Influence of heat treatment on high frequency soft magnetic properties of Finemet amorphous alloy

YANG Sha(杨 沙)1, 2, CHEN Bo-qu(陈伯渠) 1, 2, YAN Biao(严 彪) 1, 2,

LU Wei(陆 伟) 1, 2, LONG Ling(龙 玲) 1, 2, CHEN Zhi-hui(陈智慧) 1, 2

1. Shanghai Key Laboratory of D&A for Metal-Functional Materials, Tongji University, Shanghai 200092, China;

2. School of Materials Science and Engineering, Tongji University, Shanghai 200092, China

Received 15 July 2007; accepted 10 September 2007

Abstract:

In order to study high-frequency soft magnetic properties of Finemet amorphous alloy, the microstructural change and nanocrystallization under different heat treatment conditions were investigated by XRD and TEM. The crystallite size of α-Fe was calculated from the XRD pattern using the Scherrer formula, while the high frequency magnetic properties were measured at room temperature by TPS-200SA exchange tester. The results of XRD and TEM indicate that the nanocrystallization occurs at 500 ℃. When the annealing temperature increases to 560 ℃, the amorphous alloy becomes totally nanocrystallized and the crystallites distribute homogeneously, thus an excellent combination of soft magnetic properties is obtained.

Key words:

amorphous alloy; heat treatment; high frequency soft magnetic properties;

1 Introduction

In 1988, YOSHIZAWA first discovered a new type of soft magnetic materials which was derived from the conventional Fe-Si-B (Metglas) amorphous alloy system with a minor additions of Cu and M (M = Nb, Ta, Mo, W, etc.)[1-3]. After a suitable heat treatment, the alloy was obtained with α-Fe(Si) nanocrystallites embedded in an amorphous matrix consisting of Fe, Cu, Nb and B. The new alloy exhibits excellent soft magnetic properties and the typical composition is Fe73.5Cu1Nb3Si13.5B9, known as Finemet. The Finemet alloy has attracted much attention due to its unique structure and excellent soft magnetic properties (high saturation magnetic flux density, high initial permeability, low coercivity, and low loss)[4-5]. However, the current study on Finemet alloy focused on the DC or low-frequency magnetic properties and the high-frequency magnetic properties are seldom investigated. VARGA[6] has given emphasis on different methods and technologies to increase the frequency and high working temperature limit on soft magnetic nanocomposites including the Finemet amorphous alloy. SILVA[7] investigated the complex high-frequency magnetization dynamics and magnetoimpedance in Fe73.5Cu1Nb3Si13.5B9 alloys. KOLANO-BURIAN[8] studied the high-frequency soft magnetic properties of Finemet modified with Co, coupled with a thermo-magnetic treatment, causing significant reduction in its magnetic permeability and increase in cut-off frequency to over 10 MHz.

In this work, the author studied the microstructure and high-frequency magnetic properties change evolution in the process of nanocrystallization under different heat treatment conditions in order to find a suitable heat treatment for high frequency application.

2 ExperimentalRibbons of 120 mm wide and 20 μm thick with the nominal composition of Fe73.5Cu1Nb3Si13.5B9 were produced by the rapid solidification technique using a single-roller copper-wheel melt spinning equipment. Before casting, chemical composition of the master alloys was examined by X-ray microanalyzer. The ribbons were also examined by means of X-ray diffractometry.

The core samples with outer diameter of 20 mm and inner diameter of 16 mm were fabricated by winding the ribbons into toroidal cores. These specimens were annealed for nanocrystallization under Argon gas by a tubular furnace. The heating coils of the furnace were bifilarly wound around the alumina tube in order to extinguish the heating-current induced magnetic field. The annealing process were conducted at different temperatures for 30 min. The microstructure and nanocrystallization process were studied by X-ray diffractometry (XRD) with Cu Kα radiation, while the microstructural evolution in the process of nanocrystallization was observed by TEM. Afterwards, quasistatic hysteresis loops of all the treated samples were recorded at room temperature using a fully automated experimental set-up named TPS-200SA Exchange Tester to study the high frequency magnetic properties.

3 Results and discussion3.1 Phase structure

The XRD patterns of the Finemet alloy annealed at different temperature for 30 min (Fig.1) clearly show the formation of the α-Fe(Si) nanocrystals. When the annealing temperature is 460 ℃, the alloy mainly exhibits amorphous structure with a small crystallization indicated by weak diffraction peak at the (110) and (200) crystal face. With increasing annealing temperature, the diffraction peak corresponding to α-Fe(Si) phase becomes higher and narrower, which represents a crystal size increase with the nanocrystallization process. Three diffraction peaks emerge when the annealing temperature is higher than 500 ℃, which reveals that the alloy mainly exhibits amorphous structure when the temperature is below 500 ℃ and the crystallization process mainly occurs at the annealing temperature higher than 500 ℃.

