![]()

Trans. Nonferrous Met. Soc. China 22(2012) 1732-1737

Simulation of extrusion process of complicated aluminium profile and die trial

HE Zhao1, WANG He-nan1, WANG Meng-jun1,2, LI Guang-yao2

1. Key Laboratory of Nonferrous Metal Materials Science and Engineering of Ministry of Education,

Central South University, Changsha 410083, China;

2. State Key Laboratory of Advanced Design and Manufacture for Vehicle Body, Hunan University,Changsha 410082, China

Received 5 August 2011; accepted 14 December 2011

Abstract:

The arbitrary Lagrangian-Eulerian(ALE) adaptive remeshing technology and the HyperXtrude software of transient finite element simulations were used on analogue simulation of aluminium extrusion processing. The field distributions of strain rate, stress, temperature and velocity of metal flow were obtained. The results are basically consistent with the experiment, which indicates that this method may successfully predict the defects in the actual extrusion process.

Key words:

transient finite element simulations; complicated aluminium profile; arbitrary Lagrangian-Eulerian(ALE) method; die trial;

1 Introduction

At present, the use of aluminium profile is becoming wider and wider in different industries because of its excellent properties. Aluminium processing is a complex metal deformation process, including thermal deformation, heat transfer, and a complex friction state. The traditional complex section profile extrusion and the design of extrusion dies are primarily based on engineering analogue and designing experience. The defects of product in extrusion process can be eliminated by adjusting processing technique. However, it cannot satisfy the requirements of high-speed development of the aluminium processing. It is very important to build a proper “process simulation” [1,2]. The finite element method can be used for the simulation of the extrusion process. However, the application of this kind of simulations in the extrusion industry is limited because of the complexity involved.

Both finite element method (FEM) and the finite volume method (FVM) have their own advantages and have been widely adopted in the numerical simulation of aluminium extrusion process. The finite element analysis was applied to simulating the bulk forming process [3] and DEFORM 3D based on the updated Lagrangian approach was used to obtain the field distributions of strain rate,stress, temperature and velocity of metal flow [4-6]. The finite element analysis was also applied to examining the complex material flow in multi-hole extrusion process [7-9]. Finite volume method has been introduced into the simulation of plastic deformation process, especially the simulation of aluminium profile extrusion process [10]. FVM based on Euler mesh is used to simulate three-dimensional steady or transient of aluminium alloy profile hot extrusion process [11]. Thixo forward extrusion process was analyzed and simulated by finite volume method [12]. WILLIAMS et al [13] established a computational model of metal extrusion and forging processes by finite volume methods on unstructured meshes. GANVIR et al [14] proposed a method for simulation of extrudate swell using an arbitrary Lagrangian Eulerian (ALE) technique based on finite element formulation. The ALE technique provides advantages of both Lagrangian and Eulerian frameworks by allowing the computational mesh to move in an arbitrary manner, independent of the material motion. By providing an appropriate mesh form to describe the object’s displacement and maintain a reasonable element shape, and adopting the free surface modification method to describe the moving boundary of the sample, mesh distortion was avoided, and the high-precision numerical calculation was completed faster. HyperXtrude software uses the arbitrary Lagrangian Eulerian code adaptive remeshing technology.

In this work, the research object is the complex section profiles obtained from a factory. The conditions of temperature field, velocity field, stress and strain rate field are investigated and analyzed in certain parameters of metal with HyperXtrude software. The possible defects in practical extrusion process were predicted. The simulation results and mould testing results were compared.

2 Mould design and building of geometrical model

2.1 Profiles size and physical boundary conditions

The HyperXtrude software package was used for analogue simulation, which has been applied to the simulation of extrusion processes of aluminium profile. In this numerical experiment, a porthole die was designed to produce a complex section profile. Figure 1 illustrates sectional size of the profile. The minimum thickness was 1.01 mm, the section area was 844.1 mm2, the dimensions of the column billet for simulation were d220 mm×500 mm, the extrusion ratio was about 42.9, and the punch velocity was 5×10-3 m/s. The material properties of 6063 aluminium alloy were given in the HyperXtrude database, and the material of the die was H13 steel.

2.2 Material model

The constitutive equation of aluminium alloy 6063[15] is:

σ=59.5ln{[Z/(1.904×1013)]+{[Z/(1.904×1013)]2/8.47+1}1/2}(1)

where Z is ![]() exp[-173.78/(RT)]; R is the mole gas constant, 8.314 J/(mol·K); T is the thermodynamic temperature.

exp[-173.78/(RT)]; R is the mole gas constant, 8.314 J/(mol·K); T is the thermodynamic temperature.

