J. Cent. South Univ. (2020) 27: 2971-2984

DOI: https://doi.org/10.1007/s11771-020-4506-8

Mechanical response and stability analysis of rock mass in high geostress underground powerhouse caverns subjected to excavation

LI Biao(李彪)1, DING Quan-fu(丁泉富)1, XU Nu-wen(徐奴文)2, LEI Yi-fan(雷艺繁)2,

XU Yuan(许媛)3, ZHU Zhong-ping(朱忠平)4, LIU Jing-fei(刘金飞)5

1. School of Geoscience and Technology, Southwest Petroleum University, Chengdu 610500, China;

2. State Key Laboratory of Hydraulics and Mountain River Engineering, College of Water Resource and Hydropower, Sichuan University, Chengdu 610065, China;

3. Department of Engineering Science, University of Oxford, OX5 1PF, United Kingdom;

4. Sichuan Dadu River Shuangjiangkou Hydropower Development Co., Ltd., Maerkang 624099, China;

5. Power China Chengdu Engineering Co., Ltd., Chengdu 610072, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract:

To investigate the stability of rock mass in high geostress underground powerhouse caverns subjected to excavation, a microseismic (MS) monitoring system was established and the discrete element method (DEM)-based numerical simulation was carried out. The tempo-spatial damage characteristics of rock mass were analyzed. The evolution laws of MS source parameters during the formation of a rock collapse controlled by high geostress and geological structure were investigated. Additionally, a three-dimensional DEM model of the underground powerhouse caverns was built to reveal the deformation characteristics of rock mass. The results indicated that the MS events induced by excavation of high geostress underground powerhouse caverns occurred frequently. The large-stake crown of the main powerhouse was the main damage area. Prior to the rock collapse, the MS event count and accumulated energy release increased rapidly, while the apparent stress sharply increased and then decreased. The amount and proportion of shear and mixed MS events remarkably increased. The maximum displacement was generally located near the spandrel areas. The MS monitoring data and numerical simulation were in good agreement, which can provide significant references for damage evaluation and disaster forecasting in high geostress underground powerhouse caverns.

Key words:

Cite this article as:

LI Biao, DING Quan-fu, XU Nu-wen, LEI Yi-fan, XU Yuan, ZHU Zhong-ping, LIU Jing-fei. Mechanical response and stability analysis of rock mass in high geostress underground powerhouse caverns subjected to excavation [J]. Journal of Central South University, 2020, 27(10): 2971-2984.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-020-4506-81 Introduction

Most hydropower powerhouses in Southwest China are designed as underground type due to high mountains and steep slopes. Affected by intense tectonic movements and great depths, many underground powerhouse caverns are constructed in high geostress zones. In addition, the complicated geological conditions and large-scale excavation-induced unloading aggravate the instable risk of rock mass in high geostress underground powerhouse caverns. Rock mass instabilities induced by high geostress such as large deformations, rockbursts and collapses significantly restrict the normal construction of the underground powerhouse caverns [1-5].

Field monitoring and numerical simulation are regular methods to study the mechanical response and stability of underground rock mass. Field monitoring data directly reflect stress and deformation characteristics of rock mass in underground caverns. Conventional monitoring measures include extensometers, geostress measurements, strain gauges, deformation convergences, anchor stress meters, acoustic wave tests, geological radars, etc [6-12]. Based on these monitoring data, the mechanical response of rock mass can be determined for stability analysis. However, these measures can hardly capture the inner microfractures of rock mass, which represent the rock mass damage and usually occur prior to large deformations and failures of underground caverns. As a three-dimensional monitoring method, the microseismic (MS) monitoring technique fills this gap by capturing microfrcturing information of rock mass. LESNIAK et al [13] analyzed the clustering characteristics of MS events and developed a time-based function for high-energy fractures in a coal mine. HUDYMA et al [14] established an MS approach to manage hazards in underground hard rock mines. MA et al [15] investigated the focal mechanisms of induced seismicity in underground mines with the optimized moment tensor inversion method. CAI et al [16] used the MS source radius to quantify rock damage of an experiment tunnel. MA et al [17] assessed the stability of rock mass around a cross tunnel in the high slope through analyzing the tempo-spatial characteristics of MS events. FENG et al [18-21], and XU et al [22] studied the preparation mechanisms and precursor rules of rockbursts in deep-buried tunnels of a hydropower project based on MS evolution characteristics. DAI et al [23, 24] classified the factors dominating MS clusters and proposed an MS source parameters-based method for rock mass large deformation in underground powerhouse caverns.

Different modelling approaches have been developed to study the mechanical response and failure mechanism of underground caverns due to the convenience, efficiency, and repeatability. DHAWAN et al [25] established a finite element model to analyze the stability of underground powerhouse caverns. ALEJANO et al [26] applied the finite difference method (FDM) to predict the subsidence induced by flat and inclined coal seam mining. HAO et al [27] analyzed the effects of joints with different dip angles on plastic zones and displacements of underground caverns using the discrete element method (DEM). JING [28] studied the stability of fractured and anisotropic rocks of a tunnel with the discontinuous deformation analysis (DDA). Using a coupled finite difference and discrete element model, CAI et al [29] studied the distribution characteristics of rock mass stress, displacement and acoustic emission in underground powerhouse caverns subjected to excavation. YAZDANI et al [30] performed a displacement- based back analysis by employing the finite and discrete element methods and the geomechanical properties of rocks such as stress ratio and joints parameters were acquired. As a discontinuous modeling approach with the superiority in simulating the large deformation of the rock mass, DEM is suitable for studying the underground caverns under complex geological conditions.

