J. Cent. South Univ. Technol. (2007)03-0413-05

DOI: 10.1007/s11771-007-0081-5

![]()

Investigation and characterization of mining subsidence in

Kaiyang Phosphorus Mine

DENG Jian(邓 建)1, BIAN Li(边 利)2

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. School of Business, Central South University, Changsha 410083, China)

Abstract:

In Kaiyang Phosphorus Mine, serious environmental and safety problems are caused by large scale mining activities in the past 40 years. These problems include mining subsidence, low recovery ratio, too much dead ore in pillars, and pollution of phosphorus gypsum. Mining subsidence falls into four categories: curved ground and mesa, ground cracks and collapse hole, spalling and eboulement, slope slide and creeping. Measures to treat the mining subsidence were put forward: finding out and managing abandoned stopes, optimizing mining method (cut and fill mining method), selecting proper backfilling materials (phosphogypsum mixtures), avoiding disorder mining operation, and treating highway slopes. These investigations and engineering treatment methods are believed to be able to contribute to the safety extraction of ore and sustainable development in Kaiyang Phosphorus Mine.

Key words:

mining subsidence; ground cracking; safety, Kaiyang Phosphorus Mine; cut and fill mining method;

1 Introduction

After useful mineral body has been mined and drawn out, mining goaf is formed and country rocks would lose original equilibrium. When span of the goaf is long enough, even if the roof is hard and intact rock, the rock around the goaf would move towards the mining openings, and this movement would pass on to the adjoining rock mass until it reaches the surface and surface displacement can be observed. In other words, underground mining may cause ground cracking and surface subsidence, and subsidence may cause damage to buildings, highways, and farmland, etc[1-7].

Kaiyang Phosphorus Mine is famous for its large scale phosphorus deposit, which is located in southwest of China. The ore reserves is more than 4.4 thousand million tons, which belongs to one of the largest phosphorus orebody. Large scale phosphorus has been produced since 1958, when the mine went into operation. Now Kaiyang Phosphorus Mine is one of the most important base of chemical products, which plays a great role in Guizhou provincial economical development[8-10]. However, serious mining subsidence threatened the safety of ground buildings, highways and mining activity itself. Therefore, it is urgent to solve the safety mining problems under mountains and highways, and to ascertain the mine sustainable development. In this paper, mining subsidence in Kaiyang Phosphorus Mine was investigated and classified into four types. Corresponding measures to control mining subsidence were put forward.

2 Current problems in Kaiyang Phosphorus Mine

Four problems are encountered in Kaiyang Phosphorus Mine, of which mining subsidence is most serious.

1) Mining subsidence. The ore in Kaiyang Phosphorus Mine belongs to shallow sea facies-littoral facies sedimentary phosphorus deposit. It is located in mountains and gorges, which belongs to Yungui plateau, southwest of China. Overburden rocks are mainly dolomite. The direct hanging wall rock is khaki politic shale, and the direct lying wall rock is sandy shale and siliceous shale. All of the rocks are highly weathering, whose capability to keep stable is weak. Faults, joints and cracks are abundant in surrounding rocks. Mechanical stepped open-stope mining method is used in Kaiyang Phosphorus Mine for more than two decades. This mining method has many merits such as high-level mechanization and high production capacity. However, large areas of open-goafs remained in the excavated zone and ground cracks were generated. Mining subsidence threatened the safety of ground buildings, structures and highways.

2) Low recovery ratio of ore. Open-stope mining method was used and a lot of ores were kept in pillars. Recovery ratio was very low. It was reported that the recovery ratio in Yongshaba mine was only 70%. Yongshaba mine is one of the main subordinate mines in Kaiyang Phosphorus Mine. When the geological conditions were complicated, roof would fall down and much ore can not be extracted, and the recovery ratio was only 50% also. Ore resources were seriously wasted.

3) Too much dead ore in pillar. Two highways are on the top of the orebody. The ore caving angle is 70?, and the ore movement angle is 65?. In order to protect the highways, safety pillars have to be retained, and the ore in safety pillars can not be mined and so called ‘dead ore’. The orebody under safety pillars is comprised of two parts: one is the enclosed reserves according to caving angle; the other is reserves which can not be mined in scale owing to the enclosed reserves. The enclosed reserves have totally 22.62 million ton ore. These dead ore with large areas in safety pillar constrained production capacity and economic goals of Kaiyang Phosphorus Mine.

