文章编号:1004-0609(2015)-07-1929-08

基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度的方法

王家梁,马德军,孙 亮,黄 勇

(装甲兵工程学院 机械工程系,北京 100072)

摘 要:

针对传统维氏硬度测试中因Vickers压痕形貌不清晰导致的维氏硬度无法识别问题,应用量纲定理和有限元数值分析方法对仪器化Vickers压入响应进行了系统分析,同时,结合维氏硬度有限元数值计算结果,揭示仪器化Vickers压入比功、马氏硬度与维氏硬度的近似函数关系。基于上述关系,提出由Vickers压入比功We/Wt和马氏硬度HM识别材料维氏硬度HV的新方法,对该方法进行测试精度分析,验证结果表明该方法较ISO14577中所提维氏硬度仪器化Vickers压入方法具有更高的测试精度。

关键词:

中图分类号:TH140.7 文献标志码:A

Method for determining Vickers hardness of materials by Vickers instrumented indentation work ratio and martens hardness

WANG Jia-liang, MA De-jun, SUN Liang, HUANG Yong

(Department of Mechanical Engineering, Academy of Armored Force Engineering, Beijing 100072, China)

Abstract: The problem of Vickers morphology is not clear due to the Vickers hardness does not recognize during the traditional Vickers hardness testing. The instrumented indentation test were analyzed by employing dimensional theorem and finite element method, meanwhile, combined with the finite element numerical results of Vickers hardness, the approximate function relationships among Vickers indentation work ratio(We/Wt), martens hardness and Vickers hardness were revealed. Based on the relationships, a new method was then proposed to determine the Vickers hardness of materials by Vickers indentation work ratio and martens hardness, and its accuracy was analyzed. The results show that, compared with ISO14577, this method has higher accuracy.

Key words: Vickers instrumented indentation; indentation work ratio; martens hardness; Vickers hardness

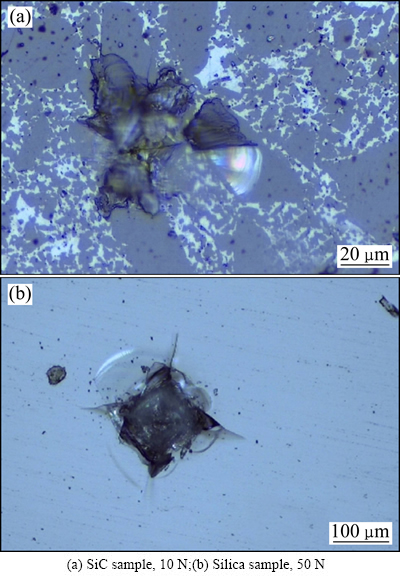

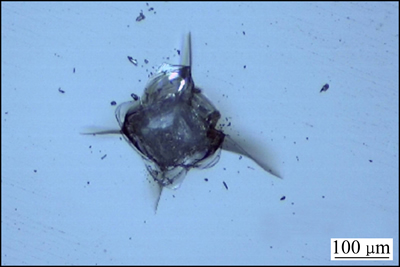

维氏硬度作为材料重要的力学性能指标,因其测试范围广、重复精度高等优点一直以来得到材料研究人员的广泛关注[1-5]。目前,传统维氏硬度[6-7]测量的关键在于借助显微镜准确量取压痕对角线长度,对于Vickers压痕形貌不清晰的被测材料(见图1),往往存在无法准确识别维氏硬度的问题。近年来,仪器化压入技术[8-13]因无需量取压痕形貌参数,可以方便地确定被测材料的仪器化压入硬度[14-16],从而有望解决因Vickers压痕形貌不清晰导致的维氏硬度无法识别问题。然而,在仪器化压入硬度与传统维氏硬度的关系问题以及如何将仪器化压入硬度转换为传统维氏硬度的研究中,一部分研究人员通过仪器化压入响应建立等效维氏硬度,这并不代表传统意义的维氏硬度值[16-18];另一部分研究人员基于实验数据建立仪器化压入硬度与维氏硬度的经验关系[19-22],而借助数值分析方法来系统分析仪器化压入响应与传统维氏硬度间的关系仍处于空白。

