Mechanical property and formability of AZ31B extruded tube at elevated temperature

HE Zhu-bin(何祝斌)1, LIU Gang(刘 钢)1, WU Jia(吴 佳)1,

YUAN Shi-jian(苑世剑)1, LIANG Ying-chun(梁迎春)2

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Research Institute of Precision Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 12 June 2008; accepted 5 September 2008

Abstract:

The mechanical properties of AZ31B magnesium alloy tube were tested by ring hoop tension test at different temperatures. The formability for tube hydroforming was also evaluated by free-expansion test. The results show that there exists a quick decrease of total elongation along hoop direction at the temperature range of 150-230 ℃, which is quite different from that along axial direction. The total elongation along hoop direction of welded tube is quite close to that of seamless tube until 230 ℃ is reached. At higher temperature, the total elongation for seamless tube begins to increase while the value for welded tube continues to decrease. The maximum free expansion ratio of seamless tube increases considerably as temperature increases and reaches the maximum value of 30% at 170 ℃, then decreases quickly at higher temperature.

Key words:

magnesium alloy tube; elongation; hydroformability; free-expansion test;

1 Introduction

Light structure can be realized by optimized structural design and usage of light materials, such as aluminum alloy and magnesium alloy. Optimized design of structure often increases its shape complexity, and hydroforming is one advanced method to manufacture this kind of components[1]. However, traditional hydroforming technique for steel tube cannot be applied for light-weight materials, due to their poor formability at room temperature[2-3]. In addition, there exists considerable property difference along axial direction and hoop direction of light-weight extruded tubes. This characteristic of extruded tubes also decreases their formability for hydroforming process[4]. The existing knowledge on material properties and process development, especially in equipment and process designs for forming these materials at elevated temperature is not sufficient.

Traditional tension test is often adopted to determine the mechanical properties of tube. As for extruded tubes with considerable property difference along axial direction and hoop direction, tension test should be carried out separately along both directions [5-6]. However, no accurate data in hoop direction can be obtained if traditional tension test is used. Ring stretch tensile test was first proposed by LINK to analysis the failure of Zircaloy cladding under transverse plane-strain deformation[7]. Later, COHEN and WANG developed this testing method in order to better describe the anisotropic characteristic of extruded tubes[8-9]. In the analytical model they developed, friction between the D-blocks and specimen was neglected, which may be invalid when testing at elevated temperature. In Ref.[10], the effect of friction between specimen and D-blocks was investigated. It was shown that uneven deformation will happen and necking and fracture tend to occur near the edge of gauge section. Therefore, special attention should be paid to measuring and analyzing the strain distribution.

Even though tension test can reveal the mechanical properties of tube, the stress—strain state is quite different from that of hydroforming. Therefore, hydrobulging test or free expansion test is often used to evaluate the formability of tube instead of traditional tension test[11-12]. The maximum expansion ratio and bursting pressure are two key parameters to characterize the formability of tube for hydroforming. However, this test has not been developed into standard method yet[13-14]. And very few results about magnesium alloy extruded tubes at elevated temperature have been reported[15-17].

In this work, tension test in hoop direction at elevated temperature is carried out to characterize the mechanical properties of AZ31B magnesium tube. The difference of mechanical properties along hoop direction and axial direction is analyzed. Free-expansion test is also employed to investigate the formability of AZ31B extruded tube at different temperatures. The properties of welded tube and seamless tube are compared and analyzed.

2 Determination of mechanical properties

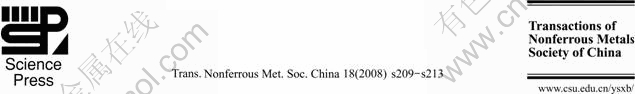

Ring hoop tension test (RHTT) developed by WANG et al[9] was adopted to test the mechanical properties of tube along hoop direction. Fig.1 shows the ring specimen and test die-set. This test used a universal tensile testing machine with a special test fixture to expand a ring specimen directly, which can avoid the effect of work hardening during specimen preparation, especially for tube with small radius. The tubes tested were AZ31B magnesium alloy tube extruded by pierce-type die and porthole die, which are called seamless tube and welded tube in this study, respectively. The tube is 44 mm in diameter and 1.8 mm in thickness, extruded with extrusion ratio of 40?1 at 410 ℃ without additional heat treatment.

