DOI:10.19476/j.ysxb.1004.0609.2018.10.04

2195铝锂合金平面应变压缩的流变行为与微观组织

李 旭1,樊祥泽1,杨庆波1,杨 谋1,张 飞1,张志清1, 2

(1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 重庆西彭产业工业园区,重庆 401326)

摘 要:

通过Gleeble-3500热模拟机在350~500℃温度范围对2195铝锂合金进行平面应变压缩实验,应变速率为0.01~1s-1,变形量60%。研究合金在高温下的流变行为并通过背散射电子衍射(EBSD)和X射线衍射(XRD)揭示了微观组织的演变规律。结果表明:流变应力随应变速率的增加而升高,而随着温度的升高流变应力降低,并且达到峰值应力和稳态流变时所需的应变也减少,建立含有双曲正弦关系的本构方程并得到合金的变形激活能Q为278.208kJ/mol;随着Zener-Hollomon参数值的增加,合金的流变集中增加,合金的软化机制主要是动态回复,此外还有动态再结晶形成,动态再结晶主要为不连续动态再结晶,而连续动态再结晶和几何动态再结晶均容易在较低Z值和较高Z值下形成;变形组织中含有大量的轧制织构,变形晶粒主要为S{123} 、Brass{011}

、Brass{011} 、Copper{112}

、Copper{112} 和Goss{011}

和Goss{011} 这4种取向。

这4种取向。

关键词:

文章编号:1004-0609(2018)-10-1980-11 中图分类号:TG146.2 文献标志码:A

Li元素是最轻的金属元素,在铝合金中每添加1%的锂可以使合金密度减少3%,弹性模量增加大约6%,并且Li元素加入铝合金可以引起很好的时效强化。铝锂合金因其低密度、高刚度、强度与断裂韧度良好的组合以及较高的疲劳裂纹抗性与腐蚀抗性等优点,而被认为是航空航天工业中理想的结构材料,在航空航天材料的激烈竞争中仍然有很强的竞争力[1-4]。AA2195铝合金是第三代铝锂合金,具有超高强度和卓越的低温性能,优良的可锻性与可焊性,由于其室温和低温下都具有出色的力学性能而得到了航空航天行业广泛的关注[2, 5]。与不含Li的传统合金2219相比,2195铝锂合金密度降低5%,而强度增加30%~40%,已经替代了2219合金而成功地在航天飞机的超轻燃料箱上得到应用[4, 6]。随着我国航空航天事业的迅猛发展,对轻质高性能铝锂合金的需求也日趋强烈,2195铝锂合金因其广泛的应用前景以及对航空航天工业的重大意义而得到了广泛研究。

出于工业应用的需求,2195铝锂合金一般需要加工为板、带等半成品,这便需要对原材料进行轧制、锻造等一系列热加工[4]。热加工过程与加工后材料的微观组织有着密切的联系,从而显著影响材料的力学性能[7],因此对热加工过程中材料的流变行为与微观组织演变的研究有重要意义。由于材料在热加工过程中会产生各种物理和力学行为,并且往往难以预测,而热加工物理模拟可以充分、精确地揭示材料热加工中组织与性能的变化规律[8],因此通过热模拟技术研究材料热加工有很大的优势。郑子樵、张志清以及印度的NAYAN等学者通过热模拟技术研究2195铝锂合金已经进行过一些工作[5, 9-12]。然而,常用的圆柱压缩容易受摩擦影响出现“鼓肚”现象,在较大应变时导致流变应力异常升高[13],对流变应力测定与微观组织观察均有影响,本文作者在之前对2195铝锂合金相同状态的圆柱压缩中也发现流变应力在稳态流变之后又出现明显升高[11]。相比之下,平面应变压缩的应力状态、变形状态、热传导等更接近于轧制,而且对流变应力的测定也更加精确[14]。通过平面应变压缩研究2195铝锂合金的流变行为,建立合金本构方程,对变形中的流变应力能有比较准确的反映,同时也能揭示微观组织演变中更多方面的信息,对该合金高温塑性加工的工艺优化与组织控制都有一定的指导意义。

1 实验

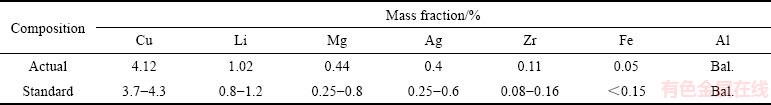

实验所用材料为西南铝业(集团)有限责任公司提供的2195铝锂合金铸锭,其化学成分如表1所示。

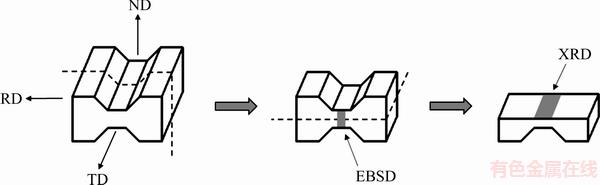

合金选用的双极均匀化工艺为(440 ℃, 16 h)+ (490 ℃, 20 h)。将均匀化后的合金线切割为20mm×15mm×10mm的试样,在Gleeble-3500热模拟机上进行恒应变速率等温平面应变压缩实验,压缩在20mm×15mm的面上进行,压头宽度为5mm,变形后在压缩面上应变量符合设定值的有效变形区为20mm×5mm。将试样以5 ℃/s分别加热到350、400、450和500℃并保温3min,分别在应变速率0.01、0.1和1s-1时进行真应变为0.916(变形量60%)的平面应变压缩,压缩后立即水淬以保留变形组织。所得流变应力数据通过Oringin 8 软件处理得到相应曲线。变形后的试样沿图1所示位置切开,对截面进行打磨与电解抛光,在TESCAN MIRA3场发射扫描电镜下使用EBSD对截面中间区域的显微组织、取向分布进行表征,并用Channel 5软件对数据进行处理。通过Rigaku 2500PC X射线衍射仪对试样进行XRD测试以分析其宏观织构。试样的分析位置如图1所示。