基于上述情况,本文作者拟通过数值分析方法来揭示仪器化Vickers压入响应与传统维氏硬度的关系,以此为基础,建立基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度的一般方法。

图1 不同压入载荷下无法准确识别维氏硬度的Vickers压痕形貌图

Fig. 1 Vickers indentation morphologies of unable to accurately identify Vickers hardness under different indentation loads

1 仪器化Vickers压入的量纲和有限元分析

马氏硬度可通过仪器化Vickers或Berkovich压入获得的载荷-位移曲线确定,它包含了材料的塑性和弹性变形,因此,适用于所有材料,是目前仪器化压入测试中广泛采用的一种硬度指标。其定义为

1) 对于Vickers压入:

(1)

(1)

(2)

(2)

2) 对于Berkovich压入:

(3)

(3)

(4)

(4)

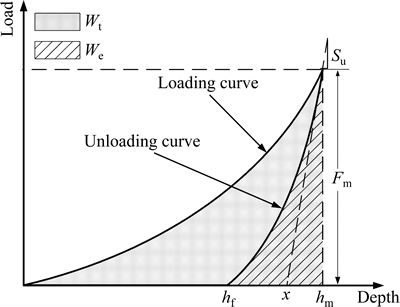

式中:Fm为最大压入载荷;hm为压头最大压入深度;As (hm)为压头最大压入深度hm时对应的压头表面积。马氏硬度的测试方法为:利用仪器化压入仪及Vickers或Berkovich压头对被测材料实施某一最大压入载荷为Fm的仪器化压入测试,获得压入载荷-位移曲线,如图2所示,其中Wt与We分别为压头在加载和卸载过程所做的功,其值分别为加载曲线和卸载曲线与载荷-位移曲线横坐标所围面积;当不考虑金刚石Vickers压头尖端钝化时 ,而考虑金刚石Vickers压头尖端钝化时,则As(hm)应由压头的面积函数As(hm)来确定,即

,而考虑金刚石Vickers压头尖端钝化时,则As(hm)应由压头的面积函数As(hm)来确定,即 。

。

图2 仪器化压入载荷-位移曲线示意图

Fig. 2 Schematic diagram of instrumented indentation load-displacement curve

为应用有限元数值分析方法建立仪器化Vickers压入响应与材料维氏硬度HV之间的函数关系,假设Vickers压头为理想弹性体,仪器化Vickers压入响应可表示为压头的弹性模量Ei、泊松比vi、被测材料的弹性模量E、泊松比v、屈服强度σy、应变硬化指数n以及最大压入深度hm的函数。定义Ei/(1-vi2)、E/(1-v2)分别为压头和被测材料的平面应变弹性模量;η=[E/(1-v2)/Ei/(1-vi2)]为平面应变弹性模量之比;HM和We/Wt分别为被测材料的基于仪器化Vickers压入所确定的马氏硬度和比功。将维氏硬度与马氏硬度之比HV/HM、仪器化Vickers压入比功We/Wt作为压入响应,可建立下列函数关系:

(5)

(5)

(6)

(6)

由式(6)可得

(7)

(7)

将式(7)代入式(5)得

(8)

(8)

应用量纲P定理同时考虑平面应变弹性模量之比η=[E/(1-v2)/Ei/(1-vi2)],则式(8)可以被改写为

(9)

(9)

为得到式(9)的显式解,可通过商用有限元软件ABAQUS[23]建立仪器化Vickers压入三维有限元模型计算结果获得。因标准Vickers压头为面角136°正四棱锥,可根据对称性取Vickers压头的1/8建立模型,如图3阴影部分所示。同时,被测材料取与压头相对应的1/8建模。被测材料整体尺寸为4000 μm× 4000 μm×2000 μm,压头最大压入深度hm=5 μm。

