DOI: 10.11817/j.ysxb.1004.0609.2020-35764

基于选冶联合的废印刷线路板铜粉源头除杂的技术路线

刘伟锋1,贾 锐1,朱鹏春1, 2,张杜超1,陈 霖1,卢苏君3,杨天足1

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 云南铜业股份有限公司,昆明 650032;

3. 镍钴资源综合利用国家重点实验室,金昌 737100)

摘 要:

废印刷线路板是重要的城市矿产资源,因其成分复杂导致其处理难度大。在详细总结废印刷线路板回收利用方法的基础上,针对主流的废印刷线路板火法冶金处理工艺存在的锡铅锌等杂质金属分散和有机物燃烧释放有害气体的问题,提出一种基于选冶联合的废印刷线路板铜粉源头除杂的技术路线:废印刷线路板铜粉通过碱性加压氧化浸出,使锡铅锌等杂质金属溶解进入浸出液,锡浸出率>98.2%,浸出液经硫化净化脱除杂质,铅和锌的沉淀率>99.5%,净化液经电积产出98.0%的粗锡;浸出渣中废印刷线路板基体和阻焊油等有机物从铜箔表面剥离,采用摇床使之分离,有机物脱除率>50.0%。采用选冶联合的方法脱除了废印刷线路板铜粉中的大部分锡杂质金属和有机物,为后续火法炼铜提供了优质原料,为废印刷线路板铜粉在火法炼铜系统的高效处理提供了新的技术路线。

关键词:

文章编号:1004-0609(2020)-05-1182-10 中图分类号:TF814 文献标志码:A

近年来,人们的生产和生活已经离不开电子电器设备[1-2]。随着电子工业的发展、技术的进步和市场的扩大,电子电器设备的升级速度加快,导致电子电器设备的使用时间远远低于产品的实际使用寿命,这就使得废旧电子电器设备(Waste electric and electronic equipment, WEEE)飞速增长[3-5]。WEEE带来了很大的环境问题,已经成为城市固体废物的主要来源之一[6-7]。我国已进入电子产品报废的高峰期,每年理论报废量超过5000万台,并且以年均20%的速度增长[8]。WEEE成分复杂,一方面,其含有多种有价金属组分,是重要的城市矿产资源;另一方面,其含有多种有毒有害物质,如果处理不当会对环境和人体健康造成危害。因此,开发环保的WEEE回收利用技术迫在眉睫。

线路板是电子工业的基础,是所有电子电器设备的重要组成部分[9]。近年来,世界线路板工业的年增长率为8.7%,我国线路板制造业的增长率高达14.4%[10]。我国每年产生的线路板达15万t,每年需要处理的废印刷线路板(Waste printed circle boards,WPCBs)达到50万t以上[11]。WPCBs具有增长速度快、利用价值高、环境危害大的特点[12]。WPCBs主要由树脂和玻璃纤维组成,并含有大量的金属,如铜、铁、锡、金、钯、银等[13-14],WPCBs中的金属品位相当于普通矿石的数十倍[15],具有极高的资源化利用价值;同时,它含有多种重金属和有毒有害物质,如铅、镉、汞、六价铬、聚氯乙烯和卤化物阻燃剂等,处理不当将会对环境和人类健康造成极大影响[16-17]。因此,开展WPCBs回收利用方面的研究,使WPCBs得到资源化和无害化处理,对促进人类可持续发展具有重要意义。

1 废电子电器设备拆解

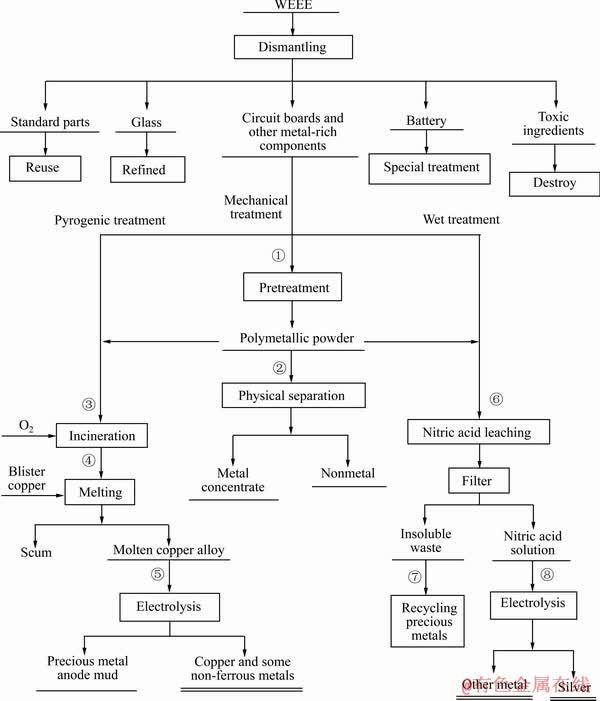

WEEE的拆解主要有以下三个目的:1) 回收可再利用的元器件;2) 拆除有毒组件进行专门处理;3) 线路板、电缆及工程塑料等高价值部件拆除后单独处理,简化后续工艺[18]。WEEE拆解及WPCBs处理工艺如图1所示,WEEE经拆解之后主要有五种产物,一是电子电器上面的标准部件,通常回收再次使用;二是玻璃成分,对其进行预处理后,回炉熔融制造玻璃容器、玻璃纤维等;三是各种电池,需要送电池回收工厂单独处理;四是各种有毒成分,主要为汞、含铅玻璃、塑料等,一般进行特殊处理;五是印刷线路板、电缆及其他富金属组件,这类组件中有价金属含量较高,回收价值大。

