DOI: 10.11817/j.ysxb.1004.0609.2020-35784

激光原位制备硼化钛与镍钛合金的摩擦磨损性能

林英华1,林振衡1,陈庆堂1,雷永平1, 2

(1. 莆田学院 机电工程学院,莆田 351100)

(2. 北京工业大学 材料科学与工程学院,北京 100124)

摘 要:

为了制备出可对比的两类复合涂层,采用TiB2和Ni+TiB2分别作为熔覆材料,在钛合金表面通过激光原位熔覆制备复合涂层。采用XRD、SEM、EPMA与摩擦磨损仪等实验手段,对合成的钛基复合涂层进行研究。结果表明:采用TiB2为熔覆材料时,可获得TiB2颗粒与TiB短纤维增强钛基复合涂层。采用Ni+TiB2为熔覆材料时,可生成NiTi合金填充在TiB2颗粒与TiB短纤维周围,但TiB2颗粒尺寸和TiB短纤维长度都得以减小。通过微动磨损测试,发现引入NiTi合金和TiB2颗粒及TiB短纤维复合强化,无法有效抵抗微动磨损性能。这主要与摩擦接触区的温度超过NiT超弹性变形的温度区间,且NiTi合金无法使裂纹扩展曲折及硬度低相关。最后,探讨了该复合涂层在抗微动磨损与干滑动磨损过程中的差异性。

关键词:

文章编号:1004-0609(2020)-05-1057-08 中图分类号:TN249;TG174.44 文献标志码:A

钛合金材料存在摩擦因数大、粘着磨损严重等问题,导致服役过程中对微动磨损特别敏感[1-2]。而TiB短纤维(简称TiBf)作为增强相已应用于钛基复合材料:一方面,TiBf具有高弹性模量、高硬度、高耐磨性、优异的抗氧化性以及与Ti之间好的相容性与稳定性;另一方面,TiBf与Ti基体具有非常相近的密度和热膨胀系数,这有利于获得粘附性强及稳定性高的TiBf/Ti复合涂层[3-4]。同时,TiBf和Ti基体之间不发生化学反应,能获得固定的取向关系,并且界面结构能以共格或半共格的形式结合[5],这有利于提高TiBf/Ti复合涂层的力学性能及疲劳性能。近年来,激光原位熔覆技术发展迅速:一方面,激光束通过聚焦获得高的能量密度,为钛合金表面制备TiBf/Ti复合涂层提供良好的热源;另一方面,激光原位熔覆加热速度快(1×105~1×109 ℃/s)、基体自冷度高(>104 ℃/s)等优势,能获得与基材呈冶金结合且组织致密的涂层[6]。目前研究表明,钛合金表面采用激光原位熔覆制备TiBf/Ti复合涂层具有一定的抗微动磨损性能,但抗磨损效果不显著[7]。

以其独特形状记忆功能的NiTi合金,由于具有超弹性、形状记忆效应、优异的力学性能及高阻尼性等特点,在工业领域已获得了应用[8-10]。近年来,研究表明[11-12],激光原位熔覆制备NiTi合金涂层能表现出优异的抗干滑动磨损性能,但需要与强化相复合使用。然而,干滑动磨损与微动磨损在摩擦过程方面存在差异,比较明显的区别是微动磨损的位移幅值较小,一般为100~300 μm之间[13-14]。虽然通过引入NiTi合金与TiBf进行复合能提高涂层的抗干滑动磨损性能,但能否提高涂层的抗微动磨损性能,目前尚未有学者进行该方面的研究。

本课题组前期研究表明[15-16],通过在钛合金表面激光原位熔覆Ni+TiB2粉可制备出BCC结构的NiTi合金、TiB短纤维与TiB2颗粒增强钛基复合涂层,且形成BCC结构的NiTi可填充在TiB短纤维和TiB2颗粒周围。而且,该复合涂层通过短纤维断裂偏移与颗粒脱粘方式诱发裂纹扩展曲折来提高复合涂层的断裂韧性[16]。为了探索NiTi合金与TiB短纤维、TiB2颗粒复合强化的抗微动磨损性能,本工作对比研究了NiTi合金引入前后复合涂层的抗微动磨损性能差异,并对复合涂层抗干滑动磨损性能与微动磨损性能的差异性进行探讨。

