Solidification of Mg-28%Zn-2%Y alloy involving

icosahedral quasicrystal phase

WAN Di-qing(万迪庆), YANG Gen-cang(杨根仓),

ZHU Man(朱 满), XU Quan(许 泉), ZHOU Yao-he(周尧和)

State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Received 16 May 2006; accepted 23 January 2007

Abstract:

Applying XRD, DTA, SEM and TEM techniques, an investigation on the solidification microstructure and solidification sequence of Mg-rich Mg-28%Zn-2%Y (mole fraction) alloy was carried out. It is found that, α-Mg dendrites, Mg7Zn3 phase and icosahedral quasicrystal phase coexist in the as-solidified alloy, where the icosahedral quasicrystal, whose structure is indentified to be a face-centered type, originates from a peritectic reaction occurring at 416 ℃. The primary phase of this peritectic reaction has the composition of Mg20Zn66Y14, which is coincident with the H phase reported by TSAI as (Zn, Mg)5Y. Furthermore, the single I-phase grain morphology was observed and its growth evolution was also discussed.

Key words:

Mg-Zn-Y alloy; icosahedral quasicrystal; microstructure; solidification;

1 Introduction

The quasicrystal, a novel crystal structure with long-range orientational order and no translational symmetry, was first reported in the rapidly cooled Al-Mn alloy by SHECHTMAN et al[1]. It offers attractive properties such as high strength, high thermal conductivity and low friction coefficient due to its special crystal structure[2-3]. Recently, great efforts have been directed towards studying equilibrium phase and microstructure of Mg-Zn-Y alloy because of the discovery of a stable icosahedral quasicrystal phase (I-phase) performing as strengthening phase both at room temperature and elevated temperature, which makes the Mg-Zn-Y alloy to be a promising potential candidate for developing advanced magnesium alloys[4-10]. Thus, in order to obtain suitable microstructure, metallurgical knowledge of Mg-Zn-Y alloy, specially the solidification behavior, is greatly required.

Recently, TSAI et al[11] studied the equilibrium phase diagram involving I-phase in Mg-Zn-Y system. However, the details of solidification behavior are not clearly correlated to microstructure of Mg-Zn-Y alloys. Therefore, the purpose of this study is to study the solidification behavior of Mg-rich Mg-28%Zn-2%Y alloy.

2 Experimental

The ternary alloy of Mg-28%Zn-2%Y (mole fraction) was prepared by melting from 99.90% Mg, 99.95% Zn and Mg-25%Y master alloy in electric furnace under the mixture of SF6/CO2 protective atmosphere. Holding for 30 min at 700 ℃, the melt was poured into steel mould that was preheated at 300 ℃, and then cooled in the atmosphere. The phases were determined by XRD with Cu Kα radiation. The micro- structure was examined by SEM with EDS. The crystallographic features were investigated by TEM. The XRD measurement was carried out on RigakuD/max-3C. Leica Cambridge S-360 and JSM-6460 were used for SEM observation and JEOL 2010 was for TEM. The single I-phase grain morphology was observed from the fractured surfaces of ingot.

3 Results and discussion

3.1 Microstructure of as-solidified Mg-Zn-Y alloy

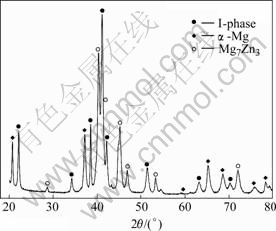

Fig.1 shows the XRD result of the as-cast Mg-28%Zn-2%Y alloy, where three different phases, α-Mg phase, Mg7Zn3 phase and I-phase, are found to coexist together.

Fig.1 XRD pattern of as-cast Mg-Zn-Y alloy

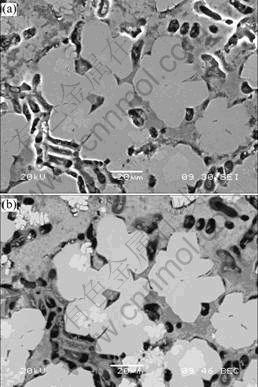

The SEM micrographs of microstructure are shown in Fig.2. Three coexisting phases, i.e. α-Mg dendrites (cavities), quasicrystal phase (petal-like) and Mg7Zn3 phase can be observed in Fig.2(a). Fig.2(b) is the back scattered image, showing a primary phase embedded in the quasicrystal phase, which indicates that the quasicrystal forms from a peritectic reaction.