4) Phosphogypsum pollution. The superphosphate factory in Kaiyang Phosphorus Mine produces 5×106 t industrial waste, phosphogypsum, each year. Phosphogypsum would be expected to increase by 5-6 times in the next two or three years. Phosphogypsum occupies large areas of arable land and would seriously pollute environment, such as water and land resources.

3 Characterization of mining subsidence

In order to control mining subsidence, physical and mechanical properties of mine body were tested in-situ and in laboratory. Mining subsidence was investigated and classified into four types.

3.1 Geological description of ore and rock

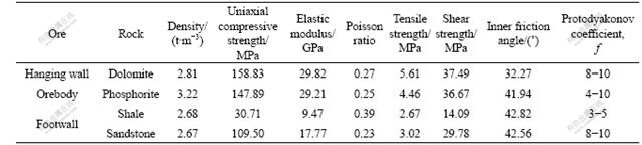

Physical and mechanical parameters of ore and country rocks in Kaiyang Phosphorus Mine are listed in Table 1[9-10]. The geological characteristics of ore and rocks are described as follows.

1) Orebody: Phosphorite has compact massive texture and zonal (banded) structure, which is full of joints and cleavages. The phosphorite near lying wall contains no intercalary strata, but the phosphorite nearhanging wall occasionally contains grayish-green shale. To make things worse, a thin dolomite strata exists in the phosphorite near the roof, with the thickness of 0.02 m also. This intercalated bed has an adverse effect on the stability of excavation, because once it exposes in the air, nicking and collapse would happen. This dolomite strata threatens the safety of workers and mining machines.

2) Lying wall: Quartz-sandstone is compact and hard, which belongs to medium-stability strata. But it is easily weathered by water. Sandy-dolomite lies between the phosphorite orebody and quartz-sandstone, which is full of joints and cleavages, with clear bedding and with thickness of 0-0.8 m. One strata in lying wall is purplish-red shale, in which there are some development drifts. This purplish-red shale is full of joints and easily weathered by water. Its expansion would easily cause nicking and collapse in the stope.

3) Hanging wall: The direct hanging wall is shale, occasionally with dolomite and phosphorite, which is 0-3 m thick. This direct roof is very easily weathered and expanded with water. Nicking and collapse would easily be caused by the country rock’s weather and expansion. The direct roof is unstable and would threaten the safety of workers and mining machines. The indirect hanging wall is compact and hard aplite dolomite, which belongs to stable strata.

3.2 Classification of mining subsidence

Sublevel open stope mining method has been used in Kaiyang Phosphorus Mine for more than 40 years. Large areas of goaf was left in the mining section[11-13]. These un-backfilled goafs caused mining subsidence and ground movement, which can be classified into four types: curved ground and mesa, ground cracks and collapse hole, spalling and eboulement, slope slide and creeping.

1) Curved ground and mesa

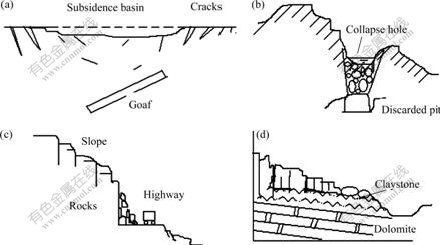

Large areas of goaf caused some ground surface subsidence as a whole, and then the curved ground came into being, as shown in Fig.1(a). Sometimes there is some water in these small subsidence basins. At the edge of small basin, cracks and subsidence mesa can be found.

Uneven subsidence is the main reason for the curved ground and mesa. Therefore, mining goaf should be disposed.

Table 1 Physical and mechanical parameters of ore and country rocks

Fig.1 Classification of mining subsidence in Kaiyang Phosphorus Mine

(a) Curved ground and mesa; (b) Ground cracks and collapse hole; (c) Spalling and eboulement; (d) Slope slide and creeping

2) Ground cracks and collapse holes

Ground cracks can be found in Kaiyang Phosphorus Mine (Fig.1(a)). For example, a few cracks with 70- 200 m length, 5-50 m depth and 2 -5 m width were found between the year of 1995 and 1996. These ground cracks threatened the safety of buildings and highways. It also changed the water supply.

Collapse holes with water are common in the ground of Kaiyang Phosphorus Mine (Fig.1(b)). Hard rocks and loose clay rock of Quaternary period unevenly existed in the ground surface. Discarded pit by disorder mining would directly generate uneven ground subsidence, and then collapse holes.

