Trans. Nonferrous Met. Soc. China 29(2019) 735-740

Effect of pulsed current on AZ31B magnesium sheets during annealing

Kai LIU1,2, Xiang-huai DONG1, Wen SHI1

1. National Engineering Research Center of Die & Mold CAD, Shanghai Jiao Tong University, Shanghai 200030, China;

2. Shanghai Aircraft Manufacturing Co., Ltd., Shanghai 201324, China

Received 25 April 2018; accepted 11 October 2018

Abstract:

The annealing tests heated by pulsed current (PC) or furnace for AZ31B magnesium sheets were carried out, and the effects of PC on the microstructure and dislocation density of the alloy were analyzed. The results show that PC strengthens the migration of boundaries, and then the twin grains, most of which distribute in the coarse grains, “spheroidize” to equiaxed grains, thus separating the coarse grains and refining the microstructure. This process homogenizes the initial microstructure and eliminate the typically lamellar twin grains. Moreover, PC also strengthens the dislocation annihilation. When the specimens were annealed by PC at 300 °C for 4 min, the dislocation density was even lower than that annealed by furnaces at 400 °C for 3 h before deformation. Furthermore, dislocation annihilation is enhanced with the increase of peak current density and the decrease of pulsed frequency.

Key words:

pulsed current; AZ31B magnesium alloy; annealing; microstructure evolution; twinning; dislocation annihilation;

1 Introduction

COHEN and BARRETT [1] observed an interactive effect between current and grain boundaries in 1954, and TROITSKII [2] proposed the conception of electro- plasticity effect to describe the extra softening and improving effect of electricity on metals during deformation in 1970. Then, OKAZAKI et al [3,4] found that 50%-70% drop of stress depends on Joule heat, and other contribution depends on electroplasticity effect. Moreover, they also proposed the electron wind hypothesis that there is a force of electron wind acting on the dislocations. Meanwhile, CONRAD [5,6] proposed the thermal activation hypothesis that current affects the thermal activation but not directly imposes a force on dislocations.

In recent years, there have been still many experts investigating the effect of electricity on metals. Some of them directly study the effect of current on the deformation behavior and microstructure evolution of materials. For instance, ZHU et al [7] studied the effect of pulsed current (PC) on microstructure and elongation of a Zn-Al alloy, and proposed that the extra effect of current stems from the accelerated movement of dislocations. KIM et al [8] studied the extra effect of current on 5052 aluminum alloy, and regarded the extra effect as a more effective annealing. They suggested that current enhances the atomic diffusion. Other researchers focused on the static processes, such as electropulsing treatment (EPT). XU et al [9,10] studied the EPT on 2024 aluminum alloy and found that PC improves the microstructure by promoting recrystallization and precipitation of T-phase particles. JEONG et al [11] studied the effect of PC on AZ91 alloy during tension, and the results showed that the dissolution of the Mg17Al12 obviously occurs during pulsed tension due to both of thermal and athermal effects of PC. This phenomenon implies that PC can improve the manufacture of AZ91 magnesium. PARK et al [12] investigated the effect of current on recrystallization of interstitial free (IF) steel and AZ31 alloy, and found that current accelerates recrystallization during annealing. Moreover, they proposed a model to quantitatively describe the recrystallization kinetics, based on Johnson-Mehl-Avrami-Kolmogorov (JMAK) equation. LI et al [13] also researched the static recrystallization (SRX) behavior of cold rolled AZ31 sheets heated by PC, and found that PC has a stronger annealing effect and the SRX can be completed at 270 °C for only 8 s.

In our previous works [14-16], we investigated the effect of PC on AZ31B magnesium during tension, and found that PC reduces the stress and changes the evolution of texture. Then, there is an extra effect of PC on AZ31B magnesium alloys that have a promising application prospect. Furthermore, we also proposed a constitutive model to predict the mechanical response. However, the investigations in the above works were focused on the effect of PC during deformation. In this work, electrically-assisted annealing (EAA) of AZ31B was investigated, which is simpler, in order to study the extra effect of PC on metals more basically. Although LI et al [13] also studied the EAA on AZ31B magnesium alloy, our research found a new phenomenon (“spheroidization” of twin lamellae) by EBSD and investigated the dislocation density evolution by XRD.

