Ferroelectric properties of dysprosium-doped Bi4Ti3O12 thin films crystallized in various atmospheres

CHENG Chuan-pin(成传品), TANG Ming-hua(唐明华), YE Zhi(叶 志), ZHOU Yi-chun(周益春), ZHENG Xue-jun(郑学军), ZHONG Xiang-li(钟向丽), HU Zeng-shun(胡增顺)Key Laboratory of Advanced Materials and Rheological Properties of Ministry of Education,

Faculty of Materials and Optoelectronic Physics, Xiangtan University, Xiangtan 411105, China

Received 10 April 2006; accepted 25 April 2006

Abstract: Dysprosium-doped Bi4Ti3O12 (Bi3.4Dy0.6Ti3O12, BDT) ferroelectric thin films were deposited on Pt(111)/Ti/SiO2/Si(111) substrates by chemical solution deposition (CSD) and crystallized in nitrogen, air and oxygen atmospheres, respectively. X-ray diffraction (XRD) and scanning electron microscopy (SEM) were used to identify the crystal structure, the surface and cross-section morphology of the deposited ferroelectric films. The results show that the crystallization atmosphere has significant effect on determining the crystallization and ferroelectric properties of the BDT films. The film crystallized in nitrogen at a relatively low temperature of 650 ℃, exhibits excellent crystallinity and ferroelectricity with a remanent polarization of 2Pr = 24.9 μC/cm2 and a coercive field of 144.5 kV/cm. While the films annealed in air and oxygen at 650 ℃ do not show good crystallinity and ferroelectricity until they are annealed at 700 ℃. The structure evolution and ferroelectric properties of BDT thin films annealed under different temperatures (600-750 ℃) were also investigated. The crystallinity of the BDT films is improved and the average grain size increases when the annealing temperature increases from 600 ℃ to 750 ℃ at an interval of 50 ℃. However, the polarization of the films is not monotonous function of the annealing temperature. Key words: BDT thin films; CSD; crystallization atmosphere1 Introduction

In modern technology, the ever-increasing demands for nonvolatile memories have led to the search for a new kind of material having large remanent polarization (2Pr) with fatigue-free characteristics for high-density memories. Among many materials that exhibit ferroelectricity, mainly two families of perovskites are currently scrutinized for their use in nonvolatile memories: 1) PZT (lead zirconate titanate)-based perovskites [1-3] and 2) layered perovskites such as strontium bismuth tantalite (SBT) [4] and lanthanum-doped bismuth titanate (BLT) [5, 6], etc. PZT has some of the best ferroelectric characteristics, such as large polarization and lower processing temperature compared to other ferroelectric candidates. But PZT thin films suffer from serious fatigue, lead toxicity and imprint problems. Although the problems could be suppressed by using various oxide electrodes, the oxide electrodes would result in lower polarization density and processing complexity. In this respect, it is necessary to develop new ferroelectric materials to replace PZT. SBT and BLT thin films show a superior fatigue resistance compared to PZT/Pt. However, SBT thin films also suffer from some disadvantages, such as high-processing temperatures and very low switchable remanent polarization (2Pr) values. Bismuth titanate (Bi4Ti3O12, BIT) thin film has been studied intensively in the past decade due to its large remanent polarization, low crystallization temperature and high Curie temperature. Substitution of various trivalent rare-earth cations (such as La3+, Sm3+, Nd3+, Eu3+ and Pr3+) [7-11] in the BIT structure is known to improve its ferroelectric properties, such as remanent polarization and fatigue characteristics. CSD method has been proven effective to produce high-quality rare-earth lanthanides doped Bi4Ti3O12(BIT) films. It has been reported that the bismuth-based perovskite films prepared by CSD method are crystallized in air and the crystallization temperature is generally near 700 °C in order to get high-quality films [12]. HOU et al [13] reported that BNT films could be crystallized at lower temperature in N2 atmosphere than in air or O2. But there have been few reports so far about the effect of annealing atmosphere on the structure and ferroelectric properties of BDT thin films. In this work, the authors report the crystallization atmosphere effect on BDT thin films.

