网络首发时间: 2019-01-28 07:00

选区激光熔化FGH4096高温合金的组织与性能

北京科技大学材料科学与工程学院

南方科技大学前沿与交叉科学研究院

深圳市高机能材料增材制造重点实验室

江苏永年激光成形技术有限公司

摘 要:

以等离子旋转电极法制备的FGH4096粉末为原材料,利用选区激光熔化(selective laser melting,SLM)技术制备了FGH4096合金,合金致密度达99. 3%。研究了SLM沉积态、直接时效态、固溶+时效态的组织和拉伸性能。SLM沉积态FGH4096合金由柱状晶构成,垂直熔池边界生长,柱状晶内排列着精细的树枝结构或等轴结构,以奥氏体γ相为主,少量的γ′相和碳化物沿树枝结构和等轴结构边界析出;直接时效处理后,大量三次γ′相析出,树枝结构或等轴结构边界粗化;固溶+时效后,回复和再结晶的发生,合金晶粒呈不规则形状,树枝结构和等轴结构消失,少量一次γ′相和碳化物在晶界析出,晶内分布少量二次γ′和大量均匀的三次γ′相。SLM沉积态FGH4096室温拉伸塑性好,热处理后强度明显提高,塑性下降,直接时效态屈服强度和拉伸强度最高,接近锻造状态。3种状态拉伸断口呈穿晶断裂,随着强度的提高,直接时效态拉伸断口出现数量较多的沿晶断裂区域。

关键词:

中图分类号: TG665;V252

作者简介:郝志博(1987-),男,河北张家口人,博士研究生,研究方向:粉末冶金,3D打印镍基高温合金,E-mail:386098874@qq.com;*葛昌纯,教授,电话:010-62334951,E-mail:ccge@mater.ustb.edu.cn;

收稿日期:2018-12-20

基金:国家自然科学基金项目(51171016);北京市科技新星计划项目(xx2018036);深圳市高机能材料增材制造重点实验室项目(ZDSYS201703031748354)资助;

Microstructure and Mechanical Properties of Powder Metallurgy Superalloy FGH4096 Fabricated by Selective Laser Melting

Hao Zhibo Tian Tian Li Xinggang Yan Qingzhi Ge Changchun Yan Yongnian

School of Materials Science and Engineering,University of Science and Technology Beijing

SUSTech Academy for Advanced Interdisciplinary Studies,Southern University of Science and Technology

Shenzhen Key Laboratory for Additive Manufacturing of High-Performance Materials

Jiangsu Yongnian Laser Forming Technology Company

Abstract:

FGH4096 alloy was prepared by selective laser melting(SLM)of metal powders produced by plasma rotating electrode process. The alloy density could reach 99.3%. The microstructure and tensile properties of the SLM as-deposited,directly aged,and solid solution+aged alloys were studied,respectively. The as-deposited FGH4096 alloy was composed of columnar crystals which grew perpendicularly at the melt pool boundary and consisted of fine dendritic or equiaxed substructure. A small number of γ′phase particles and carbides precipitated along the boundary of dendritic and equiaxed structure in the as-deposited FGH4096 alloy with austeniteγ phase as main phase. The microstructure of the directly aged alloy indicated a large number of tertiary γ′phase precipitates and coarsened grain boundaries of dendritic and equiaxed substructures. After solution+ageing treatment,the grains were irregularly shaped,and the dendritic and equiaxed substructures disappeared because of recovery and recrystallization. A small number of primary γ′phase particles and carbides precipitated at grain boundaries,while a small number of secondary γ′particles and a large number of uniform cubic tertiary γ′phase particles precipitated within the grain. The as-deposited FGH4096 had better ductility at room temperature. Although the strength increased significantly after heat treatment,the plasticity decreased. The yield strength and tensile strength of the directly aged alloy were the highest and close to the forging state. Tensile fractures of all three kinds of SLM alloys showed transgranular fractures. With the increase of the strength,the fracture appearance at the directly aged state exhibited a higher fraction of the transgranular fracture than that at the as-deposited state.