由图1可以看出,WPCBs处理分为机械处理、火法处理和湿法处理。机械处理是目前应用较广泛的一种WPCBs回收方法,具有工艺流程简单和环境污染小的优点。火法冶金从电子废物中提取金属一直是一种重要的WPCBs回收技术,基本原理是利用冶金炉高温加热剥离非金属物质,贵金属熔融于其它金属熔炼物料或熔盐中再加以分离,该工艺方法具有处理规模大和回收率高的特点。湿法处理是电子废弃物资源化处理中研究应用最早的方法之一,主要面向WPCBs中金属的回收,因其对能源和成本的要求更低,多用于产能相对较小的工厂。

图1 废电子电器设备拆解及废印刷线路板处理原则工艺流程

Fig. 1 Flow sheet of dismantling of WEEE and extracting metal from WPCBs

2 废印刷线路板机械处理技术研究进展

机械处理技术是WPCBs回收利用最广泛方法之一。机械处理技术主要包括拆解、破碎、分选等过程,既可以直接用于金属回收,如图1中的①+②,也可以作为其他处理方法的预处理过程,如图1中的①→③、①→⑥。

2.1 拆解

由于线路板含有多种电子元件,在组成和结构上跟基板有很大的差异,因此将电子元件拆解后单独处理可以减少WPCBs的后续工序[19]。目前,拆解主要由人工来完成,但随着WPCBs数量的增加,人工拆解技术既不能满足WPCBs的大规模回收利用,又造成了严重的环境污染[20]。利用加热装置融化焊料使电子元件脱离是实现自动化拆解的有效途径,基于此原理有研究人员设计了一种新型的红外加热自动拆解装置,该装置通过红外加热器加热使焊料融化,然后用钢刷将电子元件从WPCBs中扫出,利用该装置电子元件的分离效率可达到94%[21]。另有研究人员设计了一种环保的电子元件自动拆解系统,该系统包括了电子元件自动拆卸和尾气净化两部分,该系统使用电加热管在定制的自动拆解机中熔化焊料,既实现了电子元件的自动拆解又减少了污染物的排放[22]。

2.2 破碎

线路板的破碎程度直接影响着金属与非金属的分离效果,破碎成为整个机械处理流程的关键环节[23]。由于WPCBs是由多层玻璃纤维布、增强树脂和铜箔组成,具有很高的硬度和韧性,传统的破碎机无法获得良好的效果,采用具有剪、切作用的破碎设备可以达到较好的效果[24],另有研究表明,粒径为0.6~1.2 mm的颗粒易于实现金属和非金属的分离[25]。基于此研究人员采用两段破碎的方式处理WPCBs[26],粗碎机采用高速剪切机,转子刀具和定子刀具产生的剪切作用将WPCBs破碎成小颗粒,第二台破碎机是专门为WPCBs设计的锤式粉碎机,可以将WPCBs破碎到1 mm以下,达到了适合分选的粒径。

2.3 分选

分选主要利用WPCBs中材料物理性质的差异,如磁性、电性、密度和形状等,通过重力分选、磁电分选等手段分离WPCBs中的金属和非金属。空气分级技术是一种典型的重力分选的方法,研究人员利用空气分级技术来处理WPCBs可以回收96.7%的铜,但是得到铜中含有较多杂质[27]。涡流分选是一种成熟的磁性分离技术,往往被用来分离非磁导体金属,研究人员采用涡流分选从WPCBs中回收铝,铝的回收率可达到90%以上[28]。静电分离技术利用金属和非金属导电性的差异来使之分离,研究人员针对WPCBs中金属的回收设计了满足工业应用要求的三级静电分离机,可以回收95%以上的金属[29]。

3 废印刷线路板火法处理技术研究进展

火法处理技术是利用高温手段处理WPCBs,主要包括:焚烧法、热解法和熔炼法三类。

3.1 焚烧法

焚烧法是将WPCBs直接放入焚烧炉的处理过程,主要目的是为了回收WPCBs中的热值,WPCBs的焚烧与一般的城市生活垃圾焚烧相比具有减量大、热值高等优势。WPCBs中约有70%是非金属组分[30],焚烧后体积减少为原来的50%左右,焚烧产生的热值约为5MJ/kg[31]。焚烧法由于工艺简单、处理成本低,早些年被广泛用来处理WPCBs,然而WPCBs中的阻燃剂含有大量溴、氯及芳香族化合物,这些成分在氧化性气氛下燃烧极易形成二苯二噁英和二苯呋喃等有害气体[32-34],一些重金属也会在焚烧的过程中挥发进入烟气,造成重金属污染。焚烧法处理WPCBs并不是环保的方法,在我国已禁止使用。

3.2 热解法

热解法是利用有机物的热不稳定性,在缺氧或无氧的条件下,通过高温加热使WPCBs中的有机物发生分解,将大分子量的有机物转化成小分子量的油状和气态的烃类化合物,实现有机物和金属与玻璃纤维的分离[35-38]。热解产物经冷凝可以得到热解油,剩余的不凝气体回收后可作为燃料利用。采用热解技术处理WPCBs,既可以实现金属的分离回收,同时也可以实现对有机高分子化合物的资源化回收利用。

