Trans. Nonferrous Met. Soc. China 22(2012) 2806-2812

Mechanism of phosphorus removal in beneficiation of high phosphorous oolitic hematite by direct reduction roasting with dephosphorization agent

XU Cheng-yan, SUN Ti-chang, KOU Jue, LI Yong-li, MO Xiao-lan, TANG Li-gang

Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education, University of Science and Technology Beijing, Beijing 100083, China

Received 12 October 2011; accepted 21 November 2011

Abstract:

High phosphorous oolitic hematite ore is one of typical intractable iron ores in China, and the conventional beneficiation methods are found to be impracticable to remove phosphorus from the ore effectively. Better beneficiation index were gotten by direct reduction roasting with dephosphorization agent followed by two stages of grinding and magnetic separation. P content decreases from 0.82% in the raw ore to 0.06% in the magnetic concentrate, and the total iron grade increases from 43.65% to 90.23%, the recovery of iron can reach 87%. Mechanisms of phosphorus removal in the beneficiation of high phosphorous oolitic hematite ore by direct reduction roasting with dephosphorization agent were studied using XRD, SEM and EPMA. The results showed that about 20% of the apatite in the raw ore transferred into phosphorus and volatilized with the gas in the process of reduction roasting, while the rest 80% apatite was not involved in the reaction of generation of phosphorus, and remained as apatite in the roasted products, which was removed to tailings by grinding and magnetic separation. A small amount of phosphorus existed in the magnetic concentrate as apatite. The oolitic texture of raw ore was partly changed during roasting, resulting in the formation of nepheline in the reaction between the dephosphorization agent, SiO2 and Al2O3 in the raw ore, which greatly improved the liberation degree of minerals in the roasted products, and it was beneficial to the subsequent grinding and magnetic separation.

Key words:

high phosphorous oolitic hematite; direct reduction roasting; phosphorus removal; dephosphorization agent; grinding; magnetic separation;

1 Introduction

The conventional beneficiation process of iron ore is found to be less effective in phosphorus removal of high phosphorus oolitic hematite, which is one of the most refractory ores in China. One ninth of China’s iron ore resources are oolitic hematite, in which 30-40 billion tons are high phosphorus oolitic hematite. Therefore, the studying and utilization of these resources has important strategic significance to relieve the contradiction between supply and demand of iron ores [1,2].

Extensive work has been performed on the beneficiation of refractory iron ore in China. YAN and ZHANG [3] applied the process of desliming-anionic reverse flotation to treat the refractory oolitic iron ore of the western Hubei Province, China. The concentrate with total iron grade of 58.12% and phosphorus content of 0.37% was obtained in the tests. ZHU et al [4] evaluated different beneficiation processes of the high phosphorous hematite from Yichang, Hubei Province, China. The results showed that gravity separation or high intensity magnetic separation cannot obtain the expected performance, whereas the concentrate with total iron grade of 57.09% and phosphorus content of 0.163% can be obtained by reverse flotation process. JIN et al [5] employed the acid-leaching process to dephosphorize the Chengde iron ore, and the results showed that sulfuric acid was more effective in dephosphorization than hydrochloric acid and nitric acid. YI et al [6] found that the reduction roasting-reverse flotation process was more effective in the beneficiation of oolitic hematite ore than the reverse flotation, and the concentrate with a total iron grade of 60.14% and a phosphorus content of 0.22% was obtained.