Keyword:

FGH4096 superalloy; selective laser melting; microstructure; tensile property;

Received: 2018-12-20

粉末高温合金具有组织均匀、无宏观偏析、合金化程度高等优点,是制造先进航空发动机的首选材料

选区激光熔化(selective laser melting,SLM)技术是增材制造技术中最有潜力的技术之一。与传统的制造技术相比,具有材料利用率高,能够实现部件的轻量化制备,制件形状复杂程度高、组织均匀、晶粒度小、成份偏析小等特点,航空航天领域的学者和研究机构开始不断尝试将SLM技术用于高温合金材料与部件的制备

Chlebus等

1 实验

采用江苏永年激光成形技术有限公司自主研制的SLMs-I设备进行制样,该设备采用单模光纤激光器,最大功率为300 W,光斑直径90?m,激光最大扫描速度为2000 mm·s-1。成形空间为Φ300mm×300 mm,以氩气作保护气体,保持成形腔内的氧含量在100×10-6以下。

实验采用等离子旋转电极法制备的FGH4096镍基高温合金粉末为原材料,粉末粒径范围在50-100?m,合金粉末的化学成分如表1所示,合金粉末表面形貌如图1所示。

本实验采用240,260和280 W激光功率进行制样,从3种激光功率中,确定较优参数,即280W激光功率制备实验样品,激光扫描策略为上下相邻两层旋转90°,扫描速度采用420 mm·s-1,粉末层厚度25?m。成形后部分FGH4096样品采用固溶+时效和直接时效两种热处理方式,固溶温度采用1150℃,保温3 h、油淬,时效温度采用770℃,保温20 h,空冷到室温。而后分别检测SLM沉积态和热处理态试样组织性能。

表1 FGH4096合金粉末的化学成分 下载原图

Table 1 Chemical composition of FGH4096 powder(%,mass fraction)

图1 FGH4096合金粉末形貌的SEM图片

Fig.1 SEM image of FGH4096 superalloy powder

试样经过600#-2000#砂纸研磨后,用1.0?m金刚石抛光膏机械抛光,在10 g CuCl2+100 ml HCl+100 ml C2H5OH试剂中进行金相腐蚀,腐蚀时间40 s,在江南光学仪器厂XTX-200光学显微镜(OM)下观察样品金相组织。而后试样同上经过研磨和抛光后,采用30 V直流电源在20%H2SO4+80%CH3OH试剂中电解抛光45 s,然后采用5 V直流电源在9 g CrO3+90 ml H3PO4+30 ml C2H5OH试剂中进行电解腐蚀10 s,在JSM-6701F冷场发射扫描电子显微镜(field emission scanning electron microscope,FESEM)进行组织结构的观察,该设备配有X射线能谱仪(energy dispersive spectrometer,EDS),以进行试样微区成分检测。拉伸试样在济南试金集团WDW200设备上进行检测,试样断口形貌在ZeissEVO-18扫描电镜(SEM)下观察。