图3 1/8对称的Vickers压头示意图

Fig. 3 Schematic diagram of 1/8 symmetrical Vickers indenter

定义压头为理想弹性压头,其参数设定为Ei=1141 GPa,vi=0.07;假设被测材料为均匀、各向同性的率无关固体,考虑到所建仪器化Vickers压入识别材料维氏硬度方法的普适性,被测材料弹性模量分别取70 GPa、200 GPa和400 GPa,泊松比取值v=0.3,相应的平面应变弹性模量之比η=[E/(1-0.22)]/[1141/(1- 0.072)]=0.0671、0.1917和0.3834,应变硬化指数n为0、0.15、0.3、0.45;由于绝大多数工程材料比功We/Wt处于0.01~0.85之间,根据此范围(We/Wt为0.01~0.85)取相应的屈服强度值σy为0.98、42255 MPa。压头与被测材料间的摩擦因数取f=0.16[24]。根据接触核心区网格精细,远场非核心区网格稀疏的原则,最终,压头划分为23828个C3D4单元。被测材料划分为51330个C3D8R单元和158115个C3D4单元,其接触区域网格划分如图4所示。收敛性分析表明,两模型网格分析误差均不超过0.5%。整个仪器化压入数值计算采用非线性大变形理论。

图4 仪器化Vickers压入有限元模型局部网格图

Fig. 4 Local mesh diagram of Vickers instrumented indentation model

关于有限元数值分析模型计算材料维氏硬度的思路与文献[25-28]接近,即当压头加载至最大压入载荷Fm时,通过压头与被测材料间的接触应力识别被测材料对角线方向的接触边缘节点;当压头卸载至初始位置时,将此节点与压痕中心的最终距离作为压痕对角线半长d/2,从而通过维氏硬度公式:HV=2sin68°·Fm/d2确定有限元数值计算获得的维氏硬度理论值。

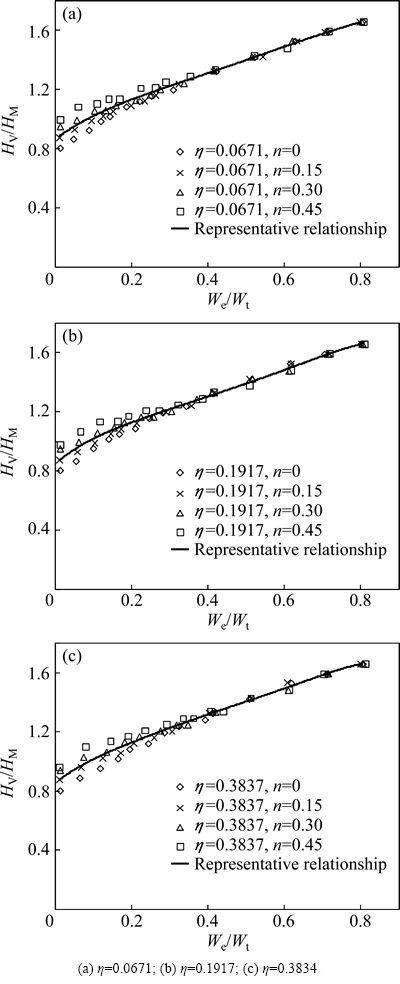

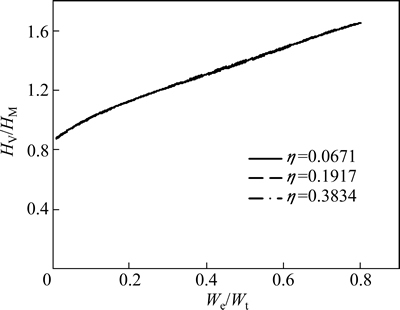

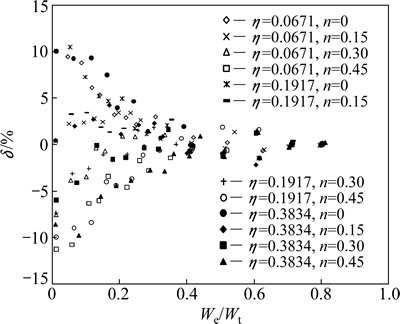

利用有限元数值计算方法可以获得式(9)的显式解,图5(a)~(c)所示为由有限元数值计算得到的对应不同平面应变弹性模量之比η和应变硬化指数n的HV/HM- We/Wt关系。

