文章编号:1004-0609(2014)11-2805-08

铝合金表面激光熔覆NiCrAl/TiC复合涂层的磨损行为和耐蚀性能

李 琦,刘洪喜,张晓伟,姚 爽,张 旭

(昆明理工大学 材料科学与工程学院,昆明 650093)

摘 要:

摘 要:为提高铝合金的摩擦磨损和耐蚀性能,在A390铝合金基体上通过激光熔覆制备NiCrAl/TiC复合涂层。采用XRD和EDS分析了涂层的物相组成,结合SEM观察了涂层的微观组织,运用摩擦磨损试验机和电化学工作站测试了涂层的摩擦磨损和耐腐蚀性能。结果表明:复合涂层主要物相为AlNi、Al3Ni2、TiC,同时含有少量的Cr13Ni5Si2、Cu9Al4和α(Al)。涂层自下至上分别为短棒状树枝晶、胞状晶、柱状树枝晶和等轴晶。相同磨损条件下,A390基体发生了严重的磨粒磨损和剥层磨损,而激光熔覆涂层只产生了轻微的磨粒磨损,熔覆层的相对耐磨性为3.16。在3.5% NaCl溶液中的极化曲线和电化学阻抗谱(EIS)显示:熔覆层自腐蚀电位较A390基体的正移,腐蚀电流密度减小;熔覆层呈单容抗特性,而A390基体在高频区表现为容抗特性,在中低频区则为感抗特性。在Bote图中,低频区熔覆层对应的相位角和中低频段熔覆层的阻抗模值均大于A390基体的,表明熔覆层的耐蚀性远高于A390基体的。熔覆层的腐蚀形貌为局部点蚀,A390基体的腐蚀形貌为晶间腐蚀和剥蚀。

关键词:

中图分类号:TN 249;TB 331 文献标志码:A

Wear behavior and corrosion resistance of NiCrAl/TiC composite coating on aluminum alloy by laser cladding

LI Qi, LIU Hong-xi, ZHANG Xiao-wei, YAO Shuang, ZHANG Xu

(Faculty of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: In order to improve the frictional wear behavior and corrosion resistance of aluminum alloy, NiCrAl/TiC composite coating was fabricated on A390 aluminum alloy by laser cladding. The phase constitution, microstructure, frictional wear behavior and corrosion resistance of the composite coating were analyzed using X-ray diffraction (XRD), energy dispersive spectrum (EDS), scanning electron microscope (SEM), friction and wear testing machine and electrochemical workstation. The results show that the coating is mainly composed of AlNi, Al3Ni2 and TiC phases, and a small amount of Cr13Ni5Si2, Cu9Al4 and α(Al) phases. The microstructures of the coating from the bottom to top are dendrite crystal, cellular crystal, columnar dendrite crystal and equiaxed crystal, respectively. Under the same wear condition, A390 substrate exhibits serious abrasive wear and peeling characteristics, while the cladding coating exhibits slight abrasive wear behavior. The relative wear resistance of cladding coating is 3.16. The polarization curves and electrochemical impedance spectroscopy (EIS) in 3.5% NaCl solution indicate that the corrosion potential of the coating is more positive than that of the matrix, and the corrosion current density decreases significantly. The coating exhibits capacitive reactance behavior, but A390 substrate exhibits capacitive reactance in high frequency area and impedance in medium low frequency area. In Bote diagram, the phase angle of composite coating in low frequency area and the impedance modulus value of coating in low-middle frequency are larger than those in the matrix. This proves that the composite coating has better corrosion resistance compared to that of A390 aluminum alloy. The corrosion morphology of the cladding coating is localized pitting, but the corrosion morphology of A390 matrix is intergranular corrosion and erosion.

Key words: aluminum alloy; composite coating; laser cladding; wear behavior; corrosion resistance

由于铝合金密度小、比强度高、热胀系数低和导热性好,具有较好的可焊性和力学性能而被普遍用作轻金属结构材料[1-2]。但摩擦磨损和耐蚀性能差又限制了其在复杂环境下的进一步广泛使用。通常铝合金零件的磨损、腐蚀发生在表面或表面层,为克服其固有不足,现已采用渗碳、渗氮,微弧氧化、物理气相沉积、化学气相沉积、离子注入、等离子体浸没离子注入与沉积等不同表面改性方法在铝合金表面制备了各种耐磨耐蚀涂层[3-8]。然而,这些方法在实际应用中普遍存在涂层薄或涂层与基材结合强度弱等缺点,而激光熔覆可将高熔点粉末熔覆在低熔点基材表面,使之形成与基材呈冶金结合特征的熔覆层,从而显著提高铝合金基材的表面硬度、耐磨性和耐蚀性等性能,因此近年来受到了研究者的青睐[9-10]。