1 实验

1.1 复合涂层制备

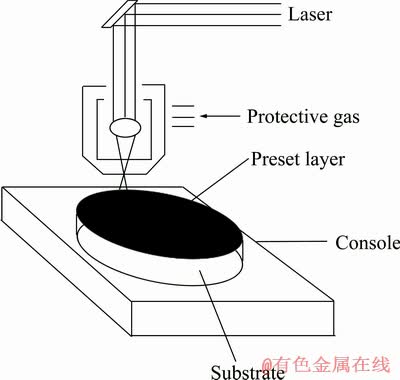

选用TC4钛合金为实验基材,并将钛合金切割成圆片状,圆片直径30 mm,圆片长度15 mm。将圆片端面用水砂纸进行逐级打磨成光滑面,并用无水乙醇清洗光滑面,以保证圆片端面无残留的氧化物和油污等杂质。选用质量分数为99.5%的TiB2粉末(晶粒尺寸5 μm)与质量分数为99.0%的Ni粉末(晶粒尺寸5 μm)为熔覆材料。为了降低熔覆材料的流失率,采用少量的 2123 酚醛树脂为粘接剂。将TiB2粉末与 Ni+TiB2粉末(n(Ni):n(TiB2)=1:1)分别预置于试样的圆片端面上, 预置涂层厚度控制为0.4 mm。然后,将预置层放置烘干箱进行烘干,温度与烘干时间分别设置为120 ℃和5 h。激光器选用YLS-6000型IPG光纤激光器,保护气选用Ar,流量设置为15 L/h。选用的激光工艺参数为: 激光功率P为1~5 kW, 激光束扫描速率v为3~10 mm/s, 光斑尺寸D为5 mm (类圆形光斑)。激光熔覆的试验方法,如图1所示。

图1 激光熔覆试验方法示意图

Fig. 1 Schematic diagram of laser cladding test method

1.2 复合涂层表征和性能测试

激光熔覆后,采用电火花线切割、研磨、抛光,用体积比为V(HNO3):V(HF):V(H2O)=3:2:95的腐蚀剂腐蚀后, 利用JSM-6490LA型扫描电镜(SEM)观察复合涂层横截面的微观组织。采用D/max 2550 VL/PC型X射线衍射仪(XRD)对复合涂层表面进行物相识别。由于B元素是低原子序数,能谱不能定量检测出其含量,本研究采用JXA-8100型电子探针(EPMA)对显微组织中相种类进行分析。

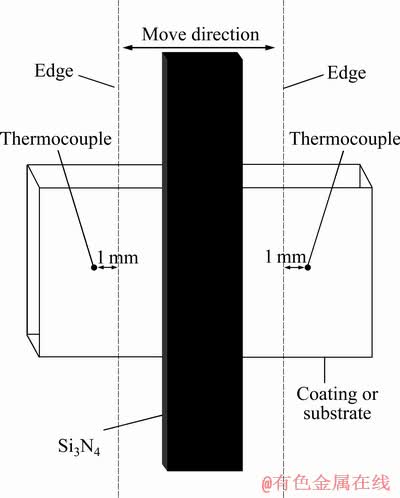

图2 摩擦磨损接触区温度测量方法示意图

Fig. 2 Schematic diagram of temperature measurement method for friction and wear contact zone

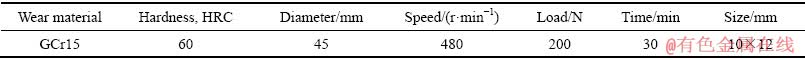

表1 干滑动磨损实验参数

Table 1 Measuring parameters of dry sliding wear test

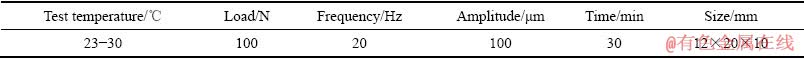

表2 微动磨损实验参数

Table 2 Measuring parameters of fretting wear test

采用MM-200型环块式磨损试验机进行复合涂层的干滑动摩擦磨损试验,实验参数如表1所示。采用FTM200微振动摩擦磨损试验机进行复合涂层的微动摩擦磨损测试,摩擦过程中的接触形式为线-面接触,实验参数如表2所示。采用多点热电偶对摩擦磨损近接触区的温度进行测试,测温试验方法,如图2所示。试样磨损后,磨痕形貌采用扫描电镜(SEM)观察,复合涂层和基材的磨痕轮廓采用Mahr-M1型轮廓仪进行测量,且根据以下公式计算微动磨损体积,公式为

V=SA

式中:V为磨损体积;S为磨痕截面积;A为位移值。

2 结果与分析

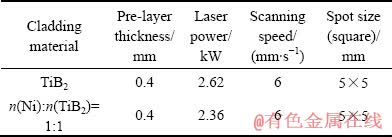

为了对比研究引入NiTi合金前后对TiB短纤维复合涂层抗微动磨损性能的影响,以TiB2和Ni+TiB2分别为熔覆材料,在钛合金表面采用激光原位熔覆制备两类复合涂层。经正交参数试验,工艺参数优化结果如表3所示。

