网络首发时间: 2016-06-22 08:23

AZ31/1060爆炸复合板界面区组织与性能研究

北京理工大学材料学院

摘 要:

爆炸焊接是应用爆炸载荷使基板和复板面复合的固相连接技术,将镁合金和纯铝复合形成层状复合材料有望拓宽镁合金的应用。本文通过爆炸焊接成功地实现了AZ31镁合金和1060纯铝的面复合,应用光学显微镜(OM),扫描电镜(SEM),透射电镜(TEM)及电子式万能试验机和维氏硬度计对AZ31/1060结合界面处的显微组织、成分分布、力学性能进行测试和分析。结果表明,应用爆炸焊接技术可以使AZ31镁合金和1060纯铝的焊合率达到99.4%;结合界面成波形结构,爆炸焊接过程中,界面处发生元素扩散;随着到界面距离的增加,镁合金的显微组织逐渐从形变带过渡到细晶区再转变为拉长晶粒区,远离界面的组织以等轴晶为主;AZ31/1060爆炸复合板抗拉强度为175 MPa,延伸率为3.3%,剪切强度为62.2 MPa,在拉伸断裂过程中镁合金先断裂然后纯铝断裂,结合界面处不发生开裂;界面处镁合金一侧存在高硬度区,厚度约为200μm。

关键词:

中图分类号: TG456.6

作者简介:吴琼(1990-),男,北京人,硕士研究生,研究方向:镁合金焊接;E-mail:1210119038@qq.com;;杨素媛,教授;电话:010-68912712;E-mail:yangsuyuan@bit.edu.cn;

收稿日期:2014-12-17

基金:国家自然科学基金项目(51571031)资助;

Microstructure and Properties of Bonding Interface in Explosive Welded AZ31/1060 Composite Plate

Wu Qiong Yang Suyuan

School of Materials Science and Engineering,Beijing Institute of Technology

Abstract:

Explosive welding was a kind of solid-state joining technique which used explosive load to connect flyer plate and base plate. Connecting magnesium alloy and pure aluminum into composite could widen the application of magnesium alloy. A composite plate of AZ31 magnesium alloy and 1060 pure aluminum was fabricated by explosive welding. The microstructure,element distribution and mechanical properties of bonding interface after explosive welding were investigated with optical microscope( OM),scanning electron microscope( SEM),transmission electron microscope( TEM),mechanical properties testing machine and Vickers-hardness tester. The results showed that,through explosive welding,the bonding rate of AZ31 magnesium alloy and 1060 pure aluminum could reach 99. 4% and the bonding interface had a wavy appearance. In the process of explosive welding,element diffusion was observed at the bonding interface. With the increase of distance to the interface,the microstructure of magnesium alloy changed from deformation bands to fine grains and then into elongated grains. Away from bonding interface,most of microstructure in magnesium alloy was equiaxed grains. The tensile strength of AZ31/1060 composite plate was 175 MPa,the elongation was 3. 3% and the shear strength was62. 2 MPa. During the tensile test,AZ31 magnesium alloy cracked firstly and then 1060 pure aluminum cracked. There was no delamination at the bonding interface in the process of fracture. The hardness of magnesium alloy near bonding interface was very high and the thickness of the high hardness zone was about 200 μm.

Keyword:

explosive welding; bonding interface; AZ31 magnesium alloy; 1060 pure aluminum;

Received: 2014-12-17

镁合金密度小、比强度和比刚度高、回收率高、无污染,被誉为21世纪“绿色”结构材料

Wang等

本文主要对AZ31/1060爆炸复合板结合界面的显微组织、成分、力学性能进行研究,并且分析了AZ31镁合金爆炸复合后不同位置处的显微组织变化。希望这些研究成果为进一步研究镁合金和铝合金爆炸焊接理论提供支撑。