但激光熔覆粉末与基材的热物理性能不匹配容易导致涂层出现气孔和裂纹等缺陷。为得到表面光滑平整、内部无气孔、裂纹且与基材结合牢固的熔覆层,人们分别从热处理、调整激光工艺参数及外加能量场等多个角度进行了探索,最终发现影响熔覆层质量的关键因素还主要在于根据基材选用合适的激光熔覆粉末材料[11-14]。而NiCrAl合金是典型的第二代快速凝固高温镍基合金,可作为一些机械零件表面耐蚀、耐高温、抗氧化的防护层,并且在铝硅合金表面激光熔覆NiCrAl合金能减小开裂倾向[15-16]。但NiCrAl熔覆涂层的耐磨性不理想,承受高温冲蚀磨损工件表面的NiCrAl涂层容易发生磨损失效。研究结果表明:TiC具有耐高温、抗氧化、强度和硬度高、导热性及韧性好等优点,且TiC增强金属基复合材料与金属配副时具有较低的摩擦因数。同时,TiC与金属Ni在1450~1500 ℃时的润湿角为17°~38°,有利于获得基材与涂层良好的界面结合[17]。鉴于此,本文作者选用NiCrAl和TiC为混合粉末,利用CO2激光器在A390铝合金表面制备了NiCrAl/TiC复合涂层,分析了涂层的表面质量和微观结构特征,测试了涂层的摩擦磨损和耐腐蚀性能,并通过磨损和腐蚀形貌观测探讨熔覆涂层的磨损与腐蚀机制。

1 实验

1.1 试样制备

基材选用过共晶Al-Si系A390铝合金,其主要化学成分(质量分数)为:Si: 16%~18%、Cu: 4%~5%、Mg: 0.45%~0.65%、余量为Al)。表面经线切割后进行喷丸处理(增加铝合金表面粗糙度,以提高铝合金表面对激光能量的吸收),并用丙酮和酒精反复擦洗,以去除试样表面残存的氧化物、杂质和油污等。熔覆材料选择纯度为99.8%、粒度100 μm的NiCrAl(Cr: 18%、Al: 6%、余量为Ni,质量分数)和纯度为99.8%、粒度100 μm的TiC混合粉末。熔覆层表面宏观形貌随TiC含量增加而变差,为兼顾熔覆层表面宏观形貌和性能,二者质量比最终定为88:12。用有机粘结剂将混合粉末预置在A390铝合金基材表面(预置层厚度1.0 mm,宽度5 mm)并放入干燥箱中70 ℃干燥5 h待用。

熔覆涂层制备在GS-TFL-6000型横流多模CO2激光器上进行。具体工艺参数如下:激光功率4.0 kW,扫描速度400 mm/min,离焦量45 mm,圆形光斑尺寸5 mm,Ar保护气流速25 L/min(纯度99.99%)。

1.2 涂层结构和性能表征

通过线切割将激光熔覆试样沿垂直于激光扫描方向切取后制成金相试样,使用王水(HNO3和HCl体积比为1:3)腐蚀金相试样截面10~15 s,并经XL30 ESEM-TMP型扫描电子显微镜(SEM)观察熔覆层的组织形貌,然后运用XL30 ESEM-TMP型扫描电镜(SEM)及其所附的Phoenix+OIM能谱仪(EDS)分析熔覆层中不同区域的元素分布。

借助D/max-3BXJ型X射线(Cu Kα)衍射仪分析激光熔覆复合涂层试样的物相组成,管压40 kV,管流30 mA,连续扫描模式,扫描速率10 (°)/min,衍射角范围20°~90°。通过MMU-5型屏显盘-销式端面摩擦磨损试验机测试涂层在室温环境和干滑动条件下的摩擦磨损性能,上试样为沿涂层表面截取的d 4 mm×15 mm圆销,下试样为Cr12MoV标准环(57~59HRC),试验力5 N,转速100 r/min,磨损时间125 min,总滑动距离1056 m。磨损质量损失采用感量为0.1 mg的电子天平称量。

熔覆层在3.5%(质量分数)NaCl溶液中的极化曲线和电化学阻抗谱(EIS)由CHI660D电化学工作站来完成。电极配制为标准三电极模式,工作电极为经砂纸打磨平整后的熔覆层,裸露在溶液中的面积1 cm2,参比电极为饱和甘汞(SCE),辅助电极为铂片。极化曲线测量电势范围-2.2~0.2 V,扫面速率10 mV/s,静置时间2 s。在自腐蚀电位下进行电化学阻抗谱测量,交流电压振幅为5 mV,频率范围为10 mHz~100 kHz。激光熔覆涂层磨损和腐蚀后的形貌通过扫描电子显微镜(SEM)观察。