Fig.2 SEM micrographs of as-solidified Mg-Zn-Y alloy:(a) Secondary electron image; (b) Back scattered image

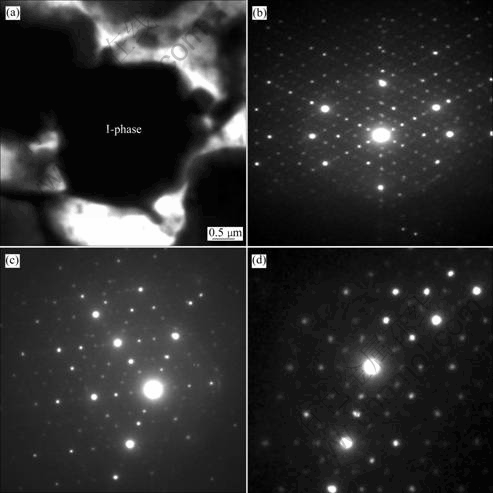

Very different from the 32 kinds of classical crystal point groups, the point group of icosahedral quasicrystal exhibits ![]() (or 532)[1]. Thus, with this special point group, as for quasicrystal, it is possible to be distinguished from the classical crystal for its dense diffraction patterns. The bright-field image of I-phase is shown in Fig.3(a) and Figs.3(b)-(d) are corresponding to the electron diffraction patterns of the icosahedral quasicrystal with 2-fold, 3-fold and 5-fold symmetry axes respectively. Moreover, it is necessary to note that there are three possible icosahedral reciprocal lattices, which can most conveniently be described as projections in three dimensions of the six-dimensional simple (P), face-centered (F), and body-centered(I) cubic Bravais lattices[12]. According to Ref.[13], the 2-fold SEDP in Fig.3(b) confirms that the I-phase obtained in Mg-Zn-Y alloy has the structure of face-centered type.

(or 532)[1]. Thus, with this special point group, as for quasicrystal, it is possible to be distinguished from the classical crystal for its dense diffraction patterns. The bright-field image of I-phase is shown in Fig.3(a) and Figs.3(b)-(d) are corresponding to the electron diffraction patterns of the icosahedral quasicrystal with 2-fold, 3-fold and 5-fold symmetry axes respectively. Moreover, it is necessary to note that there are three possible icosahedral reciprocal lattices, which can most conveniently be described as projections in three dimensions of the six-dimensional simple (P), face-centered (F), and body-centered(I) cubic Bravais lattices[12]. According to Ref.[13], the 2-fold SEDP in Fig.3(b) confirms that the I-phase obtained in Mg-Zn-Y alloy has the structure of face-centered type.

Fig.3 Bright-field image of I-phase (a) and electron diffraction patterns of 2-fold (b), 3-fold (c) and 5-fold (d) of I-phase