3) Spalling and eboulement

Rocks often weathered into fragments. Steep slope turned into talus slope. Rock spalling was triggered by blasting vibration. Rock spalling in large scale is called eboulement (Fig.2). Gravity, weather and mining are three main reasons to cause spalling and eboulement when these joining force results exceed rock’s shear strength or tensile strength. Spalling and eboulement would damage buildings and highways (Fig.1(c)).

4) Slope slide and creeping

Rocks and soils would slide and/or creep along a certain structural plane or weak intercalary strata (Fig.1(d)). In loose sedimentary soil of Quaternary

period, there does not exist structural plane as sliding plane. The sliding surface is arc owing to the maximum shear stress. In rockmass with weak intercalary strata such as joints and faults, rock and soil would slide along this weak strata. Some slide was unexpected, some deformed in a long time (creeping). Slope slide and creeping are geological disasters which are related to mining operations in Kaiyang Phosphorus Mine.

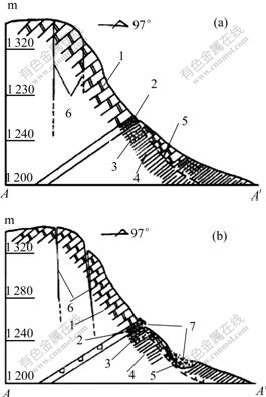

Fig.2 shows the geological cross section before and after rock slope slide in Kaiyang phosphorus mine. The orebody and phosphorite outcrop lie in the bottom of slope. After the orebody is excavated, there is no support force in slope and slide happens[13].

Fig.2 Geological cross section before and after rock slope slide in Kaiyang Phosphorus Mine

(a) Before slide; (b) After slide

1—Dolomite; 2—Phosphorite; 3—Sandstone; 4—Shale;

5—Slide; 6—Crack; 7—Stripping mining area

4 Measures to control subsidence

After a thorough investigation of mining subsidence in Kaiyang, numerical models were established and measures to control subsidence were put forward as follows.

4.1 Ascertain and treat goafs

Mechanical stepped open-stope mining method was used in Kaiyang Phosphorus Mine for more than two decades. Large areas of open-goafs haven’t been treated, which becomes the main causes to mining subsidence[14]. In order to prevent subsidence from happening, it is necessary to ascertain the location and dimension of goafs under the ground. Big goafs should be re-treated. For accessible goafs, waste rock or tailings can be used as materials to backfill them. For unaccessible goafs, holes should be drilled as an access for grouting to backfill the goafs.

4.2 Optimum mining method

The following principles should be observed in the mining method selection of Kaiyang Phosphorus Mine.

1) The upper orebody is near the highway, more pillars should be reserved in the upper level to prevent ground and highway from moving. However, less pillars in the lower level should be kept to reduce loss rate.

2) Production power should be large, labor production rate should be high, mining operation should be in large scale to obtain the maximum economic benefit at minimum costs. The candidate mining method should be easily adjusted to adapt to complicated geological conditions.

3) Backfilling materials should be used to backfill the open-stope to control the movement of surrounding rocks. Waste rocks and phosphorus gypsum should be mixed to increase the strength of backfilling and to reduce the cost of backfilling.

4) Short-delay blasting or control blasting should be used to alleviate the vibration of roof, pillar or highway slope. Cut and fill mining method with middle-deep drilling holes and ore transportation by blasting force is advised to be used.

4.3 Optimum backfilling materials

Backfilling materials are backfilled into the goaf as soon as ore rocks are excavated in cut and fill mining method. Backfills can confine the displacement and deformation of surrounding rocks and reduce the subsidence. Moreover, backfills can change the pillar’s stress state from one or two dimensions to three dimensions, and thus raise the pillar’s strength[15]. Phosphogypsum can be used as backfill materials with waste rocks. Backfill strength can be increased, backfill cost can be reduced, land can be protected and pollution can be prevented.

4.4 Avoid disorder mining operation

Disorder mining operation would lead to irregular goafs and collapse holes. Avoiding disorder mining is one of the main measures to protect highway and to prevent ground from cracking and subsidence.

4.5 Highway slope treatment

In highway slope treatment, dangerous broken stones should be cleared, subsidence basins and collapse holes should be filled and leveled up, retaining wall and anti-sliding support should be set up, and chemical grounting should be used to increase the strength of soft strata, etc. In some cases, intercepting dike or water stop sheet should be established to prevent the flood from pouring in the cracks in the slopes.