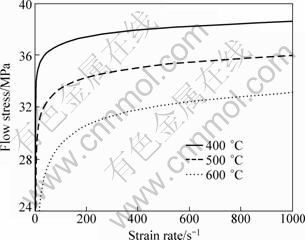

The extrusion parameters of 6063 Al alloy used in simulation are given as follows: elastic modulus is 4.0×104 MPa, density is 2.7×103 kg/m3, Poisson ratio is 0.333, heat transfer coefficient between the billets and dies is 3000 W/(m2·K), heat conductivity is 198 W/(m·K), specific heat is 900 J/(kg·K), and the initial extrusion temperatures for billets, dies and container are 480, 450 and 430 °C, respectively. Figure 2 shows the relationship between flow stress and temperature for 6063 Al alloy.

2.3 Friction model

Violent friction exists between liquid metal and dies, and has a great influence on the forming process of products during the extrusion process. Common friction model includes Coulomb friction model and the plastic shear friction model.

Coulomb friction model is defined as:

τ=μσn (2)

where μ is the friction factor; σn is contact normal stress between workpiece and dies.

Plastic shear friction model is defined as:

τ=mk (3)

where the range of linear sticky friction factor m is 0-1, and k is the shear yield stress of material.

There exists a large contact stress between the workpiece and the cavity/container during the extrusion process of aluminium profile. When the workpiece surface adheres to cavity and inner container, it is suitable for using plastic shear friction model. The friction on the bearing wall causes the flow of the workpiece to slow down in that region, also causes a large shear force. It is right to use Coulomb friction model when the workpiece comes to bearing area because of the reduction of contact stress. As a result, the friction type between workpiece and cavity/container is fit for the plastic shear friction model, and the friction factor (m) of 0.3 is used for simulation in this work. Taking Coulomb friction model for this type between billets and bearing, friction coefficient (μ) of 0.4 was performed.

Fig. 1 Cross-section shape and sectional size of extrudate (Unit: mm)

Fig. 2 Material model for 6063 Al alloy correlating flow stress with strain rate and temperature

2.4 Building of model and meshing

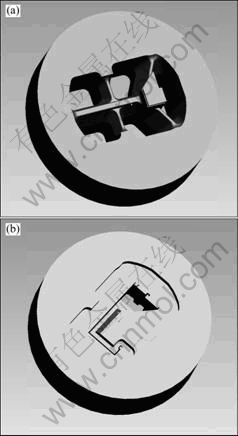

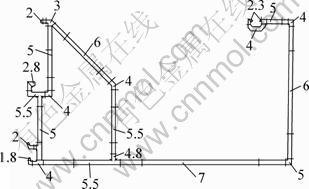

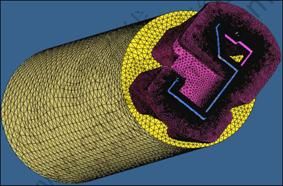

The dimensions of die mandrel and die cap are d348 mm×114 mm and d348 mm×117 mm, respectively. Figure 3 illustrates the geometrical model of die. Figure 4 shows the design of the bearing length, which is used to control the local exit velocity of the material. In the steady-state simulation it is only necessary to solve flow and heat transfer. The used mesh is presented in Fig. 5, and consists of 864 hexahedron and 135 and tetrahedron elements, which is shown in Table 1. The performed simulations are dependent on these mesh densities at this refinement level.

Fig. 3 Geometrical model of die: (a) Upper die; (b) Lower die

Fig. 4 Length of bearing used in simulation (Unit: mm)

Fig. 5 Finite element mesh of aluminium geometry used in simulation

Table 1 Distribution of mesh elements in geometries

3 Analogue simulation and discussion of results

3.1 Analysis of stress and strain rate contours

The steady-state distributions of stress and strain rate in the extrusion process are illustrated in Fig. 6, from which the complexity of metal flow from billets to the extrudate can also be seen. The welding quality in the welding plane can be affected by many process variables, when extrusion loads, welding pressure, and metal flow from a container to the die exit are examined respectively, which are based on various billet temperatures, bearing lengths, and wall thicknesses.

Fig. 6 Distribution of stress and strain rate: (a) Distribution of stress; (b) Distribution of strain rate

At first, an upsetting was used for billets under extrusion pressure. Secondly, billets were divided through several portholes that were gathered within a chamber, and then were welded under high pressure. Finally, metal from bearing wall became the products needed. This weldability classifies the quality of products and is affected by process variables and die shapes. Porthole die extrusion has a great advantage in the production of hollow sections, which is difficult to product by conventional extrusion. A greater stress—strain was formed because of a severe friction between billets and cavity/container in whole process. In Fig. 6, the maximum stress value is about 50 MPa, and the maximum strain rate value is about 460 s-1 at the exit. When the reaction forces on the aluminium–die interface are applied to the die, stresses in the die can be calculated, by which extrusion pressure was estimated to be about 23 MN.