2 结果与讨论

2.1 SLM沉积态与热处理态的组织形貌

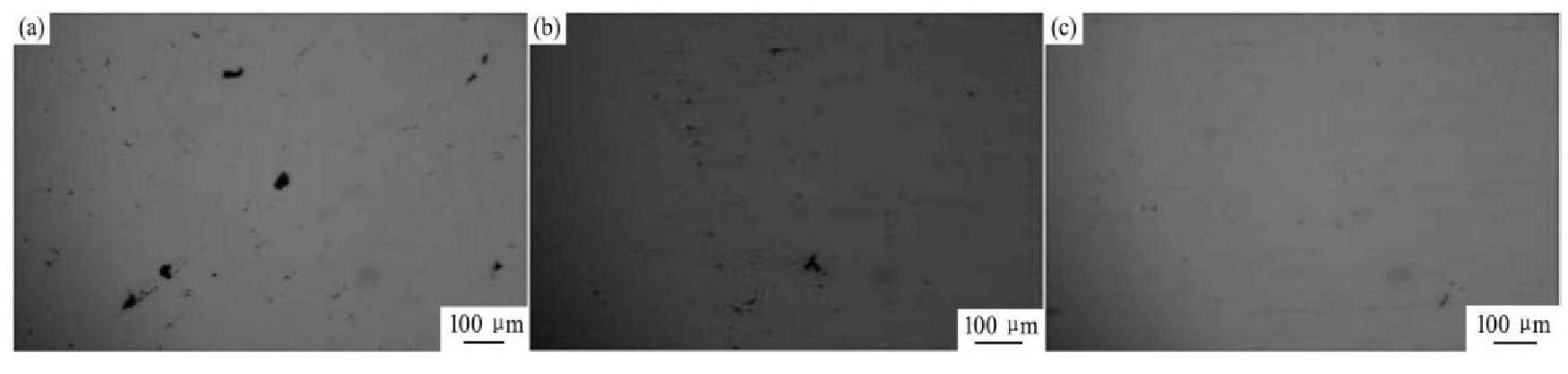

图2为SLM沉积态试样直接研磨、抛光后合金表面形貌,图2(a)为激光功率240 W试样抛光后表面,说明样品内部存在较大的不规则形状孔隙;图2(b)为激光功率260 W制件抛光后表面,与激光功率240 W的样件内部相比,孔隙数量减少,孔隙尺寸也有所降低;激光功率为280 W的成形样件抛光后表面基本没有较大的孔隙如图2(c)所示,采用阿基米德排水法测量激光功率为280 W制备的FGH4096样件致密度,该功率下样件致密度高达99.3%。因此采用280 W作为后续制备样品的激光功率。

图2 选区激光熔化FGH4096研磨、抛光后的表面以及孔隙形貌

Fig.2 Surface and pore morphology of SLM FGH4096 aftergrinding,polishing

(a)240 W;(b)260 W;(c)280 W

图3为SLM沉积态FGH4096合金的金相组织,图3(a)为合金竖直平面腐蚀后组织形貌,图右上方黑色箭头为合金成形方向,从整体上看,样品是通过线线扫描组成层,层层累积形成实体,线与线、层与层之间具有良好的冶金结合。激光在合金内形成的熔池呈拱状如图3(a)所示,这与文献

图4为SLM沉积态合金竖直截面和横截面的高倍FESEM形貌,图4(a)中区域1与区域2对比,等轴结构尺寸较小,图4(b)中的组织形貌与图3(b)相对应,由于粉末粒径分布较广且激光曝光后的熔池深度不同导致重熔区域与未重熔区域交织在同一平面内,图3(b)中亮白色的椭圆形区域内为精细的树枝状或等轴状结构,如图4(b)中嵌入图所示。这些区域对应于图3(a)中高度相对较窄的白色熔池,而暗灰色区域内部组织较亮白区域内组织粗大,因此图4(a)中的区域1对应图3(a)中的亮白色熔池,区域2对应于图3(a)中的暗黑色熔池。产生这样的形貌是由于粉末粒径较大且粉末粒径范围较广,从而影响了激光的曝光区域,进而使得熔池的深度产生差异,由此产生重熔差异。重熔部分(即区域2)由于激光的重复加热,使得树枝结构或等轴结构长大。

图3 FGH4096选区激光熔化沉积态OM形貌

Fig.3 OM images of SLM FGH4096

(a)Vertical section;(b)Cross section

图4 FGH4096选区激光熔化沉积态FESEM图片

Fig.4 FESEM images of SLM FGH4096

(a)Vertical section;(b)Cross section

从图4(a)中可以看出,SLM样件内部以柱状晶为主,基本垂直于熔池边界且部分跨边界生长,在柱状晶内部存在规则排列的外延树枝结构或者等轴胞状结构。这种结构类似于定向凝固组织或铸造结构组织