In the present study, an MS monitoring system was established in the high geostress underground powerhouse caverns being constructed at the Shuangjiangkou hydropower station, Southwest China. The relation between MS activities and field construction were analyzed. Main damage zones of the underground powerhouse caverns were delineated based on MS clusters. The evolution laws of MS source parameters during the development of a rock collapse controlled by the high geostress and geological structure were investigated. Furthermore, a DEM model of the underground powerhouse caverns was built. The deformation characteristics of rock mass were revealed and compared with the MS monitoring results.

2 Engineering background

2.1 Project description

The Shuangjiangkou hydropower station is under construction at the upstream reach of the Dadu River in Sichuan Province, Southwest China. The pivot buildings include the earth core rockfill dam, the flood releasing structures and the diversion system. The height of this dam is 312 m. The flood releasing structures are composed of the tunnel spillway, the deep spillway tunnel, the shaft spillway tunnel and the emptying tunnel. The diversion system is in the left bank mountain and comprised of headrace tunnels, underground powerhouse caverns, tailrace tunnels and access tunnels. The underground powerhouse caverns mainly include the main powerhouse, the omnibus bar caves, the main transformer chamber, the tailrace surge chamber and the drainage galleries. The main powerhouse, the main transformer chamber and the tailrace surge chamber are three main caverns and arranged parallelly. The excavation dimensions of the main powerhouse are designed as 215.7 m in length, 28.3 m in width, and 68.3 m in height. The designed excavation sizes of the main transformer chamber are 158.3 m in length, 19.4 m in width, and 27.2 m in height. The designed excavation dimensions of the tailrace surge chamber are 100.0 m in length, 20.0 m in width, 76.5 m in height. The thicknesses of rock pillars between adjacent main caverns are 45.3 m. There are four units in the main powerhouse with a total installed capacity of 2000 MW [31].

2.2 Geological conditions

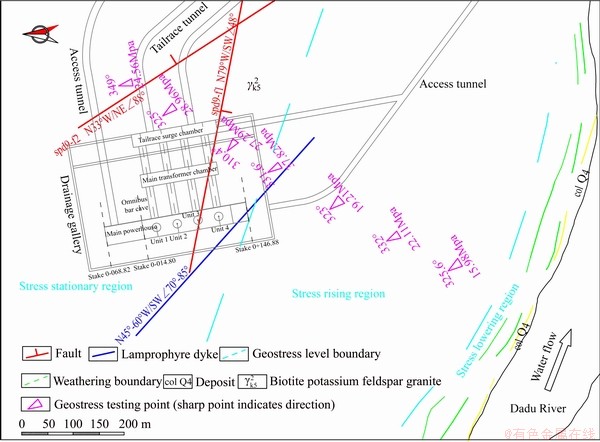

The dip angle of the left bank slope outside the underground caverns is 40°-46°. The underground main powerhouse is buried at a depth of 400-640 m horizontally and 320-500 m vertically. A reprehensive geological plane of the underground powerhouse caverns at an elevation of 2264.0 m is shown in Figure 1. The rock mass of underground powerhouse areas is mainly composed of biotite potassium feldspar granite. There are three main geological structures including two faults (spd9-f1 and spd9-f2) and a lamprophyre dyke. The attitudes of spd9-f1 and spd9-f2 are respectively N79°W/SW∠48°(N79°W: strike; SW: tendency quadrant; ∠48°: dip angle) and N33°W/NE∠88°, while the attitude of the lamprophyre dyke is N45°-60°W/SW∠70°-85°. The tectonic stress has a great influence on the area of the underground powerhouse caverns. Three tested maximum principal geostresses around the underground powerhouse caverns are all in excess of 25.00 MPa and the maximum value reaches up to 37.82 MPa, which indicates that the geostress is extremely high. The horizontal directions of the maximum principal geostresses intersect with the axes of the main caverns by small angles. The uniaxial compression strength of the rock is 70-80 MPa. Based on three main factors (i.e., rock strength, rock mass integrity and structural plane conditions) and two secondary factors (i.e., underground water and orientations of structural planes), the rock mass is classified as IIIa type. The rock mass is generally of block structure. The stability of localized rock mass is relatively poor [31].

Figure 1 Geological plane of underground powerhouse cavern areas at 2264.0 m elevation

2.3 Construction schedule

The conventional drill and blast method was used for excavation of the underground powerhouse caverns. The main powerhouse, the main transformer chamber and the tailrace surge chamber are excavated using 8, 3 and 8 benches, respectively. Influenced by complicated arrangements of structures, adverse high geostresses and various geological structures, rock mass large deformations and failures were experienced and will also threat the safety of personnel and equipment during the later bench excavation of the underground powerhouse caverns. Hence, the integrated MS monitoring technique and numerical simulation method are used to study the mechanical response and stability of rock mass subjected to excavation of the large-scale underground caverns.

3 Excavation-induced MS activities

3.1 MS monitoring system

An MS event is a rock fracture involving the generation of a new crack or extension of an existing crack in localized rock mass [16]. The MS source information such as location, energy, magnitude and apparent stress can be obtained through analyzing the waveform signals emanated by rock fractures. The MS information well reflects rock mass damage. Therefore, the potential failure regions and their formation mechanism of the underground powerhouse caverns can be studied based on the evolution characteristics of MS information.