3.2 Analysis of temperature contours

Plastic deformation temperature depends on the initial extrusion temperature of the billets and die, the thermal deformation, and the heat absorbed from the surroundings. The temperature distribution has a direct effect on the flow stress of the alloy. The flow stress strongly influences the velocity distribution in the container and die, the flow in the die, the quality of welding, and the shape of the section. It also influences the recrystallisation process and furthermore influences mechanical properties of the extruded section [16]. Surface quality was also strongly influenced by the temperature at the exit of extrusion die, especially for some online quenched profiles. By analyzing the profile of the temperature contours the energy was generated by internal friction between billets and die/container, but the energy transfer mechanism is mainly heat transfer. Therefore, the surface temperature of billets still goes down, and gradient grade shows gradient outside introversion oneself degressive change. Figure 7 presents the temperature contours of the steady-state solution. The high strain rates in the region of the bearing shown in Fig. 6 cause the temperature to rise in this region before diffusing along the length of the extrudate.

Fig. 7 Temperature distribution of workpiece

3.3 Analysis of velocity contours

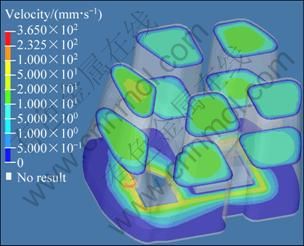

The principal goal of die design of extrusion is to obtain the stable and uniform metal flow under the condition of die life. The velocity distribution of metal flow in porthole and welding chamber is shown in Fig. 8. It illustrates that bore 1 fills most quickly, but the other bores are accordant. The flow velocity of material between die and material is much more slow than internal flow rate because of interfacial friction in each bore. When the metal reached welding chamber, metal flow at both ends became more quickly, which possibly affected local exit velocity of the material.

Fig. 8 Velocity distribution of porthole and welding chamber

Figure 9 shows the exit velocity distribution of the profile by the analogue simulation of HyperXtrude. The results of the simulation represent the velocities at the start of the extrusion process, which gives an indication of how the nose-end of the profile will be look. It is clear to see from Fig. 9 that the middle part has a relative low exit velocity compared with the end of the profile. The maximum velocity is 204 mm/s, and the minimum velocity is 87 mm/s. The difference in velocity may lead to the warped deformation. Based on these results the design of the bearing area can be modified to compensate for this velocity difference. The optimum design of this die is to shorten the bearing length of the middle part.

Fig. 9 Velocity distribution at bearing exit

4 Discussion and die testing

Most research efforts usually aimed at an optimum die design, which may achieve a balanced flow at the die exit and may avoid the defects of aluminium profile such as bending and twist. It is difficult to obtain a good experimental verification of the numerical results. However, a simple comparison with the actual exit velocity can be obtained by analyzing the nose-end of the profile.

This nose-end is shown in Fig. 10, which shows that the distribution of exit velocity has the similar trend as the calculated result. The extrusion parameters including extrusion speed, initial forming temperature and billet dimension are the same as those adopted in analogue simulation. The difference in speed will shrink if the land length of the middle becomes short. Both the finite element simulation result and the experimental verification agreed very well, which will help to design a more productive extrusion process.

Fig. 10 Nose-end of profile

It is difficult to estimate the accuracy of the simulations presented because it is nearly impossible to perform accurate measurements on the extrusion process in practice. However, the results show good agreement with overall process characteristics like total extrusion pressure and exit velocity.

5 Conclusions

1) Because of unbalanced flow at the exit of extrusion die, defects of aluminium profile such as warped deformation and bending can be successfully forecasted. Extrusion process with an optimized die land results in more uniform velocity distribution as demonstrated from the simulations.

2) The good agreement between the finite element simulation results and the experimental results shows that HyperXtrude Software of the finite method can forecast the distortion trend of extrusion process effectively.

3) It is important to design the effective dies and process. To reduce variations in the extrusion process, it is important to focus on controlling the flow and the temperature evolution in the container and die. When the complexity of aluminium profile is promoting and die design becomes more difficult, traditional die design experience of the trial and the error will be replaced by analogue simulation technology in the future.

References

[1] YAN Hong, BAO Zhong-xu, LIU He-sheng. Study progress on aluminium profile extrusion die CAD/CAE/CAMM [J]. Light Alloy Fabrication Technology, 1999, 27(10): 1-4. ( in Chinese)

[2] LIN Gao-yong, ZHOU Jia, ZHENG Xiao-yan. Numerical simulation of extrusion process of X5214 aluminum alloy profile [J]. Journal of Central South University Technology, 2008, 39(4): 748-754. ( in Chinese)

[3] LI G, JINN J T, WU W T. Recent development and applications of three-dimensional finite element modeling in bulk forming process [J]. Journal of Materials Processing Technology, 2001, 113: 40-45.