从图5(a)~(c)可知,对于确定的平面应变弹性模量之比η,HV/HM-We/Wt关系的数据点均分布在以应变硬化指数n=0和n=0.45为边界的区域内。因此,为忽略应变硬化指数n对HV/HM-We/Wt关系的影响,将HV/HM-We/Wt关系近似表示为一一对应的HV/HM-We/Wt函数关系,称之为代表性的HV/HM-We/Wt关系(Representative relationship)。为了更好地表示代表性的HV/HM-We/Wt关系,采用6次多项式对数据点进行拟合,从而确定1组η对应的HV/HM-We/Wt函数关系。分别将3组不同的η对应的代表性HV/HM-We/Wt关系放入图6中,可以看到3组代表性HV/HM-We/Wt关系曲线几乎重合,说明不同η对HV/HM-We/Wt关系已不构成影响。

图5 不同η和n下的HV/HM-We/Wt关系

Fig. 5 Relationship between HV/HM and We/Wt with different η and n

图6 不同η所对应代表性的HV/HM-We/Wt关系

Fig. 6 Representative relationship between HV/HM and We/Wt with different η

最终可采用单一6次多项式来表示上述HV/HM-We/Wt的函数关系:

(10)

(10)

由此可知,基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度的公式可表示为

(11)

(11)

2 维氏硬度的测试方法

基于式(11),本文作者提出基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度的一般方法,该方法由以下几个步骤组成。

1) 利用仪器化压入仪和金刚石Vickers压头对被测材料实施某一最大压入载荷为Fm的仪器化压入测试,获得压入载荷-位移曲线,同时利用该曲线确定金刚石Vickers压头的最大压入深度hm与马氏硬度HM=Fm/As(hm),其中,As(hm)为对应最大压入深度时的压头表面积,当不考虑金刚石Vickers压头尖端钝化时 ,而考虑金刚石Vickers压头尖端钝化时,则As(hm)应由压头的面积函数As(hm)来确定,即

,而考虑金刚石Vickers压头尖端钝化时,则As(hm)应由压头的面积函数As(hm)来确定,即 。

。

2) 通过分别积分载荷-位移曲线关系中的加载曲线和卸载曲线计算压入加载功Wt、卸载功We,并在此基础上计算压入比功We/Wt。

3) 根据维氏硬度HV与仪器化压入比功We/Wt及马氏硬度HM的关系最终确定被测材料的维氏硬度HV:

(12)

(12)

3 精度分析

定义公式(12)确定的维氏硬度理论相对误差δ为

(13)

(13)

式中:HV为通过有限元数值计算获得的维氏硬度理论值。根据有限元数值计算结果,图7所示为基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度方法的δ-We/Wt关系。可以看出,数据点(We/Wt ,δ

,δ )和数据点(We/Wt

)和数据点(We/Wt ,δ

,δ )构成了理论相对误差δ-We/Wt关系的上、下边界。因此,在We/Wt一定的情况下,通过本文方法识别的材料维氏硬度的最大理论相对误差δ+与δ-分别为

)构成了理论相对误差δ-We/Wt关系的上、下边界。因此,在We/Wt一定的情况下,通过本文方法识别的材料维氏硬度的最大理论相对误差δ+与δ-分别为

(14)

(14)

(15)

(15)

由计算结果可知,δ+与δ-的绝对值几乎相等且随We/Wt的增大最大理论相对误差δ+和δ-均减小。当We/Wt→0时,δ+和δ-均达到最大值±11.26%。因此,基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度方法的最大理论误差为±11.26%;当We/Wt由0增大到0.3时,误差δ由±11.26%减小至±2.95%;而当0.3<We/Wt<0.8时,δ稳定在±2.95%以内。