研究人员对WPCBs的热解机理和动力学进行了深入研究[39-41],从热解反应的原理上看,降低压力有利于分子裂解,因此在真空的条件下进行WPCBs的热解能够显著地提高其回收效率。利用真空热解-离心分离技术处理WPCBs[42-43],可以实现WPCBs中有机树脂和焊锡的回收利用,并且热解气体中含有大量的CH4、CO和H2,可以用做气体燃料。在热解时加入特定的添加剂可以促进固溴,减少溴的排放[44];在存在金属氧化物的情况下对WPCBs进行热解,溴化氢和溴化有机物的生成明显受到抑制[45-49]。因此,利用热解技术处理WPCBs,具有资源利用率高,环境友好的特点。

3.3 熔炼法

熔炼法是在高温下熔炼处理WPCBs,使非金属和金属得以分离,贵金属富集在铜合金中,然后再经过电解精炼等实现分离。熔炼法主要包括:焚烧熔出工艺、高温氧化熔炼工艺、精炼工艺等[50],如图1中①+③+④+⑤。

铜是WPCBs中含量最高的金属,因此世界上大规模的WPCBs回收通常在大型火法炼铜厂中进行。比利时的Umicore就利用铜火法冶炼工艺从WPCBs中回收金属,它利用WPCBs中含有的塑料和其他有机物质作为还原剂和能源,通过熔炼富集铜和贵金属[51]。熔炼法处理WPCBs的优点在于工艺简单和金属回收率高,但是存在能耗高和尾气污染大等缺点。

4 废印刷线路板湿法处理技术研究进展

湿法处理技术主要是面向WPCBs中铜和贵金属的回收,浸出是其中最为关键的步骤,湿法处理因所采用的浸出剂不同而分为酸浸法、氰化法和非氰化法。

4.1 酸浸法

酸浸法是将WPCBs通过强酸、强氧化剂处理使其中的贵金属剥离沉淀,而铜等其他有价金属则溶于酸中,沉淀物通过硝酸和王水等处理后回收其中的贵金属,含铜酸液通过净化、电解等手段得到电解铜[52]。图1中的①+⑥+⑦+⑧就是一种经典的酸浸法从电子废物中提取贵金属技术。酸浸法由于工艺简单、成本低等特点,是早期小规模作坊式生产常用的处理手段,此法会产生大量酸性废水,造成严重的环境污染,另外酸浸法选择性较差,不能做到WPCBs中有价金属的综合利用,造成了资源的浪费。

4.2 氰化法

利用氰化法从矿物资源中回收金和银已有百年历史,尽管氰化物有剧毒,但其高效率和低成本的优势使其在工业上仍优于其他非氰化物浸出剂。WPCBs中含有较多的金和银,氰化法也可用来处理WPCBs。由于WPCBs中铜含量很高,在浸出过程中铜大量溶解,降低了贵金属的浸出率[53]。因此,采用氰化法处理WPCBs应先在适当氧化剂的存在下用硫酸将铜浸出,以避免在氰化法提取贵金属时溶解铜。

4.3 非氰化法

由于氰化物对环境和人类的影响正被公众密切关注,利用非氰化物浸出剂对WPCBs进行选择性浸出的研究得到广泛重视,硫脲法和硫代硫酸盐法被认为是取代氰化法最有希望的方法。利用两步浸出法从WPCBs中回收金属,首先使用H2SO4和H2O2选择性浸出贱金属,然后通过酸性硫脲浸出金和银,金和银的浸出率分别为90%和75%[54]。研究人员从废弃手机的线路板中采用硫代硫酸盐回收其中的金,金的浸出率可达90%以上[55]。

5 废印刷线路板铜粉源头除杂技术路线

5.1 新技术路线的产生

目前,WPCBs回收的主流技术是机械分选-火法熔炼工艺。在火法工艺中,锡、铅、锌、铝等金属会分散进入渣、烟气和铜锍中,降低铜的回收率和质量,关于这些金属回收的研究较少,在WPCBs回收过程中常被视为杂质金属而除去,但是这些金属具有一定的回收价值,特别是含量较高的锡,其潜在回收价值非常可观。因此,开发一种可以回收WPCBs中锡的新工艺是必要的。此外,WPCBs中的阻燃剂含有大量溴、氯和芳香族化合物,机械预处理过程中解离不充分导致部分金属仍被塑料、阻燃剂等聚合物包裹,在熔炼过程中会产生二苯二噁英和二苯呋喃等有毒有害气体,对环境造成较大污染。

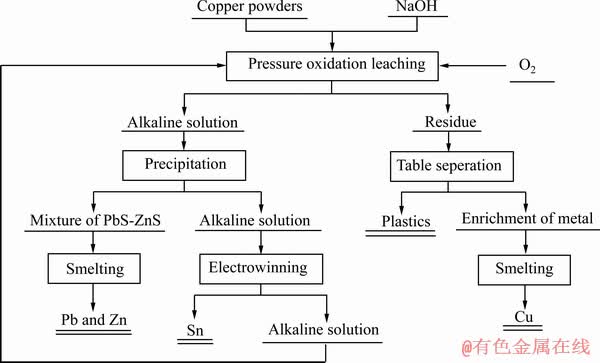

针对WPCBs传统熔炼工艺回收铜和贵金属过程中存在的锡铅锌等金属的分散和有机物燃烧释放有害气体的问题,提出了一种废印刷线路板铜粉源头除杂的技术路线,即废印刷线路板铜粉首先经过碱性加压氧化浸出,使锡、铅和锌溶解进入溶液,同时使铜箔表面残存的塑料和阻焊油与铜箔分离,碱性加压浸出液经过硫化净化后电积产出金属锡,而浸出渣通过摇床分选得到含塑料的轻颗粒物和含铜的重颗粒物,重颗粒物经过熔炼后得到粗铜,工艺流程见图2。