表3 复合涂层的工艺参数

Table 3 Process parameters of composite coating

2.1 复合涂层组织结构

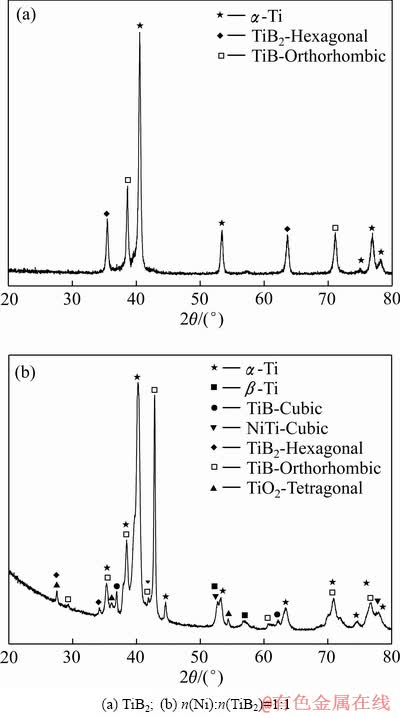

图3所示为Ni添加前后复合涂层的XRD谱。由图3可以看出,在钛合金表面采用TiB2为熔覆材料制备激光复合涂层,主要由TiB2、TiB与α-Ti 物相构成。说明在此激光条件下,Ti与TiB2会通过原位反应形成TiB。而在钛合金表面采用Ni与TiB2为熔覆材料制备激光复合涂层,主要由BCC结构的NiTi、TiB、TiB2、α-Ti、β-Ti及少量的TiO2组成。说明在此激光条件下,可原位合成NiTi合金。而之所以能避免Ni3Ti及NiTi2的形成,主要与TiB形核驱动力大、Ti原子扩散系数大及熔池形成初期Ni和Ti液分布相关[16]。

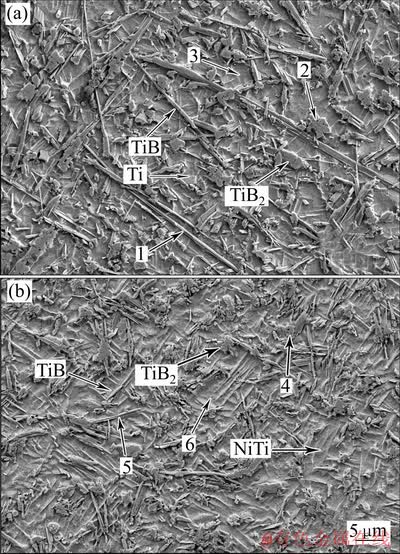

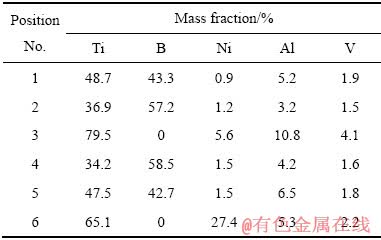

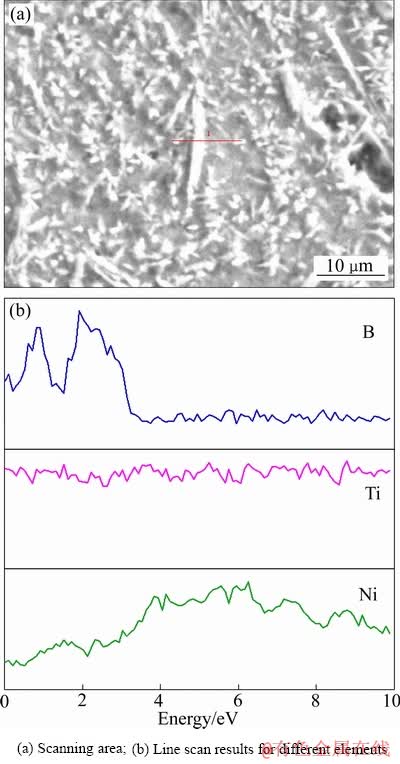

图4所示为Ni添加前后复合涂层横截面中部的SEM像。由图4可以看出,Ni添加前,复合涂层主要由颗粒与细针状组织构成,颗粒的平均尺寸为5~7 μm左右,细针状平均长度为12~15 μm左右,通过XRD和EPMA识别,发现颗粒和细针状分别为TiB2和TiB,如表4所示。而Ni添加后,复合涂层也主要由颗粒与细针状组织构成,但颗粒的数量和尺寸都呈下降趋势,颗粒的平均尺寸为3~5 μm左右。说明Ni添加明显提高了TiB2颗粒的溶解程度。细针状数量呈增多趋势,但细针状长度呈略微降低,细针状平均长度为8~10 μm左右。另外,由于Ti与NiTi的耐腐蚀性能差异小,而TiB与TiB2陶瓷相又很耐腐蚀。因此,采用EPMA线扫描进行分析,发现Ni元素与B元素的含量分布刚好呈相反趋势,结合XRD推测NiTi合金会分布在TiB周围,如图5所示。