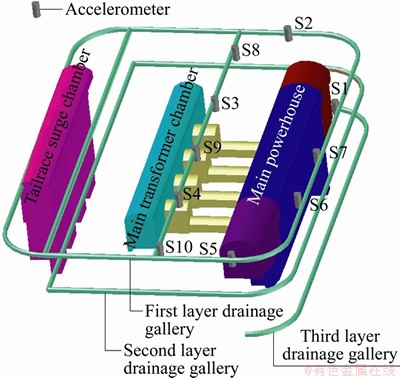

The MS monitoring system applied in Shuangjiangkou underground powerhouse caverns is mainly composed of a digital signal processing system, two digital signal acquisition stations and ten accelerometers. The elastic waves can be captured by the accelerometers and transformed as electric signals. Then the electric signals are transmitted to digital signal acquisition stations by electric cables and transformed as digital signals. Finally, the digital signals are transmitted to the digital signal processing system for analysis with network cables. The spatial arrangement of accelerometers in the underground caverns is shown in Figure 2. According to the feasibility of installation and practicability, ten accelerometers were installed in the first drainage gallery at the upstream and downstream of the main powerhouse. The accelerometers are approximately at 2285.0 m elevation and mainly cover the crown areas and the upper sidewalls of the main powerhouse and the main transformer chamber. The sensitivity of the accelerometers is 30 V/g. The sampling frequency of two digital signal acquisition stations is 10 kHz. The rock mass P-wave velocity in the MS monitoring system is set as 5000 m/s based on field measurements and fixed-point blasting tests. The waveforms are recorded automatically in the digital signal processing system. The data processing is performed through a commercial software WaveVis. The properties of the MS monitoring system and the analysis method of waveforms can be found in previous studies [3, 23].

Figure 2 Accelerometer array at underground powerhouse caverns

3.2 Temporal distribution of microseismicity

The MS monitoring system has been in operation since July 19, 2018 when the I bench excavation of the underground powerhouse caverns was in the beginning. Figure 3 illustrates the temporal distribution of MS events from July 19, 2018 to July 31, 2019. The I bench excavation and support construction was almost finished on July 31, 2019. During this period, totally 1332 MS events were recorded and the MS event rate was closely related to construction conditions. The MS events occurred frequently between July and December, 2018 when the excavation progress was fast. The number of MS events was more than 10 in many days and greatly influenced by high geostress and strong unloading [32]. Myriads of surface cracks were found in the main powerhouse. From January to April, 2019, the support measures were being carried on and the MS event rate decreased. Nevertheless, there were still a number of MS events in this phase. Though the excavation was suspended, the unloading rock mass was at the stress adjustment and redistribution process. The I bench excavation was resumed in early May. However, a severe rock collapse occurred in May 17, 2019 after the MS event rate increased for a few days. Finally, the excavation was suspended to avoid further damage and failures of rock mass. The MS event rate decreased again. Due to the effect of high geostress, the stress adjustment and redistribution process might be longer. For security reasons, the excavation was suggested to resume until the MS event rate was less than 4 and tended to be stable.