图7 不同η和n下δ和We/Wt的关系

Fig. 7 Relationship between δ and We/Wt with different η and n values

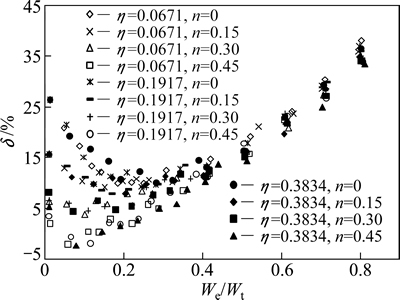

为了将本研究方法的理论精度与目前国际标准ISO14577中维氏硬度仪器化压入方法的理论精度进行比较,从而说明本研究方法的优越性,由有限元数值分析结果可以类似得到ISO14577方法识别材料维氏硬度的δ-We/Wt关系(如图8所示)。由图8可知,该方法的理论误差为-2.2%~38.1%。其中,对于We/Wt>0.3的陶瓷材料,随着We/Wt的增加,其测试误差逐渐增大。

图8 不同η和n下的δ和We/Wt的关系(ISO14577方法)

Fig. 8 Relationship between δ and We/Wt with different η and n (ISO14577 method)

4 实验验证

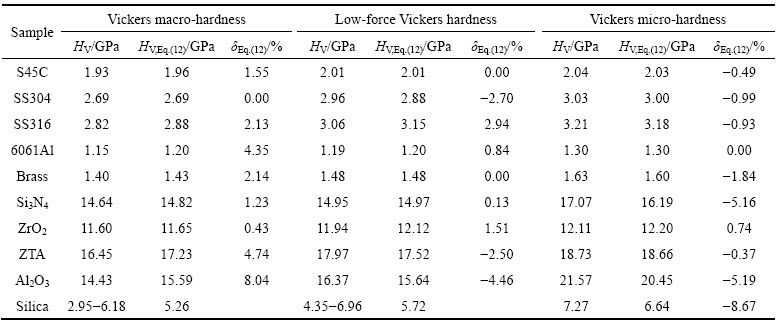

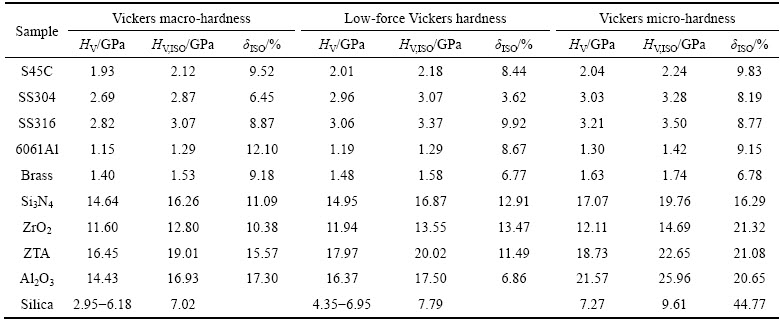

本文作者选用5种金属试样(S45C、SS304、SS316、6061Al、Brass)和5种陶瓷试样(Si3N4、ZrO2、ZTA、Al2O3、Silica)按照ISO14577[19]的要求制备成标准压入试样块。其中,5种金属材料由钢铁研究总院提供;Si3N4、ZrO2、ZTA、Al2O3试样由中国建筑材料科学研究总院陶瓷科学研究院提供;Silica试样为 宝山钢铁股份有限公司提供的纳米压入仪用标准试样(国标编号:GSB 03-2496-2008)。实验通过本课题组先期研制的高精度宏观仪器化压入仪和微观仪器化压入仪[29]在ISO14577规定的3种载荷范围内(见表1)进行仪器化压入测试,并通过显微镜测量维氏压痕对角线长度以获得材料的传统维氏硬度。以此为基础,分别采用本文作者所提仪器化Vickers压入方法和ISO14577中所提仪器化Vickers压入方法对上述10种材料识别的维氏硬度值与传统方法识别的维氏硬度值进行比较,以此验证本文方法的有效性。