图3 Ni添加前后复合涂层表层的XRD谱

Fig. 3 XRD patterns of surface of composite coating

图4 Ni添加前后复合涂层横截面中部的SEM像

Fig. 4 SEM images of middle regions of coatings before(a) and after(b) adding Ni

表4 图4中各位置的EPMA点区域测试结果

Table 4 EPMA point area test results of different positions marked in Fig. 2

图5 复合涂层线扫描测试结果

Fig. 5 Line scanning test results of coating

2.2 复合涂层抗干滑动磨损与微动磨损性能

由前期研究结果可知[17],TiB短纤维复合涂层在干滑动磨损条件下表现出优异的耐磨性能,但在微动磨损条件下该复合涂层无法有效抵抗微动疲劳。虽然TiB短纤维在抗微动疲劳方面能表现出一定的优越性,但从实验结果来看减磨效果并不显著。具有独特形状记忆功能的NiTi金属间化合物在变形过程中能产生应力诱发马氏体相变及超弹性效应而表现出良好的抗疲劳性能。王华明等[18-19]采用NiTi和其他强化相(如B4C、TiB2、TiC及Ni3Ti)增强钛基复合涂层,实验表明复合涂层在干滑动和磨粒磨损条件下都表现出优异的耐磨性能。本研究试图采用NiTi和TiB2颗粒及TiB短纤维进行复合强化来进一步提高抗微动磨损性能。

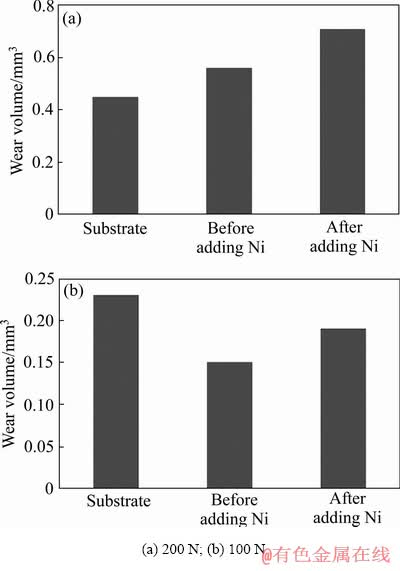

由前面分析可知,采用TiB2粉末和n(TiB2):n(Ni)= 1:1的粉末分别作为熔覆材料,在钛合金表面通过激光原位熔覆技术都能制备出TiB2颗粒和TiB短纤维增强钛基复合涂层,并且Ni的添加还可生成NiTi合金。图6所示为两种不同摩擦载荷下复合涂层和基体的磨损量。由图6可知,在高磨损载荷条件下(200 N),复合涂层的磨损体积都比基体大,并且Ni添加后,复合涂层的磨损体积更大。在低磨损载荷条件下(100 N),虽然复合涂层的磨损体积都比基体小,但Ni添加后, 复合涂层的磨损体积比Ni添加前的大。说明涂层中引入部分NiTi合金并不能改善微动磨损性能。

