DOI: 10.11817/j.issn.1672-7207.2021.04.008

生物酶改良膨胀土的动骨干曲线模型

文畅平1, 2,任睆遐1, 2

(1. 中南林业科技大学 土木工程学院,湖南 长沙,410018;

2. 中南林业科技大学 现代木结构工程材制造及应用技术湖南省工程实验室,湖南 长沙,410018)

摘 要:

n-Drnevich双曲线本构模型,研究生物酶改良膨胀土的动应力-应变关系。首先通过一系列不同生物酶掺量下的动三轴不固结不排水剪切试验,得到生物酶改良膨胀土的动骨干曲线;然后,根据三轴试验结果,分别拟合最大动弹性模量Edmax、最大动应力

关键词:

生物酶改良膨胀土;动骨干曲线模型;动应力-应变关系;动三轴试验;

中图分类号:U416.1 文献标志码:A

文章编号:1672-7207(2021)04-1109-09

Dynamic backbone curve model of bioenzyme-treated expansive soil under cyclic loading

WEN Changping1, 2, REN Huanxia1, 2

(1. School of Civil Engineering, Central South University of Forestry and Technology, Changsha 410018, China;

2. Hunan Engineering Laboratory for Manufacturing and Application Technology of Modern Timber Structural Engineering Materials, Central South University of Forestry and Technology, Changsha 410018, China)

Abstract: The dynamic stress-strain properties of bioenzyme-treated expansive soil were studied based on Hardin-Drnevich hyperbola constitutive model. Firstly, a series of the dynamic triaxial unconsolidated undrained shear tests of bioenzyme-treated expansive soil at different ratios of bioenzyme-based soil stabilizer were conducted, and a series of dynamic backbone curves were obtained. Secondly, the regression expressions between the parameters such as the maximum dynamic modulus of elasticity Edmax, the maximum dynamic stress

Key words: bioenzyme-treated expansive soil; dynamic backbone curve model; dynamic stress-strain relation; dynamic triaxial test