2 Experimental

BDT thin films were deposited on Pt(111)/Ti/SiO2/Si(111) substrates by CSD, using a repeated coating/drying cycle. Bismuth nitrate [Bi(NO3)3?5H2O], dysprosium nitrate [Dy(NO3)3?5H2O] and titanium butoxide [Ti(OC4H9)4] were used as starting materials for Bi, Dy and Ti, respectively. Bismuth nitrate (10% excess in mole fraction) and dysprosium nitrate were dissolved at 40 ℃ in glacial acetic acid [CH3-

COOH]. The 10% excess of bismuth nitrate was added to compensate for possible bismuth loss during the high temperature process. Separately, in a beaker, titanium butoxide was dissolved in glacial acetic acid, and acetylacetone [CH3COCH2COCH3] was used as chelating agent. The titanium solution was added to the bismuth-dysprosium solution with continuous stirring, and the final mixture was stirred for an additional 1 h. The concentration of BDT in the final solution was adjusted to approximately 0.1 mol/L. The preparation of the films consisted in spin coating the Pt (111)/Ti/SiO2/Si(111) substrates with the stock solution at 3 000 r/min for 30 s. The samples were then fully dried in rapid thermal processor (RTP-500) at 180 ℃ for 5 min followed by another 5 min at 400 ℃ to remove residual organic compounds. The coating and preheating process was repeated several times to obtain the desired film thickness. Finally, the coated BDT films were annealed for 6 min in air, N2 and O2 by a rapid thermal annealing process at four temperatures of 600, 650, 700, and 750 ℃, respectively. Phase identification, crystalline orientation and degree of crystallization of the prepared films were studied by a Rigaku D/max-rA X-ray diffractometer with Cu Kα radiation using normal θ-2θ scanning method. SEM (JSM-5600LV) was used to determine the prepared film’s thickness and the surface morphology. The thickness of the BDT films is about 400 nm by a cross-sectional view of SEM. The derived thin films are smooth, crack-free, uniform, dense and adhered well on the substrates. For electrical measurements, the upper Au electrodes were sputtered on the BDT thin films by DC sputtering. The ferroelectric measurements were performed using a Radiant technology precise workstation ferroelectric tester.

3 Results and discussion

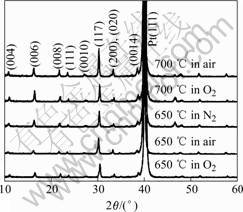

BDT thin films were first crystallized at 650 ℃ in N2, air and O2. The corresponding XRD patterns are shown in Fig.1. All the diffraction peaks were identified and indexed using the standard XRD data of BIT powder. The film crystallized in N2 shows strong and sharp BDT (00l)-and (117)-mixed-orientation, indicating that the BDT thin film annealed in N2 atmosphere has typical bismuth-based layered perovskite polycrystalline structure and the crystallization is nearly complete. However, the XRD patterns for the films crystallized in air and O2 show (00l)-and (117)-mixed-orientation peak with weak intensity and large full width at half maximum comparing to the film crystallized in N2. These results imply that BDT thin films annealed in air and O2 at 650 ℃ crystallized poorly, but the one annealed in N2 has crystallized well. The atmosphere for the crystallization of BDT films was found to have obvious effect on their crystal structure. The result is consistent with that observed in BIT films [13]. In order to check whether the degree of crystallinity increases with increasing annealing temperature, the BDT thin films were crystallized at a higher temperature in air and O2 atmosphere. As the XRD patterns shown in Fig.1, marked improvement of the crystallization was found in these films. The intensity of diffractions increases, with small full width at half maximum. These results indicate that the crystallization temperature is lowered significantly when BDT films are annealed in N2, compared with those annealed in air and O2.

Fig.1 XRD patterns of BDT films deposited on Pt(111)/Ti/SiO2/Si(111) substrates under various annealing conditions

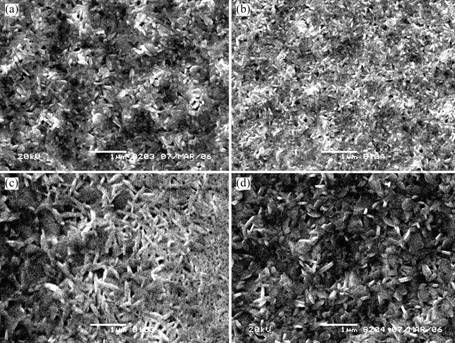

The surface morphologies of the samples annealed in N2, air and O2 at 650 ℃ are shown in Figs.2(a), (b) and (c),