2 Experimental

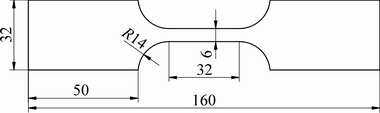

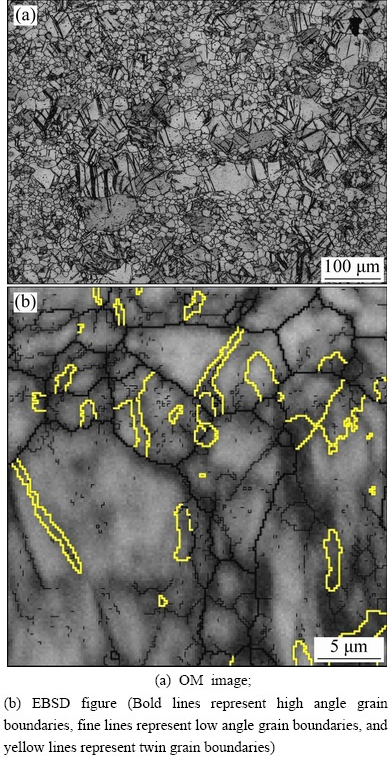

The AZ31B magnesium alloy sheets (2.75 wt.% Al, 0.64 wt.% Zn, 0.27 wt.% Mn, 0.0023 wt.% Fe, 0.018 wt.% Si, 0.0016 wt.% Cu, 0.00055 wt.% Ni and balanced Mg) with the thickness of 1.5 mm were wire-electrode cut to specimens along the rolling direction with the dimensions shown in Fig. 1. The specimens were annealed at 400 °C for 3 h to relieve the residual stress, and then were stretched to the nominal strain of 15%. These stretched samples were defined as initial ones. The surface profile of the specimens after tension is shown in Fig. 2. There are many ravines distributing on the normal surfaces, indicating that the deformation of AZ31B is inhomogeneous because of twinning, although its elongation can even reach 17% during experiments. The microstructures of the specimens after tension are shown in Fig. 3, which are the initial microstructures in this work. From Fig. 3, there are many twin lamellae in the original grains, especially in the coarse grains.

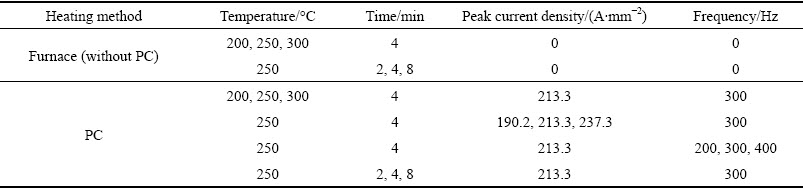

For investigating the effect of PC on annealing, the stretched specimens were annealed by different heating methods (furnace and PC) at different annealing temperatures and time, and the influences of peak current densities and pulsed frequencies were also estimated. The parameters of annealing tests are shown in Table 1.

Fig. 1 Dimensions of specimens (Unit: mm)

Fig. 2 Surface profile of AZ31B magnesium sheets stretched to nominal strain of 15%

Fig. 3 Initial microstructures of specimens

Table 1 Parameters of annealing tests

Furthermore, the temperature during EAA was controlled by blowing, monitored by a FLIR A615 infra-red (IR) thermal imaging camera (the emissivity value was set to be 1 because the monitored surfaces were blackened, and the concerned temperature during tests was the highest one). The peak current density of PC was monitored by an oscilloscope.

For further analyzing the extra effect of PC on annealing of AZ31B sheets, the specimens were observed by optical microscope (OM) and electron backscattered diffraction (EBSD). The specimens for OM observation were mechanically polished and then etched by the solution containing 2 g picric acid, 5 mL acetic acid, 5 mL water, and 35 mL ethanol, and the specimens for EBSD observation were polished by ion beam. Moreover, the specimens were analyzed by X-ray diffractometer (XRD), using Cu Kα radiation with the scanning speed of 2 (°)/min and the 2θ range from 10° to 70°, in order to investigate the influence of PC on dislocation annihilation.