2 结果与讨论

2.1 涂层的物相分析

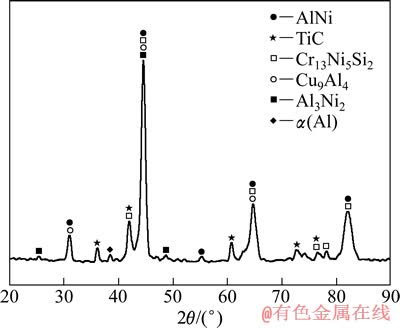

图1所示激光熔覆涂层的XRD谱。从图1可知,熔覆层主要组成为AlNi、Al3Ni2和TiC,同时还含有少量的Cr13Ni5Si2、Cu9Al4及α(Al)相。少量Cr13Ni5Si2、Cu9Al4及α(Al)相的存在表明在激光熔覆过程中,铝合金基体内部的合金元素进入到了涂层。预置粉末中n(Ni):n(Al)约为6:1,由于Ni含量较高,理应与Al反应最终形成Ni3Al相,但熔覆层却未见Ni3Al相。这主要是因为在熔覆过程中,低熔点、低密度铝合金基材熔化后与熔池上部高熔点、高密度的Ni基粉末发生对流,从而降低了熔池中Ni和Al的摩尔比,导致Ni与Al反应生成成分范围很宽且呈体心立方结构的β-AlNi相[18-19]。另外,在熔覆层中亦未发现有富余单质Ni,这从侧面也验证了熔池中对流的存在。

2.2 涂层的显微组织

图1 激光熔覆层的XRD谱

Fig. 1 XRD pattern of laser cladding coating

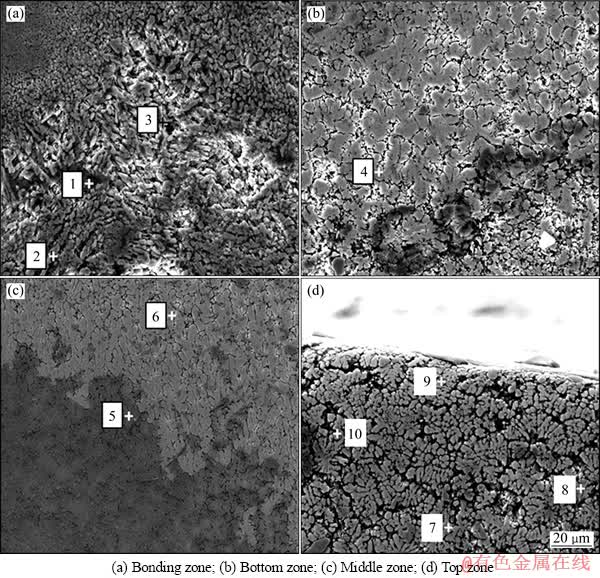

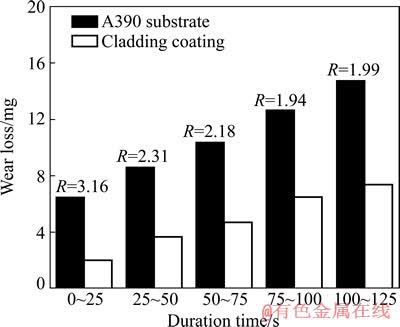

图2所示为沿垂直于激光束扫描方向熔覆层横截面的SEM像。表1所列为图2中各区域对应的元素成分含量(EDS分析结果)。

由图2可知,自结合区至熔覆层顶部分别为枝晶、胞状晶和及等轴晶。根据表1,结合区Al的稀释作用明显,这是熔覆层与基材实现冶金结合的条件。熔覆层底部n(Al):n(Ni)约为3:2,对应物相为Al3Ni2相;熔覆层中部n(Al):n(Ni)接近1:1。可见柱状树枝晶为高温稳定性较好的AlNi相(其有序-无序转变温度远高于熔点,在高温熔池中可稳定存在)。点6处n(Ti):n(C)约为1:1,表明较大TiC颗粒发生分解后在AlNi柱状晶晶间发生了Ti与C的再结晶,形成细小的TiC颗粒。熔覆层顶部等轴晶晶间镶嵌着尺寸较小的TiC颗粒(约5 μm),起到弥散强化作用。

图2 熔覆层不同部位的显微组织

Fig. 2 Microstructures of cladding coating at different positions

表1 图2中不同部位的EDS元素成分分析结果

Table 1 EDS analysis results of element chemical composition at different positions shown in Fig.2

