- Abstract:

- 1 Introduction▲

- 2 Formative mechanism of ...▲

- 3 Experimental study on p...▲

- 4 Conclusions▲

- References

- Figure

- Fig.1 Active force between molecules on surface or inside solution

- Fig.2 Pressure and surface tension on two-dimension bend surface

- Fig.3 Particle size distribution of coarse and fine samples used in column

- Fig.4 Schematic diagram of laboratory column

- Fig.5 Relationship between ore diameter and porosity

- Fig.6 Relationship between percent of immobile water and ore diameter

- Fig.7 Relationship between outflow rate and applied rate in coarse ore area

- Fig.8 Relationship between outflow rate and applied rate in fine ore area

- Fig.9 Schematic diagram of preferential solution flow in coarse and fine ore area

J. Cent. South Univ. Technol. (2007)04-0584-05

DOI: 10.1007/s11771-007-0112-2![]()

Experimental study on preferential solution flow during dump leaching of low-grade ores

YIN Sheng-hua(尹升华)1, WU Ai-xiang(吴爱祥)1, SU Yong-ding(苏永定)2, ZHANG Jie(张 杰)2

(1. School of Civil and Environment Engineering, University of Science and Technology Beijing,Beijing 100083, China;

2. School of Resource and Safety Engineering, Central South University, Changsha 410083, China)

______________________________________________________________________________________

Abstract:

The phenomenon of preferential solution flow during dump leaching of low-grade ores was studied. The formative mechanism of preferential solution flow was investigated through analyzing the relationship between permeability and ore diameter, and the relationship between surface tension and ore diameter. The preferential solution flow happened within the fine ore area when the dump was unsaturated. And it could happen within the coarse ore area when the dump became saturated. The results of experiment show that the outflow of coarse ore area increases sharply with higher applied rate. The outflow of fine ore area is greater than that of coarse ore area when the applied rate is below 3.2 L/min, and the preferential solution flow happens in fine ore area. But the preferential solution flow happens in coarse ore area when the applied rate is higher than 3.2 L/min. The result of the experiment is consistent with the mechanism analyzing.

Key words:

low-grade ore; preferential solution flow; permeability; surface tension; applied rate;

______________________________________________________________________________________

1 Introduction

At present, the amount and grade of mineral resource reduce day by day, thus how to utilize the low-grade ore sufficiently and effectively becomes more important. Solution mining has been applied widely to extract metals from minerals, especially the low-grade ores, for many of its virtues, such as simple operation, lower investment, faster effect, simper management. The prospect of solution mining is excellent[1-4].

In soil science, the macropores, such as insect cavity, plant root and soil fissures, can lead to preferential flow in soil. Not only the hydrothermal condition and solute transfer in the soil, but the validity and erosion of precipitation, irrigating water and nutrient are influenced by the preferential flow[5]. Size of ores in dump differs from each other widely. The diameter of the biggest ores can reach 1 m, while the diameter of mud and the fine ore is only about several decade microns. The coarse and fine ores will separate because of the segregation during dump constructing. The separation of coarse ore area and fine ore area provides the precondition for preferential solution flow.

The preferential solution flow in the dump is that most of the solution flows through coarse ore area or fine ore area quickly. It can speed up the percolation flow rate of solution. The leaching area of the dump is shrunk, and the circulation of the solution becomes shorter. Preferential solution flow also makes the solution flow quickly through a small part of the dump. The solute transportation is influenced. The percentage of leached is low because of the blind area in coarse or fine ore area[6-7]. In this work, the formative mechanism of the preferential solution flow was investigated by analyzing the dump permeability and solution surface tension. Relationship between preferential solution flow and applied rate was studied by column experiment.

2 Formative mechanism of preferential solution flow

Inhomogeneity of the ores is the main reason for preferential solution flow. The dump permeability and surface tension between diameters of ore is analyzed as follows.

2.1 Relationship between permeability and ore diameter

Coefficient of permeability, i.e. hydraulic conductivity, shows the degree of difficulty that the solution flows through the dump. It is determined by ore size distribution, diameter of the ore, arrangement of the ore, percent of pore void, specific surface area, shape and curvature of the pore. It is also associated with the solution density and viscosity[8-9]. The hydraulic conductivity of the dump can be described as follows:

![]() (1)

(1)

where g is the gravity acceleration constant; ρ is the solution density; η is the dynamic viscosity; k is the intrinsic permeability that is a property of ore media, k is only determined by ore itself, and has no relationship with the property of solution.