根据表1所示 ISO14577规定的维氏硬度试验力范围,宏观、小力值和显微维氏硬度的最大压入载荷分别设定为50 N、10 N和1 N。为保证测试结果的准确性,每种材料重复测试10次。表2和3所列分别为本研究方法和ISO14577方法基于Vickers压头在3种载荷范围内识别的维氏硬度均值及误差。其中,HV,Eq.(12)为研究方法识别的维氏硬度值,δEq.(12)=(HV,Eq.(12)- HV)/HV为研究方法识别的维氏硬度误差;HV,ISO为ISO4577-1方法识别的维氏硬度值;δISO=(HV,ISO- HV)/HV为ISO4577-1方法识别的维氏硬度误差;HV为传统方法识别的维氏硬度值。

表1 维氏硬度试验力范围

Table 1 Vickers hardness ranges of test force

由表2和3可知,除熔融硅试样由于载荷过大导致压痕形貌不清晰外(见图9),本研究的方法和ISO14577方法对其他9种材料的宏观维氏硬度最大识别误差分别为8.04%和17.30%;小力值维氏硬度最大识别误差分别为-4.46%和13.47%;显微维氏硬度最大识别误差分别为-5.19%和21.32%。对于Silica试样,本研究方法和ISO14577方法的显微维氏硬度最大识别误差分别为-8.67%和44.77%。

据此可知,相比ISO14577中所提维氏硬度仪器化压入识别方法,本文作者建立的基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度的方法在3种载荷下的测试精度均具有明显优势,从而验证该方法的有效性。

表2 本文研究方法识别的10种材料维氏硬度均值及误差

Table 2 Mean value and error for10 kinds of materials’ Vickers hardness determined by proposed method

表3 ISO14577方法识别的10种材料维氏硬度均值及误差

Table 3 Mean value and error for10 kinds of materials’ Vickers hardness determined by ISO14577 method

图9 最大压入载荷为50 N时熔融硅试样的Vickers压痕形貌

Fig. 9 Vickers indentation morphology of silica sample at maximum indentation load of 50 N

5 结论

1) 应用量纲定理和有限元数值分析方法对仪器化Vickers压入响应进行了系统分析,结合维氏硬度有限元数值计算结果,揭示了仪器化Vickers压入比功、马氏硬度与维氏硬度的近似函数关系,即 。

。

2) 基于函数关系 ,提出由压入比功We/Wt和马氏硬度HM识别材料维氏硬度HV的新方法,并对该方法进行测试精度分析。

,提出由压入比功We/Wt和马氏硬度HM识别材料维氏硬度HV的新方法,并对该方法进行测试精度分析。

3) 通过5种金属试样(S45C、SS304、SS316、6061Al、Brass)和5种陶瓷试样(Si3N4、ZrO2、ZTA、Al2O3、Silica)对本文作者所提仪器化Vickers压入方法和ISO14577中所提仪器化Vickers压入方法识别的维氏硬度值与传统维氏硬度值进行比较。结果表明:本研究中所建立的基于仪器化Vickers压入比功与马氏硬度识别材料维氏硬度的方法是可行和非常有效的。

REFERENCES

[1] SIDJANIN L, RAJNOVIC D, RANOGAJEC J, MOLNAR E. Measurement of Vickers hardness on ceramic floor tiles[J]. Journal of the European Ceramic Society, 2007, 27(2/3): 1767-1773.

[2] SHAHDAD S A, MCCABE J F, BULL S, RUSBY S, WASSELL R W. Hardness measured with traditional Vickers and Martens hardness methods[J]. Dental Materials, 2007, 23: 1079-1085.

[3] YEUNG J, KEONG L C. Hardness measurement of copper bonding wire[J]. Procedia Engineering, 2014, 75: 134-139.

[4] RIOS C T, COELHO A A, BATISTA W W, GONCALVES M C,CARAM R. ISE and fracture toughness evaluation by Vickers hardness testing of an Al3Nb-Nb2Al-AlNbNi in situ composite[J]. Journal of Alloys and Compounds, 2009, 472(1/2): 65-70.