2.3 涂层的磨损行为

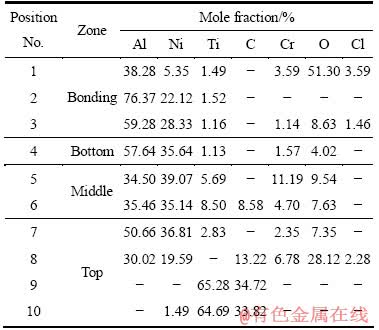

图3 A390基体和熔覆层的磨损性能

Fig. 3 Wear properties of A390 substrate and cladding coating

图3所列为基材和熔覆层在相同磨损条件下125 min内不同磨损时间段的磨损质量损失对比。从图3中可以看出,激光熔覆涂层试样在125 min内的磨损质量损失为7.4 mg,A390基材的为14.73 mg,从而求得熔覆层在125 min内的相对耐磨性R为1.99(不同磨损时间内的相对耐磨性用R表示在图中)。由于熔覆层较脆,在长时间的磨损过程中会有少量片状剥落,因此,考虑熔覆层在磨损剥落之前的相对耐磨性更能体现其耐磨性能。本研究中所制备的激光熔覆复合涂层在25 min后开始有剥落现象发生,故在仅考虑磨损参数对相对耐磨性影响的前提下,前25 min的磨损行为更符合实际,其相对耐磨性R为3.16。

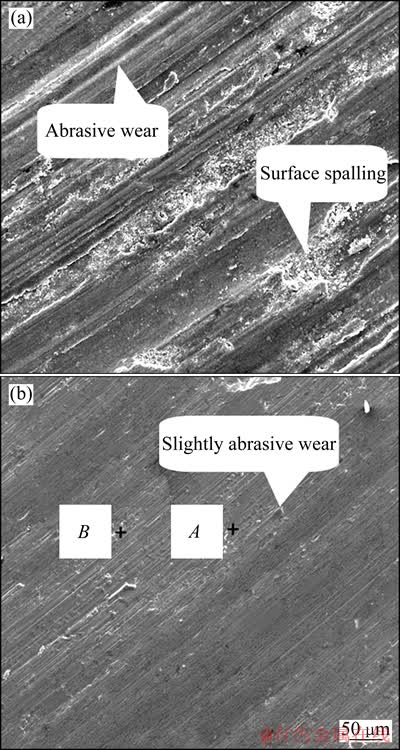

为进一步了解激光熔覆复合涂层的磨损行为,图4所示为A390铝合金基体与熔覆层磨损125 min后的SEM像。表2所列为A、B两点的EDS成分分析结果。据表2可知,A、B两点n(Ni):n(Al)为1:1,结合前面的XRD物相分析,可推断A、B两点为高硬度的AlNi金属间化合物。同时,B点n(Ti):n(C)约为1:1,可推断B点可能含有TiC硬质颗粒。

图4 A390基体和熔覆层磨损表面的SEM像

Fig. 4 SEM images of worn surface of A390 substrate (a) and cladding coating (b)

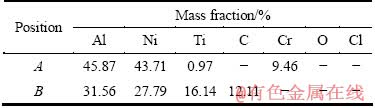

表2 A、B两点的EDS元素成分分析结果

Table 2 EDS analysis results of positions A and B shown in Fig. 3

从图4(a)中可以看出,A390铝合金基体的磨损表面粗糙不平,出现了大面积碎片脱落和反复应力作用而产生的疲劳,表现为大面积剥落坑、宽且深的犁沟及严重的显微切削。这主要是由于A390铝合金相对于对摩副Cr12MoV的硬度相差悬殊,在磨损过程中,A390铝合金表面易发生塑性变形,Cr12MoV表面的微凸体嵌入A390基体后发生了硬磨粒的犁削,脱落后受到反复挤压作用造成的。从图4(b)中可看到,熔覆层表面出现了不连续、细且浅的轻微犁沟。这主要是由于涂层中存在大量硬质颗粒(包括NiAl硬质金属间化合物及TiC硬质颗粒),在磨损过程中,硬质颗粒阻断了铝合金软基体与对摩副的直接接触,提高了抗粘着磨损能力,显著降低了接触面的磨粒磨损。可见,基材磨损机制主要为磨粒磨损和剥层磨损,激光熔覆层的磨损机制则表现为轻微的磨粒磨损。