Figure 3 Temporal distribution of MS events

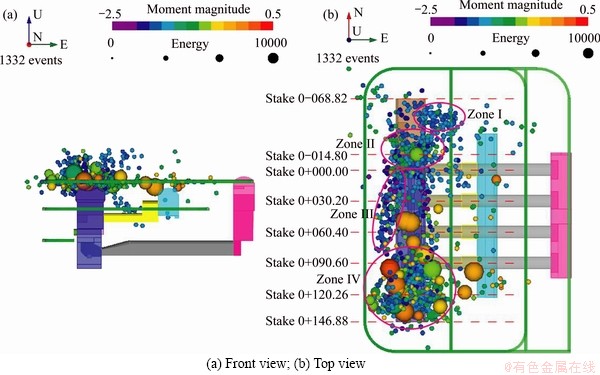

3.3 Spatial distribution of microseismicity

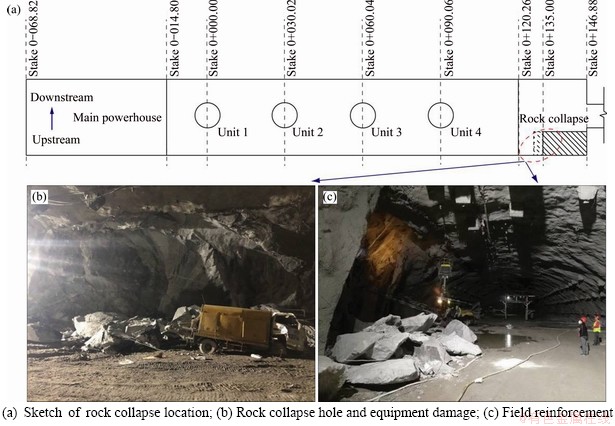

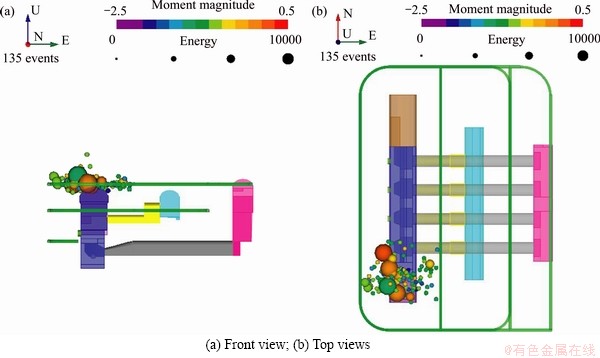

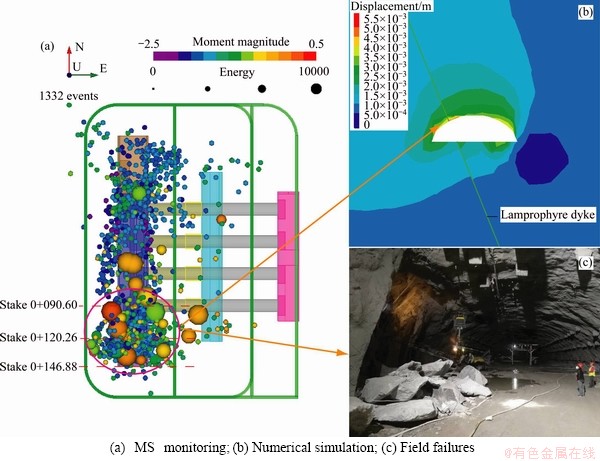

Figure 4 shows the spatial distribution of MS events (spheres) recorded between July 19, 2018 and July 31, 2019. It can be seen from Figure 4(a) that the MS events mainly distributed around the crown areas of the main powerhouse. There are four main MS clusters (Zones I, II, III and IV in Figure 4(b)) that represent the main damage regions. Zone I is located near the downstream spandrel of the main powerhouse between Stake 0-060.00 and 0-030.00. Zone II is in the crown area of the main powerhouse between Stake 0-030.00 and 0+000.00. Zone III is aligned along the upstream spandrel of the main powerhouse between Stake 0+000.00 and 0+080.00. Zone IV is distributed in the crown area of the main powerhouse between Stake 0+080.00 and 0+150.00. It is worth noting that a large number of MS events accumulate in Zone IV and many of them are of high energies and large magnitudes. Thus, this MS clustering area should be paid more attention during the excavation of the underground caverns. A rock collapse occurred at the upstream spandrel of the main powerhouse between Stake 0+120.00 and 0+140.00 (in Zone IV) on May 17, 2019 (Figure 5). The amount of the collapsed rock mass was more than 50 m3 and a vehicle near this collapse was damaged. Fortunately, there were no casualties due to an early MS warning. As shown in Figure 1, there is a lamprophyre dyke across the collapse location. The MS cluster and rock collapse in Zone IV might be controlled by integrated high geostress and geological structure. Such a type of crown rock collapses influenced by high geostress and geological structure was also encountered in some other hydropower main powerhouses [2, 33]. The MS evolution characteristics during this rock collapse were particularly researched in the following section.

Figure 4 Spatial distribution of MS events:

Figure 5 Rock collapse between Stake 0+120.00 and 0+140.00 of the main powerhouse [34]:

3.4 Evolution laws of MS source parameters during rock collapse formation

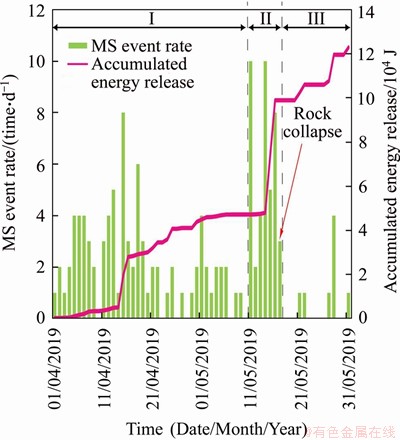

The MS events in Zone IV from April 1 to May 31, 2019 are delineated. The spatial distribution of these MS events is shown in Figure 6. There were 135 MS events occurring in this region during the selected period. The MS event count and energy release, regarded as two fundamental parameters, respectively represent fracturing frequency and intensity of rock mass. Figure 7 illustrates the evolution characteristics of MS event rate and accumulated energy release. This process can be divided into three phases. Phase I is before May 10, 2019. In this phase, the average MS event count was about 2 and the energy release increased slowly. The MS event count and accumulated energy release increased rapidly between May 11 and 17, 2019. The increment value of energy release was more than 5×104 J, which was regarded as Phase II. Phase III was after the rock collapse occurred and there were very few MS events. However, some of these MS events were of high energies, which indicated that the energy stored in the rock mass of the collapse zone was gradually released by these events. After the stored energy was released sufficiently, the stress is generally regarded as risk reduction in the collapse zone [34].

Figure 6 Spatial distribution MS events of Zone IV (from April 1 to May 31, 2019):

Figure 7 Evolution characteristics of MS event rate and accumulated energy release in Zone IV (from April 1 to May 31, 2019)

The apparent stress is defined as the radiated energy per unit volume of coseismic inelastic deformation and reflects the stress level of seismic source [35]:

(1)

(1)

where μ is the shear modulus, M0 is the seismic moment and E is the radiated energy.

As a significant mechanical parameter, the apparent stress was usually used for stability analysis of underground rock mass [21, 36]. The evolution process of the apparent stress of MS events in Figure 6 is shown as Figure 8. Before May 10, 2019, the apparent stress was relatively low with the general value less than 0.1 MPa. The apparent stress sharply increased to 0.59 MPa from May 11 and 16, 2019 and then rapidly decreased from May 16 to 17, 2019 prior to the rock collapse.

After the rock collapse occurred, the apparent stress fluctuated in a certain range.

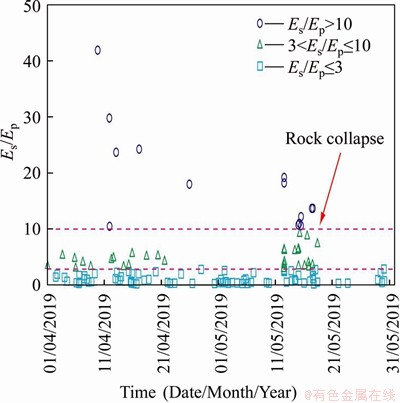

Each MS event emanates elastic waves involving the compression wave (P-wave) and the shear wave (S-wave). The P- and S-waves contain energies and the ratio of them (Es/Ep) is often used to reveal the mechanical mechanism of rock cracks [12, 37, 38]. According to previous studies,shear fractures were likely to have much higher S-wave energies than P-wave energies and the Es/Ep was usually greater than 10, while tensile fractures tended to have the Es/Ep less than 3 [39, 40]. The fractures with the Es/Ep between 3 and 10 were usually regarded as mixed failures. The Es/Ep evolution process of MS events is shown as Figure 9. Before May 10, 2019, the fracture type was mainly tensile and only a small amount and proportion of MS events were shear and mixed failures. Between May 11 and 17, 2019, the amount and proportion of shear and mixed MS events remarkably increased. After the rock collapse occurred, all the Es/Ep values of MS events were less than 3, which meant that the rock fractures were of tensile type.