2 结果与讨论

2.1 流变应力与本构方程

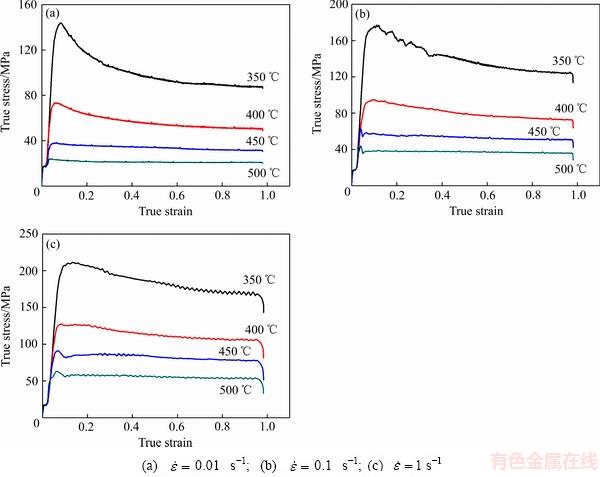

合金在变形温度为350~500℃、应变速率0.01~1s-1时的真应力-真应变曲线如图2所示。可以发现,对于本实验中所有的变形条件,随着应变的增加,流变应力均迅速上升至峰值之后再逐渐降低,直至达到稳态流变,表现为动态再结晶型的流变应力曲线[7]。在同一温度下流变应力随应变速率的增加而升高,说明2195铝锂合金有正的应变速率敏感性;在同一应变速率下,随着温度的升高,流变应力降低,并且达到峰值应力和稳态流变时的应变也减少。

金属热变形时的流变应力是变形体内部组织演变的综合反映[9],在材料热变形时,组织会发生加工硬化和动态软化这两方面变化。变形初期,位错的增殖与交互作用会造成强烈的加工硬化效果,而软化效果主要靠位错的攀移和交滑移,不足以抵消加工硬化,因此加工硬化是主要现象;随着应变的增加,变形储存能增加并开始出现动态回复和动态再结晶,动态软化逐渐增强,随着动态软化与加工硬化效果相当并随后强于加工硬化,流变应力便表现出峰值应力;随着变形进一步进行,流变应力趋于稳定,材料达到稳态流变。应变速率升高则材料变形时间减少,位错增殖和运动速度更快,高的位错密度导致更高的临界切应力[15],并且材料没有充足的时间发生动态回复和动态再结晶,流变应力更大。而变形温度升高,原子能量也会提高,位错的运动性提升,材料塑性增强,而且动态软化也更加充分[16],同时高的变形温度可以使一些析出相溶解[17],流变应力减少。此外,温度越高材料发生动态再结晶的临界应变εc和最大软化率应变ε*应变均会减少[18],更充分的动态软化可能是引起材料达到峰值应力和稳态流变所需应变量减少的原因。

材料在热变形中的流变行为与变形参数关系密切,流变应力本构方程能在一定条件下反映流变应力与变形参数之间的关系,对材料的加工工艺有较大的指导意义。研究表明热加工本构方程在低应力水平和高应力水平下分别有如下两种形式[19]。

表1 2195铝锂合金的化学成分

Table 1 Chemical composition of 2195 Al-Li alloy

图1 试样分析位置示意图

Fig. 1 Schematic diagram of observing areas of samples

图2 2195铝锂合金的真应力-真应变曲线

Fig. 2 True stress-true strain curves of 2195 Al-Li alloy deformed at different strain rates

低应力水平下:

(1)

(1)

高应力水平下:

(2)

(2)

而对于所有的应力水平,由SELLARS和MCTEGART所建立的带有双曲正弦函数的本构方程更为适用,形式如式(3)所示[20]:

(3)

(3)

本实验中采用式(3)建立2195铝锂合金的本构方程,其中A, 和n是常数;R为摩尔气体常数;Q是变形激活能,其中

和n是常数;R为摩尔气体常数;Q是变形激活能,其中 的值可由关系式

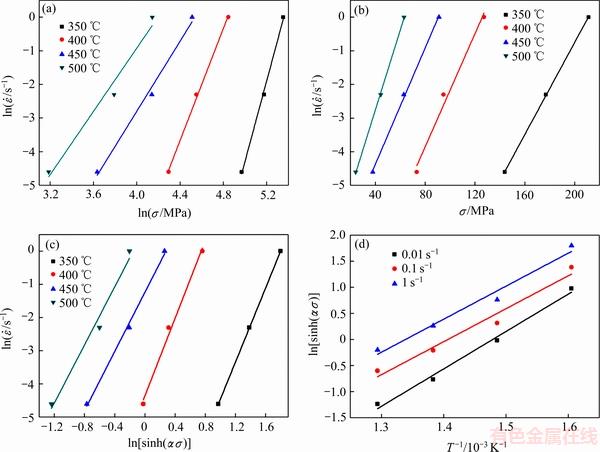

的值可由关系式 =β/n1得到。对式(1)和(2)两边分别求自然对数,取各变形条件下的峰值应力为流变应力值,图3(a)和(b)所示分别为以

=β/n1得到。对式(1)和(2)两边分别求自然对数,取各变形条件下的峰值应力为流变应力值,图3(a)和(b)所示分别为以 和

和 、

、 和

和 为坐标作图并进行线性回归的结果,

为坐标作图并进行线性回归的结果, 可由图3(a)和(b)的直线平均斜率计算出为0.01183。

可由图3(a)和(b)的直线平均斜率计算出为0.01183。

对式(3)两边取对数可得:

(4)

(4)

变形激活能Q可由式(5)求得:

(5)

(5)

图3(c)和(d)所示分别为 和

和 、

、 和1/T的关系图,由直线的平均斜率可得n=5.0679,Q=278.208 kJ/mol。

和1/T的关系图,由直线的平均斜率可得n=5.0679,Q=278.208 kJ/mol。

不同变形温度和应变速率的效果可以用ZENER和HOLLOMON[21]提出的温度补偿应变速率因子(Z参数)来表示,Z参数的表达如式(6)所示:

(6)

(6)

对式(6)两边取自然对数可得:

(7)

(7)

图3 各参数之间的关系

Fig. 3 Correlations among  -

- (a),

(a),  -

- (b),

(b),  -

- (c) and

(c) and  -1/T (d)

-1/T (d)

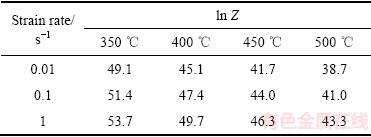

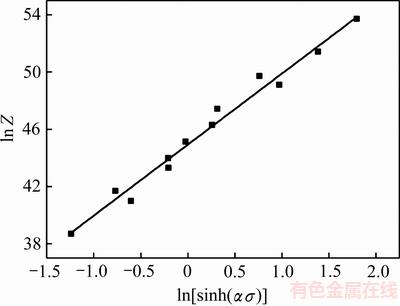

根据式(7)可求得所有变形条件下 值如表2所示,由图4中

值如表2所示,由图4中 与

与 的直线关系的截距可求得A=3.26×1019。

的直线关系的截距可求得A=3.26×1019。

由此可得出2195铝锂合金平面应变压缩的本构方程为

(8)

(8)

变形激活能Q值是一个重要的物理参量,被认为是塑性变形困难程度的反映[22]。本实验中得出2195铝锂合金的Q值为278.208 kJ/mol,略高于文献[9]、[10]计算出的2195铝锂合金变形激活能250.34 kJ/mol和226.7 kJ/mol。对Q值造成影响的因素通常有很多,由于平面应变压缩应力状态较圆柱压缩更接近于轧制,对样品有更大的端面约束,变形抗力通常大于圆柱压缩,且文献[9]实验中的加热速率更缓慢,保温时间更长,材料更易于变形,Q值较本实验中的更小;此外,本实验中的温度范围较文献[10]的更广,在更低温度下更难变形可能是造成计算出的Q值大于文献[10]所得结果的原因。

表2 不同变形条件下2195铝锂合金的ln Z值

Table 2 ln Z values of 2195 Al-Li alloy under different deformation conditions

图4 ln Z- 的关系

的关系

Fig.4 Correlation between ln Z-

2.2 微观组织

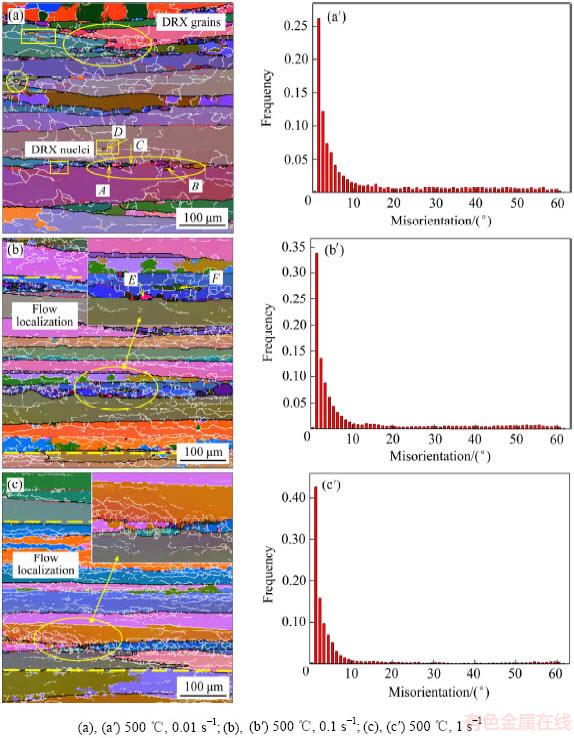

图5所示为材料在500 ℃不同应变速率下变形组织的全欧拉角图与晶界取向差分布图。全欧拉角图中白色和红色线条分别表示取向差2°~10°和10°~15°的小角晶界,黑色线条表示取向差大于15°的大角晶界。可以发现,3种应变速率下的变形组织均为沿RD方向伸长的典型带状变形组织。当应变速率为0.01s-1时,带状变形组织的宽度较大,晶界平直清晰,变形组织与晶界分布均匀。当应变速率增加至0.1s-1时,变形组织与晶界明显集中,主要分布在图5(b)中虚线之间宽度大约400μm的区域,表现出明显的流变集中现象[23]。随着应变速率增加至1s-1,变形组织与晶界的集中区域宽度更小,大约为300μm。可以看出随着应变速率增加流变集中现象更加严重,这是由于在高的应变速率下晶粒没有充足的时间进行协调,则易于变形的区域集中了更大的应变,变形组织不均匀,并且变形抗力也会升高,因此流变集中也是导致流变应力随应变速率增加而升高的一个因素。

