN Yun-xue. Agglomerating behavior of primary solid particles in magnesium alloy semisolid slurry during electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2448-2453.

[6] YU Yan-dong, Li Cai-xia. The effect of alternative low frequency electromagnetic field on the solidification microstructure and mechanical properties of ZK60 alloys[J]. Materials and Design, 2013, 44: 17-22.

[7] LI Cai-xia, YU Yan-dong. The effect of solution heat treatments on the microstructure and hardness of ZK60 magnesium alloys prepared under low-frequency altering magnetic fields[J]. Materials Science and Engineering A, 2013, 559: 22-28.

[8] NEISHI K, HORITA Z, LANGDON T G. Achieving superplasticity in a Cu-40%Zn alloy through severe plastic deformation[J]. Scripta Materialia, 2001, 45(8): 965-970.

[9] VEVECKA A, CAVALIERE P, CABBIBO M. Strengthening of a commercial Al-5754 alloy using equal channel angular pressing[J]. Journal of Materials Science Letters, 2001, 20(17): 1601-1603.

[10] SHIN D H, PARK K T. Ultrafine grained steels processed by equal channel angular pressing[J]. Materials Science and Engineering A, 2005, 410/411: 299-302.

[11] 何运斌, 潘清林, 覃银江, 刘晓艳, 李文斌, CHIU Yu-lung, CHEN John J J. 等通道挤压制备细晶ZK60镁合金的组织与力学性能[J]. 中国有色金属学报, 2010, 20(12): 2274-2282.

HE Yun-bin, PAN Qing-lin, QIN Yin-jiang, LIU Xiao-yan, LI Wen-bin, CHIU Yu-lung, CHEN John J J. Microstructure and mechanical properties of ultra-fine grain ZK60 magnesium alloy processed by equal channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(12): 2274-2282.

[12] DING R, CHUNG C, CHIU Y, LYON P. Effect of ECAP on microstructure and mechanical properties of ZE41 magnesium alloy[J]. Materials Science and Engineering A, 2010, 527(16/17): 3777-3784.

[13] MATSUBARA K, MIYAHARA Y, HORITA Z, LANGDON T G. Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP[J]. Acta Materialia, 2003, 51(11): 3073-3084.

[14] CHINO Y, KIMURA K, MABUCHI M. Twinning behavior and deformation mechanisms of extruded AZ31 Mg alloy[J]. Materials Science and Engineering A, 2008, 486(1/2): 481-488.

[15] FIGUEIREDO R B, LANGDON T G. Grain refinement and mechanical behavior of a magnesium alloy processed by ECAP[J]. Journal of Materials Science, 2010, 45(17): 4827-4836.

[16] HALL E O. The deformation and ageing of mild steel: III discussion of results[J]. Proceedings of the Physical Society: Section B, 1951, 64(9): 747-753.

(编辑 陈卫萍)

基金项目:黑龙江省自然科学基金资助项目(ZD201202)

收稿日期:2013-11-28;修订日期:2014-03-27

通信作者:于彦东,教授,博士;电话: 0451-86391277;E-mail: yyd@hrbust.edu.cn

摘 要:在合金熔炼过程中通过控制磁场的施加,分别制备无电磁搅拌和施加电磁搅拌的Mg-2.0Zn-0.7Zr-0.5Ca镁合金铸锭。采用等通道挤压(ECAP)工艺分别对这两种状态的合金进行挤压加工,研究电磁搅拌对ECAP前后合金组织和性能的影响。结果表明:与无磁场状态相比,施加电磁搅拌后,合金的显微组织和力学性能均得到很大改善。因电磁搅拌能细化铸态合金的原始晶粒,经1道次和2道次ECAP后合金的晶粒细化程度明显优于无磁场状态的铸态合金的。4道次ECAP后施加电磁搅拌合金的晶粒非常细小、均匀,且性能最佳,其硬度、屈服强度和伸长率分别达到56.3 HV、276 MPa和18.3%。