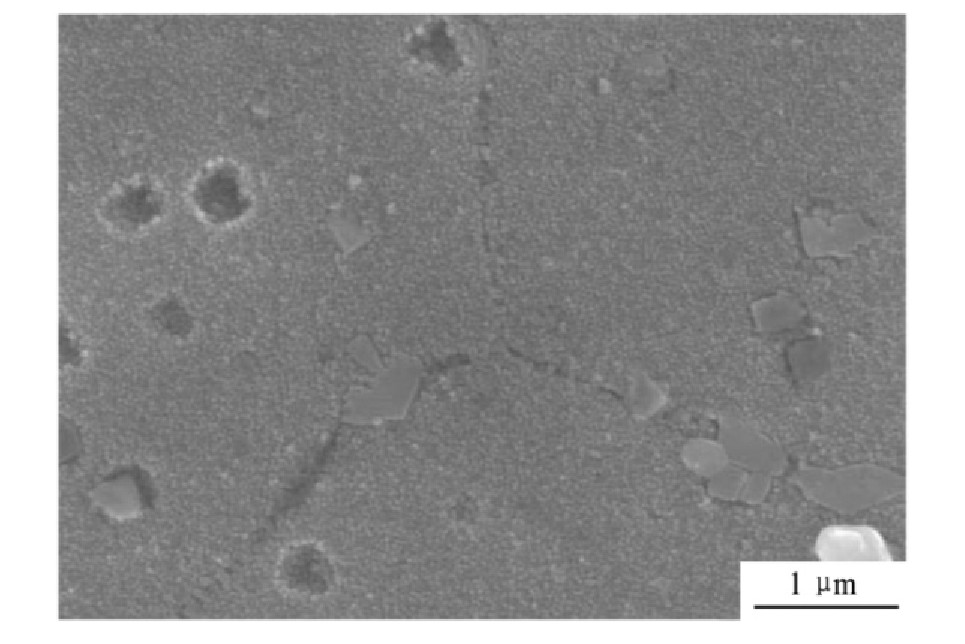

对SLM沉积态FGH4096样品进行XRD分析,如图5所示。主要显示了面心立方γ基体峰和面心立方LI2结构的Ni3(Al,Ti)-γ′的峰,这与直接热等静压FGH4096中的主要相组成是一致的。在FES-EM高倍观察如图6所示,在树枝状(或等轴胞状)结构内部存在少量尺寸约为50 nm的近球形γ′相,呈灰色,如图6白色箭头所示;在树枝(或等轴胞状)结构间析出了精细的白色方形或块状碳化物,这主要是一次MC碳化物

图5 SLM沉积态FGH4096合金试样的XRD图谱

Fig.5 XRD pattern for SLM FGH4096

图6 SLM沉积态FGH4096析出相FESEM形貌

Fig.6 FESEM image of precipitation in SLM FGH4096

FGH4096是沉淀强化型镍基高温合金,其主要强化相为γ′相,γ′相的数量、形状、大小、分布情况等直接影响FGH4096的力学性能

本文采用了直接时效和固溶+时效标准热处理两种制度对FGH4096合金进行处理、对比。图7(a)为直接时效后FGH4096的组织形貌,直接时效后的样品保持了沉积态的柱状晶组织,晶粒尺寸基本没有发生变化,柱状晶内部存在树枝结构和等轴胞状结构,但是树枝结构和等轴胞状结构边界发生粗化,图7(b)为图7(a)树枝结构边界的局部放大图,从图7(b)中可以看出γ′相在树枝结构边界处析出数量较内部多,尺寸在几十个纳米左右,呈近球形或近圆柱形。

SLM沉积态FGH4096合金经固溶+时效标准热处理后,其金相组织如图8(a)所示,柱状晶基本消失,晶粒内部的树枝结构和等轴结构基本消失。这主要受SLM制备FGH4096合金过程的影响,在沉积过程中,激光快速逐层扫描,使得合金内部产生较大的温度梯度,从而使得合金内部存在较大的储存能,而标准热处理过程中固溶温度已达到FGH4096的再结晶温度,进而促进了合金的回复和静态再结晶的发生,与此同时合金达到其晶界的扩散和迁移的激活能,回复和静态再结晶的发生以及柱状晶界的扩散、迁移,从而加速树枝、等轴结构的消失