Fig.1 XRD patterns of Finemet alloy annealed at different temperature for 30 min

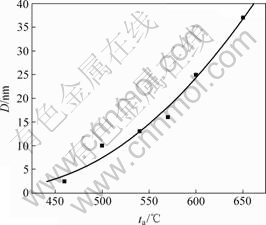

The grain size of the crystallites produced by the crystallization treatments in the first peak of crystallization was calculated from XRD spectra using the Scherrer formula[9] and its dependence on different annealing temperature is shown in Fig.2. Along with the increase of annealing temperature, the size of α-Fe grain gradually increases. When the annealing temperature is less than 500 ℃, crystallization occurs in the amorphous ribbon with a grain size less than 10 nm. When the annealing temperature is above 500 ℃, the alloy shows a significant growth of grains which are larger than 10 nm. When the annealing temperature is at 500 ℃ and 560 ℃, the grain size distributes in 10-20 nm. When the temperature is higher than 560 ℃, the grain grows further beyond 20 nm.

Fig.2 Variation of α-Fe grain size D with annealing temperature

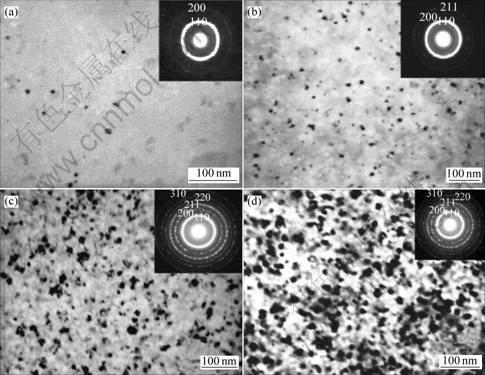

Microstructure evolution in the process of nanocrystallization induced by heat treatment was investigated by TEM. Fig.3(a) shows the bright-field image and corresponding selected area electronic diffraction pattern of the alloy on annealing at 460 ℃ for 30 min. It clearly shows that the crystals precipitate from the amorphous matrix with a size less than 10 nm. As the annealing temperature increases to 500 ℃, numerous crystals precipitate from the amorphous matrix coupled with a initial size growth to about 10 nm as shown in Fig.3(a). When the annealing temperature reaches 650 ℃, the alloy completes crystallization with a grain size of more than 20 nm. Obviously, grain size measured by TEM is in good agreement with the data calculated from XRD.

3.2 Magnetic properties of alloy

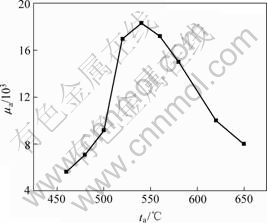

Fig.4 shows the relationship between the amplitude permeability μa and the annealing temperature under the condition of Bm=0.2 T, f=100 kHz.

Fig.3 TEM images and selected area electronic diffraction patterns of Fe73.5Cu1Nb3Si13.5B9 alloy annealed at different temperatures for 30 min: (a) 460 ℃; (b) 500 ℃; (c) 560 ℃; (d) 650 ℃

Fig.4 Variation of amplitude permeability μa with annealing temperature

We can see that the amplitude permeability is less than 104 when the annealing temperature is below 500 ℃. When the annealing temperature is above 500 ℃, the amplitude permeability increases noticeably to a maximum value at 540 ℃. Then, the amplitude permeability decreases gradually with the increase annealing temperature. So, the nanocrystalline soft magnetic alloy Fe73.5Cu1Nb3Si13.5B9 exhibits an excellent amplitude permeability after annealing at 520-560 ℃.

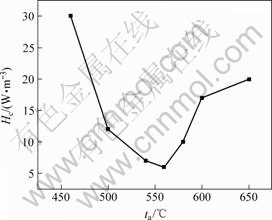

Fig.5 shows the relation of coercivity Hc with annealing temperature ta for the nanocrystalline soft magnetic alloy. The coercivity value of the nanocrystalline soft magnetic alloy is relatively low at annealing temperature of 540-560 ℃. At a primary stage, the coercivity decreases with the increase of annealing temperature, indicating a reduction of stress relaxation of this alloy. When the temperature is above 560 ℃, the coercivity increases noticeably, because the FeB phase will greatly enhance the magnetic anisotropy and lead to the increase of the coercivity[10].

