Effect of Al coating conditions on laser weldability of Al coated steel sheet

Jung-Han LEE1, Jong-Do KIM2, Jin-Seok OH2, Seo-Jeong PARK3

1. Graduate School, Korea Marine University, Busan, 606-791, Korea;

2. Division of Marine Engineering System, Korea Marine University, Busan, 606-791, Korea;

3. Welding Research Center, RIST, Pohang, 790-330, Korea

Received 18 June 2008; accepted 10 March 2009

Abstract:

Al coated steel sheets with excellent heat resistance, thermal reflection, and corrosion resistance are widely used in various applications. The laser weldability of the Al coated steel sheet for full penetration welding was reported. The phenomenon caused by intermixed aluminum and behavior of aluminum in the weld were investigated. Al coated steel sheets that have various thickness and coating mass were prepared for laser welding. The effects of parameters such as welding conditions and Al coating conditions were investigated. Al content mixed in the weld after laser welding was evaluated, and then a correlation between the mixed Al and mechanical properties was investigated. The results show that the Al-rich zones which have Fe-Al intermetallic compounds are found in the weld. The intermetallic compounds cause the decreased strength of the weld.

Key words:

Al coating; laser welding; Al coated steel sheet; mechanical properties; intermetallic compound;

1 Introduction

Carbon steels that have excellent mechanical properties and low price are widely used in various industries as structural materials. However, it is well known that the corrosion resistance of carbon steels in the presence of moisture and chloride and the oxidation resistance at elevated temperatures are relatively low. In order to enhance the corrosion and oxidation resistance of steels against hostile environments, various surface treatments are commonly used. Hot-dip coating is one of the most economical techniques for surface treatments, and the representative hot-dip coated steels are Zn coated steel and Al coated steel. Zn coated steel is easier to be manufactured and has much lower-price than Al coated steel. However, it is difficult to use Zn coated steel under high temperature because of the low melting point of zinc (approximately 419 ℃), and it shows relatively lower corrosion resistance than Al coated steel. Thus, Al coated steels are being used competitively in the applications requiring heat resistance as well as corrosion resistance[1-6].

Meanwhile, there are problems that surface treated steels have low weldablity compared with cold rolled steels. Although a lot of studies on these problems have been conducted, they have kept the focus on the Zn coated steel sheet and relatively little attention has been paid to the Al coated steel sheets[7-10].

This study, thus, is to examine the weldability of Al coated steel sheets by Nd?YAG laser according to coating conditions to understand the phenomena happening while aluminum in the coating layer flows to the weld.

2 Experimental

The specimens used for this study were Al coated steel sheets with the thickness of 0.4, 0.6, 1.2 and 1.5 mm and their coating mass, which was the total mass in both sides of steel, was 80, 120 and 160 g/m2 respectively.

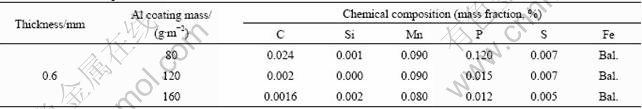

Table 1 shows the chemical composition of the representative specimens with the thickness of 0.6 mm. The specimens were welded by 2 kW CW Nd?YAG laser at the focal distance, without a gap on the lap joint under the conditions of full penetration. The main welding parameters were the laser power 1.5-2 kW, the welding speed 0.6-6 m/min, and Ar gas flow 15 L/min for the shielding gas.

Table 1 Chemical composition of Al coated steel sheet

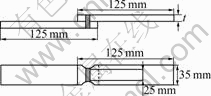

The tensile shear test was conducted to evaluate the strength of laser lap-welded joints, and the schematic of tensile test specimen is shown in Fig.1. The quantitative analyses for the aluminum within the weld were carried out, and then the findings from the analyses were used for the comparative analysis with the strength of the weld. Also, the weldability according to locations of coating layers was examined. For these, the specimens which have removed coating layer per location were prepared. And structural examination of intermixed aluminum in the weld was investigated.

Fig.1 Schematic of tensile test specimen

3 Results and discussion

3.1 Effects of coating mass on strength of laser lap- welded joint

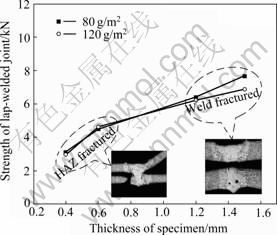

Fig.2 shows the change of the strength of laser lap- welded joints with the thickness of the specimens. The strength of laser lap-welded joint increased with the increase in the thickness of specimen, and then the rate of increase decreased on the point corresponding to 1.2 mm thickness. It is considered to be related with the fracture position of the tensile shear specimens. As a result from the tensile shear test, the specimens with 0.4 mm and 0.6 mm thickness fractured at the heat affected zone(HAZ) and the ones with 1.2 mm and 1.5 mm thickness fractured at the weld.