图7 直接时效态FGH4096组织形貌的FESEM图片

Fig.7 FESEM images of SLM FGH4096 after directly aging

(a,b)being different magnfication

图8 SLM沉积态FGH4096在固溶+时效热处理后OM形貌

Fig.8 OM images of SLM FGH4096 after solutioning and aging

(a,b)being different magnification

SLM制件过程中,过快的冷却速率使得合金内部存在较高的空位浓度和位错密度,且大量的位错分布于树枝结构和等轴结构边界处

图9 SLM沉积态FGH4096在固溶+时效热处理后的析出相形貌的FESEM图片

Fig.9 FESEM image of precipitation in SLM FGH4096 after solutioning and aging

2.2 拉伸性能

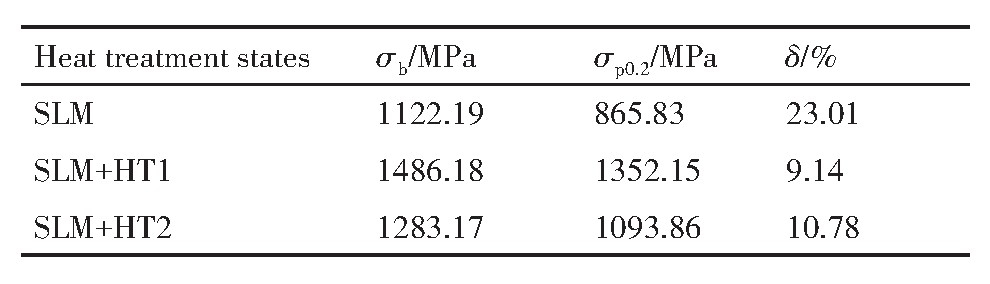

对SLM沉积态(SLM)、直接时效态(SLM+HT1)、标准热处理态(SLM+HT2)FGH4096室温拉伸性能进行对比研究(实验样品的拉伸方向垂直于沉积方向),其室温拉伸曲线如图10所示,从图10可以看出SLM沉积态拉伸样品的延伸率很高,但是拉伸强度较低,而经过热处理后合金的拉伸强度明显增加,尤其是直接时效态下的合金室温强度最高,但是塑性延伸率降低,如表2所示,其中σb为极限强度,σp0.2为屈服强度,δ为断后延伸率。

SLM沉积态与直接时效态合金晶粒尺寸和组织形貌,并没有发生较大的变化,主要区别在于时效处理后,合金内部均匀析出大量的纳米级γ′强化相,因此强化相的析出对合金的强度有较大的提高,强化相的析出阻碍了位错的滑移和合金的变形,提高合金强度的同时,塑性延伸率相对沉积态下降。

图1 0 3种处理状态的FGH4096室温拉伸曲线

Fig.10 Tensile curves for FGH4096 under three treatment states at room temperature

表2 FGH4096室温拉伸性能 下载原图

Table 2 Tensile properties of FGH4096 at room tempera-ture

通过直接时效态和固溶+时效态合金室温性能、晶粒尺寸和组织形貌的对比发现:固溶+时效态合金在晶界和晶内分布少量的一次、二次γ′相和碳化物,晶内主要以大量纳米级的三次γ′相为主,因此就析出物方面而言,固溶+时效与直接时效处理对性能差异产生的影响较小。然而直接时效与固溶+时效热处理后合金晶粒形状、尺寸差别很大,直接时效态合金仍旧保留了沉积态柱状晶组织,并且在柱状晶内存在大量的树枝结构和等轴胞状结构;而固溶+时效态合金在固溶处理过程中,由于固溶温度足够高,已经达到合金再结晶温度,合金发生回复和再结晶,晶粒内部的树枝结构和等轴胞状结构消失。直接时效后存在的大量树枝结构和等轴胞状结构对位错滑移和变形都起着一定的阻碍作用,同时一定程度上起到了细化晶粒的作用,这也是直接时效态强度高于固溶+时效态的原因。