5.2 原料

图2 碱性浸出-分选-回收工艺流程

Fig. 2 A simple flow chart of the alkaline leaching-sorting-recovery process

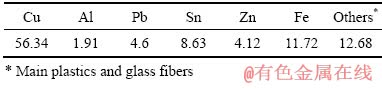

表1 废印刷线路板铜粉的化学成分

Table 1 Chemical composition of metal powder (mass fraction, %)

试验所用的原料是报废电视机WPCBs经破碎、研磨、分选得到的多金属粉末,其组成如表1所示,

因其中金属主要由铜组成,故将其称为废印刷线路板铜粉。试验中用到的氢氧化钠(NaOH,≥96%)、硫化钠(Na2S·9H2O,≥98%)均为分析纯试剂,氧气(99.5%)为工业级。

5.3 废印刷线路板铜粉碱性加压氧化浸出

废印刷线路板铜粉在碱性加压氧化浸出过程中,锡、铅、铝、锌等两性金属以含氧酸盐的形式溶解进入溶液,发生的化学反应如下:

Sn+2NaOH+O2=Na2SnO3+H2O (1)

2Pb+4NaOH+O2=2Na2PbO2+2H2O (2)

4Al+4NaOH+3O2=4NaAlO2+2H2O (3)

2Zn+4NaOH+O2=2Na2ZnO2+2H2O (4)

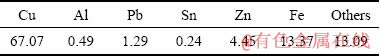

碱性加压氧化浸出的最佳工艺条件为NaOH浓度2.5 mol/L,液固比4:1,温度 150 ℃,氧压为2.0 MPa,搅拌速度1100 r/min和时间3 h,浸出渣的成分如表2所示。

对比表1和2可以看出,碱性加压氧化浸出过程在最佳条件下可以实现废印刷线路板铜粉中锡、铅和铝的分离浸出,锡、铅、铝、锌的浸出率分别为98.2%、77.6%、78.3%和6.8%,其中锌浸出率低的原因是废印刷线路板铜粉中锌主要以铜锌合金形式存在[56],阻碍了锌的氧化浸出反应。

表2 浸出渣的化学成分

Table 2 Chemical composition of leaching residue (mass fraction, %)

5.4 浸出液中金属分离回收

5.4.1 浸出液净化除铅和锌

浸出液中含有锡、铅、锌、铝等金属,由于铅和锌与锡的析出电势相差不大,净化去除铅和锌对后续电积回收锡非常重要,既可以避免阴极锡中夹杂铅和锌影响产品质量,产物又可以作为原料用于铅和锌的熔炼生产。采用硫化沉淀法脱除浸出液中的铅和锌,沉淀过程中发生的化学反应如下:

Pb2++S2-=PbS↓ (5)

Zn2++S2-=ZnS↓ (6)

最佳净化条件为:Na2S过量系数1.3、温度85 ℃、搅拌速度400 r/min和时间150 min。净化前后溶液中金属成分的对比如表3所示。由表3可知,净化后溶液中铅和锌浓度降低到了0.01 g/L以下,铅和锌的沉淀率都达到了99.5%以上。通过硫化沉淀方法实现了铅和锌与锡的高效分离而不影响主要金属锡的含量,为后续电积回收锡创造了良好的条件。

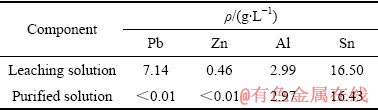

表3 净化前后溶液中金属成分

Table 3 Chemical composition of solution before and after purification

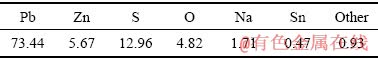

浸出液净化沉淀产物的组分如表4所示,XRD分析结果如图3所示。由表4可以看出,沉淀产物主要含铅和锌,锡含量很少。这是由于锡在碱溶液中以 形式存在,不会被硫化沉淀。

形式存在,不会被硫化沉淀。

由图3可以看出,沉淀产物主要是方铅矿。由于锌在碱性加压氧化过程中浸出率较低,而铅的浸出率远远大于锌浸出率,所以沉淀产物XRD谱中闪锌矿物相的峰被方铅矿物相的峰所掩盖,未能分析出闪锌矿物相,通过硫化沉淀得到的产物是含量较高的方铅矿精矿,可作为火法炼铅的优质原料。