图5 500℃下变形组织的全欧拉角图与取向差分布图

Fig. 5 All Euler maps and MAD histograms of 2195 Al-Li alloy deformed under different conditions

从500℃下不同应变速率的变形组织EBSD结果可以发现,应变速率为0.01s-1时,组织中含有大量取向差小于15°的小角晶界,仅有少量取向差大于15°的大角晶界,这是由于在变形过程中位错大量增殖,位错密度升高,而铝合金作为高层错能的金属很容易发生动态回复,因此在热变形中位错容易聚集,通过“多边形化”形成大量小角晶界,此外,应变速率为0.01s-1时还可以观察到有明显的动态再结晶形成,因此合金在(500℃, 0.01s-1)的热变形条件下动态回复和动态再结晶均为动态软化的方式。然而由全欧拉角图和取向差分布可知,大部分晶界为小角晶界,再结晶体积含量并不显著,则动态回复为合金的主要动态软化机制。随着应变速率增加至0.1和1s-1,大角晶界的相对含量进一步降低,动态再结晶的数目与尺寸均减少,说明动态再结晶更容易在低的应变速率下发生。这主要是由于在低的应变速率下,动态再结晶有足够的时间进行形核与长大。因此动态软化效果也更加充分,流变应力也更低。

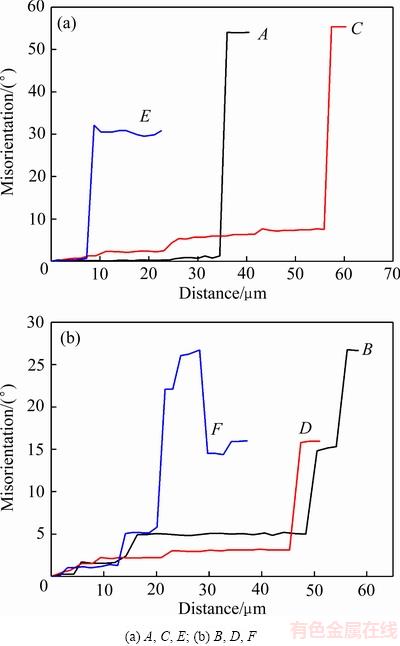

可以发现,动态再结晶主要分布在晶界节点处和原始晶界附近,形成明显的链状结构,也有少数再结晶晶粒形成于变形晶粒内部,再结晶较为明显的区域如图中圆圈所示,此外还存在正在形成动态再结晶晶核的区域(见图5中方框所示区域)。由于再结晶在形核与长大过程中仍要经受变形[24],因此有些再结晶晶粒内部存在取向差甚至小角晶界。铝合金中的动态再结晶主要有连续动态再结晶、不连续动态再结晶和几何动态再结晶这几种方式[25],其中不连续动态再结晶有明显的形核与长大过程,连续动态再结晶由小角晶界转变为大角晶界形成,而几何动态再结晶由变形晶粒的破碎产生。由图5可知,500 ℃下变形带较宽,难以观察到由弓出晶界接触引起的晶粒破碎,因此发生几何动态再结晶的可能性很小。为了区分晶界附近和变形晶粒内部两种动态再结晶的取向差变化,由变形晶粒内部沿箭头所示轨迹分别向3个晶界附近的再结晶(A, C, E)和3个变形晶粒内部的再结晶(B, D, F)取累计取向差,结果如图6所示。由图6(a)可以观察到晶界处的再结晶仅在晶界处有明显取向差变化,取向差值远大于大角晶界的临界值15°,原始晶界呈锯齿状且有明显的弓出现象,这主要是由于在变形中应变诱导晶界迁移导致晶界弓出形成再结晶晶核,因此可以判断发生了不连续动态再结晶[26]。而由图6(b)可知变形晶粒内部的再结晶晶粒在晶界附近的区域都有明显的取向差变化,沿着箭头所示轨迹取向差呈阶梯状逐渐上升,且取向差值仅略大于15°,说明此类再结晶主要是由小角晶界逐渐转变为大角晶界而形成,呈现出典型的连续动态再结晶的特征[27]。由图5(a)方块中的形核区域同样可以观察到由晶界弓出形成的不连续动态再结晶晶核以及由小角晶界转变为大角晶界形成的连续动态再结晶晶核。铝锂合金发生动态再结晶的机制并不单一,并且应变进行到一定程度,小角晶界通过旋转和吸收位错使取向差增加,才会发生连续动态再结晶[28],由此可见2195铝锂合金在500℃平面应变压缩主要发生不连续动态再结晶,此外还有少量连续动态再结晶形成。