图6 不同摩擦载荷下复合涂层和基体的磨损量

Fig. 6 Wear loss of coatings and substrate at different wear loads

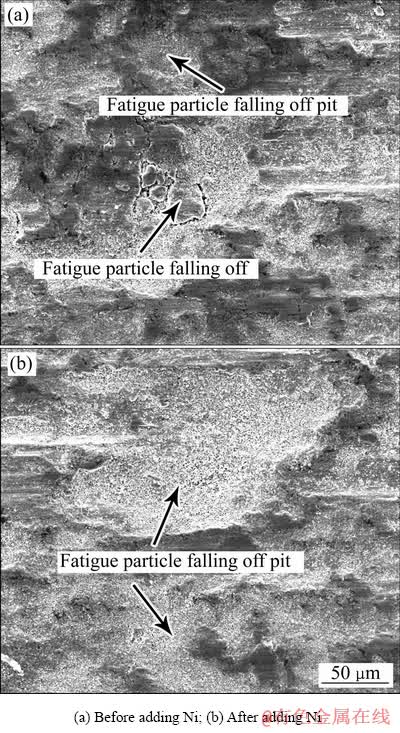

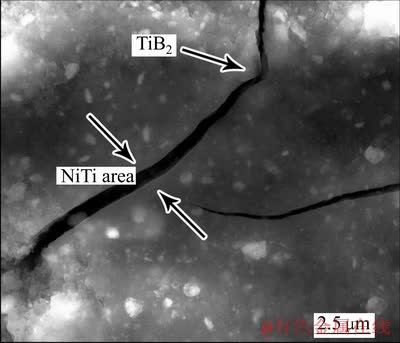

图7所示为添加Ni前后复合涂层在磨损载荷为100 N下磨痕形貌。由图7可知,Ni添加后,涂层表面的疲劳颗粒脱落面积变得更大。由此可更进一步表明涂层中NiTi合金的引入无法有效抵抗微动疲劳性能。这主要有3个方面的原因;1) 由于摩擦生热,并且微动磨损中磨屑不易排出,会导致摩擦接触区温度持续升高。从表5可知,摩擦区温度远超过132 ℃,而NiTi合金超弹性行为的有效温度区间为低于110 ℃下才能发挥明显作用[20]。2) 复合涂层中存在NiTi合金不能诱使裂纹扩展方向发生偏转。由图8可知,NiTi区周围的TiB2颗粒能明显改变裂纹扩展方向,但NiTi本身无法实现。其他研究者[21]也研究表明当使用温度高于应力诱发马氏体相变温度时,NiTi合金的裂纹扩展方向没有发生偏转。3) 当NiTi合金成为普通材料时,其硬度仅为241 HV0.2,比钛合金的硬度还低(330 HV0.2)。

图7 磨损载荷为100 N时的磨痕形貌

Fig. 7 Wear scar morphologies under 100 N of wear load

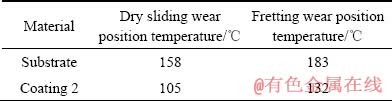

表5 干滑动磨损与微动磨损下距磨损区边缘1 mm位置的温度

Table 5 Temperature at location of 1 mm from wear area edge under dry sliding and fretting wear

图8 NiTi裂纹扩展区的形貌

Fig. 8 Morphology of crack propagation of NiTi

2.3 复合涂层干滑动与微动磨损的差异性

干滑动磨损和微动磨损,所涉及的磨损机制主要为:粘着磨损、磨粒磨损、疲劳断裂磨损和氧化磨损。由于TiB2和TiB都是抗高温陶瓷相,即分别由B—B共价键和Ti—B离子键组成的密排六方晶系和斜方晶系结构组成,具有很高的键能和化学稳定性[22-23]。因此,在常规摩擦磨损过程中,TiB2颗粒和TiB短纤维都较难与Ti、O、Si和N发生化学反应,摩擦的结果主要造成材料的磨损和转移。然而,由前面分析结果可知,相同复合涂层在抗干滑动磨损和微动磨损的效果差别很大。接下来将从以下3方面探讨干滑动磨损和微动磨损方式的差异性。

首先,摩擦因数是摩擦磨损过程中的一项重要指标,能综合反映材料的耐磨性、摩擦磨损失效等特性。根据课题组前期研究结果可知[24],基体和复合涂层的摩擦因数都呈周期性波动趋势。这种摩擦因数的周期性波动主要与磨屑的产生、弹性变形、滚动、塑性变形及溢出相关[25-27]。而课题组前期研究和大量文献研究表明[28-29],干滑动磨损过程中,摩擦因数不会出现明显的周期性波动,在整个过程中仅出现小幅度的波动。这是由于微动磨损产生的磨屑仅在小区域范围内移动,这种磨损方式会使磨屑成为“第三体”参与磨损。而干滑动磨损产生的磨屑很容易被排出摩擦区,少量未被及时排出的磨屑也引起了摩擦因数的小幅度波动。

其次,温度变化是诱发材料机械性能与化学成分改变的重要因素。由于摩擦磨损过程,会产生大量的摩擦热,使磨损接触面温度急剧升高。与干滑动磨损相比,微动磨损的位移幅值小,会导致磨屑不易被排出[30],造成了摩擦热较难被迅速扩散。由表5可知,无论基体或涂层,微动磨损下近磨损区1 mm的测试温度都比干滑动磨损下的高。尽管所测到的温度不高,不至于引起TiB2和TiB与其他成分发生化学反应,但会对基体相(如钛基体)的塑性变形和氧化造成影响,从而加剧了材料的磨损。

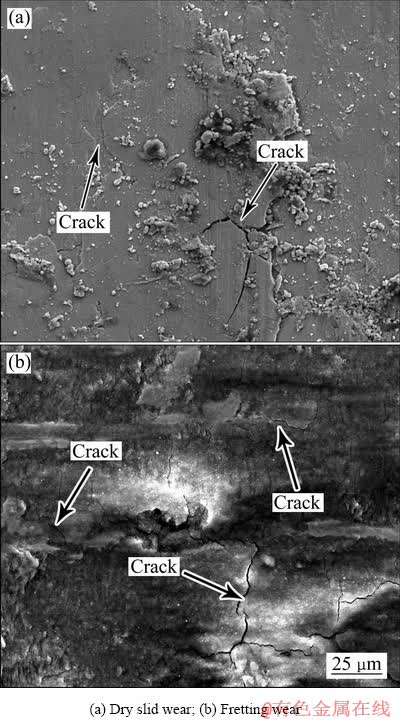

最后,在同等载荷作用下,接触面积小的材料局部承载的应力更大,于是在循环应力下会加速材料表面及亚表层结构裂纹的萌生与扩展。相比于干滑动磨损,微动磨损接触面间发生的振幅极小,导致对配件与材料表面的接触面积变小,从而使材料局部承受更大的载荷应力。图9所示为磨损载荷为200 N与磨损时间为3 min下涂层1的磨痕形貌。由图9可知,在同等载荷下,微动磨损区的裂纹数量及长度都比干滑动磨损区的多及长。这也表明在对涂层微动磨损工况的设计过程中,更应考虑涂层的疲劳要素。