3 Results and discussion

3.1Microstructure evolution

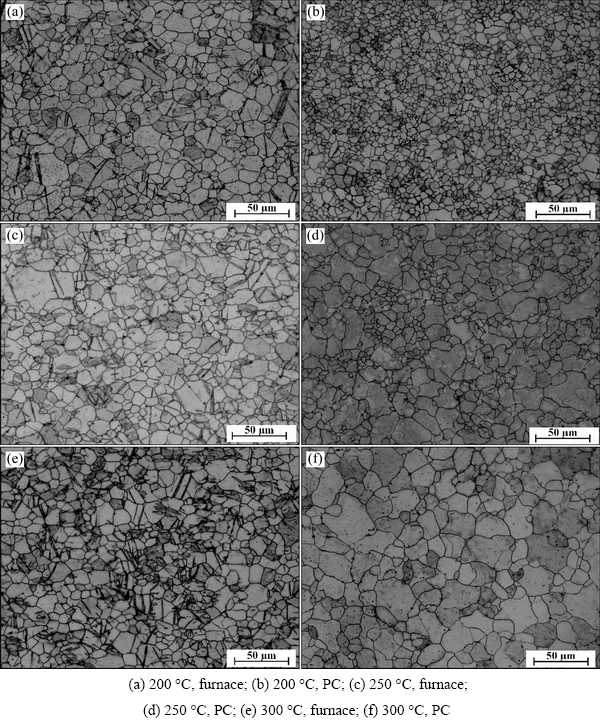

Fig. 4 Microstructures of pre-stretched AZ31B specimens annealed at 257.8 A/mm2, 300 Hz and different temperatures for 4 min

The microstructures of AZ31B magnesium annealed under different conditions for 4 min are shown in Fig. 4. From Figs. 4(a), (c) and (e), it could be seen that there were still many lamellar twin grains distributing in the equiaxed grains, which were almost the same with the initial microstructures shown in Fig. 3(a). With the increasing of temperature, the microstructure was almost not changed, and there were still many twin grains even at 300 °C. Then, the microstructure was not changed when the stretched specimens were annealed at 200-300 °C by furnace. However, when these specimens were annealed by PC, as shown in Figs. 4(b), (d) and (f), the results were so different. When the temperature was 200 °C, only a few twin grains could be observed, and the microstructures were also refined. When the temperature reached 250 °C, none twin grains could be observed, and the grains grown. When the temperature reached 300 °C, the microstructure was further coarsened, which was also more homogeneous. Therefore, there existed an extra effect of PC on stretched AZ31B specimens, obviously changing the microstructure and causing the disappearance of twin lamellae.

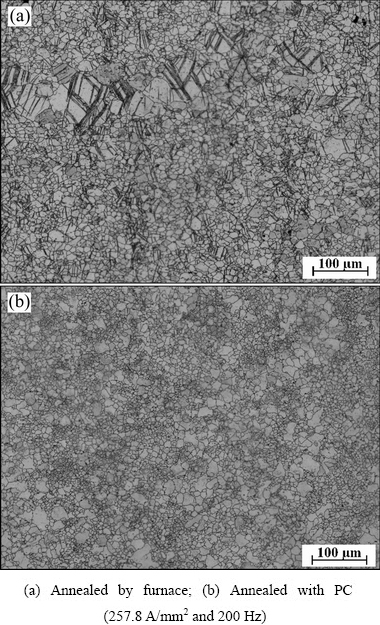

Moreover, PC refined the original coarse grains, based on the OM images with a smaller magnification in Fig. 5. When the heating type was furnace, there were still coarse grains, which were just like the microstructure in Fig. 3(a). But when the specimens were annealed by PC, nearly all the coarse grains disappeared, and then the microstructure was so homogeneous. The above phenomenon indicated that PC refined the original coarse grains stemmed from continuous casting and rolling, and then made the microstructure finer and more homogeneous.

Fig. 5 Microstructures of specimens annealed at 250 °C for 4 min

The EBSD image of the AZ31B samples after EAA at 257.8 A/mm2, 200 Hz and 250 °C for 2 min is shown in Fig. 6. Based on Fig. 6, there were still many twin grains distributing in the microstructure, although they cannot be distinguished by OM observation because their shape changed from typically lamellar, which is shown in Fig. 3(b), to equiaxed. The change of twin shape implied that PC enhanced the migration of twin boundaries, and “spheroidized” the twin lamellae. In this process, the orientation relationship between twin grains and original grains does not change, which still maintains the rotation angle of twinning, and then the twin grains can be distinguished by EBSD. This process also explained the reason why PC could refine and homogenize initial microstructure, mentioned above.