1实验

本实验以AZ31/1060为研究对象,纯铝1060作为复板,尺寸为300 mm×200 mm×2 mm,镁合金AZ31作为基板,尺寸为300 mm×200 mm×12mm,爆炸复合板由中国船舶重工集团公司第725研究所提供。材料成分如表1所示,爆炸焊接方式采用复板和基板平行放置。爆炸焊接后沿着爆轰方向在焊接界面处取样,并打磨抛光,腐蚀液为1ml HNO3,1 ml CH3COOH,1 g C2H2O4和150 ml纯净水,腐蚀时间为40 s。应用金相显微镜(OM)和能谱分析(EDS)对AZ31/1060结合界面处的组织和成分进行分析。对未经过爆炸焊接的原始母材AZ31镁合金进行金相观测,分析母材显微组织,并与爆炸焊接后的母材进行对比。借助IN-STRON5985电子式万能试验机对爆炸复合板进行拉伸和剪切实验。拉伸实验标准参照GB/T228.1-2010,剪切实验标准参照GB/T6396-2008。在LM700AT维氏硬度计下对界面两侧组织进行硬度测试,加载力为0.25 N,加载时间为10~15 s。

2结果与讨论

2.1显微组织和成分分析

图1为AZ31原始母材的显微组织。可以看到晶粒多为等轴状,但晶粒尺寸不均匀,大的晶粒直径可以达到150μm以上,在晶界上存在大量新生成的小晶粒,原始组织中存在再结晶现象。图2为AZ31/1060爆炸复合情况,起爆方向同箭头方向,应用超声波检测确定镁合金和纯铝的焊合区,黑线右侧为焊合区,黑线左侧为未焊合区,计算得出AZ31/1060爆炸复合的焊合率为99.4%。图3为爆炸焊接后界面处能谱线扫描图,可以看到铝元素的含量从1060侧到AZ31侧急剧减少,镁元素含量从AZ31侧到1060侧急剧减少,在线扫描图中形成“X”形状,说明在界面处镁元素和铝元素发生了扩散现象。

表1 AZ31镁合金和1060纯铝的成分含量表Table 1Chemical compositions of AZ31 Mg alloy and1060 pure Al(%,mass fraction) 下载原图

表1 AZ31镁合金和1060纯铝的成分含量表Table 1Chemical compositions of AZ31 Mg alloy and1060 pure Al(%,mass fraction)

图1 AZ31镁合金原始显微组织Fig.1OM image of microstructure of AZ31 magnesium alloy before explosive welding

图2 AZ31/1060爆炸复合板复合情况Fig.2 Bonding situation of explosive welded AZ31/1060 com-posite plate

图3 AZ31/1060界面处能谱线扫描图Fig.3EDS spectra of bonding interface in AZ31/1060 com-posite plate

图4为AZ31/1060爆炸复合板界面处的显微组织,上面的金属为1060纯铝,下面的金属为AZ31镁合金。可以看到结合界面成波形结构,但波形平缓。Akbari和Farhadi

图4 AZ31/1060爆炸复合板界面处的金相照片Fig.4OM image of microstructure of bonding interface in AZ31/1060 composite plate