Figure 8 Evolution characteristics of MS apparent stress in Zone IV (from April 1 to May 31, 2019)

Figure 9 Evolution characteristics of Es/Ep of MS events in Zone IV (from April 1 to May 31, 2019)

4 Numerical simulation using 3DEC

The numerical program 3DEC is on the basis of DEM and the model established in 3DEC is divided into blocks, which are composed of arbitrary polygons. A significant feature of this program is large deformation processing of rock mass along discontinuities and rotations of blocks [41]. The Shuangjiangkou underground powerhouse caverns are cut into blocks by different weak structures. Thus, this program is well suited for analyzing the mechanical response and stability of the underground powerhouse caverns.

4.1 Numerical model

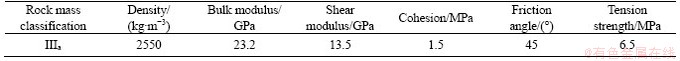

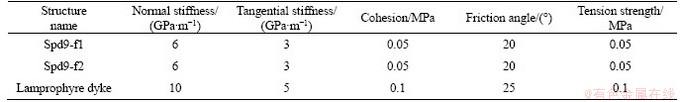

A three-dimensional model was established through synthetically considering the excavation sizes of the main caverns and geological conditions around the underground powerhouse caverns (Figure 10). The scope of the model is 600 m×385 m×850 m, and the bottom and top elevations are 2139.7 and 2989.7 m (Figure 10(a)). Three main weak structures (faults spd9-f1, spd9-f2 and the lamprophyre dyke in Figure 1) were taken into account in the model. This model was divided into 562000 elements. Figure 10(b) illustrates the bench excavation steps of the numerical model. The mechanical parameters of rock mass and structures were obtained through field and laboratory tests, as shown in Tables 1 and 2. To compare with MS monitoring results and field failures, the I bench excavation and support of the underground powerhouse caverns was particularly simulated. The main support measure was systematic rock bolts. The lengths of rock bolts are 7 and 9 m at the arch and sidewall areas and 6 and 8 m at the headwall areas. Rock bolts with different lengths are staggered. The spacing between adjacent rock bolts is 1.5 m.

Five testing points in the scope of the model were selected for geostress back analysis. The least square method and multiple linear regression were used to minimize the residual between testing and calculating values. The horizontal lateral pressure coefficients parallel and perpendicular with the axis of the caverns were respectively 1.44 and 1.09. The geostress of vertical direction was almost equivalent to the gravity. The calculating results matched up well with the testing data. The bottom boundary was constrained in the vertical direction. The upper boundary was set free. Roller boundary conditions are assumed along the two high and perpendicular lateral sides, while the other two were stress boundaries. The Mohr-Coulomb elastic- plastic constitutive model was applied for mechanical calculation of this DEM model.

Figure 10 DEM model of underground powerhouse caverns:

Table 1 Mechanical parameters of rock mass

Table 2 Mechanical parameters of weak structures

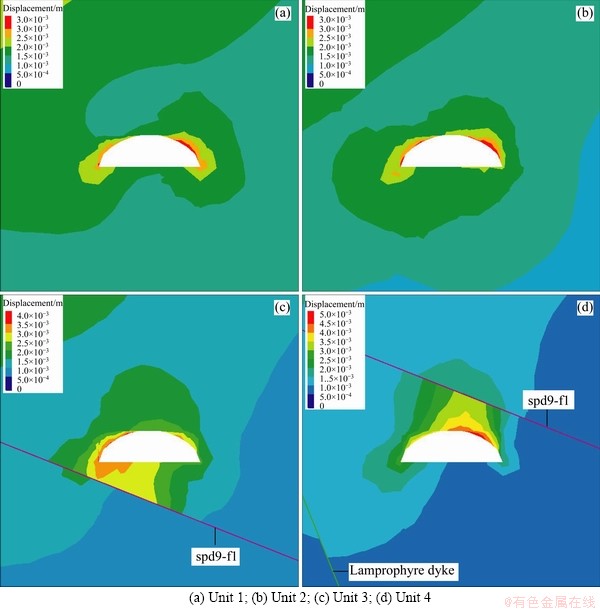

4.2 Simulation results

The main powerhouse is the most significant structure of the underground caverns and its deformation characteristics have great influences on the construction process. The representative displacements of each unit section of the main powerhouse after the I bench construction are shown in Figure 11. The main deformation of rock mass appears near the spandrels. The maximum displacements of units 1 and 2 sections are about 3.0 mm, while they are about 3.5 and 4.5 mm along units 3 and 4 sections. The fault spd9-f1 appears near the excavation elevation of units 3 and 4 sections, so the excavation-induced deformation of rock mass along units 3 and 4 sections spd9-f1 is larger. Due to the effect of stress concentration, rock mass large deformation tends to occur near the spandrels of the main powerhouse. In addition, a large number of MS events also accumulated in spandrel regions (Figure 4). Therefore, the spandrels of the main powerhouse are the main potential risk areas during the I bench construction.

Figure 12 illustrates the comparison among MS monitoring, numerical simulation and field failures. Lots of MS events accumulated near the lamprophyre dyke and many of them were of high energies and large magnitudes. Correspondingly, the simulated displacement of the rock mass in this region is the largest with the value more than 5.0 mm. A rock collapse occurred here, which was regarded as an integrated effect by high geostress and geological structure. The existence of geological structures around the arch areas of the main powerhouse would increase the failure risk of rock mass and must be particularly concerned.

Figure 11 Displacement contours of unit sections of main powerhouse after I bench excavation and support:

5 Discussion

As for high geostress underground powerhouse caverns, a lot of energies are stored in the deep rock mass. Intense unloading will cause frequent MS activities during the excavation construction. Thus, severe damage and failures of rock mass are likely to occur. In addition, the excavation-unloading induced stress adjustment and redistribution have a long process. Though the excavation has been finished, the MS activities may last for weeks or months. Therefore, time-dependent deformation of rock mass usually appears in high geostress underground powerhouse caverns.