The mineral phase transformation of oolitic hematite treated by coal-based reduction roasting was studied by many scholars. YU and QI [7] and AI et al [8] turned weakly magnetic hematite into ferromagnetism mineral by magnetization roasting process, and recovered the iron concentrate by low intensity magnetic separation. The concentrate had a total iron grade of 58.40%,but its phosphorus content was higher than 0.2%. SHEN et al [9], SUN et al [10], LI [11] and LI et al [12] applied the direct reduction roasting followed by low intensity magnetic separation in the beneficiation of oolitic hematite. LI [11] obtained the product of directly reduced iron (DRI) with high phosphorus content of 0.3%. SHEN et al [9], SUN et al [10] and LI et al [12] did not mention the content of phosphorus in the DRI, which was due to the complex dissemination of the iron-bearing and phosphorus- bearing minerals and the ultra fine grain size. A direct reduction with additive and magnetic separation process was developed by LI et al [13], and a metallic iron concentrate with total iron grade of 93.84% and phosphorous content of 0.083% was obtained by this process. TANG et al [14] evaluated the dephosphorization performance of gas-based reduction and melt separation in the beneficiation of high phosphorous (1.20%) iron ore from Wuhan Iron and Steel Company, China. The results showed that there was 0.27% phosphorus in the metal sample, the oolitic mineral structure was not destroyed during reduction and P remained in the Ca3(PO4)2 after reduction. Similar studies in foreign countries were also reported. CHENG et al [15] used the process of roasting followed by acid-leaching to dephosphorize the Western Australian iron ore, and the phosphorus content was reduced from 0.126% in the raw ore to 0.042% in the concentrate. KANUNGO and MISHRA [16] employed the process of roasting with sodium chloride followed by leaching in dilute nitric acid to dephosphorize high-phosphorous manganese ores from Southern Orissa and Andhra Pradesh India. The phosphorus content can be reduced from 0.58% in the raw ore to 0.15% in the concentrate. DELVASTO et al [17] investigated a biological dephosphorization route to beneficiate the iron ore from Jangada Mines, Minas Gerais, Brazil, and the dephosphorization degree of 30% can be obtained by long term treatment (21 days).

YANG et al [18-20] conducted a lot of studies in the beneficiation of high phosphorus oolitic hematite. In comparison with the conventional methods, the direct reduction roasting using dephosphorization agent followed by grinding and magnetic separation showed better beneficiation performance [18,19]. However, the knowledge on the mechanism of phosphorus removal and reduction reactions has not been well understood. The purpose of this work is to investigate the transformation of phosphorus in reduction roasting with dephosphorization agent and elucidate the mechanism of phosphorus removal in this process.

2 Experimental

2.1 Materials

The high phosphorous oolitic hematite (hereinafter referred to as raw ore) used in the study was taken from Western Hubei Province, China, and the total iron and phosphorus grade were 43.65% and 0.83%, respectively. The valuable minerals were hematite and a small amount of limonite, and 97.82% of iron existed in the raw ore as hematite/limonite. The main gangue minerals were quartz, other silica minerals including chalcedony and opal, chlorite (oolitic chlorite, thuringite), and clay minerals (kaolinite, water mica). Phosphorus existed mainly in the form of collophane, and more detailed characteristics of the raw ore were reported previously [18].

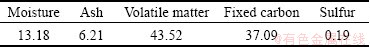

The reductant used in this study was lignite, and the proximate analyses are shown in Table 1. It can be seen that the lignite had comparatively high moisture of 13.18% with low ash and sulfur of 6.21% and 0.19%, respectively. The mixture of SY1 and SY2 was used as dephosphorization agent in the experiments. SY1 and SY2 are the mixture of sodium salts.

Table 1 Proximate analysis of lignite (mass fraction, %)

2.2 Methods

The raw ore and reductant were crushed to 100% less than 2 mm. A mixture of raw ore, reductant and dephosphorization agent with a mass ratio of 100:40:20 was used throughout the study, and the mass ratio of SY1:SY2 was 2:1. The details of tests procedure of direct reduction roasting with dephosphorization agent followed by grinding and magnetic separation were reported in the previous studies [19,20], in which the optimum condition of roasting was set at 1000 °C of roasting temperature, and 60 min of roasting time. The roasted products were treated by two stages of wet grinding with rod mill followed by magnetic separation, and the grinding fineness was 67.05% less than 74 μm (the first stage), and 97.15% less than 25 μm (the second stage), with the magnetic intensity of 89.13 kA/m. The magnetic concentrate with a grade of total iron and phosphorus of 90.23% and 0.06%, respectively, was obtained, and the iron recovery was 87%.