2.1 Seamless tube

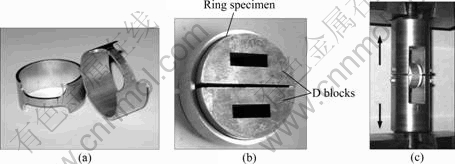

First, ring hoop tension tests were carried out at different temperatures to determine the mechanical properties of seamless tube along hoop direction. The test temperature varied from room temperature to 300 ℃. Molykote D-321R, one anti-friction coating spray from Dow Corning was used to eliminate the effect of friction between the specimen and D-blocks. The tested specimens are shown in Fig.2.

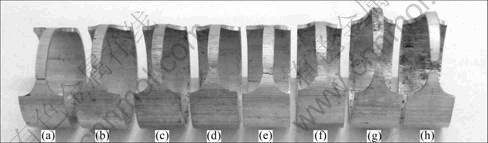

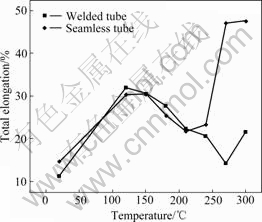

Because no extensometer was used at elevated temperature, it was impossible to get the real stress—strain curve. Therefore, the total elongation after fracturing was measured and calculated by the grids printed in the gauge section of the specimen prior to testing. Fig.3 gives the calculated total elongation along hoop direction at different temperatures, together with the corresponding axial tension result reported in Ref.[16]. It can be found that the tube has very poor properties at room temperature. As temperature was increased, the total elongation along hoop direction began to increase and reached the first peak of about 30% at 150 ℃. After that, the total elongation value began to decrease until 210 ℃. As temperature increased higher, the total elongation began to increase again and was about 47% when temperature reached 300 ℃.

From Fig.3 it can also be seen that the total elongation along axial direction is higher than that along hoop direction, especially at the temperature range of

Fig.1 Ring specimen and hoop tension test die-set: (a) Ring specimen; (b) D-block; (c) Die-set

Fig.2 Tested ring specimen at different temperatures: (a) RT; (b) 120 ℃; (c) 150 ℃; (d) 180 ℃; (e) 210 ℃; (f) 240 ℃; (g) 270 ℃; (h) 300 ℃

Fig.3 Total elongation in hoop and axial directions at different temperatures

150-230 ℃. This difference in elongation has very large effect on the whole formability of the tube and should be taken into account in tube hydroforming. It should be pointed out that the testing temperature was up to 350 ℃, because no thermal oil that can work at higher temperature was available for warm hydroforming practice.

2.2 Welded tube

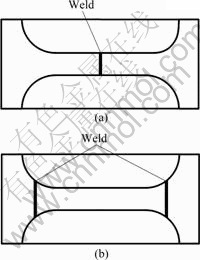

For the tube manufactured by porthole die extrusion, the metal was divided first and then flowed around the mandrel supports and re-welded together before they exited through the die. The quality of tubes manufactured by this method mainly depended on the quality of welding lines that may be the weakest areas when subjected to internal pressure. In order to avoid the effect of these welds, ring specimens were cut and prepared with the gauge section away from the welds, as shown in Fig.4(b).

Fig.4 Position of weld on ring specimen: (a) Weld in middle; (b) Weld at edges

Then, ring hoop tension tests were carried out at different temperatures as the seamless tube above, and the tested total elongation is shown in Fig.5.

Fig.5 Total elongation of two kinds of tubes at different temperatures

It can be seen from Fig.5 that the total elongations of two kinds of tubes are close to each other at the temperature from room temperature to 230 ℃. As temperature increased higher, the total elongation of welded tube continued to decrease while the value of seamless tube began to increase rapidly. The effect of high temperature on the microstructure of welds may be the reason for this phenomenon. When the welds were heated to a certain temperature, grain may grow quickly and poor microstructures appear which leads to early fracture in these positions. This characteristic of the welded tube should be overcome before it can be used for forming magnesium tubular part by warm hydroforming.