Previous experience holds that when the geostress is extremely high, the weak structures in underground caverns have little effect on rock mass deformation and failures. That is to say, the dominant factor is high geostress. However, as mentioned in Section 3.3, a rock collapse controlled by integrated high geostress and geological structure was encountered in Shuangjiangkou underground powerhouse caverns. Similar failures also occurred in several other high geostress underground powerhouse caverns. These results indicate that even in high geostress underground caverns, the effects of weak structures still need to be paid enough attention.

Figure 12 Comparison among MS monitoring, numerical simulation and field failures:

Prior to a rock collapse controlled by integrated high geostress and geological structure, the MS activities show particular evolution laws, which were obtained in underground high geostress environment during the intense excavation construction process. For different geostress levels and construction states, the amount, energy release and apparent stress of MS events will have obvious differences, even though these parameters may have similar variation trends. Besides, the fracturing types of MS events are influenced by multiple factors and the amount and proportion of different fracturing types have more uncertainties for underground caverns under different geostress levels and construction states.

6 Conclusions

1) An MS monitoring system was established during the I bench excavation of the Shuangjiangkou underground powerhouse caverns. Due to the effect of high geostress, the MS events occurred frequently during the excavation period. However, a number of MS events still occurred when the excavation was suspended, as a result of the long process of stress adjustment and redistribution induced by excavation unloading. Four main damage zones (Zone I, II, III and IV in Figure 6(b)) around the arch areas of the main powerhouse were delineated.

2) A rock collapse influenced by high geostress and geological structure was encountered, which was not an exception at underground powerhouse engineering. Prior to such an instable disaster in underground high geostress environment during the intense excavation construction process, the MS event count and accumulated energy release increased rapidly. The apparent stress sharply increased and then decreased. In addition, the amount and proportion of shear and mixed MS events remarkably increased. The evolution mechanism of MS source parameters contributes to disaster forecasting and prevention of underground caverns.

3) The simulated maximum displacement of each section is generally located near the spandrel areas. The maximum displacement appears at the large-stake upstream spandrel where the lamprophyre dyke was exposed during the I bench excavation. The numerical simulation results were in good agreement with the MS monitoring data and field failures of rock mass. The geological structures in high geostress underground powerhouse caverns have great averse influences on rock mass damage and deformation.

Contributors

LI Biao conducted the literature review and wrote the first draft of the manuscript. DING Quan-fu carried out the numerical simulation. XU Nu-wen developed the overarching research goals and edited the draft of the manuscript. LEI Yi-fan processed the monitoring data. XU Yuan analyzed the evolution laws of MS parameters. ZHU Zhong-ping and LIU Jin-fei investigated and collected the geological and construction information of the engineering.

Conflict of interest

LI Biao, DING Quan-fu, XU Nu-wen, LEI Yi-fan, XU Yuan, ZHU Zhong-ping and LIU Jin-fei declare that they have no conflict of interest.

References

[1] QIAN Qi-hu, ZHOU Xiao-ping. Failure behaviors and rock deformation during excavation of underground cavern group for Jinping I Hydropower Station [J]. Rock Mechanics and Rock Engineering, 2018, 51(8): 2639-2651. DOI: 10.1007/s00603-018-1518-x.

[2] XIAO Ya-xun, FENG Xia-ting, FENG Guang-liang, LIU Hua-ji, JIANG Quan, QIU Shi-li. Mechanism of evolution of stress–structure controlled collapse of surrounding rock in caverns: A case study from the Baihetan hydropower station in China [J]. Tunnelling and Underground Space Technology, 2016, 51: 56-67. DOI: 10.1016/j.tust.2015.10.020.

[3] XU Nu-wen, LI Tian-bin, DAI Feng, LI Biao, ZHU Yong- guo, YANG Dian-sen. Microseismic monitoring and stability evaluation for the large scale underground caverns at the Houziyan hydropower station in Southwest China [J]. Engineering Geology, 2015, 188: 48-67. DOI: 10.1016/ j.enggeo.2015.01.020.

[4] GONG Feng-qiang, SI Xue-feng, LI Xi-bing, WANG Shan-yong. Experimental investigation of strain rockburst in circular caverns under deep three-dimensional high-stress conditions [J]. Rock Mechanics and Rock Engineering, 2019, 52(5): 1459-1474. DOI: 10.1007/s00603-018-1660-5.

[5] LUO Yong, GONG Feng-qiang, LI Xi-bing, WANG Shan-yong. Experimental simulation investigation of the influence of depth on spalling characteristics in circular hard rock tunnel [J]. Journal of Central South University, 2020, 27(3): 891-910. DOI: 10.1007/s11771-020-4339-5.

[6] MARTIN C D, READ R S, MARTINO J B. Observations of brittle failure around a circular test tunnel [J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(7): 1065-1073.DOI: 10.1016/S1365-1609(97)90200-8.

[7] ANDERSSON J C, MARTIN C D. The Aspo pillar stability experiment: Part I—experiment design [J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46(5): 865-878. DOI: 10.1016/j.ijrmms.2009.02.010.

[8] MAEJIMA T, MORIOKA H, MORI T, AOKI K. Evaluation of loosened zones on excavation of a large underground rock cavern and application of observational construction techniques [J]. Tunnelling and Underground Space Technology, 2003, 18(2, 3): 223-232. DOI: 10.1016/ S0886-7798(03)00031-2.

[9] KWON S, LEE C S, CHO S J, JEON S W, CHO W J. An investigation of the excavation damaged zone at the Kaeri underground research tunnel [J]. Tunnelling and Underground Space Technology, 2009, 24(1): 1-13. DOI: 10.1016/j.tust.2008.01.004.

[10] YAN Chang-bin. Blasting cumulative damage effects of underground engineering rock mass based on sonic wave measurement [J]. Journal of Central South University, 2007, 14(2): 230-235. DOI: 10.1007/s11771-007-0046-8.