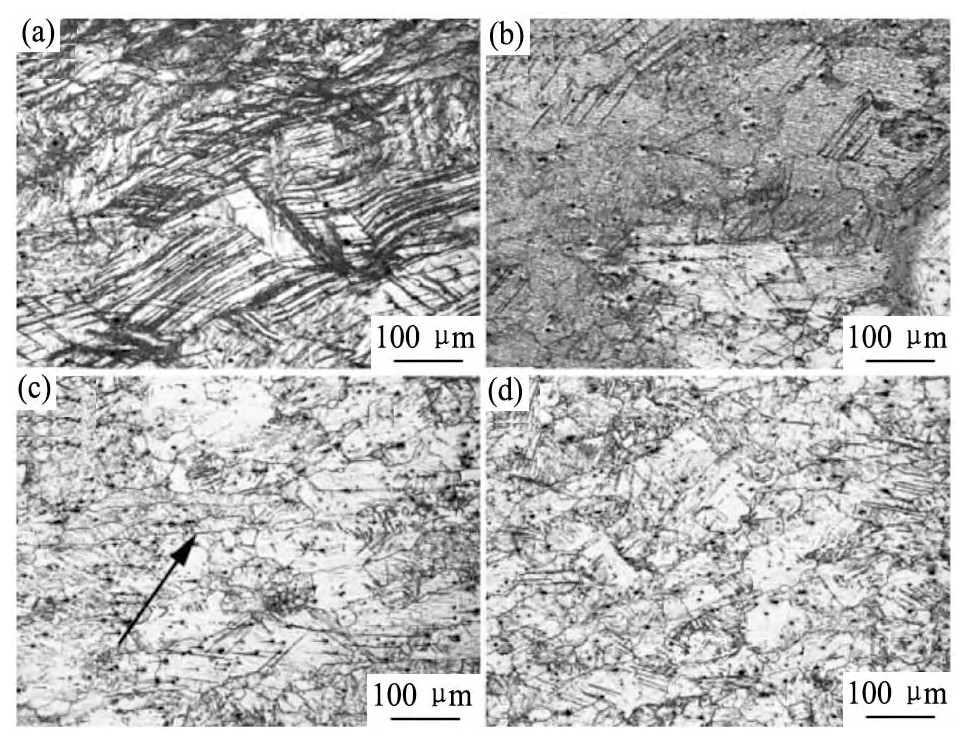

图5 爆炸复合板AZ31侧不同位置的金相图Fig.5OM images of AZ31 selected from different zones in AZ31/1060 composite plate

(a)Near interface;(b)Farther than(a)from interface;(c)Farther than(b)from interface;(d)Farther than(c)from interface

2.2力学性能分析

图6为AZ31/1060爆炸复合板准静态拉伸真应力-真应变曲线,复合板抗拉强度为175 MPa,延伸率为3.3%。在材料断裂时,曲线上出现陡峭的起伏(如箭头所示)。复合板材在断裂的时候AZ31镁合金由于塑性没有1060纯铝好,因此先发生了断裂。当镁合金断裂后,在断裂处试样横截面积急剧减小,使得未断裂的1060纯铝受到的拉应力骤然增加,超过纯铝的抗拉强度,镁合金断裂后,纯铝迅速断裂,因此在AZ31/1060爆炸复合板准静态拉伸真应力-真应变曲线上出现了陡峭起伏。图7是AZ31/1060复合板拉伸断裂后结合界面的金相照片,可以看到复合板在断裂后,AZ31镁合金和1060纯铝结合牢固,界面处没有发生开裂现象。