Fig. 2. SEM photographs of BDT films under different annealing conditions: (a) Air, 650℃; (b) O2, 650 ℃; (c) N2, 650 ℃; (d) Air, 700 ℃

respectively. It can be found that all the films have smooth and dense microstructures. Fig.2(d) shows the surface microstructure of the sample annealed in air at 700 ℃. Compared with Fig.2(a), it can be noted that the average grain size of the film annealed in air increases with increasing the annealing temperature, which indicates better crystallinity and is consistent with the above XRD results. As shown in Fig.2, all BDT films have rod-like grains and plate-like grains. It has been reported that, for La-doped BIT films, the rod-like grains are presented in (117) preferentially oriented films, while the plate-like grains may correspond to the c-axis preferred orientation [13]. Thus, the present SEM surface microstructures are consistent with the XRD results as shown in Fig.1.

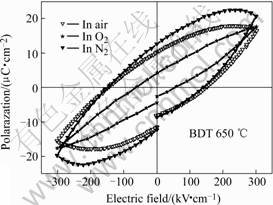

Fig.3 shows the P-E hysteresis loops of BDT films deposited on Pt(111)/Ti/SiO2/Si(111) substrates under various annealing conditions. The 2Pr values of the samples measured from the hysteresis loops of films crystallized at 650 ℃ in N2, air and O2 under a maximum applied field of 300 kV/cm are 24.9, 15.08 and 8.5 μC/cm2, and corresponding coercive field (Ec) are 144.5, 148.2 and 59 kV/cm, respectively. The film annealed at 650 ℃ in N2 has the highest 2Pr value compared with the films annealed at 650 ℃ in air and O2. This fact is consistent with the XRD results showing that the film annealed in N2 has better crystallinity than other samples. The high 2Pr value (24.9 μC/cm2) and the coercive value (144.5 kV/cm) of the BDT film crystallized in N2 at 650 ℃ are comparable to the films

Fig.3 P-E hysteresis loops of BDT films deposited on Pt(111)/Ti/SiO2/Si(111) substrates annealed at 650 ℃ in various atmospheres

crystallized in air and O2 at 700 ℃.The 2Pr values of the BDT films crystallized in air and O2 at 700 ℃ are 33.7 and 21.2 μC/cm2 respectively. In this study, it is also found that the remanent polarization increases with the increase of annealing temperature when the sample is annealed in air and O2. This is again consistent with the XRD results in which the improvement of crystallinity is observed with increasing the annealing temperature in air and O2 atmosphere. In order to investigate the dependence of the 2Pr value on the annealing temperature, the BDT films were annealed at different temperatures in N2, air and O2.

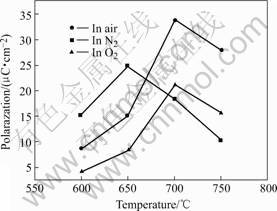

The 2Pr values of BDT films are shown in Fig.4 as a function of the crystallization temperature. As shown in Fig.4, the 2Pr values of the BDT films annealed in N2 atmosphere reach their maximum at 650 ℃. The 2Pr values of the BDT films annealed in air and O2 reach their maximum values at 700 ℃. Generally, the crystal-

inity of the films will be improved with increasing the annealing temperature, leading to the increase of the 2Pr value. However, in the present study, the remnant polarizations of the BDT films crystallized in N2, O2 and air atmosphere, respectively, will decrease with increasing the annealing temperature after an optimal crystalline temperature reaches for each case. There are two possible reasons for these phenomena. One is that the element of bismuth in the film is evaporative, especially at higher annealing temperature. Another may be that the relative intensity of the (117) and (00l) in the films will change with the crystalline temperature, leading to the changing of the ferroelectric properties [13].

Fig.4 Variations of 2Pr against annealing temperature in BDT thin films

4 Conclusions

The effect of crystallization atmosphere on crystal structure and ferroelectric properties of the CSD derived BDT films have been investigated. BDT thin film crystallized in nitrogen at a relatively low temperature of 650 ℃ exhibits excellent crystallinity and ferroelectricity with a remanent polarization of 24.9μC/cm2, and a coercive field of 144.5 kV/cm. On the other hand, BDT films annealed in air and oxygen do not show good crystallinity and ferroelectricity until they are annealed at 700 ℃.