3 Results and discussion

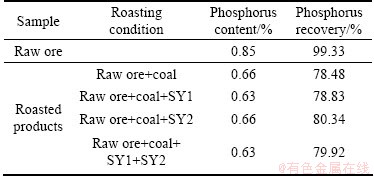

3.1 Change of phosphorus in roasting process

To investigate the mass change of phosphorus during the process of direct reduction roasting, phosphorus in the roasted products was assayed, and the results are listed in Table 2. It can be seen that the phosphorus recovery was 78.48% after reduction roasting using lignite as reductant, which was 20% lower than that of roasting without reductant. No significant changes were observed with the addition of SY1. 80.34% of phosphorus recovery was obtained when using SY2, which was 2% higher than that using SY1. Therefore, it can be concluded that about 20% of phosphorus in the raw ore was lost with gas during the direct reduction roasting process.

Table 2 Phosphorus recovery and content of roasted products and raw ore at different conditions

3.2 XRD analysis

3.2.1 XRD analysis of roasted products

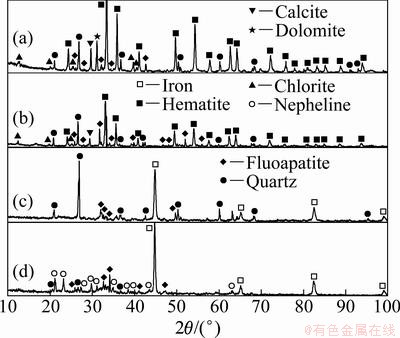

Analysis of the mineral phases in this study was carried out using X-ray diffraction. To better understand the phase transformation of apatite in the direct reduction roasting process, pure apatite was mixed with raw ore to augment the reactions in relation to phosphorus. In the tests, the mixed samples of raw ore (fineness: 100% less than 2 mm) and pure apatite (fineness: 100% less than 0.018 mm) with the mass ratio of 9:1(hereinafter referred to the mixed samples) was mixed with coal and dephosphorization agent, and then loaded into the muffle furnace.

Figure 1 presents the XRD patterns of the roasted products of the mixed samples with and without dephosphorization agent. As can be seen from Fig. 1, an increasing diffraction intensity of apatite in the mixed samples was observed in comparison with that of the raw ore (Fig. 1(a)), and metallic iron was newly generated in the roasted product without dephosphorization agent. In comparison with the diffraction intensity of apatite in the mixed samples, a decrease of diffraction intensity of apatite can be observed in the roasted product without dephosphorization agent, which was the same as the result gotten before, because of the volatilization of phosphorus created by part of apatite. Figure 1(c) also shows some new diffraction peaks attributed to nepheline (NaAlSO4) and iron in the roasted product. In comparison with the roasted product without dephosphorization agent, the decreasing diffraction intensity of quartz can be observed in Fig. 1(c). Therefore, it can be concluded that quartz in the raw ore reacts with the dephosphorization agent and other gangue minerals such as Al2O3, SiO2, resulting in the formation of nepheline as shown in reactions (1) and (2). No significant change was observed in the diffraction intensity of apatite in the roasted product with dephosphorization agent, which indicated that the apatite was not involved in the reaction elucidated as reactions (1) and (2) [21].

Na2SO4+Al2O3+mSiO2+CO=Na2O·Al2O3·mSiO2+SO2+CO2 (1)

Na2CO3+Al2O3+mSiO2=Na2O·Al2O3·mSiO2+CO2 (m=4.6) (2)

Fig. 1 XRD patterns of raw ore (a), mixed samples (b), roasted product without dephosphorization agent (c) and roasted product with dephosphorization agent (d)