[11] LI Shou-ju, YU He, LIU Ying-xi, WU Feng-ji. Results from in-situ monitoring of displacement, bolt load, and disturbed zone of a powerhouse cavern during excavation process [J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45: 1519-1525. DOI: 10.1016/j.ijrmms. 2008.01.012.

[12] YAN Peng, LU Wen-bo, CHEN Ming, HU Ying-guo, ZHOU Chuang-bing, WU Xin-xia. Contributions of in-situ stress transient redistribution to blasting excavation damage zone of deep tunnels [J]. Rock Mechanics and Rock Engineering, 2015, 48(2): 715-726. DOI: 10.1007/s00603-014-0571-3.

[13] LESNIAK A, ISAKOW Z. Space–time clustering of seismic events and hazard assessment in the Zabrze-Bielszowice coal mine, Poland [J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46: 918-928. DOI: 10.1016/ j.ijrmms.2008.12.003.

[14] HUDYMA M, POTVIN Y H. An engineering approach to seismic risk management in hardrock mines [J]. Rock Mechanics and Rock Engineering, 2010, 43: 891-906. DOI: 10.1007/s00603-009-0070-0.

[15] MA Ju, DONG Long-jun, ZHAO Guo-yan, LI Xi-bing. Focal mechanism of mining-induced seismicity in fault zones: A case study of Yongshaba Mine in China [J]. Rock Mechanics and Rock Engineering, 2019, 52: 3341-3352. DOI: 10.1007/s00603-019-01761-4.

[16] CAI M, KAISER P K, MARTIN C D. Quantification of rock mass damage in underground excavations from microseismic event monitoring [J]. International Journal of Rock Mechanics and Mining Sciences, 2001, 38: 1135-1145. DOI: 10.1016/S1365-1609(01)00068-5.

[17] MA Ke, TANG Chun-an, XU Nu-wen, LIU Feng, XU Jing-wu. Failure precursor of surrounding rock mass around cross tunnel in high-steep rock slope [J]. Journal of Central South University, 2013, 20: 207-217. DOI: 10.1007/ s11771-013-1478-y.

[18] FENG Guang-liang, FENG Xia-ting, CHEN Bing-rui, XIAO Ya-yun, YU Yang. A microseismic method for dynamic warning of rockburst development processes in tunnels [J]. Rock Mechanics and Rock Engineering, 2015, 48: 2061-2076. DOI: 10.1007/s00603-014-0689-3.

[19] FENG Guang-liang, FENG Xia-ting, CHEN Bing-rui, XIAO Ya-xun. Microseismic sequences associated with rockbursts in the tunnels of the Jinping II hydropower station [J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 80: 89-100. DOI: 10.1016/j.ijrmms.2015.06. 011.

[20] FENG Guang-liang, FENG Xia-ting, CHEN Bing-rui, XIAO Ya-xun, LIU Guo-feng, ZHANG Wei, HU Lei. Characteristics of microseismicity during breakthrough in deep tunnels: Case study of Jinping-II hydropower station in China [J]. International Journal of Geomechanics, 2020, 20(2): 04019163. DOI: 10.1061/(ASCE)GM.1943-5622. 0001574.

[21] FENG Guang-liang, FENG Xia-ting, CHEN Bing-rui, XIAO Ya-xun, ZHAO Zhou-neng. Effects of structural planes on the microseismicity associated with rockburst development processes in deep tunnels of the Jinping-II Hydropower Station, China [J]. Tunnelling and Underground Space Technology, 2019, 84: 273-280. DOI: 10.1016/j.tust.2018. 11.008.

[22] XU Nu-wen, LI Tian-bin, DAI Feng, ZHANG Ru, TANG Chun-an, TANG Lie-xian. Microseismic monitoring of Strainburst activities in deep tunnels at the Jinping II hydropower station, China [J]. Rock Mechanics and Rock Engineering, 2016, 49(3): 981-1000. DOI: 10.1007/s00603- 015-0784-0.

[23] DAI Feng, LI Biao, XU Nu-wen, FAN Yi-lin, ZHANG Chuan-qing. Deformation forecasting and stability analysis of large-scale underground powerhouse caverns from microseismic monitoring [J]. International Journal of Rock Mechanics and Mining Sciences, 2016, 86: 269-281. DOI: 10.1016/j.ijrmms.2016.05.001.

[24] DAI Feng, LI Biao, XU Nu-wen, ZHU Yong-guo. Microseismic early warning of surrounding rock mass deformation in the underground powerhouse of the Houziyan hydropower station, China [J]. Tunnelling and Underground Space Technology, 2017, 62: 64-74. DOI: 10.1016/j.tust. 2016.11.009.

[25] DHAWAN K R, SINGH D N, GUPTA I D. Three- dimensional finite element analysis of underground caverns [J]. International Journal of Geomechanics, 2004, 4: 224- 228. DOI: 10.1061/(ASCE)1532-3641(2004)4:3(224).

[26] ALEJANOA L R, REZ-OYANGUREN P, TABOADA J. FDM predictive methodology for subsidence due to flat and inclined coal seam mining [J]. International Journal of Rock Mechanics and Mining Sciences, 1999, 36(4): 475-491. DOI: 10.1016/S0148-9062(99)00022-4.

[27] HAO Y H, AZZAM R. The plastic zones and displacements around underground openings in rock masses containing a fault [J]. Tunnelling and Underground Space Technology, 2005, 20(1): 49-61. DOI: 10.1016/j.tust.2004.05.003.

[28] JING L. Formulation of discontinuous deformation analysis (DDA)—An implicit discrete element model for block systems [J]. Engineering Geology, 1998, 49(3): 371-381. DOI: 10.1016/S0013-7952(97)00069-0.

[29] CAI M, KAISER P K, MORIOKA H, MINAMI M, MAEJIMA T, TASAKA Y, KUROSE H. FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations [J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44: 550-564. DOI: 10.1016/j.ijrmms. 2006.09.013.