References[1] RYOO S N, YOON S G, KIM S H. Improvement in ferroelectric properties of Pb(Zr0.35Ti0.65)O3 thin films using a Pb2Ru2O7-x conductive interfacial layer for ferroelectric random access memory application [J]. Applied Physics Letters, 2003, 83 (14): 2880-2883.

[2] ASANO G, MORIOKA H, FUNAKUBO H, SHIBUTAMI T, OSHIMA N. Fatigue-free RuO2/Pb(Zr,Ti)O3/RuO2 capacitor prepared by metalorganic chemical vapor deposition at 395 ℃ [J]. Applied Physics Letters, 2003, 83(26): 5506-5508.

[3] MOON B K, ISHIWARA H, TOKUMITSU E, YOSHIMOTO M. Characteristics of ferroelectric Pb(Zr,Ti)O3 films epitaxially grown on CeO2(111)/Si(111) substrates [J]. Thin Solid Films, 2001, 385: 307-310.

[4] LIM M, JOSHI V, NARAYAN S, CELINSKA J, KARASAWA J. Sub-100 nm SrBi2Ta2O9 film with ultrathin BiTaO4 capping layer for 3 V or lower-voltage ferroelectric memory operation [J]. Applied Physics Letters, 2002, 81 (10): 1863-1865.

[5] HOU Y, XU X H, WANG H, WANG M, SHANG S X. Bi3.25La0.75Ti3O12 thin films prepared on Si (111) by metalorganic decomposition method [J]. Applied Physics Letters, 2001, 78 (12): 1733-1735.

[6] ZHAI J W, SHEN B, YAO X, CHEN H. Growth and ferroelectric study of Bi3.25La0.75Ti3O12 thin films on different substrates [J]. Journal of Crystal Growth, 2004, 267: 110-116.

[7] WANG H, REN M F. Low temperature synthesis and ferroelectric properties of La substituted Bi4Ti3O12 thin films by sol-gel [J]. Materials Science and Engineering B, 2005,122: 201-205.

[8] YANG C H, WANG Z, XU H Y, SUNX Q, HAN J R. Samarium-doped Bi4Ti3O12 thin films grown on SiO2/p-Si (1 1 1) by spin coating metalorganic solution decomposition method [J]. Materials Chemistry and Physics, 2004, 88: 67-70.

[9] CAO Z P, DING A L, HE X Y, CHENG W X, QIU P S. Optical properties of BNT thin films grown on Pt/Ti/SiO2/Si(100) substrates by a CSD processing [J]. Journal of Crystal Growth, 2004, 270: 168-173.

[10] CHON U, SHIM J S, JANG H M. Ferroelectric properties and crystal structure of praseodymium-modified bismuth titanate [J]. Journal of Applied Physics, 2003, 93(8): 4769-4775.

[11] KIM W J, KIM S S, JANG K, BAE J C, Song T K, LEE Y I. Ferroelectric Bi3.4Eu0.6Ti3O12 thin films deposited on Si(100) and Pt/Ti/SiO2/Si(100) substrates by a sol–gel process [J]. Journal of Crystal Growth, 2004, 262: 327-333.

[12] HOU F, SHEN M R. Effect of crystallization temperature on microstructure and ferroelectric properties of (Bi, Nd)4Ti3O12 thin films prepared by chemical solution deposition [J]. Materials Science and Engineering B, 2005, 122: 164-168.

[13] HOU F, SHEN M R, CAO W W. Ferroelectric properties of neodymium-doped Bi4Ti3O12 thin films crystallized in different environments [J]. Thin Solid Films, 2005, 471: 35-39.

Foundation item: Project (05FJ2005) supported by the Key Project of Scientific and Technological Department of Hunan Province, China; Project (05C095) supported by the Research Funds of Educational Department of Hunan Province, China

Corresponding author: TANG Ming-hua; Tel: +86-732-8293577; Fax: +86-732-8292468; E-mail: mhtang@ xtu.edu.cn