Therefore, PC increases the diffusion of atoms and strengthens the migration of boundaries, including twin grains and original equiaxed grains. Then, the twin grains, most of which distribute in the coarse grains, “spheroidize” into equiaxed grains because of the decreasing of the whole interface energy, thus separating the coarse grains and refining the microstructure. This process homogenizes the initial microstructure and eliminates the typically lamellar twin grains, which is not just SRX process proposed by LI et al [13]. Moreover, PC also strengthens the growth of equiaxed grains, and then the microstructure annealed by PC at a higher temperature is coarser than that annealed by furnace.

Fig. 6 EBSD image of AZ31B samples after annealing at 257.8 A/mm2, 200 Hz and 250 °C for 2 min

3.2 Dislocation annihilation

During annealing, the dislocation density would decrease because of thermal activation, and then the influence of PC on dislocation annihilation was studied in order to further estimate the extra effect of PC. Dislocation density can be estimated by many methods, one of which is XRD. When the instrumental conditions are the same and the grain size does not reach nanoscale, the dislocations density is the prime reason broadening the full width at half maximum (FWHM) of XRD peaks [8,17]. In this work, the change of dislocation density under different conditions was investigated based on the broadening of FWHM, which was similar to the results in Refs. [8,18] and was also used in the previous work [14]. For describing the change of FWHM, the broadening of FWHM is defined by

Δ=W-W0 (1)

where Δ is the broadening of FWHM, W is the FWHM, and W0 is the FWHM of the specimens which were just annealed at 400 °C for 3 h but without subsequent tension and annealing (they were not the initial specimens). Then, Δ can be used to roughly estimate the change of dislocation density.

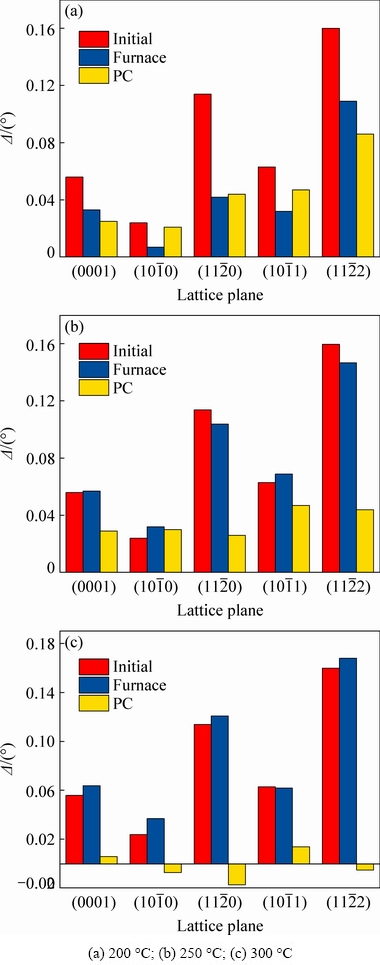

The values of Δ at different temperatures are shown in Fig. 7. When the annealing temperature was 200 °C, the difference of Δ between both annealing methods can be neglected, indicating that the extra effect of PC was feeble at a relatively low temperature, which was similar to the fact that the softening effect of PC was also weak at 200 °C during tension in Ref. [15]. When the temperature was heated to 250 °C, the values of Δ in different lattice planes, annealed by PC, were less than those by furnace. When the temperature reached 300 °C, the values of Δ even decreased to be negative, indicating that the dislocation density of the specimens annealed by PC at 300 °C was smaller than that just relieving the residual stress at 400 °C for 3 h. This phenomenon was also observed at the EAA on 5052 aluminum investigated by KIM et al [8]. The above observation implies that the extra annealing effect just exists at a higher temperature and is strengthened with the increase of temperature.