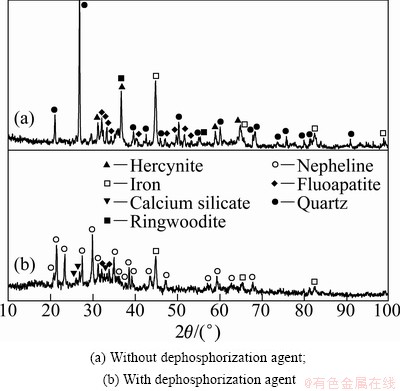

3.2.2 XRD analysis of middlings from magnetic separation

Two-stage grinding and magnetic separation of the roasted products with and without dephosphorization agent was carried out, and the middlings were collected. To better understand the mineral phase transformation of phosphorus, the middlings were analyzed by XRD, and the results are shown in Fig. 2. It can be seen that the phosphorus existed in the middlings with and without dephosphorization agent as apatite. The diffraction intensity of quartz, ferrospinel and fayalite in the middling without dephosphorization agent was stronger than that of the roasted product as well, which is probably due to the enrichment of these minerals after grinding and magnetic separation. The major phase was nepheline in the middling with dephosphorization agent, and the diffraction intensity was dramatically strengthened in comparison with that of the roasted product, which was the same reason mentioned above. In addition, calcium silicate was observed in the middling from the roasted product with dephosphorization agent. According to the data in Table 2, about 20% of apatite in the raw ore reacted with quartz and coal, forming phosphorus at high temperature. The reaction can be described as:

2Ca3(PO4)2+6SiO2+10C 6CaSiO3+10CO↑+4P↑ (3)

6CaSiO3+10CO↑+4P↑ (3)

Fig. 2 XRD patterns of middlings from magnetic separation of different roasted products

3.3 EPMA analysis of roasted product

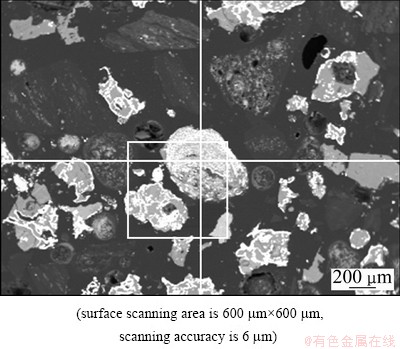

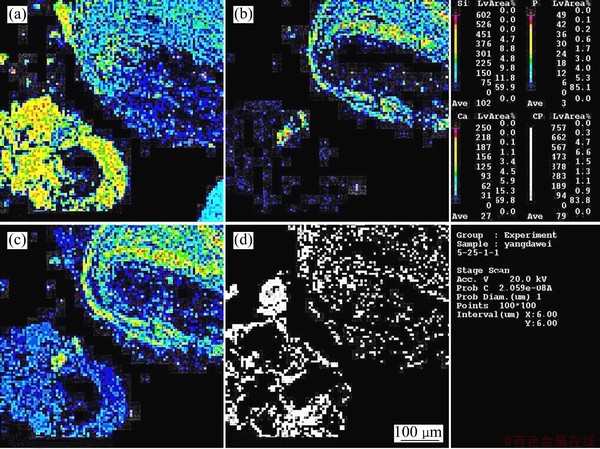

EPMA analysis of the roasted products with dephosphorization agent was carried out, and Fig. 3 shows the image of roasted product, in which the red square was the scanning area by EPMA. Figure 4 shows the distribution of Si, Ca and P elements in this area at scanning accuracy of 6 μm. Figure 4(d) shows the secondary electron image of the roasted product.

As shown in Fig. 4, phosphorus scattered in the roasted product separately with significantly high content in several particles. It can be seen that phosphorus and calcium associated closely. Particles with high phosphorus content also contained high calcium (white square in Fig. 4), which had the structure of oolitic texture. Apatite and iron-bearing minerals in the raw ore had no significant change after reduction roasting with dephosphorization agent. According to XRD analysis, phosphorus still existed as apatite in the roasted product with dephosphorization agent, not involved in the reaction of generation of nepheline. In addition, the whole content of silicon was higher in the roasted product.