Fig.2 Variation of strength of lap-welded joints with thickness of specimen

Fig.3 shows the relationship between the thickness of specimen and Wj/t, where Wj and t are the width of joint and the thickness of specimen, respectively. As shown in Fig.3, the joint widths of the specimens with 0.4 and 0.6 mm thickness are larger than those of 1.2 mm and 1.5 mm thickness.

Fig.3 Variation of Wj/t with thickness of specimen

Thus, the strength of lap-welded joint is thought to be most greatly influenced by the width of the joint which is related to fracture position and to be affected additionally by the amount of intermixed aluminum from the coating layer.

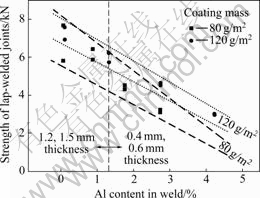

The aluminum within the weld was analyzed quantitatively to figure out the effects of the intermixed aluminum on the strength of the welded joint. First, the area of the aluminum coating layer per unit area of the weld was theoretically examined on the assumption that the coating layer consists of only aluminum and all the aluminum flows to the weld without loss of evaporation. Second, the ICP(inductively coupled plasma) analysis was carried out for comparing and verifying the results of the theoretical examination. As a result, there was no significant difference between the two values. Fig.4 shows the variation of the strength of lap-welded joint with Al content in the weld by calculation. As shown in the figure, the more aluminum content in the weld, the less the strength of welded joint.

Fig.4 Variation of strength of lap-welded joints with Al content in weld

3.2 Change of weld morphology with location of coating layers

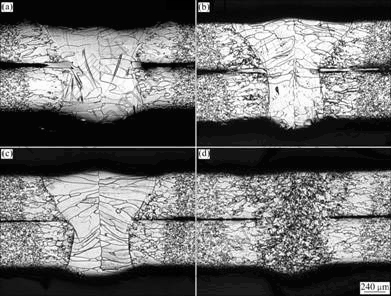

To investigate the effect of coating layers on the weld morphology, some pre-treated specimens were prepared. Fig.5 shows the cross-section of the weld with the location of the coating layers.

As shown in the figure, there was no significant difference in the macrostructures among the test specimens having both-layer coating, removed upper layer coating and removed lap layer coating. However, the specimen having removed both-layer coating revealed a significant difference with others. In other words, the steel sheet with aluminum coating had coarse weld structure and distinct fusion boundaries. Whereas the steel sheet having removed both-layer coating had fine weld structure and showed vague fusion boundaries. It is considered that the aluminum in the coating layer causes the coarsening of the weld structure.

Fig.5 Cross-section images of weld of surface pre-treated specimens (specimen thickness: 0.6 mm; coating mass: 120 g/m2; welding conditions: P=1.5 kW, v=2.7 m/min, fd=0 mm): (a) Both-layer coating; (b) Removed upper layer coating; (c) Removed lap layer coating; (d) Removed both-layer coating

3.3 Behavior of aluminum in weld

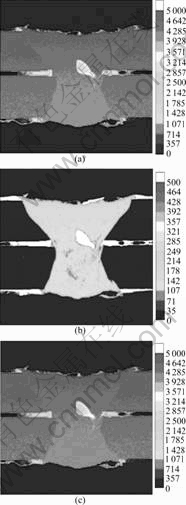

Fig.6 shows the cross-section images of the weld with variation of coating mass. From the figure, unique areas which are incompletely fused to the base metal were partially observed in the weld. It is considered to be an aluminum zone. The existence of this area was increased with increasing coating mass, and it was principally observed near the lap-welded interface.

Fig.6 Weld cross-section images of Al coated steel sheet (specimen thickness: 0.6 mm; welding conditions: P=1.5 kW; v=2.7 m/min; fd=0): (a) 80 g/m2; (b) 120 g/m2; (c) 160 g/m2

To verify the presence of Al-rich zone, EPMA analysis was performed. Fig.7 shows the results of EPMA analysis for the weld.

Fig.7 EPMA analysis showing Al-rich zone in weld (specimen thickness: 0.6 mm; coating mass: 160 g/m2; welding conditions: P=1.5 kW, v=2.7 m/min): (a) Fe; (b) Al; (c) Si

There was small amount of aluminum which spread out evenly through the weld. And Al-rich zones were observed partially in the weld. It is considered that the intermixed aluminum from the lapped part of specimens has difficulty in mixing with the molten metal owing to the characteristics of the laser processes such as rapid heating and cooling. As a result, Al-rich zones come to be partially formed near the joint part.