[5] ASIKUZUN E, OZTURK O, CETINKARA H A, YILDIRIM G, VARILCI A, YILMAZLAR M, TERZIOGLU C. Vickers hardness measurements and some physical properties of Pr2O3 doped Bi-2212 superconductors[J]. Journal of Materials Science (Materials in Electronics), 2012, 23(5): 1001-1010.

[6] TABOR D. The hardness of metals[M]. Oxford: Clarendon Press, 1951.

[7] ISO6507-1-2005. Metallic materials-Vickers hardness test -Part 1: Test method[S].

[8] CHENG Y T, CHENG C M. Scaling, dimensional analysis, and indentation measurements[R]. Materials Science and Engineering, 2004, 44(4/5): 91-149.

[9] SAKHAROVA N A, OLIVEIRA M C, ANTUNES J M, FERNANDES J V. On the determination of the film hardness in hard film/substrate composites using depth-sensing indentation[J]. Ceramics International, 2013, 39(6): 6251-6263.

[10] 马德军. 材料弹性模量的仪器化压入测试方法[J]. 中国有色金属学报, 2010, 20(12): 2336-2343.

MA De-jun. Method for determining elastic modulus by instrumented indentation test[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(12): 2336-2343.

[11] 宋仲康, 马德军, 郭俊宏, 陈 伟. 一种改进的纳米压入测试方法[J]. 中国有色金属学报, 2012, 22(2): 520-525.

SONG Zhong-kang, MA De-jun, GUO Jun-hong, CHEN Wei. A modified method of nanoindentation testing method[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 520-525.

[12] CHICOT D, BEMPORAD E, GALTIERI G, ROUDET F, ALVISI M, LESAGE J. Analysis of data from various indentation techniques for thin films intrinsic hardness modelling[J]. Thin Solid Films, 2008, 516(8): 1964-1971.

[13] CHEN X, YAN J, KARLSSON A M. On the determination of residual stress and mechanical properties by indentation[J]. Materials Science and Engineering A, 2006, 416(1/2): 139-149.

[14] OLIVER W C, PHARR G M. An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments[J]. Journal of Materials Research, 1992, 7(6): 1564-1583.

[15] OLIVER W C, PHARR G M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology[J]. Journal of Materials Research, 2004, 19(1): 3-20.

[16] ISO14577-2002. Metallic materials-Instrumented indentation test for hardness and materials parameters Part 1: Test method[S].

[17] 邢思明. 硬度标度的统一与维氏硬度试验的数字化[J]. 武汉工业大学学报, 2000, 22(6): 43-45.

XING Si-ming. Unification of hardness scale connected with digitization of Vickers hardness test[J]. Journal of Wuhan University of Technology, 2000, 22(6): 43-45.

[18] 邢思明, 郧建平. 维氏硬度计数字化原理[J]. 武汉大学学报, 2002, 35(1): 51-54.

XING Si-ming, YUN Jian-ping. Digitalization principle of Vickers hardness tester[J]. Engineering Journal of Wuhan University, 2002, 35(1): 51-54.

[19] 王春亮. 纳米压痕试验方法研究[D]. 上海: 机械科学研究院, 2007.

WANG Chun-liang. Study on the methods of nanoindentation testing[D]. Shanghai: Mechanical Science Research Institute, 2007.

[20] KANG S K, KIM J Y, PARK C P, KIM H U, KWON D. Conventional Vickers and true instrumented indentation hardness determined by instrumented indentation tests[J]. Journal of Materials Research, 2010, 25(2): 337-343.

[21] KANG S K, KIM Y C, LEE J W, KWON D, KIM J Y. Effect of contact angle on contact morphology and Vickers hardness measurement in instrumented indentation testing[J]. International Journal of Mechanical Sciences, 2014, 85: 104-109.

[22] 马德军. 材料力学性能仪器化压入测试原理[M]. 北京: 国防工业出版社, 2010.

MA De-jun. Principles of measuring mechanical properties of materials by instrumented indentation[M]. Beijing: National Defence Industry Press, 2010.

[23] HIBBITT, KARLSSON, SORENSEN Inc. ABAQUS theory manual version 6.2[M]. US: Pawtucket, 2000.