2.4 涂层的耐腐蚀性能

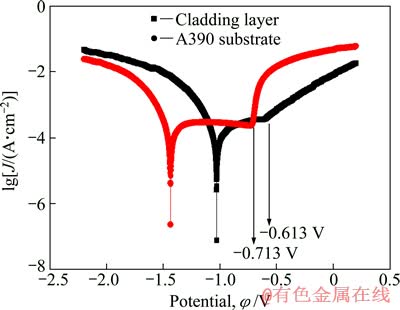

图5所示为A390铝合金基体和激光熔覆层在3.5% NaCl溶液中的动电位极化曲线。表3所列为由Tafel外推法得到的自腐蚀电位(φcorr)、腐蚀电流密度(Jcorr)和极化电阻Rp等拟合参数。

图5 A390基体和熔覆层的动电位极化曲线

Fig. 5 Potentiodynamic polarization curves of A390 aluminum alloy substrate and cladding coating

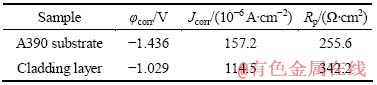

表3 极化曲线拟合的腐蚀参数

Table 3 Fitting corrosion parameters from polarization curve

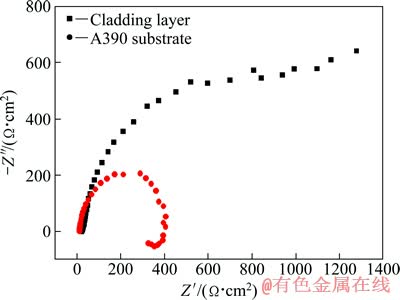

图6 熔覆层与A390基体在3.5% NaCl溶液中的阻抗谱(EIS)

Fig. 6 Electrochemical impedance spectroscopy of cladding coating and A390 aluminum alloy in 3.5% NaCl

由表3可知,熔覆层的自腐蚀电位(-1.029 V(vs SCE))相比A390基体(-1.436 VSCE)明显正移,熔覆层腐蚀电流密度(114.5×10-6 A/cm2)低于A390基体腐蚀电流密度(157.2×10-6 A/cm2)。熔覆层极化曲线位于A390基体右下方,自腐蚀电位的正移和腐蚀电流密度的下降表明熔覆层的耐蚀性能较A390基体得到了较大提高。同时,由图5所示极化曲线还可看出,A390基体出现了一个明显的活化-钝化过渡区,熔覆层相比于A390基体显示出了理想的钝化效果。图中A390基体的极化电位增加至-0.713 V时,电流密度急剧上升,这是因为试样表面局部钝化膜遭到破坏发生点蚀的结果,而熔覆层的极化电流密度在击穿电位达到-0.613 V后逐渐增大,表明熔覆层的点蚀是由于溶液中渗透能力强的Cl-离子被钝化膜表面吸附并与之发生反应,从而加速钝化膜溶解所造成的。此外,表3中熔覆层的极化电阻Rp也大于A390基体的,而极化电阻是一个与腐蚀速率密切相关的物理量。通常,极化电阻越大,相应腐蚀速率就越小。

由以上分析结果可知,熔覆层的耐腐蚀性能优于A390基体的,主要原因在于NiCrAl合金本身为耐腐蚀材料,Cr在腐蚀时能形成Cr2O3钝化膜,可有效阻碍腐蚀的继续发生,减缓腐蚀速率。同时,在激光熔覆过程中,熔池内的强烈对流及快速凝固使其内部获得均匀分布的细小硬质相颗粒及均匀细化的组织结构,均匀的显微组织结构、高致密度的涂层对于优先开始于晶粒边界的电化学腐蚀起到了重要作用[20-22]。

为进一步了解激光熔覆复合涂层的耐腐蚀行为,图5所示为熔覆层与A390基体在3.5% NaCl溶液中的电化学阻抗谱(EIS)。在电化学阻抗谱中,曲线初始端为高频区域,随着曲线的伸展,频率逐渐降低。图中Z′与Z″分别为阻抗的实部和虚部。由图5可知,熔覆层呈现出单容抗性,容抗弧的半径明显大于A390基体的,高频部分的容抗弧是涂层表面受到输入扰动信号产生的,而中低频的容抗弧可以显著增加涂层表面的反应电阻,此时熔覆层还没有发生活化而仍处于钝化状态[23]。相比于熔覆层,A390基体则表现出高频容抗特性及中低频感抗特性。其中,高频容抗弧与双电层电容、传递电阻有关,低频感抗弧则源于铝合金表面剥蚀露出与溶液相接处的新界面。在中频区,A390基体容抗弧重心下降,表明试样出现了点蚀,并最终导致晶间腐蚀及剥蚀[24]。通过对比熔覆层和A390基体的电化学阻抗谱可发现,熔覆层的容抗弧半径大,而A390基体容抗弧半径小,且在低频区有感抗弧存在。说明随着腐蚀的进行,腐蚀产物及新表面增多,A390基体在低频区受到腐蚀液中Cl-离子的点蚀加剧,并最终导致孔蚀等严重的腐蚀破坏[25-26]。