表4 浸出液净化沉淀产物主要组分表

Table 4 Chemical composition of precipitate

图3 浸出液净化沉淀产物XRD谱

Fig. 3 XRD pattern of product obtained by sulfide precipitation

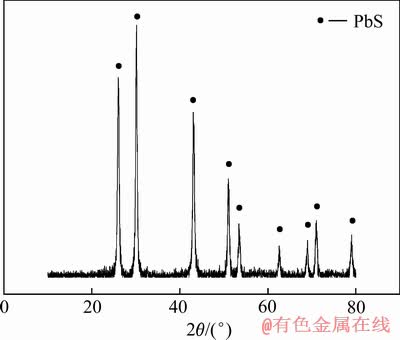

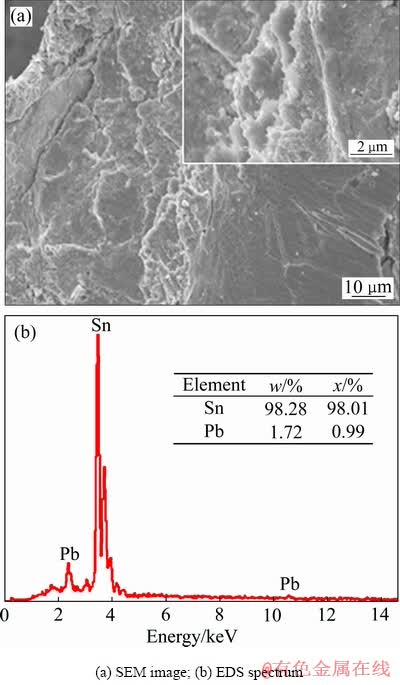

5.4.2 净化后液中锡的回收

温度65 ℃、槽电压2.5 V、电流密度100 A/m2、时间4 h和溶液循环流速5 L/min,净化后液电积产物的SEM-EDS分析结果如图4所示。由图4可以看出,电积产物较为均匀并呈现密实的片层状结构,EDS分析结果表明电积产物中锡含量达到98%,此外,电积产物中含极少量的铅,这是由残留于净化后液的微量Pb电积所导致的。电积后液可以返回碱性加压氧化浸出工序循环利用。

图4 电积产物SEM-EDS能谱

Fig. 4 SEM-EDS image of product obtained by electro- winning

5.5 浸出渣摇床分选

废印刷线路板铜粉经过碱性加压氧化浸出处理后,锡、铅、锌、铝等金属溶解进入浸出液中,WPCBs机械预处理过程中因解离不完全而包裹在金属颗粒表面的塑料、阻燃剂等有机物在浸出过程中从金属表面脱落,使部分被包裹的金属暴露出来。因此,碱性加压氧化浸出渣可进一步将废印刷线路板铜粉中残存的有机物分离出来,浸出渣摇床分选得到少量的轻颗粒物和富集大量金属的重颗粒物,重颗粒物可用作铜冶炼的原料,有效减少冶炼过程中有机物燃烧释放有害气体。

试验条件:物料2000 g,水流大小30 L/min,给料速度200 g/min,床面横向坡度5°,冲程20 mm,冲次250 min-1。WPCBs中含碳物主要是塑料和阻燃剂,通过对样品中含碳量的测定可以反映其中有机物的含量。为了确定摇床分选过程中有机组分的分布情况,对原料和浸出渣分选物进行含碳量分析检测,含碳量分析结果如表5所示。

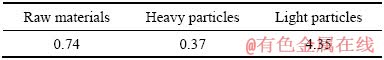

表5 原料和分选产物含碳量

Table 5 Carbon content of raw materials and sorting products(Mass fraction, %)

由表5可以看出,最初废印刷线路板铜粉中碳含量达0.74%,经过碱性加压氧化浸出和摇床分选处理后,含碳量从0.74%降低至0.37%,减少约50%。分选得到的轻颗粒物碳含量4.35%,表明经摇床分选后废印刷线路板铜粉中的塑料和阻燃剂等有机物富集于轻颗粒物中。

6 结论

1) 废旧电子电器设备(WEEE)是重要的城市矿产资源,其中废印刷线路板(WPCBs)是回收铜及稀贵金属的重要原料,WPCBs通常采用机械方法、火法和湿法处理。WPCBs机械分选-火法熔炼是目前应用最广泛的工艺,针对该过程中存在的锡铅锌等金属的分散和有机物燃烧释放有害气体的问题,提出了一种废印刷线路板铜粉源头除杂的技术路线。

2) 废印刷线路板铜粉经过碱性加压氧化浸出,使锡和铅氧化溶解,锡和铅的浸出率达到98.2%和77.6%,同时,废印刷线路板铜粉中包裹在金属表面的残余塑料、阻燃剂等有机物可被有效剥离;浸出渣再采用摇床分选,废印刷线路板铜粉中有机物脱除率达到50%左右。

3) 碱性加压氧化浸出液采用硫化沉淀脱除铅和锌,铅和锌的沉淀率达到99.5%以上,浸出液净化沉淀产物可作为铅冶炼的优质原料;净化后液采用电沉积回收溶液中的锡,阴极锡中锡含量达到98%。

REFERENCES

[1] GHOSH B, GHOSH M K, PARHI P, MUKHERJEE P S, MISHRA B K. Waste Printed Circuit Boards recycling: An extensive assessment of current status[J]. Journal of Cleaner Production, 2015, 94: 5-19.

[2] YANG Tian-zu, ZHU Peng-chun, LIU Wei-feng, CHEN Lin, ZHANG Du-chao. Recovery of tin from metal powders of waste printed circuit boards[J]. Waste Management, 2017, 68: 449-457.

[3] Rahmani M, Nabizadeh R, Yaghmaeian K, MAHVI A H, YUNESIAN M. Estimation of waste from computers and mobile phones in Iran[J]. Resources, Conservation and Recycling, 2014, 87: 21-29.

[4] WANG Fang-fang, ZHAO Yue-ming, ZHANG Tao, DUAN Chen-long, WANG Li-zhang. Mineralogical analysis of dust collected from typical recycling line of waste printed circuit boards[J]. Waste Management, 2015, 43: 434-441.

[5] YOSHIDA A, TERAZONO A, Ballesteros F C, Nguyen D Q, Sukandar S, Kojima M, Sakata S. E-waste recycling processes in Indonesia, the Philippines, and Vietnam: A case study of cathode ray tube TVs and monitors[J]. Resources, Conservation and Recycling, 2016, 106: 48-58.

[6] WANG Jan-bo, XU Zhen-ming. Disposing and recycling waste printed circuit boards: Disconnecting, resource recovery, and pollution control[J]. Environmental Science & Technology, 2015, 49(2): 721-733.