Hubbert has done an experiment by using the uniformity glass pellet whose diameter was d to constitute an ideal pore media, density of the fluid was ρ, and the fluid viscosity was η. He discovered that percolation flow rate is proportional to not only the fluid pressure gradient, but also the squared particle size and mass of the fluid. But the percolation rate is inversely proportional to fluid dynamic viscosity, hence,

![]() (2)

(2)

Formula (2) can be changed into an equation as follows:

![]() (3)

(3)

where C is proportional constant that is determined by sphericity, compactness, diameter and size distribution of the particles.

Comparing Eqn.(1) and Darcy’s Law, we can obtain

![]() (4)

(4)

Substituting K of Eqn.(1) into Eqn.(4) yields

k=Cd2 (5)

Usually the ore particles are inhomogenous. So the effective particle diameter is usually used as ore size.

Distribution of ore diameter varies from space because of segregation during dump constructing and sliming of the ore. According to the relationship between permeability and ore diameter, and the intrinsic permeability and hydraulic conductivity of the coarse ore area are greater than those in fine ore area. The velocity of solution flow in coarse ore area is bigger than that in fine ore area. The preferential solution flow happens in coarse ore area.

2.2 Relationship between surface tension and ore diameter

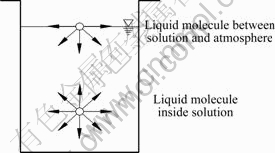

Surface tension is the character of the surface between solution and atmosphere. As shown in Fig.1, surface tension appears because of the imbalance force of the liquid molecule. The forces of the liquid molecule inside the solution are the same as these in all directions. Liquid molecules of the shrinking film have an imbalance force pointing to the inner of the solution. A strain is produced within the shrinking film in order to maintain the balance. The character that shrinking film bears a tension is called surface tension Ts. Its direction is tangency with the shrinking film surface, while its value decreases with the increase of temperature[10-12].

Fig.1 Active force between molecules on surface or inside solution

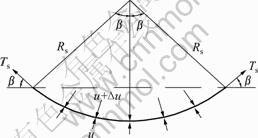

Surface tension endows the shrinking film with the elastic film’s shape similar to that of balloon filled with gas. When different pressures are added to the sides of an elastic two-dimensional film, the surface tension appeared with film’s concavity bending to the side with higher pressure to maintain its balance. According to the balance condition shown in Fig.2, the relationship between pressure difference and value of surface tension and film curvature radius can be established as follows:

Fig.2 Pressure and surface tension on two-dimension bend surface

![]() (6)

(6)

where (ua-uw) is the difference between air pressure and hydraulic pressure of pore on the shrinking film, namely matric suction. The curvature radius of the shrinking film decreases with the increase of the ore’s suction. It becomes infinity when the pore air pressure equals the pore hydraulic press. And the interface between solution and atmosphere becomes plane.

Inside the unsaturated dump, solution is sunk into dump and ore particles by the micropore and crannies act as capillary. The air pressure of local site equals 0. The pressure of capillary water is negative comparing with the air pressure of pore. Negative water pressure of pore can reach a high value at the low degree of saturation.

The negative water pressure of pore is very high in the fine ore area of dump under the condition of unsaturation because of its small pore size. Solution can enter into the micropores and crannies of the fine ore area under the effect of high negative water pressure of pore. So the preferential solution flow happens in the fine ore area when the applied flux is small enough. Fine ore areas become saturated with the increase of applied rate. Solution begins flowing laterally because the negative water pressure of pore disappears. Preferential solution flow happens in the coarse ore area when plenty of solution flows into this area.

3 Experimental study on preferential solution flow

3.1 Experimental material

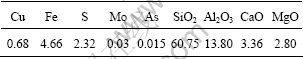

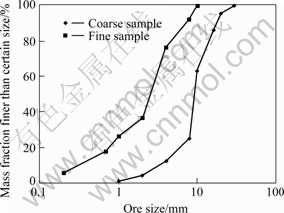

The experimental materials were collected from the dump of Dexing Copper Mine. Table 1 lists the result of elemental analysis. According to the local condition, two samples with different grain sizes were prepared, one was the coarse ore sample, the other was the fine ore sample. The mass of each sample was 18 kg. Fig.3 shows the grain size curve of each sample.