大量研究和工程实践结果表明,掺石灰、水泥等无机钙基材料是改良膨胀土最有效的方法[1]。但这种化学改良方法的不足也很突出,体现在:1) 生产石灰、水泥需要消耗矿产资源和能源,并且伴随有大量的碳排放,因此,被认为是一种成本较高、对环境不友好的膨胀土改良方法[2];2) 干湿循环或土体中含水量的变化对改良膨胀土的耐久性产生较大影响[3]。随着干湿循环次数增加,钙基无机材料将产生钙矾石之类的膨胀矿物,使得改良膨胀土的膨胀潜势增大[4],并且强度逐渐丧失[5],因此,必须进行能够满足可持续发展需要、环境友好型的膨胀土非传统改良材料的研究[6]。土体改良材料一般可分为传统型材料和非传统型材料[7]。传统型改良材料包括石灰、水泥等无机钙基材料,而生物酶之类的土体改良材料属于非传统型材料[8]。目前大多将传统型与非传统型材料结合使用对土体进行改良。生物酶是一种通过植物发酵而提取的无毒、无腐蚀性的液体酶制剂[8]。有研究表明,生物酶是一种低成本、环保型的土壤改良材料[9]。对于膨胀土,其膨胀机制一般认为是其亲水矿物晶格的膨胀以及黏土颗粒间的膨胀[10]。当膨胀土中的亲水矿物蒙脱石吸水后矿物晶格膨胀,使得土体产生膨胀。又由于土体吸收水分后,引起黏土颗粒间的毛细管张力松弛,黏土颗粒间距增大,土体也发生膨胀。生物酶是一种生物表面活性剂,其分子结构具有亲水键和疏水键[9],亲水键可紧紧包裹在黏土颗粒表面,而疏水键则阻滞水分进入土体,从而保持土体含水量稳定。此外,生物酶中含有乙醇影响土体的介电常数,减小吸附水的厚度。有研究发现,生物酶易于与土体均匀拌和[8],能显著降低膨胀土的膨胀潜势[11],提高膨胀土的无侧限抗压强度(UCS)、加州承载比(CBR)、弹性模量等力学指标以及改善其工程特性[12],并且在干湿循环下的耐久性[10]、动力特性[9]等方面性能优良。现有研究表明,生物酶作为膨胀土改良材料的研究仍然停留在试验室研究阶段,较少应用于工程实践,研究成果主要集中在膨胀土改良后的物理特性、工程特性以及静力学特性等方面,较少涉及动力学特性。膨胀土改良后作为路基填料,路基本体承受各类车辆荷载的循环作用,因而,研究生物酶改良膨胀土的动力特性,是该方面研究成果应用于工程实践前的重要环节,但目前人们对生物酶改良膨胀土的动力特性研究不多。在土体动力特性研究中,动骨干曲线及其模型是主要研究内容。动骨干曲线反映了土体的动应力-应变关系,构建动骨干曲线模型是分析土体动应力-应变关系特性的前提和基础性工作,国内外学者在该方面开展了大量研究。目前,主要是基于Masing法则、通过相应的动力试验得到动骨干曲线,然后构建相应的动骨干曲线模型。基于Masing法则的动骨干曲线模型实际上是经验类模型,一般可分为以下几类:1) 双直线模型;2) 基于Kondner双曲线假设的Hardin-Drnevich两参数模型、Martin-Davidenkov三参数模型;3) Ramberg-Osgood三参数模型等。上述模型各具特色和适用范围。周文权等[13]通过研究发现,基于双直线模型建立的饱和粗粒土动骨干曲线模型能够反映土体的刚度变化规律。张勇等[14]发现基于Hardin-Drnevich模型所建立的动骨干曲线模型能够反映土体的刚度软化特性。Hardin-Drnevich模型实际上是Martin-Davidenkov模型的特例。KRAVCHENKO等[15]基于Martin-Davidenkov模型建立了聚丙烯纤维改良黏土的动骨干曲线模型,认为该模型能够很好地描述冻融循环下的动应力-应变关系。迟世春等[16]认为变参数Ramberg-Osgood模型能够较好地描述筑坝土石料的动力特性。Hardin-Drnevich模型[17]的动骨干曲线采用了KONDNER[18]的双曲线假设,即动剪应力与动剪应变为双曲线关系。该模型数学表达式简洁,参数只有2个并且物理意义明确,易于通过试验拟合,广泛应用于土体动骨干曲线模型的研究。ZHAO等[19]认为Hardin-Drnevich双曲线模型可以很好地描述冻结粉土在动荷载作用下的动应力-应变响应关系。WU等[20]以含水量、冻结压力等参数为变量,得到了青藏高原冻结粉质黏土最大动剪切模量与Hardin-Drnevich模型两参数之间的关系。庄妍等[21]基于Hardin-Drnevich模型,提出了考虑超固结比、孔隙比影响的饱和粉质黏土动骨干曲线模型。SHANG等[22]基于Hardin-Drnevich模型研究了重载铁路路基水泥改良膨胀土的动骨干曲线模型。ZHANG等[23]通过研究天水黄土动应力应变关系认为Hardin-Drnevich模型能够很好地描述其动骨干曲线的应力-应变关系特性。LING等[24]在研究冻融循环作用下冻土的动力特性时,提出了基于动荷载循环作用次数、温度、初始含水量、动荷载频率、围压的修正Hardin-Drnevich模型,由该修正模型所得动骨干曲线与试验得到的动骨干曲线有较好的一致性。WANG等[25]基于Hardin-Drnevich模型研究了石灰改良膨胀土的动骨干曲线模型。这些研究只有少数针对改良膨胀土的动力特性,但没有分析动骨干曲线的归一化特性。为此,本文作者基于现有研究成果,以生物酶改良膨胀土的动应力-应变关系为研究对象,通过一系列动三轴固结不排水剪切试验,基于Hardin-Drnevich模型分析生物酶掺量对模型参数的影响规律,建立考虑生物酶掺量影响的生物酶改良膨胀土的动骨干曲线模型以及动骨干曲线应力-应变归一化方程。