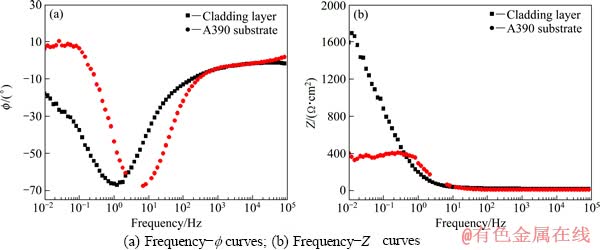

另外,电化学阻抗谱中交流电压频率范围很宽(10 mHz~100 kHz),为压缩坐标,在做频率特性曲线时,频率f采用对数刻度,相位角Φ及阻抗模值Z采用线性刻度,这样的曲线称为波特图(Bote)。图7(a)所示为熔覆层与A390基体在3.5% NaCl溶液中频率响应的相位角对频率变化的Bote图。通过观察图中波峰或波谷的个数可以求出时间常数,从而判断电极过程的表面反应有几个状态变量。图7(b)所示为熔覆层

与A390基体在3.5% NaCl溶液中频率响应的阻抗模值(电阻和电抗平方和的开方)对频率变化的Bote图。通常,可采用低频阻抗模值评价涂层的防护性能[27-28],即在低频区,随着阻抗模值变化率减小,涂层防护性能逐渐降低直至完全丧失。

从图7(a)可以看到,在低频区,熔覆层对应的相位角要大于A390基体的,说明氧化膜对熔覆层的保护作用更好,且在频率为0.1 Hz附近时,A390基体的Bote图上出现一个新的时间常数,说明基体的点蚀加剧,这与A390基体的交流阻抗谱低频区感抗弧的存在相对应。图7(b)中,在中低频段,熔覆层的阻抗模值逐渐高于A390基体的,同时有一个明显上升的趋势且显示没有达到极限的迹象,说明相对于熔覆层而言,A390基体的表面防护性能逐渐降低直至消失。

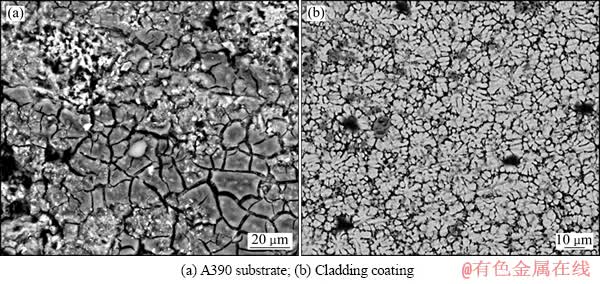

为进一步了解熔覆涂层的腐蚀行为,图8所示为A390基体和熔覆层在3.5%NaCl溶液中腐蚀后的SEM像。图8(a)中,A390基体出现了严重的腐蚀破坏,形成疏松、多孔的蜂窝状结构和龟裂裂纹。这主要归因于点蚀加剧并沿晶界相互连接形成大的点蚀坑,并最终导致晶间腐蚀和剥蚀。图8(b)中,熔覆层在AlNi晶间出现了局部点蚀现象,但无大的点蚀坑,因此,整个涂层表面晶间腐蚀现象并不明显。

在快速凝固过程中,熔池内存在的高熔点、先结晶析出的TiC对熔池内部的晶粒起到细化作用,使得腐蚀过程中表面活性点减少,电位趋于一致,减少了腐蚀微观电池数目。同时,熔覆层中大量存在的AlNi相和TiC颗粒本身就具有很强的耐腐蚀性,在3.5% NaCl溶液中的化学性质稳定,有效阻止了腐蚀现象的发生,这些因素都有利于熔覆层耐腐蚀性能的提高。

图7 熔覆层与A390基体在3.5%NaCl溶液中电化学阻抗谱Bote图

Fig. 7 EIS Bote graphs of cladding coating and A390 substrate in 3.5% NaCl solution

图8 A390基体与熔覆层的腐蚀形貌

Fig. 8 Corrosion morphologies of A390 substrate and cladding coating

3 结论

1) 在A390铝合金基体表面制备了NiCrAl/TiC激光熔覆复合涂层。XRD分析表明:复合涂层主要物相为AlNi、Al3Ni2、TiC,同时含有少量的Cr13Ni5Si2、Cu9Al4和α(Al)。SEM形貌观察显示:涂层自下至上分别为短棒状树枝晶、胞状晶、柱状树枝晶和等轴晶。