以上分析可知,干滑动磨损与微动磨损的差异,直观上表现为摩擦因数、温度与承载应力的不同。而从材料角度看,干滑动磨损过程与微动磨损过程出现的是磨屑排出、基体相塑性和氧化、接触区裂纹扩展的不同。

图9 涂层1在200 N载荷下磨损3 min后磨损区的形貌

Fig. 9 Wear scar morphology of coating 1 under load of 200 N for 3 min

3 结论

1) Ni添加前,钛合金表面激光原位熔覆TiB2粉可制备出TiB2颗粒与TiB短纤维增强钛基复合涂层;Ni添加后,通过激光原位熔覆制备出NiTi合金填充在TiB2颗粒与TiB短纤维周围,但TiB2颗粒尺寸和TiB短纤维长度都得以减小。

2) 通过微动磨损实验,发现引入NiTi合金和TiB2颗粒及TiB短纤维复合强化,无法有效抵抗微动疲劳性能。这可能与摩擦接触区的温度超过NiT超弹性行为的温度区间,且NiTi合金无法使裂纹扩展曲折相关。

3) 微动磨损的近磨损区温度高于干滑动近磨损区的温度,并且微动磨损区的裂纹数量和长度多于干滑动磨损区的裂纹数量和长度。

REFERENCES

[1] 丁 燕, 梁 军, 邓 凯, 柏 林, 戴振东. 损伤容限型钛合金TC4-DT的微动磨损性能[J]. 中国有色金属学报, 2017, 27(3): 532-538.

DING Yan, LIANG Jun, DENG Kai, BO lin, DAI Zhen-dong. Fretting wear of damage tolerance TC4-DT alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 532-538.

[2] ZHOU Y, SHEN M X, CAI Z B, PENG J F, ZHU M H. Study on dual rotary fretting wear behavior of Ti6Al4V titanium alloy[J]. Wear, 2017, 376/377: 670-679.

[3] BA J, LI H, REN B X, QI B X, ZHENG X H, NING R, QI J L, CAO J, CAI W, FENG J C. In situ formation of TiB whiskers to reinforce SiO2-BN/Ti6Al4V brazed joints[J]. Ceramics International, 2019, 45: 8054-8057.

[4] 黄立国, 陈玉勇. 少量TiB晶须对Ti-B20合金β晶粒长大行为的影响[J]. 中国有色金属学报, 2015, 25(8): 2108-2114.

HUANG Li-guo, CHEN Yu-yong. Influence of trace TiB whisker on grain growth behavior of β grain in Ti-B20 alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2108-2114.

[5] PANDA K B, RAVI CHANDRAN K S. First principles determination of elastic constants and chemical bonding of titanium boride (TiB) on the basis of density functional theory[J]. Acta Materialia, 2006, 54: 1641-1657.

[6] FENG Y Q, FENG K, YAO C W, LI Z G, SUN J H. Microstructure and properties of in-situ synthesized (Ti3Al+TiB)/Ti composites by laser cladding[J]. Materials and Design, 2018, 157: 258-272.

[7] LIN Y H, JIANG C C, LIN Z H, CHEN Q T, LEI Y P. Laser in-situ synthesis of high aspect ratio TiB fiber bundle reinforced titanium matrix composite coating[J]. Optics and Laser Technology, 2019, 115: 364-373.

[8] JIANG S Y, ZHAO Y N, ZHANG Y Q, HU L, LIANG Y L. Effect of solution treatment and aging on microstructural evolution and mechanical behavior of NiTi shape memory alloy[J]. Transaction of Nonferrous Metals Society of China, 2013, 23(12): 3658-3667.

[9] HAN T, SOHN Y H, PARK S J, KIM Y C, LEE K S, KIM H S, YOON S G, KIM D J, HAN J H. Reduction of magnetic resonance image artifacts of NiTi implant by carbon coating[J]. Materials Science and Engineering C, 2019, 98: 1-8.

[10] HSU W N, POLATIDIS E, SMID M, PETEGEM S V, CASATI N, SWYGENHOVEN H V. Deformation and degradation of superelastic NiTi under multiaxial loading[J]. Acta Materialia, 2019, 167: 149-158.

[11] FERNANDEZ J, ISALGUE A, CINCA N, GARCIA-CANO I, VENTAYOL J. Comparison of mechanical and tribological properties of TiC- NiTi and TiC-TiB2-NiTi coatings[J]. Physics Procedia, 2010, 10: 65-68.