[30] YAZDANI M, SHARIFZADEH M, KAMRANI K, GHORBANI M. Displacement-based numerical back analysis for estimation of rock mass parameters in Siah Bisheh powerhouse cavern using continuum and discontinuum approach [J]. Tunnelling and Underground Space Technology, 2012, 28: 41-48. DOI: 10.1016/j.tust. 2011.09.002.

[31] Sichuan Dadu River Shuangjiangkou Hydropower Development Co., Ltd. Bidding document for the diversion system construction of the Shuangjiangkou hydropower station at the Dadu River, Sichuan Province [R]. 2016. (in Chinese)

[32] SI Xue-feng, GONG Feng-qiang. Strength-weakening effect and shear-tension failure mode transformation mechanism of rockburst for fine-grained granite under triaxial unloading compression [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 131: 104347. DOI: 10.1016/ j.ijrmms.2020.104347.

[33] ZHANG Bo-hu, DENG Jian-hui. Microseismic monitoring analysis methods for disaster prevention in underground engineering [J]. Disaster Advances, 2012, 5(4): 1420-1424.

[34] FENG Guang-liang, FENG Xia-ting, XIAO Ya-xun, YAO Zhi-bin, HU Lei, NIU Wen-jing, LI Tong. Characteristic microseismicity during the development process of intermittent rockburst in a deep railway tunnel [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 124: 104135. DOI: 10.1016/j.ijrmms.2019. 104135.

[35] WYSS M, BRUNE J N. Seismic moment, stress and source dimensions for earthquakes in the California-Nevada region [J]. Journal of Geophysical Research, 1968, 73(14): 4681- 4694. DOI: 10.1029/JB073i014p04681.

[36] ZHANG Peng-hai, YANG Tian-hong, YU Qing-lei, XU Tao, ZHU Wan-cheng, LIU Hong-lei, ZHOU Jing-ren, ZHAO Yong-chuan. Microseismicity induced by fault activation during the fracture process of a crown pillar [J]. Rock Mechanics and Rock Engineering, 2015, 48(4): 1673-1682. DOI: 10.1007/s00603-014-0659-9.

[37] LI Biao, XU Nu-wen, DAI Feng, ZHANG Gu-lan, XIAO Pei-wei. Dynamic analysis of rock mass deformation in large underground caverns considering microseismic data [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 122: 104078. DOI: 10.1016/j.ijrmms.2019. 104078.

[38] CAI M, KAISER P K, MARTIN C D. A Tensile model for the interpretation of microseismic events near underground openings [J]. Pure and Applied Geophysics, 1998, 153: 67-92. DOI: 10.1007/s000240050185.

[39] BOATWRIGHT J, FLETCHER J B. The partition of radiated energy between P and S waves [J]. Bulletin of the Seismological Society of America, 1984, 74(2): 361-376.

[40] GIBOWICZ S J, KIJKO A. An introduction to mining seismology [M]. San Diego: Academic Press, 1994: .

[41] ITASCA. 3 Dimensional Distinct Element Code User’s Guide [EB/OL]. Itasca Consulting Group, Inc.2016. https:// www.itascacg.com/software/3dec.

(Edited by HE Yun-bin)

中文导读

高地应力地下厂房洞室群开挖卸荷围岩力学响应与稳定性分析

摘要:为了研究中国西南地区双江口水电站高地应力地下厂房洞室群开挖卸荷围岩力学响应与稳定性,构建高精度微震监测系统,并采用离散元法开展数值模拟。分析了开挖卸荷引起的围岩时空损伤特征,研究了高地应力与结构面共同控制下围岩塌方形成过程微震震源参数演化规律。建立了地下厂房洞室群三维离散元数值模型,揭示了开挖卸荷引起的围岩变形特征。研究结果表明,高地应力地下厂房洞室群开挖卸荷引起的微震事件活动频繁,主厂房大桩号顶拱区域围岩损伤严重;在塌方发生前,微震事件数量和累积能量释放快速增长,视应力陡增之后出现下降,剪切以及混合型式的微破裂数量和占比显著增加;地下洞室最大位移基本位于拱肩区域。微震监测数据和数值模拟结果显示出较好的一致性,可为高地应力地下厂房洞室群围岩损伤评估和灾害预警提供重要参考。

关键词:高地应力;地下厂房洞室群;微震监测;离散元模拟;稳定性分析

Foundation item: Project(2017YFC1501100) supported by the National Key R &D Program of China; Projects(51809221, 51679158) supported by the National Natural Science Foundation of China

Received date: 2020-06-15; Accepted date: 2020-09-03

Corresponding author: XU Nu-wen, PhD, Professor; Tel: +86-28-85406701; E-mail: xunuwen@scu.edu.cn; ORCID: https://orcid.org/ 0000-0001-7714-7930

Abstract: To investigate the stability of rock mass in high geostress underground powerhouse caverns subjected to excavation, a microseismic (MS) monitoring system was established and the discrete element method (DEM)-based numerical simulation was carried out. The tempo-spatial damage characteristics of rock mass were analyzed. The evolution laws of MS source parameters during the formation of a rock collapse controlled by high geostress and geological structure were investigated. Additionally, a three-dimensional DEM model of the underground powerhouse caverns was built to reveal the deformation characteristics of rock mass. The results indicated that the MS events induced by excavation of high geostress underground powerhouse caverns occurred frequently. The large-stake crown of the main powerhouse was the main damage area. Prior to the rock collapse, the MS event count and accumulated energy release increased rapidly, while the apparent stress sharply increased and then decreased. The amount and proportion of shear and mixed MS events remarkably increased. The maximum displacement was generally located near the spandrel areas. The MS monitoring data and numerical simulation were in good agreement, which can provide significant references for damage evaluation and disaster forecasting in high geostress underground powerhouse caverns.