图6 箭头方向累计取向差

Fig. 6 Cumulative misorientation along arrows shown in Fig. 5

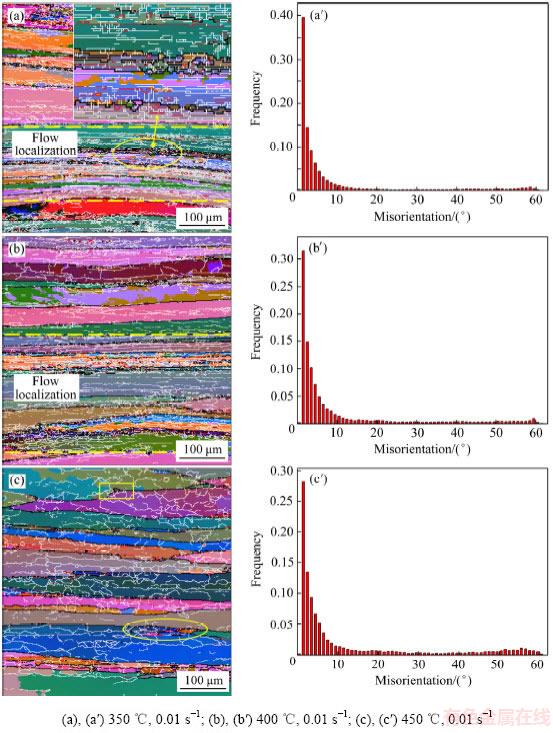

图7所示为应变速率为0.01 s-1变形温度为350~450 ℃时变形组织的全欧拉角图与取向差分布图。由图7可以发现,在同一应变速率下,随着温度的降低同样有更加明显的流变集中现象,各温度下的动态软化仍然主要是动态回复,且均有动态再结晶的发生,仍以原始晶界附近的不连续动态再结晶为主,这也与应力应变曲线均为动态再结晶型的结果吻合,随着温度的升高,动态再结晶的数目与尺寸均增加,说明温度越高动态再结晶进行的越充分。温度为350℃和400℃时很难观察到连续动态再结晶,但有明显的晶粒破碎以及贯穿变形带的新形成的晶粒,如图7(a)的流变集中区域所示,沿变形晶粒伸长方向有颜色相同(即表示取向基本相同)的细小晶粒分布,这是由于在低温下流变集中严重且变形带宽度很小,弓出的晶界容易接触使变形晶粒破碎形成新的晶粒,因此可以判断在350℃和400℃下还发生了少量几何动态再结晶,而450℃时变形带已经较宽且流变集中不明显,难以观察到几何动态再结晶但有少量连续动态再结晶。由此可知几何动态再结晶更容易在低温形成,高温更容易发生连续动态再结晶。应变速率与变形温度的综合效果可由Z参数描述,可以发现,在Z值低的状态下(如(500℃, 0.01s-1),(500℃, 0.1s-1))变形组织更均匀,更容易观察到连续动态再结晶,很难发生几何动态再结晶,而在Z值高的状态下(如(350℃, 0.01s-1),(400℃、0.01s-1))流变集中严重,更容易发生几何动态再结晶而很难观察到连续动态再结晶。

图7 应变速率0.01s-1时的全欧拉角图与取向差分布图

Fig. 7 All Euler maps and MAD histograms of 2195 Al-Li alloy deformed under different conditions

综上可知,在本文所有Z参数下合金的动态软化机制主要为动态回复,此外均有动态再结晶发生,低的Z值下动态再结晶进行的更充分,动态再结晶以不连续动态再结晶为主,此外还有少量其他方式形成的再结晶。随着Z值升高流变集中增加,更有可能出现几何动态再结晶,而连续动态再结晶更容易在低的Z值下形成。

2.3 宏观织构

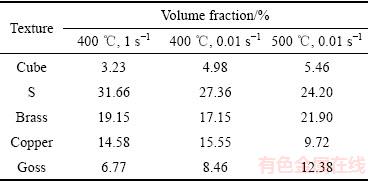

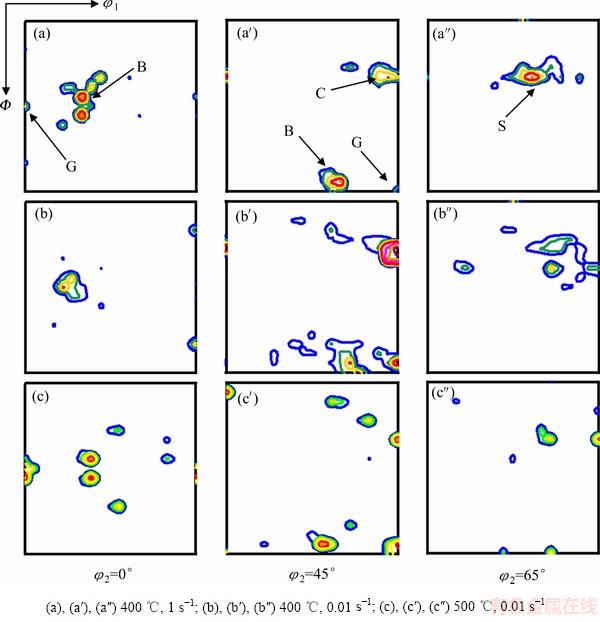

图8所示为(400℃, 1s-1)、(400℃, 0.01s-1)、(500℃, 0.01s-1)下变形组织几种主要织构的ODF图。由图8可以观察到3种变形条件下组织含有明显的Brass{011} 、Copper{112}

、Copper{112} 、Goss{011}

、Goss{011} 和S{123}

和S{123} 织构,织构种类没有明显差别,均为典型的轧制织构。通过Labtex软件以相对于理想取向15°的欧拉角偏差为标准对3种变形状态下几种典型织构的体积分数进行计算,结果如表3所示。可以发现变形试样均含有强烈的S和Brass织构,其中S织构体积分数最大,而Copper织构和Goss织构的含量较少且试样之间略有差别,Cube晶粒的含量微弱同样可以说明再结晶进行的不充分。因此2195铝锂合金经平面压缩之后变形晶粒主要为这4种轧制取向的晶粒。织构可以造成2195铝锂合金严重的各向异性[29],各向异性是制约铝锂合金广泛应用的障碍之一,并且有研究表明变形晶粒的取向与动态再结晶的形成也有密切的联系[30],而再结晶的形成又可以削弱合金的各向异性[2],因此对织构的控制可以改善合金的微观组织与力学性能,相关的问题尚需进一步研究。