1 试验材料与方法

1.1 试验材料

试验所用材料为膨胀土、生物酶。其中,膨胀土试验土样取自湖南省益阳—娄底高速公路K28+980处,取土深度为1.7 m左右。该膨胀土样为中膨胀土,呈黄褐色,夹灰白色土,见图1,其主要物理力学指标见表1。所采用的生物酶试剂为Terra-Zyme。

表1 膨胀土试样的主要物理力学指标

Table 1 Physical and mechanical behavior of expansive soil samples

图1 膨胀土试样

Fig. 1 Expansive soil sample

1.2 试验方法

1.2.1 试验设备

试验采用GDS动三轴试验系统,其轴向最大负荷为10 kN;最大围压为2 MPa,精度为1 kPa;最大频率为5 Hz,轴向位移最大量程为100 mm。

1.2.2 土样试件制备

1) 动三轴试验采用直径为39.1 mm、高度为80.0 mm的圆柱形试件。

2) 生物酶掺量(设为z)为膨胀土干质量分数,设定为0,1%,2%,3%,4%,据此分别制作5类土样的试件。制作土样试件时均统一采用干密度

3) 土样试件制备方法为:首先将膨胀土试样烘干碾散,过孔径为2 mm的土工筛,加入配置好的生物酶溶液并拌合均匀,静置风干,再掺加规定的含水量。将配置好的土料分4层依次装入成型筒,各层接触面刨毛,分层静压成型。

1.2.3 试验方案

本文研究生物酶掺量z、围压

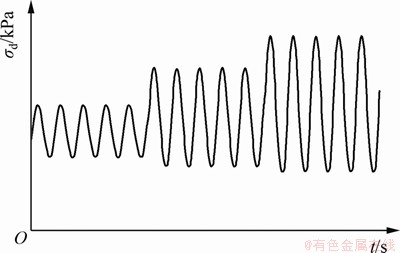

循环动荷载为等幅值正弦波荷载,循环荷载分级加载方式示意图如图2所示,动荷载振动频率f为1 Hz。

图2 循环荷载分级加载方式示意图

Fig. 2 Sketch of multi-stage cyclic loading

动三轴试验采用应力控制加载方式。试验前,将土样试件进行抽气饱和,再装入压力室进行反压饱和。根据设定的围压

2 试验结果与分析

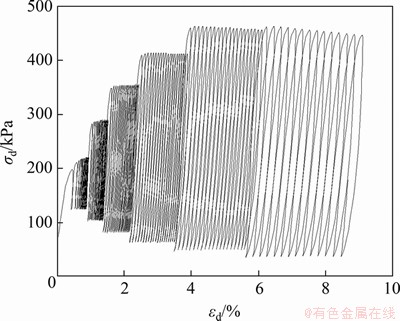

生物酶掺量z=3%的土样试件在

图3 滞回曲线

Fig. 3 Hysteretic curve

1) 生物酶改良膨胀土的动应力(

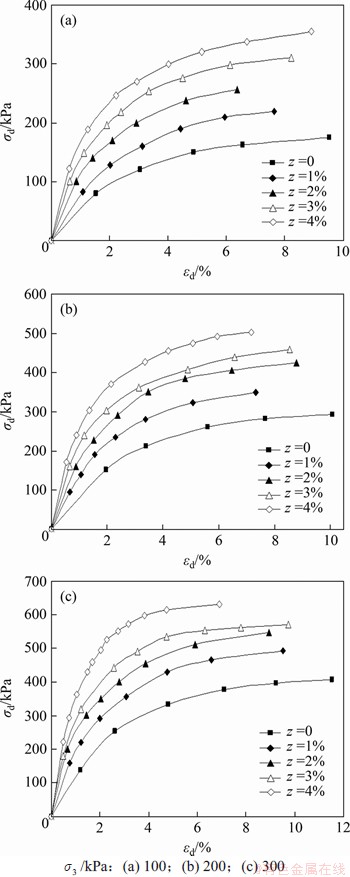

图4 不同围压下的动骨干曲线

Fig. 4 Dynamic backbone curves under different confining pressures

2) 随着围压

根据Hardin-Drnevich模型,循环动荷载作用下土体的动应力-应变关系的骨干曲线采用双曲线表达,即

式中:

将式(1)改写为

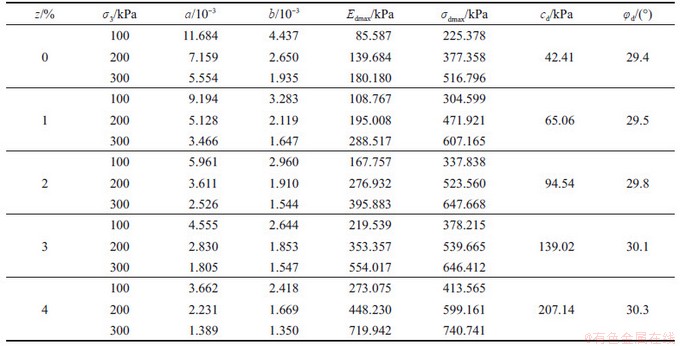

表2 动骨干曲线参数拟合结果

Table 2 Parameters fitting results of dynamic backbone curves

2.1 最大动弹性模量Edmax

根据表2,考虑生物酶掺量z、围压

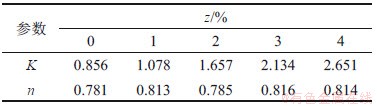

根据表3中的K和n拟合结果,取

式中:

式(2)表明,随着围压

表3 参数K和n的拟合结果

Table 3 Fitting results of K and n

2.2 最大动应力

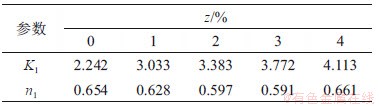

根据表2,按照

表4 参数K1和n1拟合结果

Table 4 Fitting results of K1 and n1

根据表4中K1和n1的拟合结果,取n1=0.626。设

式中:

式(3)表明,随着围压

2.3 动切线变形模量Edt

参照KARG等[26]利用Duncan-Chang模型拟合动骨干曲线的方法,建立动骨干曲线切线变形模量Edt的回归方程。

对于双曲线关系的动骨干曲线,根据式(1)可得到

根据式(1),动应变

式中:

式(5)为反映生物酶掺量z、围压

根据表2,

3 动骨干曲线归一化特性

有研究表明,土的应力-应变本构关系具有归一化性状[27]。土的应力-应变关系归一化就是采用统一的本构方程表达其应力-应变关系。选取合适的归一化因子是研究土的应力-应变关系归一化特性的关键。

根据式(1),动骨干曲线归一化的应力-应变关系可表示为

式中:

该式表明,作为归一化因子的

根据不同生物酶掺量z、不同围压

该回归方程的相关系数为R2=0.959 4,也就是说,采用最大动应力

结合式(3)和式(8)可得

该式即为生物酶改良膨胀土的动骨干曲线应力-应变关系归一化方程。

令

式中:

4 结论

1) Hardin-Drnevich双曲线模型能较好地描述生物酶改良膨胀土的动骨干曲线特性。建立的最大动弹性模量Edmax、最大动应力

2) 生物酶掺量z以及围压

3) 采用最大动应力

参考文献:

[1] IKEAGWUANI C C, NWONU D C. Emerging trends in expansive soil stabilization:a review[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2019, 11(2): 423-440.

[2] BEHNOOD A. Soil and clay stabilization with calcium- and non-calcium-based additives: a state-of-the-art review of challenges, approaches and techniques[J]. Transportation Geotechnics, 2018, 17: 14-32.

[3] YONG R N, OUHADI V R. Experimental study on instability of bases on natural and lime/cement-stabilized clayey soils[J]. Applied Clay Science, 2007, 35(3/4): 238-249.

[4] CELIK E, NALBANTOGLU Z. Effects of ground granulated blastfurnace slag (GGBS) on the swelling properties of lime-stabilized sulfate-bearing soils[J]. Engineering Geology, 2013, 163: 20-25.

[5] STOLTZ G, CUISINIER O, MASROURI F. Weathering of a lime-treated clayey soil by drying and wetting cycles[J]. Engineering Geology, 2014, 181: 281-289.