Fig. 3 Secondary electron image of roasted products with EPMA analysis area

Fig. 4 EPMA mapping of silicon (a), phosphorus (b), calcium (c) and CP in roasted product (d)

3.4 SEM-EDS analysis of roasted products

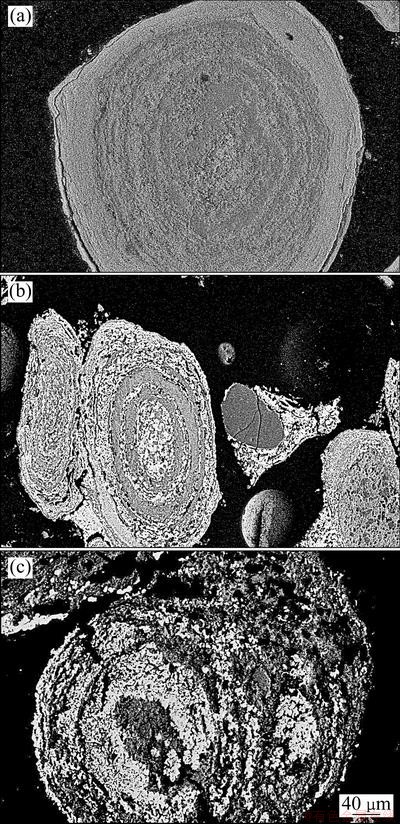

The SEM images of the raw ore and roasted products at different conditions are shown in Fig. 5. It can be seen from Fig. 5(a) that hematite (gray) and gangue minerals (dark gray) formed the oolitic texture in the raw ore. Oolitic structures with slightly breakage were also shown in the roasted products, in which metallic iron in white, and gangue minerals in dark gray were weaved together (as shown in Fig. 6). In addition, the metallic iron crystallite (hereinafter referred to as iron crystallite) in the roasted products aggregated significantly, and was apart from the gangue mineral with clear boundary. In comparison with the roasted products without dephosphorization agent (Fig. 5(b)), iron crystallite aggregated more significantly in the roasted products with dephosphorization agent. Thus, the destruction of the oolitic texture was more significant in the roasted product with dephosphorization agent (Fig. 5(c)). According to the analysis of XRD, it was demonstrated that the reaction between dephosphoriza- tion agent, quartz, and Al2O3 in the raw ore generated nepheline which partly damaged the oolitic texture, resulting in the improved liberation degree of minerals in the roasted products.

Fig. 5 SEM images of raw ore (a), roasted products without dephosphorization agent (b) and with dephosphorization agent (c)