[24] ANTUNES J M, MENEZES L F, FERNANDES J V. Three-dimensional numerical simulation of Vickers indentation tests[J]. International Journal of Solids and Structures, 2006, 43: 784-806.

[25] BOUZAKIS K D, MICHAILIDIS N, ERKENS G. Thin hard coatings stress-strain curve determination through a FEM supported evaluation of nanoindentation test results[J]. Surface and Coatings Technology, 2001, 142/144: 102-109.

[26] BOUZAKIS K D, MICHAILIDIS N, HADJIYIANNIS S, SKORDARIS G, ERKENS Z. Continuous FEM simulation of the nanoindentation to determine actual indenter tip geometries, elastic-plastic material deformation laws and universal hardness[J]. Zeitschrift für Metallkunde, 2002, 93: 862-869.

[27] BOUZAKIS K D, MICHAILIDIS N. Indenter surface area and hardness determination by means of a FEM-supported simulation of nanoindentation[J]. Thin Solid Films, 2006, 494: 155-160.

[28] BOUZAKIS K D, MICHAILIDIS N, SKORDARIS G. Hardness determination by means of a FEM-supported simulation of nanoindentation and applications in thin hard coatings[J]. Surface and Coatings Technology, 2005, 200: 867-871.

[29] 马德军, 宋仲康, 郭俊宏, 陈 伟. 一种高精度压入仪及金刚石压头压入试样深度的计算方法[P]. 中国, CN102288500A. 2011-12-21.

MA De-jun, SONG Zhong-kang, GUO Jun-hong, CHEN Wei. A high accuracy indentation tester and calculation method for depth of diamond indenter pressed into the sample[P]. CN Patent, CN102288500A. 2011-12-21.

(编辑 李艳红)

基金项目:军队科研计划项目(2014CJ011)

收稿日期:2014-12-15;修订日期:2015-04-10

通信作者:马德军,教授,博士;电话:18511281587;E-mail:dejunma@yahoo.com.cn

摘 要:针对传统维氏硬度测试中因Vickers压痕形貌不清晰导致的维氏硬度无法识别问题,应用量纲定理和有限元数值分析方法对仪器化Vickers压入响应进行了系统分析,同时,结合维氏硬度有限元数值计算结果,揭示仪器化Vickers压入比功、马氏硬度与维氏硬度的近似函数关系。基于上述关系,提出由Vickers压入比功We/Wt和马氏硬度HM识别材料维氏硬度HV的新方法,对该方法进行测试精度分析,验证结果表明该方法较ISO14577中所提维氏硬度仪器化Vickers压入方法具有更高的测试精度。

[6] TABOR D. The hardness of metals[M]. Oxford: Clarendon Press, 1951.

[7] ISO6507-1-2005. Metallic materials-Vickers hardness test -Part 1: Test method[S].

[10] 马德军. 材料弹性模量的仪器化压入测试方法[J]. 中国有色金属学报, 2010, 20(12): 2336-2343.

[11] 宋仲康, 马德军, 郭俊宏, 陈 伟. 一种改进的纳米压入测试方法[J]. 中国有色金属学报, 2012, 22(2): 520-525.

[17] 邢思明. 硬度标度的统一与维氏硬度试验的数字化[J]. 武汉工业大学学报, 2000, 22(6): 43-45.

[18] 邢思明, 郧建平. 维氏硬度计数字化原理[J]. 武汉大学学报, 2002, 35(1): 51-54.

[19] 王春亮. 纳米压痕试验方法研究[D]. 上海: 机械科学研究院, 2007.

[22] 马德军. 材料力学性能仪器化压入测试原理[M]. 北京: 国防工业出版社, 2010.

[23] HIBBITT, KARLSSON, SORENSEN Inc. ABAQUS theory manual version 6.2[M]. US: Pawtucket, 2000.

[29] 马德军, 宋仲康, 郭俊宏, 陈 伟. 一种高精度压入仪及金刚石压头压入试样深度的计算方法[P]. 中国, CN102288500A. 2011-12-21.