[6] TINGLE J S, NEWMAN J K, LARSON S L, et al. Stabilization mechanisms of nontraditional additives[J]. Transportation Research Record: Journal of the Transportation Research Board, 2007 (1): 59-67.

[7] LATIFI N, MEEHAN C L, MAJID M Z A, et al. Strengthening montmorillonitic and kaolinitic clays using a calcium-based non-traditional additive: a micro-level study[J]. Applied Clay Science, 2016, 132/133: 182-193.

[8] KANNIYAPPAN S P, DHILIP K R G, FAIZUNEESA A, et al. Experimental investigation on black cotton soil using bio-enzyme as a soil stabilizer in road construction[J]. CIKITUSI Journal for Multidisciplinary Research, 2019, 6(5): 234-250.

[9] THOMAS A, TRIPATHI R K, YADU L. Application of Taguchi method for optimization of various factors in improving the shear modulus of enzyme treated soil[J]. National Academy Science Letters, 2020, 43(2): 171-175.

[10] POONI J, GIUSTOZZI F, ROBERT D, et al. Durability of enzyme stabilized expansive soil in road pavements subjected to moisture degradation[J]. Transportation Geotechnics, 2019, 21: 100255.

[11] NAAGESH S, GANGADHARA S. Swelling behaviour of bio-enzyme treated expansive soil[J]. International Journal of Earth Sciences and Engineering, 2011, 4(3): 555-560.

[12] SURESH K, KUMAR P S. Efficacy of Terrazyme-a bioenzyme on strength characteristics of expansive soil[J]. Global Journal of Engineering Science and Researches, 2018,5(2): 89-96.

[13] 周文权, 冷伍明, 刘文劼, 等. 低围压循环荷载作用下饱和粗粒土的动力特性与骨干曲线模型研究[J]. 岩土力学, 2016, 37(2): 415-423.

ZHOU Wenquan, LENG Wuming, LIU Wenjie, et al. Dynamic behavior and backbone curve model of saturated coarse-grained soil under cyclic loading and low confining pressure[J]. Rock and Soil Mechanics, 2016, 37(2): 415-423.

[14] 张勇, 孔令伟, 李雄威. 循环荷载下饱和软黏土的动骨干曲线模型研究[J]. 岩土力学, 2010, 31(6): 1699-1704.

ZHANG Yong, KONG Lingwei, LI Xiongwei. Dynamic backbone curve model of saturated soft clay under cyclic loading[J]. Rock and Soil Mechanics, 2010, 31(6): 1699-1704.

[15] KRAVCHENKO E, LIU Jiankun, KRAINIUKOV A, et al. Dynamic behavior of clay modified with polypropylene fiber under freeze-thaw cycles[J]. Transportation Geotechnics, 2019, 21: 100282.

[16] 迟世春, 陈崇茂, 贾宇峰. 筑坝土石料的变参数Ramberg-Osgood模型及其适应性研究[J]. 岩土力学, 2013, 34(1): 1-5.

CHI Shichun, CHEN Chongmao, JIA Yufeng. Ramberg-Osgood model with variable parameters of earth-rock materials for earth-rock dam and its adaptability[J]. Rock and Soil Mechanics, 2013, 34(1): 1-5.

[17] HARDIN B O, DRNEVICH V P. Shear modulus and damping in soils:design equations and curves[J]. Journal of the Soil Mechanics and Foundations Division, 1972, 98(SM7): 667-692.

[18] KONDNER R L. Hyperbolic stress-strain response: cohesive soil[J]. Journal of the Soil Mechanics and Foundations Division, 1963, 89(SM1): 115-143.

[19] ZHAO Futang, CHANG Lijun, ZHANG Wuyu. Experimental investigation of dynamic shear modulus and damping ratio of Qinghai―Tibet frozen silt under multi-stage cyclic loading[J]. Cold Regions Science and Technology, 2020, 170: 102938.

[20] WU Zhijian, ZHANG Dan, ZHAO Tao, et al. An experimental research on damping ratio and dynamic shear modulus ratio of frozen silty clay of the Qinghai―Tibet engineering corridor[J]. Transportation Geotechnics, 2019, 21: 100269.