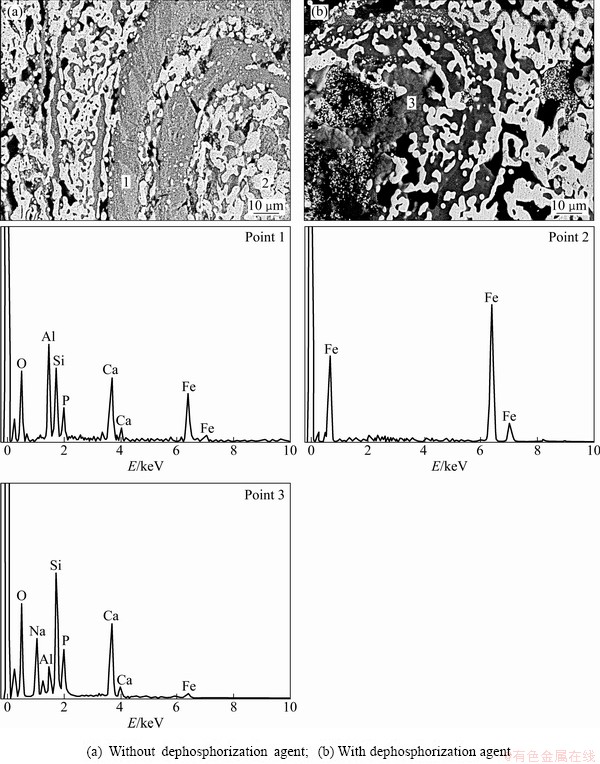

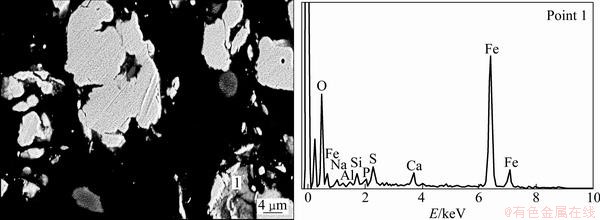

Fig. 6 SEM images and EDS spectra of roasted products

Figure 6 shows the SEM images and EDS spectra of the roasted products with and without dephosphorization agent. It can be seen that gangue minerals in the roasted products without dephosphorization agent contained the elements of Al, Si, Fe, and O (point 1), which illustrated that the iron crystallite (point 2) associated closely with the gangue minerals. The disseminated relationship was more complex, which was not beneficial to the subsequent grinding and magnetic separation, so it was difficult to attain the separation of iron and phosphorous minerals. The gangue minerals of the roasted products with dephosphorization agent contained the elements of Al, Si, Na, and O (point 3), which was nepheline. It was also found less Fe at point 3, which demonstrated that iron crystallite and gangue minerals were less intergrown and “clean” separation of iron and gangue by grinding and magnetic separation was easier after roasting.

In conclusion, direct reduction roasting with dephosphorization agent can improve the aggregation of iron crystallite and partly break the oolitic structure, which was beneficial to the subsequent grinding and magnetic separation. Additionally, gangue minerals in the roasted products contained Ca, P and O, which was identified to be apatite according to the XRD results.

3.5 SEM-EDS analysis of magnetic concentration

A small amount of phosphorus still existed in the magnetic concentrate of roasted product with dephosphorization agent followed by two stages of grinding and magnetic separation. SEM-EDS analysis was carried out to investigate the phase of phosphorus in the magnetic concentrate, and the results are shown in Fig. 7. It was evident that the magnetic concentrate mainly consisted of metallic iron (particles in bright white). It can be seen from the EDS spectrum in Fig. 7 that those small dark particles scattered in the magnetic concentrate mainly consisted of Ca, P, Na, Al, Si, and S. According to the XRD results mentioned above, phosphorus existed in the roasted product as apatite, and no transformation was observed during the subsequent grinding and magnetic separation. Therefore, those phosphorus-containing gangue minerals in magnetic concentrate were mainly apatite.

4 Conclusions

1) XRD and SEM analyses showed that the different phase transformation was produced in the reduction roasting with and without dephosphorization agent. In comparison with the roasting without dephosphorization agent, the oolitic structure and mineral morphology of the roasted product with dephosphorization agent changed more significantly, which indicated that the reaction between dephosphorization agent and gangue minerals partly destroyed the oolitic structure, and improved the liberation degree of minerals in the roasted products, which strongly affected the subsequent grinding and magnetic separation.

2) EPMA analysis showed that the disseminated relationship of phosphorus and calcium in the raw ore did not change after roasting with dephosphorization agent.

3) The mechanism of phosphorus removal by direct reduction roasting with dephosphorization agent was that during the process of roasting, 20% of apatite reacted with SiO2, Al2O3 in the raw ore and carbon in the reductant, generated the elemental phosphorus and then volatilized with gas. The rest 80% phosphorus remained in the roasted product as apatite, and was removed into the tailings by grinding and magnetic separation. A small amount of phosphorus existed in the magnetic concentrate as apatite.

Fig. 7 SEM image and EDS spectrum of magnetic concentrate with dephosphorization agent

References

[1] SUN Bing-quan. Progress in China’s beneficiation technology for complex refractory iron ore [J]. Metal Mine, 2006(3): 11-13. (in Chinese).

[2] WU J, WEN Z, CEN M. Development of technologies for high phosphorus politic hematite utilization [J]. Steel Research International, 2011, 82(5): 494-500.