[12] GAO F, WANG H M. Abrasive wear property of laser melting/deposited Ti2Ni/TiNi intermetallic alloy[J]. Transaction of Nonferrous Metals Society of China, 2007, 17: 1358-1362.

[13] 张晓宇, 任平弟, 蔡振兵, 彭金方, 刘建华, 朱旻昊. 300 ℃氮气中交变载荷条件下Inconel 690合金的微动磨损特性[J]. 中国有色金属学报, 2016, 26(3): 544-550.

ZHANG Xiao-yu, REN Ping-di, CAI Zhen-bing, PENG Jin-fang, LIU Jian-hua, ZHU Min-hao. Fretting wear behavior of Inconel 690 alloy under alternating load conditions at 300 ℃ in nitrogen environment[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(3): 544-550.

[14] LIN Y, LIN Z H, CHEN Q T, LEI Y P, FU H G. Laser in-situ synthesis of titanium matrix composite coating with Ti B-Ti network-like structure reinforcement[J]. Transaction of Nonferrous Metals Society of China, 2019, 29: 1665-1676.

[15] 林英华, 雷永平, 符寒光, 林 健. 激光原位制备硼化钛与镍钛合金增强钛基复合涂层[J]. 金属学报, 2014, 50(12): 1513-1519.

LIN Ying-hua, LEI Yong-ping, FU Han-guang, LIN Jian. Laser in situ synthesized titanium diboride and nitinol reinforce titanium matrix composite coatings[J]. Acta Metallurgica Sinica, 2014, 50(12): 1513-1519.

[16] 林英华, 雷永平, 符寒光, 林 健. Ni添加对TiB2/TiB钛基复合涂层组织与力学性能的影响[J]. 金属学报, 2014, 50(12): 1520-1528.

LIN Ying-hua, LEI Yong-ping, FU Han-guang, LIN Jian. Effect of Ni addition on microstructure and mechanical properties of TiB2/TiB titanium matrix composite coatings[J]. Acta Metallurgica Sinica, 2014, 50(12): 1520-1528.

[17] LIN Y H, YAO J H, WANG L, ZAHNG Q L, LI X Q, LEI Y P, FU H G. Effects of TiB2 particle and short fiber sizes on the microstructure and properties of TiB2-reinforced composite coatings[J]. Journal of Materials Engineering and Performance, 2018, 27: 1876-1889.

[18] WANG H M, CAO F, CAI L X, TANG H B, YU R L, ZHANG L Y. Microstructure and tribological properties of laser clad Ti2Ni3Si/NiTi intermetallic coatings[J]. Acta Materialia, 2003, 51(20): 6319-6327.

[19] GAO F, WANG H M. Effect of TiNi in dry sliding wear of laser melt deposited Ti2Ni/TiNi alloys[J]. Materials Characterization, 2008, 59(9): 1349-1354.

[20] XIAO Y, ZENG P, LEI L P. Micromechanical modelling on thermomechanical coupling of superelastic NiTi alloy[J]. International Journal of Mechanical Sciences, 2019, 153/154: 36-47.

[21] AHADI A, SUN Q P. Grain size dependence of fracture toughness and crack-growth resistance of superelastic NiTi[J]. Scripta Materialia, 2016, 113: 171-175.

[22] LU W J, ZHANG D, ZHANG X N, WU R J, SAKATA T, MORI H. HREM study of TiB/Ti interfaces in a TiB-TiC in situ composite[J]. Scripta Materialia, 2001, 44(7): 1069-1075.

[23] GAO Q, WU S S, LU S L, DUAN X C, ZHONG Z Y. Preparation of in-situ TiB2 and Mg2Si hybrid particulates reinforced Al-matrix composites[J]. Journal of Alloys and Compounds, 2015, 651: 521-527.

[24] LIN Y H, YAO J H, LEI Y P, FU H G, WANG L. Microstructure and properties of TiB2-TiB reinforced titanium matrix composite coating by laser cladding[J]. Optics and Lasers in Engineering, 2016, 86: 216-227.

[25] PEARSON S R, SHIPWAY P H. Is the wear coefficient dependent upon slip amplitude in fretting? Vingsbo and Soderberg revisited[J]. Wear, 2015, 330/331: 93-102.

[26] HINTIKKA J, LEHTOVAARA A, MANTYLA A. Fretting-induced friction and wear in large flat-on-flat contact with quenched and tempered steel[J]. Tribology International, 2015, 92: 191-202.

[27] WANG S, WANG F, LIAO Z H, WANG Q L, LIU Y H, LIU W Q. Study on torsional fretting wear behavior of a ball-on-socket contact configuration simulating an artificial cervical disk[J]. Materials Science and Engineering C, 2015, 55: 22-33.