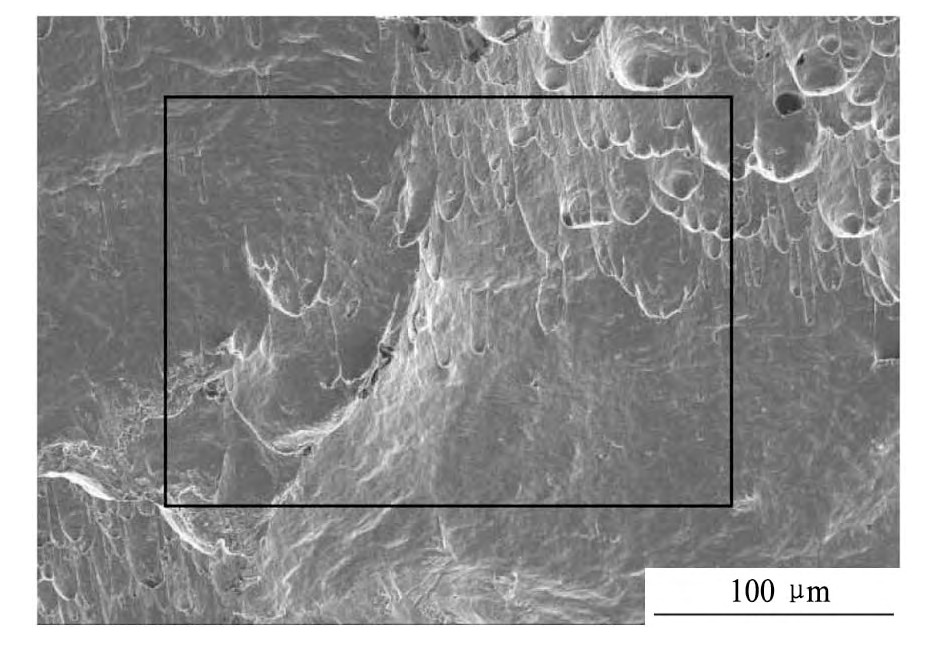

图8为AZ31/1060爆炸复合板在剪切实验中的载荷-位移曲线,复合板剪切强度为62.2 MPa,当1060纯铝与AZ31镁合金彻底分离时,位移已经超过了剪切试样上纯铝的宽度,说明在剪切过程中纯铝与镁合金有明显粘连。图9为AZ31/1060爆炸复合板剪切断口,断口存在大量拉长韧窝,拉长方向与剪切方向一致。在断口区进行能谱分析,测得(质量分数)Mg 10.59%,Al 89.41%,可以看到断口处镁合金和纯铝混合,在剪切过程中,纯铝粘连在镁合金一侧,说明镁合金和纯铝结合牢固。

图6 AZ31/1060准静态拉伸真应力-真应变曲线Fig.6True stress-strain curve of AZ31/1060 composite plate obtained from quasi static tensile experiment

图7 AZ31/1060爆炸复合板拉伸断裂的金相图Fig.7 OM image of AZ31/1060 composite fracture plate after quasistatic tensile test

图8 AZ31/1060复合板剪切载荷-位移曲线Fig.8 Load-displacement curve of AZ31/1060 composite plate obtained from shear test

图9 AZ31/1060爆炸复合板剪切断口Fig.9 SEM image of fracture of AZ31/1060 composite plate

图10为AZ31/1060爆炸复合板界面两侧的硬度分布,可以看到,在纯铝一侧,随着到界面距离的增加,硬度值没有明显变化,硬度在HV0.02540左右。在镁合金一侧,靠近界面处硬度明显增高,硬度最高值达到HV0.025197,随着到界面距离的增加,硬度值下降最终趋于稳定值HV0.02590左右,镁合金靠近界面处最高硬度值可以达到镁合金基体的两倍。镁合金一侧出现高硬度是因为在爆炸焊接过程中,镁合金发生剧烈塑性变形,位错大量滑移缠结,发生加工硬化效应,使得硬度值增高,高硬度层厚度为200μm左右。图11为AZ31/1060爆炸复合板界面处透射电镜(TEM)照片,从图11(a)中可以看到界面处镁合金的晶粒内部存在大量位错,因此界面处镁合金硬度值升高。在图11(b)中发现界面处纯铝内位错密度较小,因此纯铝的硬度值变化不显著。

图1 0 AZ31/1060爆炸复合板界面两侧的硬度分布Fig.10 Hardness across bonding interface of AZ31/1060 com-posite plate after explosive welding

图1 1 AZ31/1060爆炸复合板界面两侧透射电镜照片Fig.11TEM images of AZ31/1060 composite plate near bonding interface

(a)AZ31;(b)1060

3结论

1.通过爆炸焊接的方法可以有效地使AZ31镁合金和1060纯铝面复合,焊合率可以达到99.4%。

2.AZ31镁合金和1060纯铝结合界面成波形结构,在镁合金一侧存在大量形变带,随着到界面距离的增加,显微组织依次为形变带区、细小晶粒区、拉长晶粒区和等轴晶区。

3.AZ31/1060爆炸复合板的抗拉强度为175MPa,延伸率为3.3%,剪切强度为62.2 MPa。在拉伸断裂时,镁合金先断裂,纯铝在镁合金断裂后立刻断裂,在断裂过程中,两种材料在界面处不开裂。在剪切过程中,纯铝粘连在镁合金一侧,两种材料结合牢固。

4.结合界面处纯铝一侧硬度变化不大,镁合金一侧硬度值升高到HV0.025197且随着到界面距离的增加,硬度值逐渐减小最后趋于稳定值HV0.02590左右,硬度层厚度约为200μm。

参考文献

[11] Findik F.Recent developments in explosive welding[J].Materials&Design,2011,32(3):1081.