3.2 Solidification sequence of Mg-28%Zn-2%Y alloy

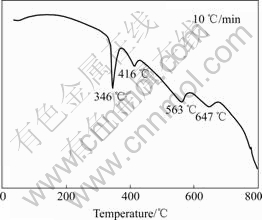

In order to investigate the solidification sequence of Mg-28%Zn-2%Y alloy, the DTA is carried out. In addition, icosahedral quasicrystal phase in Mg-Zn-Y alloy is generally supported to be formed by a peritectic reaction[14]. The back scattered image of microstructure (Fig.2(b)) shows that a primary phase is encapsulated by the quasicrystal phase, which is an obvious evidence of the peritectic reaction. The primary phase of this peritectic reaction is determined to have composition Mg20Zn66Y14 by EDS as well as Mg32Zn60Y8 for I-phase. The primary phase is coincident with the H phase reported by TSAI as (Zn, Mg)5 Y with the hexagonal structure[14]. The structure of H phase is related to the binary hexagonal phases of Zn5Y. Due to the Zn atom being replaced by Mg atom in the binary Zn5Y phase, it causes the Mg or Zn content varying a lot but basically fixed Y content of 13%-15% (mole fraction) in H phase[14]. The DTA result is shown in Fig.4. Obviously, four endothermic peaks occur at 647, 563, 416 and 346℃, respectively. As far as we know, the above peaks stand up for the formation of α-Mg dendrites, the formation of the primary phase, the peritectic reaction, and the formation of Mg7Zn3 phase, respectively[14-16]. Therefore, the solidification sequence of as-cast Mg-Zn-Y alloy is as follows: firstly the α-Mg crystallizes from the melt and then H phase secondary forms; when the temperature is cooled down to 416 ℃, the I-phase forms, undergoing a peritectic reaction between the remained melt and H phase; subsequently, when the melt hardly contains the Y element, the Mg7Zn3 phase forms.

Fig.4 DTA curve of Mg-Zn-Y alloy

3.3 Perfect I-phase grain morphology and its evolu- tion

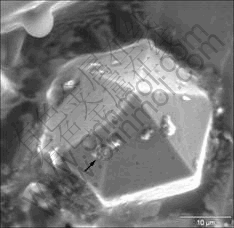

Because translation symmetry is lacking, it seems unlikely that quasicrystal builds up by the attachment of single atoms, thereby generating the whole network just like crystals do. The growth mechanism of quasicrystal still remains an unsolved and challenging problem in condensed matter[17]. Hence, the information of quasicrystal growth is required. Single I-phase grain morphology can provide us with direct and visible evidence of I-phase growth and evolution. The SEM examination of single I-phase grain, which was observed from fracture surface of as-solidified Mg-Zn-Y alloy is shown in Fig.5, where a typical morphology of icosahedral phase is observed. It is well known that, there are 20 three-fold equilateral triangle-shaped faces, 12 five-fold vertices and 30 two-fold edges in an icosahedron. Surprisingly, as marked by arrowhead in Fig.5, a small triangle-shape face is formed between two icosahedral faces. This is likely to be regarded as an intermediate face due to I-phase grain evolution.

Fig.5 Perfect morphology of icosahedral quasicrystal in Mg-Zn-Y alloy

It is well known from the solidification fundaments that, during the solidification process of alloys, the overmuch solute element will be excluded from the solid phase into the remained liquid. Thus, during the growth of I-phase, the overmuch Mg element should be rejected from I-phase into the liquid as well as the Y element diffuses to supply the growth of I-phase. It causes the concentration of Mg element on I-phase grain surface to pin its growth. Fortunately, the similar phenomenon of Al element rejection from Al-Pd-Mn icosahedral quasicrystal was recently reported to pin the I-phase grain faces growth by NGUYEN-THI and his co-workers [17]. Therefore, the rejection of Mg element from the growing I-phase in Mg-Zn-Y alloy should play the dominating role in its grain growth evolution.

4 Conclusions

1) α-Mg dendrites, Mg7Zn3 phase and icosahedral phase coeixt in the as-cast Mg-Zn-Y alloy. I-phase obtained in Mg-Zn-Y alloy has the structure of face-centered type with the composition of Mg32Zn60Y8. The I-phase formation undergoes a peritectic reaction between the H-phase and the remained melt.

2) The solidification sequence is clearly corelated to the microstructure, which shows that α-Mg first crystallizes from the melt at 647 ℃ and then H phase secondary forms at 563 ℃; the peritectic reaction of I-phase formation takes place nearly at 416 ℃; Mg7Zn3 phase last forms.

3) Moreover, perfect single grain morphology of icosahedral quasicrystal in Mg-Zn-Y alloy is observed. Mg element rejections from the I-phase during its growth should be of effect on I-phase grain growth evolution.

AcknowledgementsThe authors should like to thank Dr. LI Ming-run from State Key Lab of Materials Modification, Dalian University of Technology for his beneficial discussion and Mrs. ZOU in Xi’an Jiaotong University for her technical supports on TEM.