Fig.5 Variation of coercivity Hc with annealing temperature

Based on the above data, it is clearly shown that the nanocrystalline soft magnetic alloy exhibits an excellent combined AC magnetic properties at annealing temperature from 540 ℃ to 560 ℃. This is attributed to the nano-microstructure and internal defects, coupled with the reduction of stress[11-12]. Under such treatment, this alloy has the lowest saturation magnetostriction coefficient, as well as the effective magnetic anisotropy. With the increase of annealing temperature, the lattice constant of Fe73.5Cu1Nb3Si13.5B9 alloy achieves a minimum value at 560 ℃, implying a minimum crystal plane spacing. Generally speaking, the lattice constant of α-Fe(Si) is less than that of pure Fe (2.866 4 ?). When the annealing temperature increases to 560 ℃, the lattice constant goes down, indicating that some small Si atoms have a solid solution in α-Fe phase. As annealing temperature is further increased to 650 ℃, the lattice constants also rise, indicating the Si exsolution in the α-Fe phase. So the Si concentration in α-Fe phase is related to the lattice constant, which is in accordance with the previous results[13-15].

4 Conclusions1) The nanocrystalline soft magnetic alloy exhibits an excellent combined AC magnetic properties at annealing temperature from 540 ℃ to 560 ℃.

2) TEM and XRD patterns further confirm that the crystallization process of the nanocrystalline soft magnetic alloy Fe73.5Cu1Nb3Si13.5B9 mainly occurs above 500 ℃. At 560 ℃, the alloy is fully nanocrystallized and the nanocrystalline distributes homogeneously, which benefits the excellent soft magnetic properties.

3) The lattice constant decreases with the annealing temperature increasing to 560 ℃, while with annealing temperature further increasing to 650 ℃, the lattice constant rises.

References

[1] YOSHIZAWA Y, OGUMA S, YAMAUCHI K. New Fe-based soft magnetic alloys composed of ultrafine grain structure[J]. J Appl Phys, 1988, 64: 6044-6046.

[2] HERZER G, WARLIMONT H. Nanocrystalline soft magnetic materials by partial crystallization of amorphous alloys[J]. Nanostruct Mater, 1992, 1(3): 263-268.

[3] HERZER G. IEEE grain structure and magnetism of nanocrystalline ferromagnets[J]. Trans Magn, 1989, 5(25): 3327-3329.

[4] YOSHIZAWA Y, YAMAUCHI K. Fe-based soft magnetic alloys composed of ultrafine grain structure[J]. Mater Trans Jpn Int Metals, 1990, 31(4): 307-314.

[5] YOSHIZAWA Y. Magnetic properties and applications of nanostructured soft magnetic materials[J]. Scripta Materialia, 2001, 44(8/9): 1321-1325.

[6] VARGA L K. Soft magnetic nanocomposites for high-frequency and high-temperature applications[J]. J Magn Magn Mater, 2007, 312(2): 442-447.

[7] DA SILVA R B, VIEGAS A D C, CORREA M A, DE ANDRADE A M H, SOMMER R L. Complex high-frequency magnetization dynamics and magnetoimpedance in thin films[J]. Physica B: Condensed Matter, 2006, 384(1/2): 172-174.

[8] KOLANO-BURIAN A, VARGA L K. High-frequency soft magnetic properties of Finemet modified with Co[J]. J Magn Magn Mater, 2007, 316(2): e820-e822.

[9] CULLITY B D. Elements of X-ray diffraction[M]. Addison-Wesley. 1977: 81-82.

[10] FERN?NDEZ-MARTINEZ A, GORR?A P, CUELLO G J, SANTOS J D, P?REZ M J. Kinetics of crystallization of FeB-based amorphous alloys studied by neutron thermo-diffractometry[J]. Journal of Non-Crystalline Solids, 2007, 353(8/10): 855-858.

[11] FERN?NDEZA L, ITURRIZA N. Magnetic behavior and microstructure of Finemet-type ribbons in both, surface and bulk[J]. Journal of Non-Crystalline Solids, 2007, 353(8/10): 777-781.

[12] LU Wei, YANG Lei, YAN Biao. Nanocrystallization kinetics of amorphous Fe73.5Cu1Nb3Si13.5B9 alloy[J]. J Alloy Compd, 2006, 420(1/2): 186-192.

[13] DING Yan-hong, LIU Xuan, ZHAO Shui-sheng, LONG Yi, YE Rong-chang, CHANG Yong-qin. Magnetic properties of nanocrystalline Finemet alloys with Co addition[J]. J Alloy Compd, 2007, 440(1/2): 220-224.

[14] ITURRIZA N, FERN?NDEZ L M, et al. Nanostructure and magnetic properties of Ni-substituted Finemet ribbons[J]. J Magn Magn Mater, 2007, 316(2): e74-e77.

[15] PRABHU D, GANESAN K, NARAYANASAMY A, CHATTOPADHYAY K, PONPANDIAN N. Magnetic properties of amorphous Fe73.5Cu1Mo3Si12.5Al1B9 alloy[J]. Mater Sci Eng A, 2007, 449/451: 452-455.

Foundation item: Projects(0552nm028; 04DZ05616) supported by Shanghai Science and Technology Committee, China

Corresponding author: YAN Biao; Tel: +86-21-65981178; E-mail: yanbiao@vip.sina.com