Fig. 7 Values of Δ at different temperatures (213.3 A/mm2, 300 Hz and 4 min)

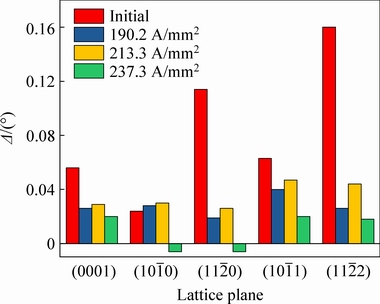

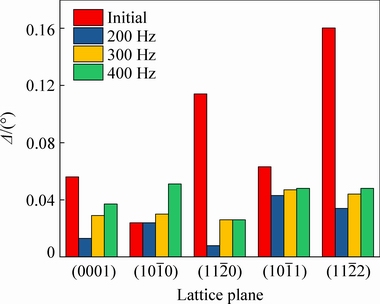

The influences of peak current density and frequency on the extra effect of PC are shown in Figs. 8 and 9, respectively. From Fig. 8, it can be seen that the annealing effect of PC is nearly invariable when peak current density is less than 213.3 A/mm2, but there is a strong dislocation annihilation at 237.3 A/mm2, which is like the annealing effect at 300 °C in Fig. 7(c). Then, the acceleration effect of PC on dislocation annihilation is strengthened with the increase of peak current density, which is not gradual, but is jumping when the peak current density is enhanced to a specific one. However, higher frequency weakens the annealing effect of PC, based on Fig. 9.

Fig. 8 Values of Δ at different peak current densities (250 °C, 300 Hz and 4 min)

Fig. 9 Values of Δ at different pulsed frequencies (250 °C, 213.3 A/mm2 and 4 min)

Furthermore, different peak current densities do not change the softening effect of PC, but higher frequency strengthens it during tension in our previous works [14,15], and then the phenomenon here is so different from the previous one. It may be because larger peak current density enhances the dislocation annihilation, whose influence is weaker than the interaction between dislocations, controlled by frequency, during deformation. Then, peak current density is the primary PC parameter during annealing, and frequency is the dominating parameter during deformation.

4 Conclusions

(1) PC increases the diffusion of atoms, and strengthens the migration of boundaries, including twin grains and original equiaxed grains.

(2) The twin grains, most of which are distributed in the coarse grains, “spheroidize” to equiaxed grains because of the decreasing of the whole interface energy, thus separating the coarse grains and refining the microstructure.

(3) PC strengthens the dislocation annihilation, which is enhanced with the increase of peak current density and the decrease of frequency.

References

[1] COHEN M H, BARRETT C S. Interaction of electrons with grain boundaries [J]. Physical Review B, 1954, 95: 1094-1095.

[2] TROITSKII O A. Electroplastic effect in metals [J]. Soviet Physics Solid-State, 1970, 26: 28-33.

[3] OKAZAKI K, KAGAWA M, CONRAD H. A study of the electoplastic effect in metals [J]. Scripta Metallurgica, 1978, 12: 1063-1068.

[4] OKAZAKI K, KAGAWA M, CONRAD H. An evaluation of the contributions of skin, pinch and heating effects to the electroplastic effect in titanium [J]. Materials Science and Engineering A, 1980, 45: 109-116.

[5] CONRAD H. Thermally activated plastic flow of metals and ceramics with an electric field or current [J]. Materials Science and Engineering A, 2002, 322: 100-107.

[6] CONRAD H. Electroplasticity in metals and ceramics [J]. Materials Science and Engineering A, 2000, 287: 276-287.

[7] ZHU Y H, TO S, LEE W B, LIU X M, JIANG Y B, TANG G Y. Effects of dynamic electropulsing on microstructure and elongation of a Zn-Al alloy [J]. Materials Science and Engineering A, 2009, 501: 125-132.

[8] KIM M J, LEE K H, OH K H, CHOI I S, YU H H, HONG S T, HAN H N. Electric current-induced annealing during uniaxial tension of aluminum alloy [J]. Scripta Materialia, 2014, 75: 58-61.

[9] XU Xiao-feng, ZHAO Yu-guang, MA Bing-dong, ZHANG Ming. Rapid precipitation of T-phase in the 2024 aluminum alloy via cyclic electropulsing treatment [J]. Journal of Alloys and Compounds, 2014, 610: 506-510.

[10] XU Xiao-feng, ZHAO Yu-guang, MA Bing-dong, ZHANG Jia-tao, ZHANG Ming. Rapid grain refinement of 2024 Al alloy through recrystallization induced by electropulsing [J]. Materials Science and Engineering A, 2014, 612: 223-226.