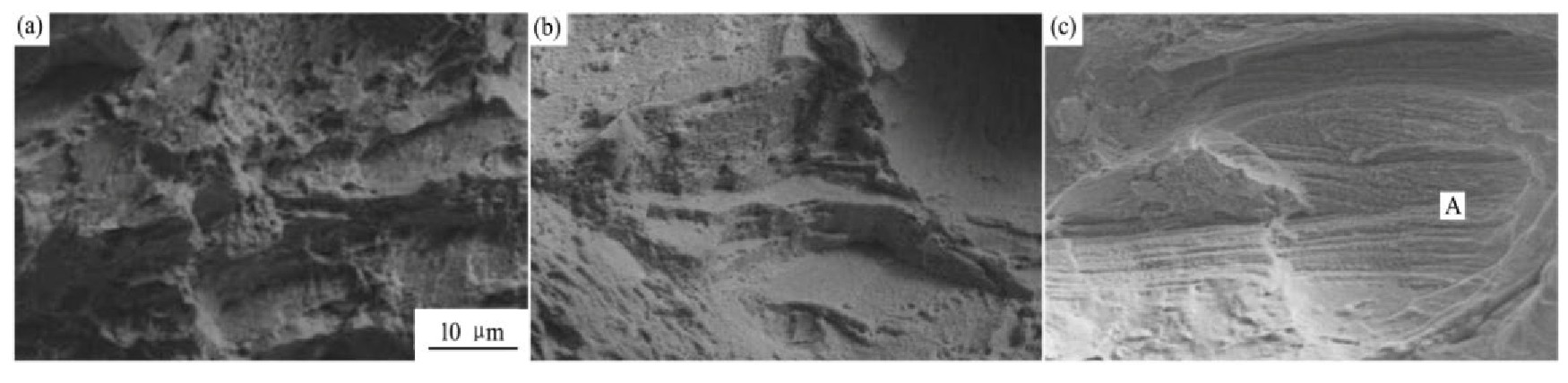

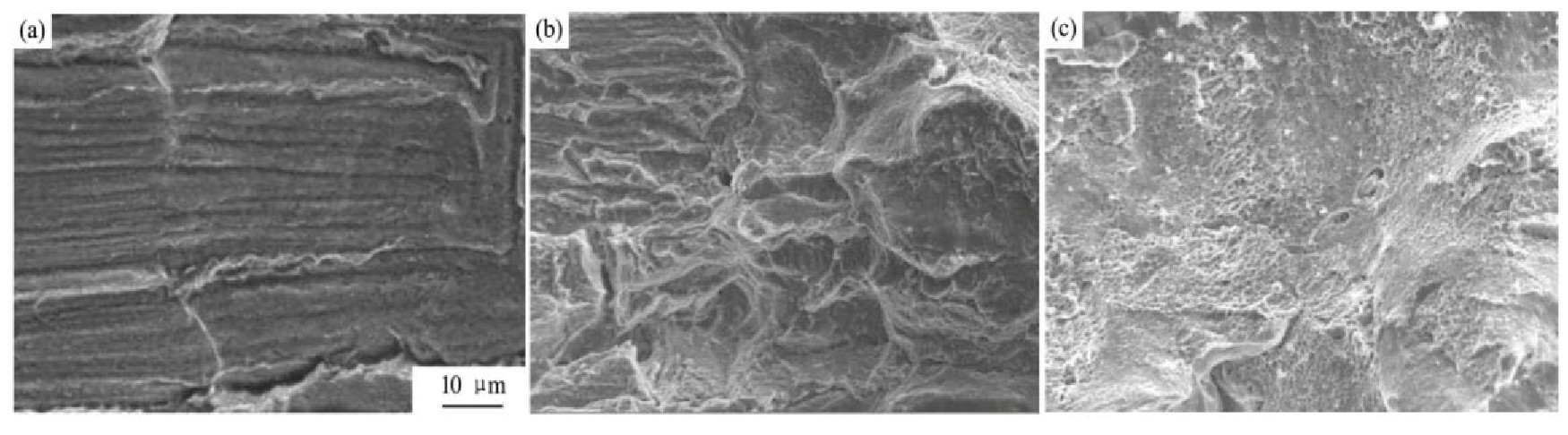

对不同处理状态下的室温拉伸断口进行分析:图11为沉积态拉伸断口表面形貌,从图中可以看出断口以穿晶断裂为主,图11(a,b)所示断口中存在大量韧窝,且韧窝较深,说明沉积态合金的断裂形式为塑性断裂,断口中存在少量解理断裂台阶如图11(b)所示,在沉积态的拉伸断口中存在少量沿晶断裂形貌,如图11(c)所示,两不同取向的树枝结构呈束状交汇在A处,说明不同取向树枝结构的交界处为合金薄弱区,易产生裂纹。