2) 相同磨损条件下,A390基体发生了严重的磨粒磨损和剥层磨损,而激光熔覆涂层只产生了轻微的磨粒磨损,熔覆层的相对耐磨性为3.16。

3) 熔覆层自腐蚀电位较A390基体正移,腐蚀电流密度减小。熔覆层呈单容抗特性,而A390基体在高频区表现为容抗特性,在中低频则为感抗特性。低频区熔覆层对应相位角和中低频段熔覆层的阻抗模值均大于A390基体的,说明熔覆层耐蚀性能良好。熔覆层的腐蚀形貌为局部点蚀,A390铝合金基体的腐 蚀形貌则为晶间腐蚀和剥蚀。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小峰, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials & Design, 2014, 56(4): 862-871.

[3] ANJA B A D, HEINZ J S, ROLF Z. Studies of technological parameters influencing the nitriding behavior of spray-formed Al alloys[J]. Surface & Coatings Technology, 2013, 236: 63-69.

[4]  KLECZEWSKA J. Wear resistant carbon coatings deposited at room temperature by pulsed laser deposition method on 7075 aluminum alloy[J]. Vacuum, 2013, 97(11): 20-25.

KLECZEWSKA J. Wear resistant carbon coatings deposited at room temperature by pulsed laser deposition method on 7075 aluminum alloy[J]. Vacuum, 2013, 97(11): 20-25.

[5] D'AMATO C, BETTS J C, BUHAGIAR J. Laser surface alloying of an A356 aluminium alloy using nickel and Ni-Ti-C: A corrosion study[J]. Surface and Coatings Technology, 2014, 2014(4): 194-202.

[6] SHCHEDRINA I, RAKOCH A G, HENRION G, MARTIN J. Non-destructive methods to control the properties of MAO coatings on the surface of 2024 aluminium alloy[J]. Surface and Coatings Technology, 2014, 238 (1): 27-44.

[7] JIANG Ye-hua, LIU Hong-xi, ZHOU Rong, TANG Bao-yin. Tribological behaviors and corrosion resistance of aluminum alloys by nitrogen plasma immersion ion implantation[J]. Reviews on Advanced Materials Science, 2013. 33 (3): 281-286.

[8] PUCHI-CABRERA E S, STAIA M H, SANTANA Y Y, MORA-ZORRILLA E J, LESAGE J, CHICOT D, LA BARBERA-SOSA J G, OCHOA-PEREZ E, VILLALOBOS- GUTIERREZ C J. Fatigue behavior of AA7075-T6 aluminum alloy coated with a WC-10Co-4Cr cermet by HVOF thermal spray[J]. Surface and Coatings Technology, 2013, 220(4): 122-130.

[9] RAGHUKIRAN N, KUMAR R. Processing and dry sliding wear performance of spray deposited hyper-eutectic aluminum-silicon alloys[J]. Journal of Materials Processing Technology, 2013, 213: 401-410.

[10] QIAN M, LI D, LIU S B, GONG S L. Corrosion performance of laser-remelted Al-Si coating on magnesium alloy AZ91D[J]. Corrosion Science, 2010, 52(10): 3554-3560.

[11] LIU Hong-xi, WANG Chuan-qi, ZHANG Xiao-wei, JIANG Ye-hua, CAI Chuan-xiong, TANG Shu-jun. Improving the corrosion resistance and mechanical property of 45 steel surface by laser cladding with Ni60CuMoW alloy powder[J]. Surface and Coatings Technology, 2013, 228(8): S296-S300.

[12] EMAMIAN A, CORBIN S F, KHAJEPOUR A. Effect of laser cladding process parameters on clad quality and in-situ formed microstructure of Fe-TiC composite coatings[J]. Surface & Coatings Technology, 2001, 205: 2007-2015.

[13] OBADELE B A, OLUBAMBI P A, JOHNSON O T. Effects of TiC addition on properties of laser particle deposited WC-Co-Cr and WC-Ni coatings[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3634-3642.

[14] ZHOU Sheng-feng, DAI Xiao-qin, ZHENG Hai-zhong. Microstructure and wear resistance of Fe-based WC coating by multi-track overlapping laser induction hybrid rapid cladding[J]. Optics & Laser Technology, 2012, 44(1): 190-197.

[15] LIANG G Y, WONG T T, SU J Y. Amorphous structure in laser clad Ni-Cr-Al coating on Al-Si alloy[J]. Journal of Materials Science Letters, 2000, 19: 1193-1196.

[16] 李 垚, 马 彬, 赵九蓬, 魏庆元, 苏 柯. 盐雾条件下NiCrAl涂层的耐腐蚀性研究[J]. 稀有金属材料与工程, 2010, 39(12): 2181-2184.