织构,织构种类没有明显差别,均为典型的轧制织构。通过Labtex软件以相对于理想取向15°的欧拉角偏差为标准对3种变形状态下几种典型织构的体积分数进行计算,结果如表3所示。可以发现变形试样均含有强烈的S和Brass织构,其中S织构体积分数最大,而Copper织构和Goss织构的含量较少且试样之间略有差别,Cube晶粒的含量微弱同样可以说明再结晶进行的不充分。因此2195铝锂合金经平面压缩之后变形晶粒主要为这4种轧制取向的晶粒。织构可以造成2195铝锂合金严重的各向异性[29],各向异性是制约铝锂合金广泛应用的障碍之一,并且有研究表明变形晶粒的取向与动态再结晶的形成也有密切的联系[30],而再结晶的形成又可以削弱合金的各向异性[2],因此对织构的控制可以改善合金的微观组织与力学性能,相关的问题尚需进一步研究。

表3 不同变形状态下几种重要织构组分的体积分数

Table 3 Volume fraction of several important texture components under different deformation conditions

图8 2195铝锂合金中变形组织的ODF图

Fig. 8 ODF sections of 2195 Al-Li alloy deformed under different conditions

3 结论

1) 2195铝锂合金平面应变压缩时,流变应力随应变速率的增加而升高,随着变形温度的升高流变应力降低,并且达到峰值应力和稳态流变时所需的应变也减少。合金的本构方程为

。

。

2) 合金在热变形过程中的软化机制主要是动态回复,并且有动态再结晶发生,随着变形温度的升高与应变速率的降低,变形组织更加均匀,大角晶界相对含量增加,动态再结晶进行的更充分,即动态再结晶更容易在低的Z值下形成。

3) 合金的动态再结晶机制主要为不连续动态再结晶,此外还有少量其他种类的再结晶形成;Z值越高流变集中越严重,更容易发生几何动态再结晶,而连续动态再结晶更容易在低的Z值下形成。

4) 合金在平面应变压缩后的变形组织含有典型的轧制织构,变形晶粒主要有S{123} 、Brass{011}

、Brass{011} 、Copper{112}

、Copper{112} 和Goss{011}

和Goss{011}  四种取向,以S和Brass取向最为强烈。

四种取向,以S和Brass取向最为强烈。

REFERENCES

[1] 郑子樵, 李劲风, 陈志国, 李红英, 李世晨, 谭澄宇. 铝锂合金的合金化与微观组织演化[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

ZHENG Zi-qiao, LI Jin-feng, CHEN Zhi-guo, LI Hong-ying, LI Shi-chen, TAN Cheng-yu. Alloying and microstructural evolution of Al-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2337-2351.

[2] RIOJA R J. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications[J]. Materials Science and Engineering A, 1998, 257(1): 100-107.

[3] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56(4): 862-871.

[4] NAYAN N, MURTY S V S N, CHHANGANI S, PRAKASH A, PRASAD M J N V, SAMAJDAR I. Effect of temperature and strain rate on hot deformation behavior and microstructure of Al-Cu-Li alloy[J]. Journal of Alloys and Compounds, 2017, 723: 548-558.

[5] 蒋 呐, 李劲风, 郑子樵, 任文达, 韩冬峰. 2195铝锂合金多道次热变形流变应力的模拟研究[J]. 稀有金属材料与工程, 2007, 36(6): 949-953.

JIANG Na, LI Jin-feng, ZHENG Zi-qiao, REN Wen-da, HAN Dong-feng. Simulation on flow stress of multi-pass hot deformation of 2195 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2007, 36(6): 949-953.

[6] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[7] ZHU Rui-hua, LIU Qing, LI Jin-feng, XIANG Sheng, CHEN Yong-lai, ZHANG Xu-hu. Dynamic restoration mechanism and physically based constitutive model of 2050 Al-Li alloy during hot compression[J]. Journal of Alloys and Compounds, 2015, 650: 75-85.

[8] 高 增, 牛济泰. 材料物理模拟技术的发展及其在中国的应用[J]. 机械工程材料, 2014, 38(11): 1-6.

GAO Zeng, NIU Ji-tai. Development of materials physical simulation technology and its application in China[J]. Materials for Mechanical Engineering, 2014, 38(11): 1-6.

[9] 韩冬峰, 郑子樵, 蒋 呐, 李劲风. 高强可焊2195铝-锂合金热压缩变形的流变应力[J]. 中国有色金属学报, 2004, 14(12): 2090-2095.

HAN Dong-feng, ZHENG Zi-qiao, JIANG Na, LI Jin-feng. Flow stress of high-strength weldable 2195 aluminium-lithium alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2090-2095.

[10] YANG Qing-bo, WANG Xin-zhu, LI Xu, DENG Zan-hui, JIA Zhi-hong, ZHANG Zhi-qing, HUANG Guang-jie, LIU Qing. Hot deformation behavior and microstructure of AA2195 alloy under plane strain compression[J]. Materials Characterization, 2017, 131: 500-507.