[28] SUN Q C, HU T C, FAN H Z, ZHANG Y S, HU L T. Dry sliding wear behavior of TC11 alloy at 500 ℃: Influence of laser surface texturing[J]. Tribology International, 2015, 92: 136-145.

[29] UYSAL M, AKBULUT H, TOKUR M, ALGUL H, CETINKAYA T. Structural and sliding wear properties of Ag/Graphene/WC hybrid nanocomposites produced by electroless co-deposition[J]. Journal of Alloys and Compounds, 2016, 654: 185-195.

[30] CAI Z B, ZHU M H, YANG S, XIAO X B, LIN X Z, YU H Y. In situ observations of the real-time wear of PMMA flat against steel ball under torsional fretting[J]. Wear, 2011, 271(9/10): 2242-2251.

Friction and wear properties of laser in situ synthesized titanium diboride and NiTi alloy

LIN Ying-hua1, LIN Zhen-heng1, CHEN Qing-tang1, LEI Yong-ping1, 2

(1. School of Mechanical and Electrical Engineering, Putian University, Putian 351100, China;

2. College of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China)

Abstract: In order to prepare two kinds of composite coatings for comparison, TiB2 and Ni+TiB2 were, respectively, used as cladding materials, and the composite coatings were prepared by laser in-situ cladding technique on the surface of titanium alloy. The synthesized titanium-based composite coatings were studied by XRD, SEM, EPMA and friction and wear instruments. The results show that TiB2 particle and TiB short fiber reinforced titanium-based composite coating can be obtained when TiB2 is used as the cladding material. When Ni+TiB2 is used as the cladding material, the NiTi alloy can be formed to be filled around the TiB2 particles and the TiB short fibers, but the size of the TiB2 particles and the length of the TiB short fibers are all reduced. Through the fretting wear test, it is found that the composite reinforcement of NiTi alloy and TiB2 particles and TiB short fiber can not effectively resist the fretting wear performance. There are three reasons for this: the temperature of the friction contact zone exceeds the temperature of the NiTi superelastic deformation, the crack propagation cannot be deflected by the introduction of NiTi, the hardness of the NiTi alloy is low. Finally, the difference between the anti-friction wear and dry sliding wear of the composite coating was discussed.

Key words: laser cladding; TiB short fiber; NiTi alloy; friction; wear

Foundation item: Projects(2019J01813, 2018J01557) supported by the Natural Science Foundation of Fujian Province, China; Project(2019GP004) supported by the Science and Technology Project of Putian, China; Project(2019016) supported by the Talent Introduction project of Putian University, China

Received date: 2019-04-23; Accepted date: 2020-01-07

Corresponding author: LIN Zhen-heng; Tel: +86-594-2822156; E-mail: 147121176@qq.com

(编辑 李艳红)

基金项目:福建省自然科学基金资助项目(2019J01813,2018J01557);莆田市科技项目资助(2019GP004);莆田学院人才引进项目资助(2019016)

收稿日期:2019-04-23;修订日期:2020-01-07

通信作者:林振衡,教授,博士;电话:0594-2822156;E-mail:147121176@qq.com

摘 要:为了制备出可对比的两类复合涂层,采用TiB2和Ni+TiB2分别作为熔覆材料,在钛合金表面通过激光原位熔覆制备复合涂层。采用XRD、SEM、EPMA与摩擦磨损仪等实验手段,对合成的钛基复合涂层进行研究。结果表明:采用TiB2为熔覆材料时,可获得TiB2颗粒与TiB短纤维增强钛基复合涂层。采用Ni+TiB2为熔覆材料时,可生成NiTi合金填充在TiB2颗粒与TiB短纤维周围,但TiB2颗粒尺寸和TiB短纤维长度都得以减小。通过微动磨损测试,发现引入NiTi合金和TiB2颗粒及TiB短纤维复合强化,无法有效抵抗微动磨损性能。这主要与摩擦接触区的温度超过NiT超弹性变形的温度区间,且NiTi合金无法使裂纹扩展曲折及硬度低相关。最后,探讨了该复合涂层在抗微动磨损与干滑动磨损过程中的差异性。

[1] 丁 燕, 梁 军, 邓 凯, 柏 林, 戴振东. 损伤容限型钛合金TC4-DT的微动磨损性能[J]. 中国有色金属学报, 2017, 27(3): 532-538.

[4] 黄立国, 陈玉勇. 少量TiB晶须对Ti-B20合金β晶粒长大行为的影响[J]. 中国有色金属学报, 2015, 25(8): 2108-2114.

[15] 林英华, 雷永平, 符寒光, 林 健. 激光原位制备硼化钛与镍钛合金增强钛基复合涂层[J]. 金属学报, 2014, 50(12): 1513-1519.

[16] 林英华, 雷永平, 符寒光, 林 健. Ni添加对TiB2/TiB钛基复合涂层组织与力学性能的影响[J]. 金属学报, 2014, 50(12): 1520-1528.