[7] Parajuly K, Habib K, LIU Gang. Waste electrical and electronic equipment (WEEE) in Denmark: Flows, quantities and management[J]. Resources Conservation and Recycling, 2017, 123: 85-92.

[8] LIU Wei, LIANG Chao, QIN Wen-qing, JIAO Fen. A new technology for recovery of metals from waste printed circuit boards[J]. Applied Mechanics and Materials, 2014, 675/677: 698-703.

[9] NING Chao, LIN C S K, HUI D C W, MCKAY G. Waste printed circuit board (PCB) recycling techniques[J]. Topics in Current Chemistry, 2017, 375(2): 43.

[10] LI Huan, EKSTEEN J, ORABY E. Hydrometallurgical recovery of metals from waste printed circuit boards (WPCBs): Current status and perspectives—A review[J]. Resources, Conservation and Recycling, 2018, 139: 122-139.

[11] 夏明晨, 王亚萍, 彭堂见, 周洪波, 刘学端, 姜 涛, 邱冠周, 曾伟民. 废弃线路板分选尾渣微生物浸出过程中的参数优化[J]. 中国有色金属学报, 2016, 26(4): 928-935.

XIA Ming-chen, WANG Ya-ping, PENG Tang-jian, ZHOU Hong-bo, LIU Xue-rui, JIANG Tao, QIU Guan-zhou, ZENG Wei-min. Parameter optimization during micro-bioleaching slags separated from waste printed circuit boards[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 928-935.

[12] 郭学益, 严 康, 张婧熙, 黄国勇, 田庆华. 典型电子废弃物中金属资源开采潜力分析[J]. 中国有色金属学报, 2018, 28(2): 365-376.

GUO Xue-yi, YAN Kang, ZHANG Jing-xi, HUANG Guo-yong, TIAN Qing-hua. Exploitation potentiality analysis of metal resources in typical electronic waste[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(2): 365-376.

[13] Choubey P K, Panda R, Jha M K, Lee J, Pathak D D. Recovery of copper and recycling of acid from the leach liquor of discarded printed circuit boards (PCBs)[J]. Separation and Purification Technology, 2015, 156(9): 269-275.

[14] Gu Yi-fan, Wu Yu-feng, Xu Ming, Wang Huai-dong, Zuo Tie-yong. The stability and profitability of the informal WEEE collector in developing countries: A case study of China[J]. Resources, Conservation and Recycling, 2016, 107: 18-26.

[15] HE Jing-feng, DUAN Chen-long. Recovery of metallic concentrations from waste printed circuit boards via reverse floatation[J]. Waste Management, 2017, 60: 618-628.

[16] Awasthi A K, Zeng Xian-lai, Li Jin-hu. Environmental pollution of electronic waste recycling in India: A critical review[J]. Environmental Pollution, 2016, 211: 259-270.

[17] Li Jin-hui, He Xin, Zeng Xian-lai. Designing and examining e-waste recycling process: Methodology and case studies[J]. Environmental Technology Letters, 2017, 38(6): 652-660.

[18] Rocchetti L, Amato A, Beolchini F. Printed circuit board recycling: A patent review[J]. Journal of Cleaner Production, 2018, 178: 814-832.

[19] Vanegas P, Peeters J R, Cattrysse D, Tecchio P, Ardente F, Mathieux F, Dewulf W, Duflou J R. Ease of disassembly of products to support circular economy strategies[J]. Resources, Conservation and Recycling, 2017, 135: 323-334.

[20] GUO Jie, ZHANG Ran, XU Zhen-ming. Polybrominated diphenyl ethers (PBDEs) emitted from heating machine for waste printed wiring boards disassembling[J]. Procedia Environmental Sciences, 2016, 31: 849-854.

[21] Park S, Kim S, Han Y, Park J. Apparatus for electronic component disassembly from printed circuit board assembly in e-wastes[J]. International Journal of Mineral Processing, 2015, 144: 11-15.

[22] WANG Jian-bo, GUO Jie, XU Zhen-ming. An environmentally friendly technology of disassembling electronic components from waste printed circuit boards[J]. Waste Management, 2016, 53: 218-224.

[23] ZHANG Lin-gen, XU Zhen-ming. A review of current progress of recycling technologies for metals from waste electrical and electronic equipment[J]. Journal of Cleaner Production, 2016, 127: 19-36.

[24] WANG Rui-xue, XU Zhen-ming. Recycling of non-metallic fractions from waste electrical and electronic equipment (WEEE): A review[J]. Waste Management, 2014, 34(8): 1455-1469.

[25] KAYA M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes[J]. Waste Management, 2016, 57: 64-90.

[26] HADI P, XU Meng, LIN C S K, HUI Chi-wai, MCKAY G. Waste printed circuit board recycling techniques and product utilization[J]. Journal of Hazardous Materials, 2015, 283: 234-243.

[27] ZHANG Guang-wen, HE Ya-qun, WANG Hai-feng, ZHANG Tao, WANG Shuai, YANG Xing, XIA Wen-cheng. New technology for recovering residual metals from nonmetallic fractions of waste printed circuit boards[J]. Waste Management, 2017, 64: 228-235.

[28] Ventura E, Futuro A, Pinho S C, Almeida M F, Dias J M. Physical and thermal processing of waste printed circuit boards aiming for the recovery of gold and copper[J]. Journal of Environmental Management, 2018, 223: 297-305.

[29] Salama A, Richard G, Medles K, Zeghloul T, Dascalescu L. Distinct recovery of copper and aluminum from waste electric wires using a roll-type electrostatic separator[J]. Waste Management, 2018, 76: 207-216.