[11] 杨庆波, 李 旭, 张 飞, 向晨星, 张志清, 林 林. AA2195铝合金圆柱体单向压缩热变形行为和微观组织演变[J]. 功能材料, 2017, 48(7): 7163-7168.

YANG Qing-bo, LI Xu, ZHANG Fei, XIANG Chen-xing, ZHANG Zhi-qing, LIN Lin. Hot deformation behavior microstructure evolution of AA2195 aluminum alloy under cylinder uniaxial compression[J]. Journal of Functional Materials, 2017, 48(7): 7163-7168.

[12] NAYAN N, GURAO N P, MURTY S V S N, JHA A K, PANT B, SHARMA S C, GEPRGE K M. Microstructure and micro-texture evolution during large strain deformation of an aluminium-copper-lithium alloy AA 2195[J]. Materials and Design, 2015, 65: 862-868.

[13] Li Y P, ONODERA E, MATSUMOTO H, CHIBA A. Correcting the stress-strain curve in hot compression process to high strain level[J]. Metallurgical and Materials Transactions A, 2009, 40(4): 982-990.

[14] 潘红波, 唐 荻, 胡水平, 王潇潇. 平面应变压缩技术的研究[J]. 锻压技术, 2008, 33(2): 75-79.

PAN Hong-bo, TANG Di, HU Shui-ping, WANG Xiao-xiao. Study on plane strain physical compression technology[J]. Forging and Stamping Technology, 2008, 33(2): 75-79.

[15] WU B, LI M Q, MA D W. The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy[J]. Materials Science and Engineering A, 2012, 542(18): 79-87.

[16] YIN Hao, LI Hong-ying, SU Xiong-jie, HUANG De-sheng. Processing maps and microstructural evolution of isothermal compressed Al-Cu-Li alloy[J]. Materials Science and Engineering A, 2013, 586(6): 115-122.

[17] HUANG Xu-dong, ZHANG Hui, HAN Yi, WU Wen-xiang, CHEN Jiang-hua. Hot deformation behavior of 2026 aluminum alloy during compression at elevated temperature[J]. Materials Science and Engineering A, 2010, 527(3): 485-490.

[18] 杨胜利, 沈 健, 闫晓东, 李锡武, 孙宝庆, 毛柏平. 基于Al-Cu-Li合金流变行为的动态再结晶动力学与形核机制[J]. 中国有色金属学报, 2016, 26(2): 365-374.

YANG Sheng-li, SHEN Jian, YAN Xiao-dong, LI Xi-wu, SUN Bao-qing, MAO Bai-ping. Dynamic recrystallization kinetics and nucleation mechanism of Al-Cu-Li alloy based on flow behavior[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 365-374.

[19] MCQUEEN H J, RVAN N D. Constitutive analysis in hot working[J]. Materials Science and Engineering A, 2002, 322(1): 43-63.

[20] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[21] ZENER C, HOLLOMON J H. Effect of Strain Rate Upon Plastic Flow of Steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[22] LIU Wen-yi, ZHAO Huan, LI Dan, ZHANG Zhi-qing, HUANG Guang-jie, LIU Qing. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature[J]. Materials Science and Engineering A, 2015, 596(4): 176-182.

[23] YANG Xu-sheng, CHAI Lin-jiang, HUANG Wei-jiu, MA Yan-long, ZHANG Zhen-hao. EBSD analysis on restoration mechanism of as-extruded AA2099 Al-Li alloy after various thermomechanical processes[J]. Materials Chemistry and Physics, 2017, 191: 99-105.

[24] 杨胜利, 沈 健, 闫晓东, 李锡武, 孙宝庆, 张 飞. Al-Cu-Li-Mg-Mn-Zn-Ag合金的热变形流变行为与本构方程[J]. 中国有色金属学报, 2015, 25(8): 2083-2090.

YANG Sheng-li, SHEN Jian, YAN Xiao-dong, LI Xi-wu, SUN Bao-qing, ZHANG Fei. Flow behavior and constitutive equations of Al-Cu-Li-Mg-Mn-Zn-Ag alloy during isothermal compression[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2083-2090.

[25] GOURDET S, MONTHEILLET F. An experimental study of the recrystallization mechanism during hot deformation of aluminium[J]. Materials Science and Engineering A, 2000, 283(1/2): 274-288.

[26] KASHIHARA K, KONISHI H, SHIBAVANAGI T. Strain-induced grain boundary migration in {112} / {100}

/ {100} and {123}

and {123} /{100}

/{100} aluminum bicrystals[J]. Materials Science and Engineering A, 2011, 528(29/30): 8443-8450.

aluminum bicrystals[J]. Materials Science and Engineering A, 2011, 528(29/30): 8443-8450.

[27] GOURDET S, MONTHEILLET F. A model of continuous dynamic recrystallization[J]. Acta Materialia, 2003, 51(9): 2685-2699.

[28] SHEN Bo, DENG Lei, WANG Xin-yun. A new dynamic recrystallisation model of an extruded Al-Cu-Li alloy during high-temperature deformation[J]. Materials Science and Engineering A, 2015, 625: 288-295.

[29] 李红英, 欧 玲, 郑子樵. 2195铝锂合金的各向异性研究[J]. 材料工程, 2005, 10: 31-34.

LI Hong-ying, OU Ling, ZHENG Zi-qiao. Study on the Anisotropy of 2195 Al-Li alloy[J]. Journal of Materials Engineering, 2005, 10: 31-34.