LI Yao, MA Bin, ZHAO Jiu-peng, WEI Qing-yuan, SU Ke. Corrosion resistance of NiCrAI coatings in the salt spray tests[J]. Rare Metal Materials and Engineering, 2010, 39(12): 2181-2184.

[17] SONG Bo, DONG Shu-juan, CODDET P, LIAO Han-lin, CODDET C. Fabrication of NiCr alloy parts by selective laser melting: Columnar microstructure and anisotropic mechanical behavior[J]. Materials & Design, 2014, 53(1): 1-7.

[18] ALEXANDER C A, OGDEN J S, RISSER S M. Thermodynamic characterization of NiAl[J]. Journal of Chemical Thermodynamics, 2009, 5(41): 610-616.

[19] WANG Qian, LENG Xue-song, YANG Tian-hao, YAN Jiu-chun. Effects of Fe-Al intermetallic compounds on interfacial bonding of clad materials[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 279-284.

[20] KWOK C T, MAN H C, CHENG F T. Cavitation erosion-corrosion behavior of laser surface alloyed AISI 1050 mild steel using NiCrSiB[J]. Materials Science and Engineering A, 2001, 303(1/2): 250-261.

[21] CAI L X, WANG H M, WANG C M. Corrosion resistance of laser clad Cr-alloyed Ni2Si/NiSi intermetallic coatings[J]. Surface & Coatings Techmology, 2004, 182(2/3): 294-299.

[22] WANG Bin-bin, WANG Zhen-yao, HAN Wei, WANG Chuan, KE Wei. Effects of magnesium chloride-based multicomponent salts on atmospheric corrosion of aluminum alloy 2024[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 1199-1208.

[23] 贺俊光, 文九巴, 李旭东, 郝庆国. Al-Zn-Sn-Ga 阳极腐蚀过程的电化学阻抗谱[J]. 中国有色金属学报, 2012, 22(1): 187-193.

HE Jun-guan, WEN Jiu-ba, LI Xu-don, HAO Qing-guo. Electrochemical impedance spectra of AI-Zn-Sn-Ga anode during corrosion process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 187-193.

[24] 李晓丹, 翟玉春, 邱 峰, 刘涛涛. 纳米SiC颗粒强化7075铝合金在NaCl溶液中的电化学腐蚀行为[J]. 腐蚀科学与防护技术, 2012, 24(2): 139-143.

LI Xiao-dan, ZHAI Yu-chun, QIU Feng, LIU Tao-tao. Corrosion characteristics of AA7075 reinforced with Nano-SiC particles in NaCl solution[J]. Corrosion Science and Protection Technology, 2012, 24(2): 139-143.

[25] CONDE A, DAMBORENEA J. Electrochemical modeling of exfoliation corrosion behavior of 8090 alloy[J]. Electrochimica Acta, 1998, 43(8): 849-852.

[26] KEDDAM M, KUNTZ C, TAKENOUTI H. Exfoliation corrosion of aluminum alloys examined by electrode impedance[J]. Electrochimica Acta, 1997, 42(7): 87-92.

[27] ZUBIELEWICZ M, GNOT W. Mehanisms of non-toxic anticorrosive pigments in organic waterborne coatings[J]. Progress in Organic Coatings, 2004, 49(4): 358-371.

[28] de ROSA R L, EARL D A, BIERWAGEN G P. Statistical evaluation of EIS and ENM data collected for monitoring corrosion barrier properties of organic coatings on Al-2024-T3[J]. Corrosion Science, 2002, 44(7): 1607-1620.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(61368003);昆明理工大学分析测试基金资助项目(2011008)

收稿日期:2014-03-25;修订日期:2014-07-14

通信作者:刘洪喜,教授,博士;电话:13987634786;E-mail:piiiliuhx@sina.com

[1] 刘 兵, 彭超群, 王日初, 王小峰, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

[16] 李 垚, 马 彬, 赵九蓬, 魏庆元, 苏 柯. 盐雾条件下NiCrAl涂层的耐腐蚀性研究[J]. 稀有金属材料与工程, 2010, 39(12): 2181-2184.

[23] 贺俊光, 文九巴, 李旭东, 郝庆国. Al-Zn-Sn-Ga 阳极腐蚀过程的电化学阻抗谱[J]. 中国有色金属学报, 2012, 22(1): 187-193.

[24] 李晓丹, 翟玉春, 邱 峰, 刘涛涛. 纳米SiC颗粒强化7075铝合金在NaCl溶液中的电化学腐蚀行为[J]. 腐蚀科学与防护技术, 2012, 24(2): 139-143.