[30] DUAN Hua-bo, HU Jiu-kun, YUAN Wen-yi, WANG Yan-jie, YU Dan-feng, SONG Qing-bin. Characterizing the environmental implications of the recycling of non-metallic fractions from waste printed circuit boards[J]. Journal of Cleaner Production, 2016, 137: 546-554.

[31] Komilis D, Evangelou A, Giannakis G, Lymperis C. Revisiting the elemental composition and the calorific value of the organic fraction of municipal solid wastes[J]. Waste Management, 2012, 32(3): 372-381.

[32] Zhang Meng-mei, Buekens A, LI Xiao-dong. Brominated flame retardants and the formation of dioxins and furans in fires and combustion[J]. Journal of Hazardous Materials, 2016, 304: 26-39.

[33] PENG Ya-qi, CHEN Jing-hao, LU Sheng-yong, HUANG Jian-xin, ZHANG Meng-mei, Buekens A, LI Xiao-dong, YAN Jian-hua. Chlorophenols in municipal solid waste incineration: A review[J]. Chemical Engineering Journal, 2016, 292: 398-414.

[34] ZHANG Meng-mei, BUEKENS A, LI Xiao-dong. Dioxins from biomass combustion: An overview[J]. Waste and Biomass Valorization, 2017, 8(1): 1-20.

[35] CHEN De-zhen, YIN Li-ji, WANG Huan, HE Pin-jing. Pyrolysis technologies for municipal solid waste: A review[J]. Waste Management, 2014, 34(12): 2466-2486.

[36] Jayapradha A, Abbasmohaideen J, Kumar P S, Kavitha V, Narendrakumar G. Management of printed circuit boards by newly designed thermal pyrolytic process: Process optimization by RSM approach[J]. Environmental Progress & Sustainable Energy, 2019, 38(2): 489-499.

[37] YE Zi-wei, YANG Fan, LIN Wei-xiong, LI Shou-peng, SUN Shui-yu. Improvement of pyrolysis oil obtained from co-pyrolysis of WPCBs and compound additive during two stage pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2018, 135: 415-421.

[38] Santella C, Cafiero L, Angelis D D, Marca F L, Tuffi R. Thermal and catalytic pyrolysis of a mixture of plastics from small waste electrical and electronic equipment (WEEE)[J]. Waste Management, 2016, 54: 143-152.

[39] MA Hong-ting, DU Na, LIN Xue-yin, LI Chen, LAI Jun-wen, LI Zi-hao. Experimental study on the heat transfer characteristics of waste printed circuit boards pyrolysis[J]. Science of the Total Environment, 2018, 633: 264-270.

[40] LIU Wei, XU Jia-qi, HAN Jun-wei, JIAO Fen, QIN Wen-qing, LI Zhu-zhang. Kinetic and mechanism studies on pyrolysis of printed circuit boards in the absence and presence of copper[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(2): 1879-1889.

[41] Diaz F, Flerus B, Nagraj S, Bokelmann K, Stauber R, Friedrich B. Comparative analysis about degradation mechanisms of printed circuit boards (PCBs) in slow and fast pyrolysis: The influence of heating speed[J]. Journal of Sustainable Metallurgy, 2018, 4(2): 205-221.

[42] MENG Long, ZHONG Yi-wei, WANG Zhe, CHEN Kui-yuan, GUO Zhan-cheng. Low-temperature melting and centrifugation of lead and tin from metal-rich particles of crushed waste printed circuit boards[J]. Chemical Engineering and Processing-Process Intensification, 2018, 130: 192-200.

[43] NIU Bo, CEHN Zhen-yang, XU Zhen-ming. Recovery of valuable materials from waste tantalum capacitors by vacuum pyrolysis combined with mechanical-physical separation[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(3):2639-2647.

[44] WU Wen-biao, QIU Ke-qiang. Vacuum co-pyrolysis of Chinese fir sawdust and waste printed circuit boards. Part II: Influence of heating conditions[J]. Journal of Analytical and Applied Pyrolysis, 2015, 111:216-223.

[45] GAO Rui-tong, XU Zhen-ming. Pyrolysis and utilization of nonmetal materials in waste printed circuit boards: Debromination pyrolysis, temperature-controlled condensation, and synthesis of oil-based resin[J]. Journal of Hazardous Materials, 2019, 364: 1-10.

[46] XIE Yi-biao, SUNShui-yu, LIU Jing-yong, LIN Wei-xiong, CHEN Nan-wei, YE Mao-you. The effect of additives on migration and transformation of gaseous pollutants in the vacuum pyrolysis process of waste printed circuit boards[J]. Waste Management &Research, 2017, 35(2): 190-199.

[47] MA Chuan, Kamo t. Two-stage catalytic pyrolysis and debromination of printed circuit boards: Effect of zero-valent Fe and Ni metals[J]. Journal of Analytical and Applied Pyrolysis, 2018, 134: 614-620.

[48] WANG Yi, SUN Shui-yu, YANG Fan, LI Shen-yong, WU Jia-qi, LIU Jing-yong, ZHONG Sheng, ZENG Jia-jun. The effects of activated Al2O3 on the recycling of light oil from the catalytic pyrolysis of waste printed circuit boards[J]. Process Safety and Environmental Protection, 2015, 98: 276-284.

[49] CHIANG H L, LIN K H. Exhaust constituent emission factors of printed circuit board pyrolysis processes and its exhaust control[J]. Journal of Hazardous Materials, 2014, 264: 545-551.