[30] WANG Xin-yun, SHEN Bo, DENG Lei, LI Jian-jun. Effects of original orientation combination on substructure characteristics during continuous dynamic recrystallization in an extruded Al-Cu-Li alloy[J]. Materials Characterization, 2017, 130: 113-122.

Flow behavior and microstructure of 2195 Al-Li alloy during plane strain compression

LI Xu1, FAN Xiang-ze1, YANG Qing-bo1, YANG Mou1, ZHANG Fei1, ZHANG Zhi-qing1, 2

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Chongqing Xipeng Industrial Park, Chongqing 401326, China)

Abstract: Plane strain compression tests of AA2195 aluminum alloy were conducted on Gleeble-3500 system in the temperature range from 350 ℃ to 500 ℃ and at strain rate range from 0.01s-1 to 1s-1 with 60% thickness reduction. The flow behavior was studied in present work and the microstructure was revealed by electron backscatter diffractometry(EBSD) and X-ray diffractometry(XRD). The results show that the stress increases with the increase of strain rate whereas decreases with the increase of temperature, the peak strain and the critical strain for attaining steady state decreases with increasing temperature. A constitutive equation based on the hyperbolic sine equation is established with the deformation activation energy is calculated to be 278.208 kJ/mol. Flow localization increases with the increase of the value of Zener-Hollomon parameter, the basic softening mechanism is dynamic recovery(DRV), besides, dynamic recrystallization(DRX) occurs and is mainly discontinuous recrystallization(DDRX), continuous recrystallization(CDRX) and geometric recrystallization(GDRX) occurs more easily in lower Z value and higher Z value, respectively. Significant amounts of the major rolling texture components, namely, S{123} , Brass{011}

, Brass{011} , Copper{112}

, Copper{112} and Goss{011}

and Goss{011} are observed at deformed samples.

are observed at deformed samples.

Key words: 2195 Al-Li alloy; plane strain compression; flow behavior; microstructure

Foundation item: Project(106112017CDJQJ328840) supported by the Fundamental Research Funds for the Central Universities of China

Received date: 2017-03-28; Accepted date: 2018-07-25

Corresponding author: ZHANG Zhi-qing; Tel: +86 -10-65678750; E-mail: zqzhang@cqu.edu.cn

(编辑 龙怀中)

基金项目:中央高校基本科研基金资助项目(106112017CDJQJ328840)

收稿日期:2017-03-28;修订日期:2018-07-25

通信作者:张志清,教授,博士;电话:023-65678750;E-mail: zqzhang@cqu.edu.cn

摘 要:通过Gleeble-3500热模拟机在350~500℃温度范围对2195铝锂合金进行平面应变压缩实验,应变速率为0.01~1s-1,变形量60%。研究合金在高温下的流变行为并通过背散射电子衍射(EBSD)和X射线衍射(XRD)揭示了微观组织的演变规律。结果表明:流变应力随应变速率的增加而升高,而随着温度的升高流变应力降低,并且达到峰值应力和稳态流变时所需的应变也减少,建立含有双曲正弦关系的本构方程并得到合金的变形激活能Q为278.208kJ/mol;随着Zener-Hollomon参数值的增加,合金的流变集中增加,合金的软化机制主要是动态回复,此外还有动态再结晶形成,动态再结晶主要为不连续动态再结晶,而连续动态再结晶和几何动态再结晶均容易在较低Z值和较高Z值下形成;变形组织中含有大量的轧制织构,变形晶粒主要为S{123} 、Brass{011}

、Brass{011} 、Copper{112}

、Copper{112} 和Goss{011}

和Goss{011} 这4种取向。

这4种取向。

[1] 郑子樵, 李劲风, 陈志国, 李红英, 李世晨, 谭澄宇. 铝锂合金的合金化与微观组织演化[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

[5] 蒋 呐, 李劲风, 郑子樵, 任文达, 韩冬峰. 2195铝锂合金多道次热变形流变应力的模拟研究[J]. 稀有金属材料与工程, 2007, 36(6): 949-953.

[8] 高 增, 牛济泰. 材料物理模拟技术的发展及其在中国的应用[J]. 机械工程材料, 2014, 38(11): 1-6.

[9] 韩冬峰, 郑子樵, 蒋 呐, 李劲风. 高强可焊2195铝-锂合金热压缩变形的流变应力[J]. 中国有色金属学报, 2004, 14(12): 2090-2095.

[11] 杨庆波, 李 旭, 张 飞, 向晨星, 张志清, 林 林. AA2195铝合金圆柱体单向压缩热变形行为和微观组织演变[J]. 功能材料, 2017, 48(7): 7163-7168.

[14] 潘红波, 唐 荻, 胡水平, 王潇潇. 平面应变压缩技术的研究[J]. 锻压技术, 2008, 33(2): 75-79.

[29] 李红英, 欧 玲, 郑子樵. 2195铝锂合金的各向异性研究[J]. 材料工程, 2005, 10: 31-34.

LI Xu1, FAN Xiang-ze1, YANG Qing-bo1, YANG Mou1, ZHANG Fei1, ZHANG Zhi-qing1, 2

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Chongqing Xipeng Industrial Park, Chongqing 401326, China)

Key words: 2195 Al-Li alloy; plane strain compression; flow behavior; microstructure

Received date: 2017-03-28; Accepted date: 2018-07-25

Corresponding author: ZHANG Zhi-qing; Tel: +86 -10-65678750; E-mail: zqzhang@cqu.edu.cn