Table 1 Contents of major elements of material (mass fraction/%)

Fig.3 Particle size distribution of coarse and fine samples used in column

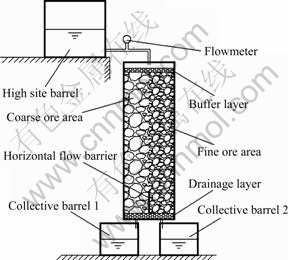

3.2 Experimental apparatus

The experimental apparatus is shown in Fig.4. There was plenty of solution in the high site barrel used for spraying into the column. The applied rate was adjusted by the flowmeter beyond the exit of the barrel. Coarse and fine samples were loaded in the two sides of the column separately. A layer of glass ball with uniform diameter was spread as a buffer layer on the top of the column in order to apply the solution equably. A drainage layer made of grit sand was set up to make the solution flow out of the column quickly, rather than cumulated in the bottom of the column. A horizontal flow barrier was set to prevent the solution from laterally flow to improve the precision of this experiment. There were two outflow ports for coarse and fine ore area, under which there were two collective barrels used for collecting solution flow from each areas.

Fig.4 Schematic diagram of laboratory column

3.3 Results and discussion

3.3.1 Porosity of sample

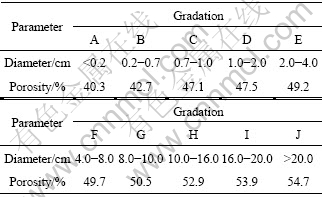

The materials were classified into 10 gradations by vibrating screen after being crushed. The porosity of each gradation is listed in Table 2.

Table 2 Porosity of each gradation

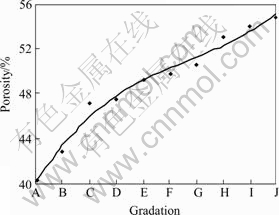

From Fig.5 it can be seen that ore porosity increases with increasing ore diameter. So the porosity and diameter of the pores in the coarse ore area are larger than those in fine ore area.

Fig.5 Relationship between ore diameter and porosity

3.3.2 Percent of immobile water of sample

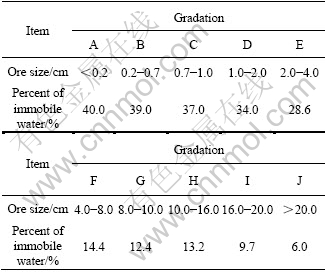

Immobile water is one of the components of the dump. It plays an important role during the leaching reaction and solute transportation. Table 3 shows the percent of immobile water of the different gradations.

Table 3 Percent of immobile water of different gradations

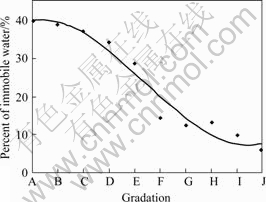

Fig.6 shows that the percent of immobile water in the dump decreases with the increase of ore diameter. There are two reasons to account for it. One is that the bound water on the ore surface decreases because of the increase of ore diameter and the decrease of specific surface area. The other is that the capillary water in the micropores decreases because of the larger ore diameter and pore size.

Fig.6 Relationship between percent of immobile water and ore diameter

3.3.3 Relationship between outflow and applied rate

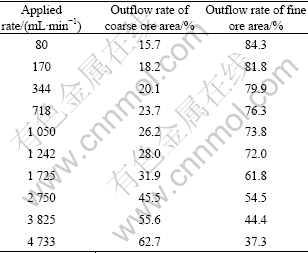

10 groups applied rate were selected in this experiment. Under each group applied rate, the volumes of solution flow from both the coarse and fine ore areas within the same time were measured separately. The outflow rate of coarse and fine ore areas for each group applied rate are listed in Table 4.

Table 4 Outflow rate of coarse and fine ore areas for each group applied rate

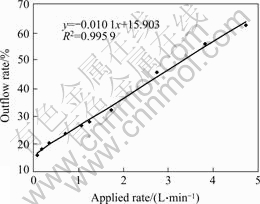

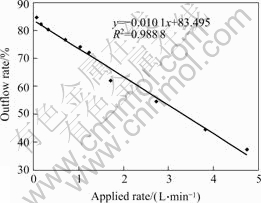

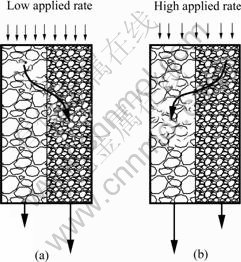

As shown in Fig.7 and Fig.8, the outflow rate of coarse ore area is increased sharply at higher applied rate, while that of fine ore area is decreased. The outflow rate of coarse ore area is smaller than that of the fine ore area when the applied rate is below 3.2 L/min because the specific surface area of the fine ore area is bigger, so the adoption for the solution is stronger. The other reason is that diameters of the pores in fine ore area are small, a bigger negative pore water pressure appears under unsaturated condition. The solution flows into the fine ore area from the coarse ore area, as shown in Fig.9. It is proved further that the preferential solution flow happens in the fine ore area at the low applied rate.