5 Conclusions

1) The current situations of Kaiyang Phosphorus Mine were discussed in detail. Four problems were encountered, of which mining subsidence was the most serious. Ground cracking and mining subsidence were investigated, and four types of subsidence were presented: curved ground and mesa, ground cracks and collapse hole, spalling and eboulement, slope slide and creeping. It can be concluded that ground cracking and mining subsidence have a close relationship with the open-stope mining method.

2) Measures to control the mining subsidence were put forward, i.e. finding out and managing abandoned stopes, optimizing mining method, selecting proper backfilling materials, avoiding disorder mining, and treating highway slope. Cut and fill mining method with middle-deep drilling holes and ore transportation by blasting force is advised to be used in Kaiyang Phosphorus Mine. Phosphogypsum can be used as backfill materials with waste rocks.

3) These investigation and measures were believed to be able to contribute to the safety extraction of orebody in Kaiyang Phosphorus Mine. It is evident that this research is also helpful for other mines in dealing with mining subsidence.

References

[1] ‘Mining Handbook’ Editing Committee. Mining Handbook[M]. Beijing: Metallurgical Industry Press, 1999. (in Chinese)

[2] KRATZSCH H. Mining Subsidence Engineering[M]. Berlin: Springer-Verlag, 1983.

[3] QIAN Ming-gao, MIAO Xie-xing. Mining strata mechanics—A new branch of applied mechanics[J]. Jiangsu Mechanics, 1997, 13(1): 7-10.(in Chinese)

[4] XU Shui-tai, RAO Yun-zhang, PAN Jian-ping. Mechanism of ground surface displacement and uneven subsidence caused by underground mining[J]. Mining Engineering, 2004, 2(1): 31-33.(in Chinese)

[5] AMBROZIC T, TURK G. Prediction of subsidence due to underground mining by artificial neural networks[J]. Computers & Geosciences, 2003, 29(5): 627-637.

[6] ZHOU You-feng, DENG Ka-zhong, MA Wei-min. Mining Subsidence Engineering[M]. Xuzhou: China Mining University Press, 2003.

[7] FANG Jian-qin, PENG Zhen-bin, YAN Rong-gui. The law of tectonic stress mining ground surface subsidence and its engineering treatment method[J]. Journal of Central South University: Science and Technology, 2004,35(3): 506-510. (in Chinese)

[8] DENG Jian, BIAN Li, LI Xi-bing, et al. Analysis of factors and countermeasures of mining subsidence in Kaiyang Phosphorus Mine[J]. Journal of Central South University: Science and Technology, 2006, 13(6): 733-737.

[9] Central South University, Kaiyang Phosphorus Mine. Report on mining method under highway in Yongshaba Phosphorus Mine[R]. 2004. (in Chinese)

[10] Central South University, Kaiyang Phosphorus Mine. Report on general mining techniques under highway in Kaiyang Phosphorus Mine[R]. 2004. (in Chinese)

[11] TANG Xian-yong. Mine exploitation and environment synthetic treatment at Yangshui field in Kaiyang Phosphorite of Guizhou[J]. Guizhou Geology, 2001, 18(1): 64-67. (in Chinese)

[12] FENG Chao-fu. Construction technique and deformation treatment of broken shaft in Kaiyang Phosphorite Mine[J]. Express Information of Mining Industry, 2001, 10(8): 5-8. (in Chinese)

[13] JIAN Ming-xing, NIE Yong-jie. The slope deformation at Guniubei in Yongshaba ore block of Kaiyang phosphorite mine[J]. Guizhou Geology, 1999, 16(2): 157-161. (in Chinese)

[14] SONG You-hong. Finite Element Analysis of Mining Method Under Highway in Kaiyang Phosphorus Mine[D]. Changsha: Central South University, 2005. (in Chinese)

[15] LIU Bao-chen. Ground surface movement due to underground excavation in P. R. China[C]// HUDSON J A. Comprehensive Rock Engineering. Pergamon Press, 1993: 781-817.

Foundation item: Projects(50404010; 50574098) supported by the National Natural Science Foundation of China; Projects (05JJ10010) supported by the Hunan Provincial Natural Science Foundation of Distinguished Young Scholars

Received date: 2006-10-24; Accepted date: 2006-12-27

Corresponding author: DENG Jian, Professor; Tel:+86-731-8879612; E-mail: jdengj@sina.com

- Investigation and characterization of mining subsidence in Kaiyang Phosphorus Mine