[4] ZHOU J, LI L, DUSZCZYK J. 3D FEM simulation of the whole cycle of aluminum extrusion throughout the transient state and the steady state using the updated Lagrangian approach [J]. Journal of Materials Processing Technology, 2003, 134: 383-397.

[5] LI Q, SMITH C J, HARRIS C. Finite element investigations upon the influence of pocket die designs on metal flow in aluminum extrusion Part I. Effect on pocket angle and volume on metal flow [J]. Journal of Materials Processing Technology, 2003, 135:189-196.

[6] CHANDA T, ZHOU J, DUSZCZYK J. FEM analysis of aluminum extrusion through square and round dies [J]. Materials and Design, 2000, 21: 323-335.

[7] CHEN F K, CHUANG W C, SHAN T. Finite element analysis of mutli-hole extrusion of aluminum-alloy tubes [J]. Journal of Materials Processing Technology, 2008, 201: 150-155.

[8] FANG G, ZHOU J, DUSZCZYK J. FEM simulation of aluminum extrusion through two-hole multi-step pocket dies [J]. Journal of Materials Processing Technology, 2009, 209:1891-1990.

[9] PENG Z, SHEPPARD T. Effect of die pockets on multi-hole die extrusion [J]. Materials Science and Engineering A, 2005, 407: 89-97.

[10] LI Da-yong, LUO Chao, ZHOU Fei, PENG Ying-hong. Simulation of thin-walled aluminum decoration part extrusion process with multi-stage finite volume method [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 1360-1365. (in Chinese)

[11] LOU S M, ZHAO G Q, WANG R, WU X H. Modeling of aluminum alloy profile extrusion process using finite volume method [J]. Journal of Materials Processing Technology, 2008, 206: 481-490.

[12] JAFARI M R, ZEBARJAD S M, KOLAHAN F. Simulation of thixoformability of A356 aluminum ally using finite volume method [J]. Materials Science and Engineering A, 2007, 454-455: 558-563.

[13] WILLIAMS A J, CROFT T N, CROSS M. Computational modeling of metal extrusion and forging process [J]. Journal of Materials Processing Technology, 2002, 125-126: 573-582.

[14] GANVIR V, LELE A, THAOKAR R, GAUTHAM B P. Prediction of extrudate swell in polymer melt extrusion using an arbitrary Lagrangian Eulerian (ALE) based finite element method [J]. Journal of non-Newtonian Fluid Mechanics, 2009, 156:21-28.

[15] WANG Meng-jun, YANG Li-bin, GAN Chun-lei, PENG Da-shu. Constitutive equation of the flow for 6063 aluminium alloy at elevated temperature [J]. Journal of Huazhong University of Science and Technology: Natural Science Edition, 2003, 31(6): 20-22. (in Chinese)

[16] LOF J, BLOKHUIS Y. FEM simulations of the extrusion of complex thin-walled aluminium sections [J]. Journal of Materials Processing Technology, 2002, 122: 344-354.

复杂铝型材挤压过程的模拟与试模

何 钊1,王赫男1,王孟君1,2,李光耀2

1. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

2. 湖南大学 汽车车身先进设计与制造实验室,长沙 410082

摘 要:采用任意拉格朗日-欧拉描述法(ALE) 的自适应网格划分技术,运用HyperXtrude软件对铝加工的挤压过程进行仿真模拟,获得挤压时金属流动的应力—应变场、温度场以及速度场,并将模拟仿真结果与试模结果进行对比分析,其结果基本一致,证明运用该仿真模拟方法可以预测实际生产过程中的一些缺陷。

关键词:瞬态有限元模拟;复杂铝型材;任意拉格朗日-欧拉描述法;试模

(Edited by YANG Hua)

Foundation item: Project (2009A080205003) supported by the Major Science and Technology Project of Guangdong Province, China; Project (30815009) supported by the Foundation of State Key Laboratory of Advanced Design and Manufacture for Vehicle Body, China

Corresponding author: WANG Meng-jun; Tel: +86-731-88836408; E-mail: wmj1965@yahoo.com.cn

DOI: 10.1016/S1003-6326(11)61380-0

Abstract: The arbitrary Lagrangian-Eulerian(ALE) adaptive remeshing technology and the HyperXtrude software of transient finite element simulations were used on analogue simulation of aluminium extrusion processing. The field distributions of strain rate, stress, temperature and velocity of metal flow were obtained. The results are basically consistent with the experiment, which indicates that this method may successfully predict the defects in the actual extrusion process.