Fig.7 Relationship between outflow rate and applied rate in coarse ore area

Fig.8 Relationship between outflow rate and applied rate in fine ore area

Fig.9 Schematic diagram of preferential solution flow in coarse and fine ore area

(a) Low applied rate; (b) High applied rate

Fine ore area becomes saturated with increasing the applied rate. Solution begins flowing laterally into the coarse ore area. So the outflow rate of fine ore area decreases, while that of coarse ore area increases. The outflow rate of coarse ore area is larger than that of the fine ore area when the applied rate reaches 3.2 L/min. The preferential solution flow happens in the coarse ore area.

4 Conclusions

1) Permeability of the coarse ore area is larger than that of fine ore area, because it is proportional to the square of particle size. When the whole dump reaches saturation, the speed of solution flow in coarse ore area is greater than that in fine ore area under the same hydraulic head. The preferential solution flow happens in the coarse ore area.

2) Under the unsaturated condition, negative pore water pressure of the fine ore area is higher because of the small diameter of the pores and crannies. Solution flows quickly into the microporosities of fine ore area under the effect of both high negative pore water pressure and surface tension. So the preferential solution flow happens in the fine coarse ore area when the applied rate is low.

3) The porosity of the experimental material increases with increasing the ore size, while the immobile water rate decreases. The outflow rate of coarse ore area increases with increasing the applied rate, while that of the fine ore area declines. Outflow rate of the coarse ore is smaller than that of fine ore area when the applied rate is bellow 3.2 L/min. Preferential solution flow happens in the coarse ore area when the applied rate is higher than 3.2 L/min.

References

[1] ZHANG Guang-ji, FANG Zhao-heng. The contribution of direct and indirect actions in bioleaching of pentlandite[J]. Hydrometallergy, 2005(80): 59-66.

[2] CRUNDWELL F K. How do bacteria interact with minerals[J]. Hydrometallergy, 2003(71): 75-81.

[3] ZHOU Hong-ming, ZHENG Shi-li, ZHANG Yi. Leaching of a low-grade niobium-tantalum ore by highly concentrated caustic potash solution[J]. Hydrometallurgy, 2005(80): 83-89.

[4] ACAR S, BRIERLEY J A, WAN Rong-yu. Conditions for bioleaching a covellite-bearing ore[J]. Hydrometallurgy, 2005(77): 239-246.

[5] NI Yu-wen,OU Zi-qing. Research advance of soil preferential flow and pollutant priority migrate[J]. Soil and Environment, 2000, 9(1): 60-63.(in Chinese)

[6] WU Ai-xiang, YIN Sheng-hua, LIU Jin-zhi, et al. Formative mechanism of preferential solution flow during dump leaching[J]. Journal of Central South University of Technology, 2006, 13(5): 590-594.

[7] WU Ai-xiang, WANG Hong-jiang JIANG Huai-chun. Rule of oxygen transmission in dump leaching[J]. Journal of Central South University of Technology, 2006, 13(3): 295-299.

[8] CHEN Yong-ping, SHI Ming-heng. Determination of permeability for porous media using fractal theory[J]. Journal of Tsinghua University: Science and Technology, 2000, 40(42): 94-97.(in Chinese)

[9] LIU Xiao-li, LIANG Bing, XUE Qiang. Fractal description of porous media permeability[J]. Advances in Water Science, 2003, 14(6): 769-773. (in Chinese)

[10] LIU Jun-rong, QIN Ji-shun, WU Xiao-dong. Experimental study on relation between temperature and rocky permeability[J]. Journal of the University of Petroleum: Edition of Natural Science, 2001, 25(4): 51-53. (in Chinese)

[11] ZOU, Z Y, YOUNG M H, LI Z, et al. Estimation of depth averaged unsaturated soil hydraulic properties from infiltration experiments[J]. Journal of Hydrology, 2001 (242): 26-42.

[12] SIMUNEK J, van GENUCHTEN M T. Estimating unsaturated soil hydraulic properties from tension disc infiltrometer data by numerical inversion[J]. Water Resour Res, 1996(32): 2683-2696.

___________________________

Foundation item: Project(50325415)supported by the National Science Fund for Distinguished Young Scholars; Project (50621603) supported by China Science Fund for Distinguished Group; Project (2004CB619200) supported by National Key Fundamental Research and Development Program of China; Project (50574099) supported by National Natural Science Foundation of China

Received date: 2006-12-24; Accepted date: 2007-03-27

Corresponding author: YIN Sheng-hua, Doctoral candidate; Tel: +86-13811668481; E-mail: csuysh@yahoo.com.cn

- Experimental study on preferential solution flow during dump leaching of low-grade ores