[3] YAN Wu, ZHANG Yu-shu. Experimental research on the desliming- inverse flotation for Exi refractory oolitic iron ores [J]. Metal Mine, 2008(11): 183-185. (in Chinese)

[4] ZHU Jiang, XIAO Gan, WANG Gui-ping. Research on beneficiation technology for certain high phosphorous hematite ore from Yichang, Hubei [J].Metal Mine, 2006(8): 189-191. (in Chinese)

[5] JIN Y, JIANG T, YANG Y, LI Q, LI G, GUO Y F. Removal of phosphorus from iron ores by chemical leaching [J]. Journal of Central South University of Technology, 2006, 13(6): 673-677.

[6] YI Xiao-xiang, YANG Da-bing, LI Ya-wei. Research on dressing technology of iron increase phosphorous reduction of oolitic hematite ore in southern Hezhang [J]. Metal Mine, 2008(11): 179-182. (in Chinese)

[7] YU Y, QI C. Magnetizing roasting mechanism and effective ore dressing process for oolitic hematite ore [J]. Journal of Wuhan University of Technology: Mater Sci, 2011, 26(2):177-182.

[8] AI Guang-hua, YU Xin-yang, WEI Zong-wu. Research on iron increase and dephosphorization of refractory high-phosphorus hematite-limonite ore [J]. Mining and Metallurgical Engineering, 2009, 29(2): 43-45. (in Chinese)

[9] SHEN Hui-ting, ZHOU Bo, HUANG Xiao-yi, ZHANG Yan-jun, LIN Xiang-wei. Roasting-magnetic separation and direct reduction of a refractory oolitic-hematite ore [J]. Mining and Metallurgical Engineering, 2008, 28(5): 30-34. (in Chinese)

[10] SUN Yong-sheng, LI Shu-fei, SHI Guang-quan, HAN Yue-xin, LI Yan-jun. Research on deep reduction of an oolitic hematite [J]. Metal Mine, 2009(5): 80-83. (in Chinese)

[11] LI Guang-tao. Experimental research on beneficiation of Sichuan high-phosphorus oolitic hematite-limonite ore [D]. Kunming: Kunming University of Science and Technology, 2008. (in Chinese)

[12] LI K, NI W, ZHU M, ZHENG M, LI Y. Iron extraction from oolitic iron ore by a deep reduction process [J]. Journal of Iron and Steel Research, International, 2011, 18(8): 9-13.

[13] LI G, XIE C, ZHANG Y, LI Q, JIANG T. Influence of additives on dephosphorization of oolitic hematite by direct reduction process [C]//TMS 2010. 139th Annual Meeting and Exhibition. Supplemental Proceedings. Volume 1: Materials Processing and Properties. TMS, Seattle, WA, USA, 2010: 505-513.

[14] TANG H, GUO Z, ZHAO Z. Phosphorus removal of high phosphorus iron ore by gas-based reduction and melt separation [J]. Journal of Iron and Steel Research, 2010, 17(9): 1-6.

[15] CHENG C Y, MISRA V N, CLOUGH J, MUN R. Dephosphorization of Western Australian iron ore by hydrometallurgical process [J]. Minerals Engineering, 1999, 12(9): 1083-1092.

[16] KANUNGO S B, MISHRA S K. Dephosphorization of high- phosphorous manganese ores from Andhra Pradesh and Southern Orissa, India by roasting [J]. Mineral and Metallurgical Processing, 2000, 17(1): 37-40.

[17] DELVASTO P, BALLESTER A, MUNOZ J A, BLAZQUEZ M L, GONZALEZ F, GARCIA-BALBOA C. Dephosphorization of an iron ore by a filamentous fungus [C]//XXII Brazilian National Meeting of Mineral Treatment and Extractive Metallurgy/VII Meeting of the Southern Hemisphere on Mineral Technology. Ouro Preto, Brazil, 2007: 285-293.