3 Evaluation of formability

The mechanical properties of the extruded tube determined by ring hoop tension test can better describe the properties in hoop direction than by traditional axial tension test. However, it is not sufficient to describe the formability of tube during hydroforming process. Therefore, free expansion test is carried out.

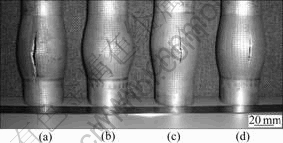

Free expansion test of the seamless tube was carried out at the temperature from room temperature to 230 ℃, as shown in Fig.6. The expansion length was 60 mm, about 1.5 time of tube diameter.

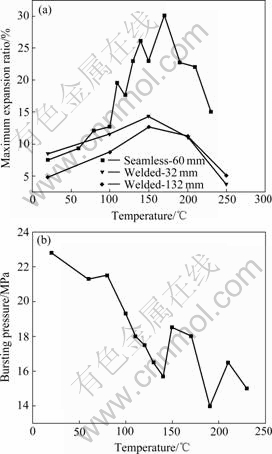

It can be seen from Fig.6 that the tube fractured in typical brittle pattern even when tested at warm temperature, and no obvious thinning or necking occurred before fracture. The maximum expansion ratio and bursting pressure are given in Fig.7, together with the result of the welded tube reported in Ref.[16] where the expansion lengths were 32 mm and 132 mm, respectively. It can be found that for the seamless tube, the maximum expansion ratio increased rapidly as temperature increased from room temperature to 170 ℃ and reached the value of about 30%. After 170 ℃, the maximum expansion ratio began to decrease rapidly. The maximum expansion ratio of the welded tube had a similar changing curve, but was obviously lower than that of the seamless tube. In Fig.7(b), the bursting pressure of seamless tube decreased rapidly as temperature increased.

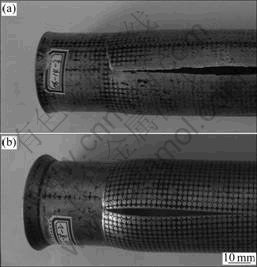

Fig.8 shows the fractures of welded tube at room temperature and 250 ℃. The fracture at room tempera-ture is typical brittle fracture, while the fracture at 250 ℃ is very straight and different from traditional brittle fracture or ductile fracture. Flaring test at 250 ℃ was conducted to further investigate the fracture of tube at elevated temperature. Quite similar fracture was seen in flaring test, which positioned symmetrically along the hoop direction. It is reasonable to conclude that these fractures are located along the welds formed during extrusion process, and can be called weld line fracture in contrast to traditional brittle fracture or ductile fracture.

Fig.6 Free expanded seamless tube at different temperatures: (a) 150 ℃; (b) 170 ℃; (c) 190 ℃; (d) 210 ℃

Fig.7 Free expansion results for seamless tube at different temperatures: (a) Maximum expansion ratio; (b) Bursting pressure

Fig.8 Fractures of welded tube at different temperatures: (a) Room temperature; (b) 250 ℃

4 Conclusions

1) The total elongation of seamless tube along hoop direction presents a quick decrease at the temperature range of 150-230 ℃, which is quite different from that along axial direction. The total elongation value along hoop direction of the welded tube is quite close to that of the seamless tube until temperature 230 ℃ is reached. At higher temperature, the total elongation for seamless tube begins to increase while the welded tube continues to decrease.

2) In free expansion test of seamless tube, the maximum expansion ratio increases considerably as temperature increases and reaches the maximum value of 30% at 170 ℃, then decreases quickly at temperature above 170 ℃. The bursting pressure also decreases considerably as temperature increases.

3) For welded tube, the welds formed during extrusion process tend to be the weakest positions when subjected to internal pressure, especially at elevated temperature. The strength of these welds should be improved before this kind of tube can be used for warm hydroforming.

References

[1] MERKLEIN M, GEIGER M. New materials and production technologies for innovative lightweight constructions [J]. Journal of Materials Processing Technology, 2002, 125/126: 532-536.