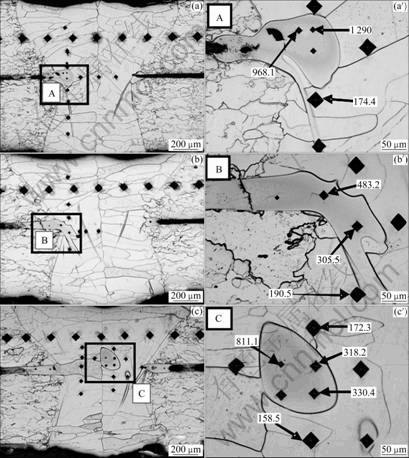

Fig.8 shows the result of the micro-hardness test (1 N) to find out the effects of Al-rich zones on the strength of the weld. The hardness of the Al-rich zones is from HV 318 to HV 1 290, having a tendency of higher values than the average hardness of the weld, approximately HV 172. The tendency is thought to be caused by the hard compounds formed by Fe and Al.

Fig.8 Micro-hardness results of weld and Al-rich zone (specimen thickness: 0.6 mm; welding conditions: P=1.5 kW, v=2.7 m/min): (a) 80 g/m2; (b) 120 g/m2; (c) 160 g/m2

Fig.9 shows the result of the TEM analysis for the Al-rich zones. The intermetallic compounds, Fe2Al5 and FeAl, were found in the Al-rich zones. In addition, we can detect other intermetallic compounds in the Al-rich zones from Table 2. Considering the Al-rich zones having intermetallic compounds are distributed near the lap-welded parts, it is thought that the intermetallic compounds having relatively higher brittleness deteriorate the strength and ductility of the weld.

Table 2 Micro-hardness of intermetallic compounds in Fe-Al system

Fig.9 TEM result of Al-rich zone (specimen thickness: 0.6 mm; coating mass: 80 g/m2; welding conditions: P=1.5 kW, v=2.7 m/min)

Consequently, the decreasing of strength of the weld with the increase of the intermixed aluminum in the weld is due to the effect of coarsened structure and those intermetallic compounds generated by the intermixed aluminum.

4 Conclusions

1) According to the tensile shear test, what affects most greatly the strength of the weld is the width of the joint, and the intermixed aluminum from the coating layer has an additional impact on the strength.

2) From the quantitative analysis on the aluminum in the weld, the more the aluminum intermixed, the less the strength of the weld.

3) When comparing the weld of the specimens having removed coating layers per location with the steel sheet having coating layers in both sides, it is found out that the aluminum in the weld causes the coarsening of the weld structure.

4) The aluminum flowed to the weld during the process of laser welding has difficulty in fusing into the molten metal and forms Al-rich zones especially near the lap-welded interface.

5) The Al-rich zone has higher values of hardness, compared with those of the neighboring weld.

6) Intermetallic compounds of Fe-Al system are observed in the Al-rich zones, and the reason that the strength of the weld decreases gradually with the increased intermixed aluminum in the weld is the coarsened structure and those intermetallic compounds having strong brittleness, generated due to the intermixed aluminum.

References

[1] ANDOH A, UCHIDA J, ENTANI H, KATO C, KURODA H. Recent advanced in coated steel sheets [J]. Journal of the Iron & Steel Institute of Japan, 2003, 89(1): 3-17.

[2] FUJIWARA S, KONDO T. Development of hot-dipped aluminum- coated steel sheet with excellent formability and high strength at elevated temperatures [J]. Nisshin Steel Technical Report, 2002, 83: 13-19.

[3] TAKETSU H, MORITA Y, MORIKAWA S, KAMOSHIDA S I. Hop-dip aluminized steel sheet “Alstar” for automotive fuel tank [J]. Nisshin Steel Technical Report, 2002, 83: 47-83.

[4] SUEHIRO M, MAKI J, KUSUMI K. Properties of aluminum coated steels for hot-forming [J]. Nippon Steel Technical Report, 2003, 378: 15-20.

[5] KUROSAKI M, MATUSMURA K, IZAKI T. Pb-free coated steel sheet for fuel tanks [J]. Nippon Steel Technical Report, 2003, 378: 46-50.

[6] LI Ya-jiang, WANG Juan, ZHANG Yong-lan, HOLLY X. Fine structure in Fe3Al alloy layer of a new hop dip aluminized steel [J]. Bulletin of Materials Science, 2002, 25(7): 635-639.

[7] MATSUDA H, ONO M. Spot and laser weldability of coated steel sheets [J]. Journal of the Japan Welding Society, 2004, 73(3): 32-38.

[8] GU Hong-ping. A new method of lap welding of zinc-coated steel sheet. Section C-ICALEO, 2000: 1-6.

[9] BAGGER C, MIYAMOTO I, OLSEN F, MARUO H. Process behavior during high power CO2 laser welding of zinc coated steel [C]// Proceedings of LAMP. 1992: 553-558.

[10] ONO M, KAIZU T, OHMURA M. Laser welding of zinc coated steel sheets [J]. Quarterly Journal of the Japan Welding Society, 1997, 15(3): 438-444.

Corresponding author: Jong-Do KIM; Tel: +82-51-410-4253; E-mail: jdkim@hhu.ac.kr

DOI: 10.1016/S1003-6326(08)60383-0