[50] WANG Huai-dong, ZAHNG Shu-hao, LI Bin,PAN De-an, WU Yu-feng, ZUO Tie-yong. Recovery of waste printed circuit boards through pyrometallurgical processing: A review[J]. Resources, Conservation & Recycling, 2017, 126: 209-218.

[51] Ghodrat M, Rhamdhani M A, Brooks G, Masood S, Corder G. Techno economic analysis of electronic waste processing through black copper smelting route[J]. Journal of Cleaner Production, 2016, 126: 178-190.

[52] ZHANG Yan-hua, LIU Shi-li, XIE Heng-hua, ZENG Xian-lai, LI Jin-hui. Current status on leaching precious metals from waste printed circuit boards[J]. Procedia Environmental Sciences, 2012, 16(4): 560-568.

[53] Akcil A, Erust C, Gahan C S, Ozgun M, Sahin M, Tuncuk A. Precious metal recovery from waste printed circuit boards using cyanide and non-cyanide lixiviants—A review[J]. Waste Management, 2015, 45: 258-271.

[54] Birloaga L, Veglio F. Study of multi-step hydrometallurgical methods to extract the valuable content of gold, silver and copper from waste printed circuit boards[J]. Journal of Environmental Chemical Engineering, 2016, 4(1): 20-29.

[55] Ha V H , Lee J C , Huynh T H , Jeong J, Pandey B D. Optimizing the thiosulfate leaching of gold from printed circuit boards of discarded mobile phone[J]. Hydrometallurgy, 2014, 149: 118-126.

[56] Silvas F P C, Correa M M J, Caldas M P K, de Moraes V T, Espinosa D C R, Tenorio J A S. Printed circuit board recycling: Physical processing and copper extraction by selective leaching[J]. Waste Management, 2015, 46: 503-510.

Technical route for removing impurities from copper powder of waste printed circuit boards using combination method of beneficiation and metallurgy

LIU Wei-feng1, JIA Rui1, ZHU Peng-chun1, 2, ZHANG Du-chao1, CHEN Lin1, LU Su-jun3, YANG Tian-zu1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. YCC Southwest Cooper Branch, Kunming 650032, China;

3.State Key Laboratory of Nickel and Cobalt Resources Comprehensive Utilization, Jinchang 737100, China)

Abstract: The waste printed circuit boards are important urban mineral resources. However, it is difficult to treat and utilize due to its complicated composition. In this study, the current recycling technologies from waste printed circuit boards were reviewed. Aiming at the adverse effects of tin, lead, zinc and organics on pyrometallurgy treatments of waste printed circuit boards, a technical route for removing impurities from copper powder of waste printed circuit boards using the combination method of beneficiation and metallurgy was proposed. The copper powders of waste circuit board were leached in an alkaline solution by pressurized oxidation process. Tin, lead, zinc and other impurity metals were leached into the leaching solution, and the leaching rate was above 98.2%.The leaching solution was purified by sulfide precipitation, and the precipitation rate of lead and zinc were up to 99.5%. Then, the crude tin containing more than 98% tin was produced from the leaching solution by electrowinning. The organics in leaching residue, such as the substrate of waste circuit board and solder mask, were striped from the copper foil by shaking table, and the removal rate of organics was more than 50.0%. In this process, the impurity metal of tin and organics from copper powders of waste printed circuit boards were removed by the combination method of beneficiation and metallurgy, which provides high quality raw materials for copper pyrometallurgy. Meanwhile, this process provides a new technical route to the efficient treatment for copper powder of waste printed circuit boards in copper pyrometallurgy process.

Key words: waste printed circuit boards; copper; pressurized oxidation; shaking table; tin

Foundation item: Projects(2018YFC1901605, 2018YFC1901604) supported by the National Key Research and Development Program of China; Project(201806375047) supported by the Visiting Scholar of China Scholarship Council; Project(2019zzts505) supported by the Fundamental Research Funds for the Central Universities of Central South University, China

Received date: 2019-04-16; Accepted date: 2019-12-02

Corresponding author: LIU Wei-feng; Tel: +86-13548654403; E-mail: liuweifeng@csu.edu.cn

(编辑 何学锋)

基金项目:国家重点研发计划项目(2018YFC1901605,2018YFC1901604);国家留学基金委访问学者项目(201806375047);中南大学中央高校基本科研业务费专项资金资助项目(2019zzts505)

收稿日期:2019-04-16;修订日期:2019-12-02

通信作者:刘伟锋,副教授,博士;电话:13548654403;E-mail:liuweifeng@csu.edu.cn

摘 要:废印刷线路板是重要的城市矿产资源,因其成分复杂导致其处理难度大。在详细总结废印刷线路板回收利用方法的基础上,针对主流的废印刷线路板火法冶金处理工艺存在的锡铅锌等杂质金属分散和有机物燃烧释放有害气体的问题,提出一种基于选冶联合的废印刷线路板铜粉源头除杂的技术路线:废印刷线路板铜粉通过碱性加压氧化浸出,使锡铅锌等杂质金属溶解进入浸出液,锡浸出率>98.2%,浸出液经硫化净化脱除杂质,铅和锌的沉淀率>99.5%,净化液经电积产出98.0%的粗锡;浸出渣中废印刷线路板基体和阻焊油等有机物从铜箔表面剥离,采用摇床使之分离,有机物脱除率>50.0%。采用选冶联合的方法脱除了废印刷线路板铜粉中的大部分锡杂质金属和有机物,为后续火法炼铜提供了优质原料,为废印刷线路板铜粉在火法炼铜系统的高效处理提供了新的技术路线。