[11] JEONG H J, KIM M J, PARK J W, YIM C D, KIM J J, KWON O D, MADAKASHIRA P P, HAN H N. Effect of pulsed electric current on dissolution of Mg17Al12 phases in as-extruded AZ91 magnesium alloy [J]. Materials Science and Engineering A, 2017, 684: 668-676.

[12] PARK J W, JEONG H J, JIN S W, KIM M J, LEE K Y, KIM J J, HONG S T, HAN H N. Effect of electric current on recrystallization kinetics in interstitial free steel and AZ31 magnesium alloy [J]. Materials Characterization, 2017, 133: 70-76.

[13] LI Xiao-pei, LI Xiao-hui, ZHU K S, TANG Guo-yi. A comparative study on the static recrystallization behavior of cold-rolled Mg-3Al-1Zn alloy stimulated by electropulse treatment and conventional heat treatment [J]. Metallurgical and Materials Transactions A, 2018, 49: 613-627.

[14] LIU Kai, DONG Xiang-huai, XIE Huan-yang, WU Yun-jian, PENG Fang. Influence of pulsed current on deformation mechanism of AZ31B sheets during tension [J]. Journal of Alloys and Compounds, 2016, 676: 106-112.

[15] LIU Kai, DONG Xiang-huai, XIE Huan-yang, PENG Fang. Effect of pulsed current on the deformation behavior of AZ31B magnesium alloy [J]. Materials Science and Engineering A, 2015, 623: 97-103.

[16] XIE Huan-yang, WANG Qian, PENG Fang, LIU Kai, DONG Xiang-huai, WANG Jian-feng. Electroplastic effect in AZ31B magnesium alloy sheet through uniaxial tensile tests [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2686-2692.

[17] UNGAR T, OTT S, SANDERS P G, BORBELY A, WEERTMAN J R. Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis [J]. Acta Materialia, 1998, 46: 3693-3699.

[18] UNGAR T. Microstructural parameters from X-ray diffraction peak broadening [J]. Scripta Materialia, 2004, 51: 777-781.

脉冲电流对AZ31B镁合金板材退火过程的影响

刘 凯1,2,董湘怀1,石 文1

1. 上海交通大学 模具CAD国家工程研究中心,上海 200030;

2. 上海飞机制造有限公司,上海 201324

摘 要:通过脉冲电流和热处理炉对AZ31B镁合金板材进行退火处理,并分析脉冲电流对合金显微组织及位错密度演化的影响。结果表明:脉冲电流能增强晶界的迁移,使孪生晶粒球化成等轴晶,从而切割原始粗大晶粒并细化显微组织。该过程能使原始显微组织更加均匀,并消除典型的层片状孪晶。此外,脉冲电流还能增强位错的湮灭。当材料在300 °C下脉冲电流辅助退火4 min后,其位错密度甚至低于在400 °C的热处理炉中退火3 h且未发生塑性变形的组织。不仅如此,脉冲电流对位错湮灭的促进作用随峰值电流密度的增强及脉冲频率的降低而增强。

关键词:脉冲电流;AZ31B镁合金;退火;显微组织演化;孪生;位错湮灭

(Edited by Wei-ping CHEN)

Foundation item: Project (51635005) supported by the National Natural Science Foundation of China

Corresponding author: Xiang-huai DONG; Tel/Fax: +86-21-62932298; E-mail: dongxh@sjtu.edu.cn

DOI: 10.1016/S1003-6326(19)64983-6

Abstract: The annealing tests heated by pulsed current (PC) or furnace for AZ31B magnesium sheets were carried out, and the effects of PC on the microstructure and dislocation density of the alloy were analyzed. The results show that PC strengthens the migration of boundaries, and then the twin grains, most of which distribute in the coarse grains, “spheroidize” to equiaxed grains, thus separating the coarse grains and refining the microstructure. This process homogenizes the initial microstructure and eliminate the typically lamellar twin grains. Moreover, PC also strengthens the dislocation annihilation. When the specimens were annealed by PC at 300 °C for 4 min, the dislocation density was even lower than that annealed by furnaces at 400 °C for 3 h before deformation. Furthermore, dislocation annihilation is enhanced with the increase of peak current density and the decrease of pulsed frequency.