[18] YANG Da-wei, SUN Ti-chang, XU Cheng-yan, QI Chao-ying, LI Zhi-xiang. Beneficiation test on iron increase and phosphorous reduction of a high-phosphorous oolitic hematite in Western Hubei [J]. Metal Mine, 2009(10): 81-83. (in Chinese)

[19] YANG Da-wei, SUN Ti-chang, XU Cheng-yan. Reducing roasting and a synchronized dephosphorization of a high-phosphorous oolitic hematite [J]. Mining and Metallurgical Engineering, 2010, 30(1): 29-31. (in Chinese)

[20] YANG Da-wei, SUN Ti-chang, YANG Hui-fen, XU Cheng-yan, QI Chao-ying, LI Zhi-xiang. Study on the mechanism of dephosphorization in roasting process for direct reduction of high-phosphorus oolitic hematite in West Hubei [J]. Journal of University of Science and Technology Beijing, 2010, 32(8): 968-974. (in Chinese)

[1] LI G, JIANG T, LIU F, ZHOU T, FAN X, QIU G. Beneficiation of high-aluminium-content hematite ore by soda ash roasting [J]. Mineral Processing and Extractive Metallurgy Review, 2010, 31: 150-164.

高磷鲕状赤铁矿添加脱磷剂还原焙烧脱磷机理

徐承焱,孙体昌,寇 珏,李永利,莫晓兰,唐利刚

北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京 100083

摘 要:高磷鲕状赤铁矿是一种典型的难处理铁矿石,采用常规的选矿方法难以得到较好的提铁降磷指标。采用添加脱磷剂还原焙烧,然后对焙烧产物进行两段磨矿磁选来处理此类矿石,获得了较好的选别指标。实验结果表明,铁的品位从43.65%(原矿)提高到90.23%(磁选精矿),磷含量从0.82%(原矿)降低到0.06%(磁选精矿),铁的回收率达到87%。采用XRD、SEM、EPMA等分析方法对焙烧产物进行脱磷机理研究。结果表明,在还原焙烧过程中,原矿中有20%的磷灰石生成单质磷随气体挥发,80%的磷灰石没有参与生成单质磷的反应,仍以磷灰石的物相存在于焙烧产物中,而通过磨矿磁选被脱除到尾矿中。磁选精矿中少量的磷以磷灰石的形态存在。在焙烧过程中,加入的脱磷剂与原矿中的脉石矿物(SiO2、Al2O3)反应生成铝硅酸钠,此反应部分破坏原矿的鲕状结构,充分改善焙烧产物中矿物的单体解离程度,有利于后续的磨矿磁选。

关键词:高磷鲕状赤铁矿;还原焙烧;脱磷;脱磷剂;磨矿;磁选

(Edited by YUAN Sai-qian)

Foundation item: Project (51074016) support by the National Natural Science Foundation of China

Corresponding author: XU Cheng-yan; Tel: +86-10-13581691929; E-mail:chengyan12325@gmail.com

DOI: 10.1016/S1003-6326(11)61536-7

Abstract: High phosphorous oolitic hematite ore is one of typical intractable iron ores in China, and the conventional beneficiation methods are found to be impracticable to remove phosphorus from the ore effectively. Better beneficiation index were gotten by direct reduction roasting with dephosphorization agent followed by two stages of grinding and magnetic separation. P content decreases from 0.82% in the raw ore to 0.06% in the magnetic concentrate, and the total iron grade increases from 43.65% to 90.23%, the recovery of iron can reach 87%. Mechanisms of phosphorus removal in the beneficiation of high phosphorous oolitic hematite ore by direct reduction roasting with dephosphorization agent were studied using XRD, SEM and EPMA. The results showed that about 20% of the apatite in the raw ore transferred into phosphorus and volatilized with the gas in the process of reduction roasting, while the rest 80% apatite was not involved in the reaction of generation of phosphorus, and remained as apatite in the roasted products, which was removed to tailings by grinding and magnetic separation. A small amount of phosphorus existed in the magnetic concentrate as apatite. The oolitic texture of raw ore was partly changed during roasting, resulting in the formation of nepheline in the reaction between the dephosphorization agent, SiO2 and Al2O3 in the raw ore, which greatly improved the liberation degree of minerals in the roasted products, and it was beneficial to the subsequent grinding and magnetic separation.