[21] 庄妍, 朱伟, 张飞. 饱和粉质黏土动弹性模量影响因素分析及骨干曲线模型研究[J]. 中南大学学报(自然科学版), 2019, 50(2): 445-451.

ZHUANG Yan, ZHU Wei, ZHANG Fei. Analysis of factors affecting dynamic modulus of elasticity of saturated silty clay and research on backbone curve model[J]. Journal of Central South University(Science and Technology), 2019, 50(2): 445-451.

[22] SHANG Yonghui, XU Linrong, ZHAO Y, et al. Experimental study on the dynamic features of cement-stabilized expansive soil as subgrade filling of heavy haul railway[J]. Journal of Engineering Science and Technology Review, 2017, 10(6): 136-145.

[23] ZHANG Zelin, WANG Tao, WU Shuren, et al. Dynamics stress-strain behavior of Tianshui soils[J]. Landslides, 2017, 14(1): 323-335.

[24] LING X Z, ZHANG F, LI Q L, et al. Dynamic shear modulus and damping ratio of frozen compacted sand subjected to freeze-thaw cycle under multi-stage cyclic loading[J]. Soil Dynamics and Earthquake Engineering, 2015, 76: 111-121.

[25] WANG Min, KONG Lingwei, ZHAO Chong, et al. Dynamic characteristics of lime-treated expansive soil under cyclic loading[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2012, 4(4): 352-359.

[26] KARG C, HAEGEMAN W. Elasto-plastic long-term behavior of granular soils: Experimental investigation[J]. Soil Dynamics and Earthquake Engineering, 2009, 29(1): 155-172.

[27] VARDANEGA P J, BOLTON M D. Stiffness of clays and silts: normalizing shear modulus and shear strain[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2013, 139(9): 1575-1589.

(编辑 陈灿华)

收稿日期: 2020 -05 -24; 修回日期: 2020 -07 -24

基金项目(Foundation item):国家国际科技合作专项(2014DFA53120);现代木结构工程材制造及应用技术湖南省工程实验室开放基金资助项目(HELFMTS1707);湖南省重点学科建设项目(2013ZDXK006) (Project(2014DFA53120) supported by the National Special Program for International Scientific and Technology Cooperation; Project(HELFMTS1707) supported by the Open Fund of Hunan Engineering Laboratory for Manufacturing and Application Technology of Modern Timber Structural Engineering Materials; Project(2013ZDXK006) supported by the Key Discipline Construction Program of Hunan Province)

通信作者:文畅平,博士,教授,从事岩土工程研究;E-mail:wenchangping@163.com

引用格式: 文畅平, 任睆遐. 生物酶改良膨胀土的动骨干曲线模型[J]. 中南大学学报(自然科学版), 2021, 52(4): 1109-1117.

Citation: WEN Changping, REN Huanxia. Dynamic backbone curve model of bioenzyme-treated expansive soil under cyclic loading[J]. Journal of Central South University(Science and Technology), 2021, 52(4): 1109-1117.

摘要:基于Hardin-Drnevich双曲线本构模型,研究生物酶改良膨胀土的动应力-应变关系。首先通过一系列不同生物酶掺量下的动三轴不固结不排水剪切试验,得到生物酶改良膨胀土的动骨干曲线;然后,根据三轴试验结果,分别拟合最大动弹性模量Edmax、最大动应力

[13] 周文权, 冷伍明, 刘文劼, 等. 低围压循环荷载作用下饱和粗粒土的动力特性与骨干曲线模型研究[J]. 岩土力学, 2016, 37(2): 415-423.

[14] 张勇, 孔令伟, 李雄威. 循环荷载下饱和软黏土的动骨干曲线模型研究[J]. 岩土力学, 2010, 31(6): 1699-1704.

[16] 迟世春, 陈崇茂, 贾宇峰. 筑坝土石料的变参数Ramberg-Osgood模型及其适应性研究[J]. 岩土力学, 2013, 34(1): 1-5.

[21] 庄妍, 朱伟, 张飞. 饱和粉质黏土动弹性模量影响因素分析及骨干曲线模型研究[J]. 中南大学学报(自然科学版), 2019, 50(2): 445-451.