[2] GEIGER M, MERKLEIN M. Sheet and tube hydroforming at elevated temperatures [C]// SIEGERT K. Proceedings of the 3rd International Conference on Hydroforming. Fellbach, Germany: MAT INFO Werkstoff-Informationsgesellschaft, 2003: 259-277.

[3] VOLLERTSEN F. Hydroforming of aluminum alloys using heated oil [C]// Proceedings of the 9th International Conference on Sheet Metal. Leuven, Germany, 2001: 157-164.

[4] GROCHE P, BREITENBACH G. Influence of tube manufacturing processes on hydroforming [C]// LIEWALD M. Proceedings of Hydroforming of Tubes, Extrusions and Sheet Metals. Fellbach, Germany: MAT INFO Werkstoff-Informationsgesellschaft, 2005: 219-240

[5] LI D M, GHOSH A K. Biaxial warm forming behavior of aluminum sheet alloys [J]. Journal of Materials Processing Technology, 2004, 145: 281-293.

[6] LI D M, GHOSH A K. Tensile deformation behavior of aluminum alloys at warm forming temperatures [J]. Materials Science and Engineering A, 2003, 352: 279-286.

[7] LINK T M, KOSS D A, MOTTA A T. Failure of Zircaloy cladding under transverse plane-strain deformation [J]. Nuclear Engineering and Design, 1998, 186: 379-394.

[8] COHEN A B, MAJUMDAR S, RUTHER W E. Modified ring stretch tensile testing of Zr-1Nb cladding [R]. Report of Energy Technology Division, Argonne National Laboratory, 1999.

[9] WANG H, BOUCHARD R, EAGLESON R, MARTIN P, TYSON W R. Ring hoop tension test (RHTT): A test for transverse tensile properties of tubular materials [J]. Journal of Testing and Evaluation, 2002, 30(5): 382-391.

[10] HE Zhu-bin, YUAN Shi-jian, ZHA Wei-wei, LIANG Ying-chun. Force and deformation analysis of tube ring specimen during hoop tension test [J]. Acta Metallurgica Sinica, 2008, 44(4): 423-427. (in Chinese)

[11] SOKOLOWSKI T, GERKE K, AHMETOGLU M, ALTAN T. Evaluation of tube formability and material characteristics: Hydraulic bulge testing of tubes [J]. Journal of Materials Processing Technology, 2000, 98: 34-40.

[12] FUCHIZAWA S, KONDO H, SHIRAYORI A, NARAZAKI M. Forming limit of aluminum tube subjected to internal pressure and axial load [C]// Japan Society for Technology of Plasticity. Proceedings of the 53rd Japanese Joint Conference for the Technology of Plasticity. Hamamatsu, Japan, 2002: 219-220.

[13] KIM B J, PARK K S, RYU J S, MOON Y H. Experimental analysis for the tubular hydroformability of aluminum alloys at elevated temperatures [J]. Materials Science Forum, 2005, 475/479: 4215-4218.

[14] YUAN Shi-jian, QI Jun, HE Zhu-bin. An experimental investigation into the formability of hydroforming 5A02 Al tubes at elevated temperature [J]. Journal of Materials Processing Technology, 2006, 177: 680-683.

[15] SIEGERT K, JAGER S, VULCAN M. Pneumatic bulging of magnesium AZ31 sheet metal at elevated temperatures [J]. Annals of the CIRP, 2003, 51(1): 241-244.

[16] HE Zhu-bin, WANG Xiao-song, YUAN Shi-jian, XU Ai-jun. Formability of AZ31B magnesium alloy extruded tube under internal pressure [J]. Acta Metallurgica Sinica, 2007, 43(5): 534-538. (in Chinese)

[17] YINGYOT Aue-u-lan. Hydroforming of tubular materials at various temperatures [D]. The Ohio State University, 2007.

(Edited by YUAN Sai-qian)

Foundation item: Project(2006BAE04B03) supported by the National Key Technology Support Program; Project(20070410901) supported by China Postdoctoral Science Foundation

Corresponding author: HE Zhu-bin; Tel: +86-451-86414751; E-mail: hithe@hit.edu.cn