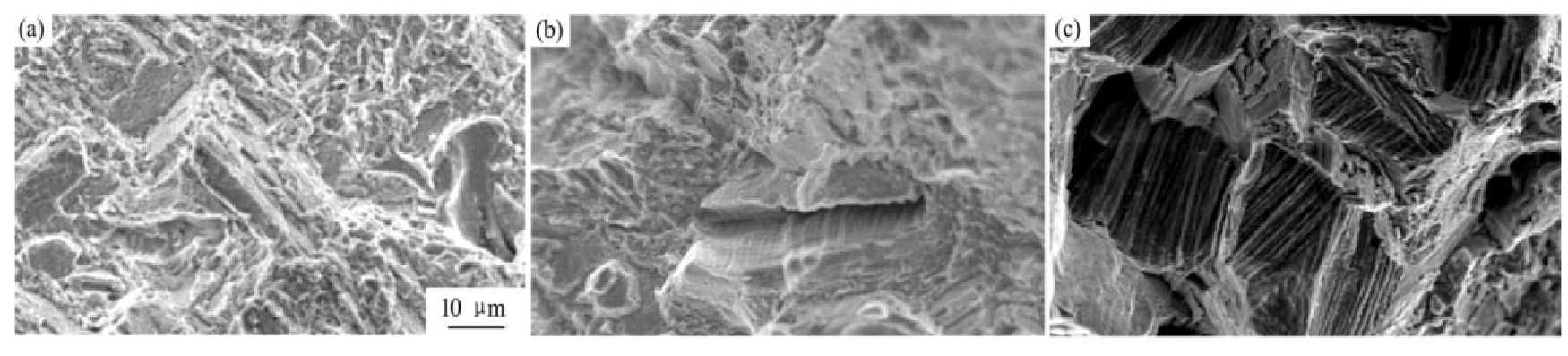

图12所示为直接时效态室温拉伸断口表面形貌,断口仍以穿晶断裂为主。图12(a)所示直接时效态断口中存在大量的解理断裂台阶,相对沉积态韧窝数量少且浅,呈现出趋于脆性断裂的特征,这一现象与图10室温拉伸曲线一致。图12(b,c)为直接时效态沿晶断裂形貌,相对沉积态合金,直接时效态合金沿晶断裂程度要高一些

图1 1 FGH4096沉积态拉伸断口SEM图片

Fig 11 SEM images of tensile fracture appearances of SLM FGH4096

(a)Dimple;(b)Step;(c)Intergranular fracture

图1 2 FGH4096直接时效处理局部拉伸断口SEM图片

Fig.12 SEM images of tensile fracture appearances of SLM FGH4096 after direct aging

(a)Step;(b)Tearing edge;(c)Intergranular fracture

图1 3 FGH4096固溶+时效处理局部拉伸断口SEM图片

Fig.13 SEM images of tensile fracture appearances of SLM FGH4096 after solutioning and aging

(a)Intragranular fracture;(b)Initial zone;(c)Shear lip zone

图12(b)为平行于拉伸方向的晶界,在晶界处可以看见较为明显的撕裂棱,因此平行于拉伸方向的树枝结构有利于合金的塑性延伸。图12(c)为垂直于拉伸方向的沿晶断裂,这种断裂方式相对容易发生,数量较多,从图12(c)中可以发现几个晶界的交汇处或者熔池的交界处为合金的薄弱区域。

图13为固溶+时效态室温拉伸断口表面形貌,以穿晶断裂为主,与沉积态和直接时效态断口明显不同,呈河流状解理断裂,试样断口平整近脆性断裂如图13(a)所示。图13(b)所示断口中存在少量的浅韧窝和滑移带。图13(c)为剪切唇区的浅韧窝,数量相对较多,但整体呈现脆断特征,断口中并未出现如沉积态和直接时效态的树枝结构状沿晶断裂。说明经过固溶热处理后,晶粒内部回复和再结晶的发生消除了SLM沉积态的树枝结构和等轴结构,树枝结构和等轴结构的消除降低了合金的拉伸强度

3 结论

1.SLM沉积态FGH4096合金主要以由树枝结构和等轴结构组成的柱状晶构成,柱状晶沿垂直熔池边界的方向生长。直接时效处理后的合金组织与沉积态相似,树枝结构和等轴结构边界由于第二相的析出发生粗化。固溶+时效态合金组织与沉积态和直接时效态明显不同,由于回复和再结晶的发生,树枝结构和等轴结构消失,形成不规则近等轴晶粒。

2.SLM沉积态FGH4096合金主要以奥氏体γ相为主,少量的γ′相和碳化物沿树枝结构和等轴结构边界析出。直接时效处理和固溶+时效处理后大量的三次γ′相析出,不同的是固溶+时效后少量的碳化物和一次γ′相在晶界上析出,晶内出现少量的二次γ′相,而直接时效后合金内部只存在大量的三次γ′相。

3.SLM沉积态FGH4096塑性非常突出,断后延伸率达23.01%,通过直接时效和固溶+时效热处理后屈服强度、拉伸强度明显增加,但塑性下降幅度也较大。直接时效态合金屈服强度和拉伸强度最高,分别为1352.15和1486.18 MPa,基本达到锻造水平。

种不同状态下的拉伸断口以穿晶断裂为主,直接时效态断口沿晶断裂程度较沉积态要高。由于树枝结构和等轴结构的存在使得沉积态、直接时效态断口与固溶+时效态断口产生明显差异。

参考文献