References[1] SHECHTMAN D, BLECH I, GRATIAS D, CAHN J W. Metallic phase with long-range orientational order and no translational symmetry [J]. Phys Rev Lett, 1984, 53(20): 1951-1953.

[2] DUBOIS J M. Quasicrystals [J]. J Phys: Condens Matter, 2001, 13: 7753-7762.

[3] JANOT C H, DUBOIS J M. Quasicrystals [J]. J Phys F: Met Phys, 1988, 18: 2303-2343.

[4] LUO Zhi-ping, ZHANG Shao-qing, TANG Ya-li, ZHAO Dong-shan. Quasicrystals in as-cast Mg-Zn-RE alloys [J]. Scripta Metall Mater, 1993, 28(11): 1513-1518.

[5] BAE D H, LEE M H, KIM K T, KIM W T, KIM D H. Application of quasicrystalline particles as a strengthening phase in Mg-Zn-Y alloys [J]. Journal of Alloys and Compounds, 2002, 342: 445-450.

[6] WAN Di-qing, YANG Gen-cang, ZHU Man, ZHOU Yao-he. Growth morphology and evolution of icosahedral quasicrystal in Mg-Zn-Y ternary alloys [J]. Rare Metal Materials and Engineering, 2006, 35(9): 1404-1407. (in Chinese)

[7] SHI Fei, GUO Xue-feng, ZHANG Zhong-ming. Quasicrystal of as-cast Mg-Zn-Y alloy [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 112-116. (in Chinese)

[8] BAE D H, KIM S H, KIM D H, KIM W T. Deformation behavior of Mg-Zn-Y alloys reinforced by icosahedral quasicrystalline particles [J]. Acta Materialia, 2002, 50: 2343-2356.

[9] SINGH A, NAKAMURA M, WATANABE M, KATO A, TSAI A P. Quasicrystal strengthened Mg-Zn-Y alloys by extrusion [J]. Scripta Materialia, 2003, 49: 417-422.

[10] TSAI A P, NIIKURA A, INOUE A, MASUMOTO T. Stoichiometric icosahedral phase in the Zn-Mg-Y system [J]. J Mater Res, 1997, 12(6): 1468-1471.

[11] TSAI A, MURAKAMI Y, NIIKURA A. The Zn-Mg-Y phase diagram involving quasicrystals [J]. Philosophical Magazine A, 2000, 80(5): 1043-1054.

[12] EBALARD S, SPAEPEN F. The body-centered-cubic-type icosahedral reciprocal lattice of the Al-Cu-Fe quasicrystal [J]. J Mater Res, 1989, 4(1): 39-43.

[13] ZHAO Dong-shan, TANG Ya-li, LUO Zhi-ping, SHEN Ning-fu, WANG Ren-hui, ZHANG Shao-qing. The face-centered icosahedral quasicrystalline phase in Mg-Zn-Y-Zr alloys [J]. Materials Letters, 1995, 23: 277-281.

[14] LI M R, KUO K H. Intermetallic phases and phase reactions in Zn-Mg (<40 at.%)-Y (<20 at.%) region [J]. Journal of Alloys and Compounds, 2007, 432: 81-89.

[15] LANGSDORF A, RITTER F, ASSMUS W. Determination of the primary solidification area of the icosahedral phase in the ternary phase diagram of Zn-Mg-Y [J]. Philos Mag Lett, 1997, 75(6): 381-388.

[16] SHI Fei, GUO Xue-feng, ZHANG Zhong-ming. Study on the quasicrytal phase in Mg74Zn25Y1 alloy [J]. Chinese Journal of Mechanical Engineering, 2003, 39(8): 142-144. (in Chinese)

[17] NGUYEN-THI H, GASTALDI J, SCHENK T, REINHART G, MANGELINCK-NOEL N, CRISTIGLIO V, BILLIA B, GRUSHKO B, HARTWIG J, KLEIN H, BARUCHEL J. In situ and real-time probing of quasicrystal solidification dynamics by synchrotron imaging [J]. Phys Rev E, 2006, 74: 031605(1-5).

Foundation item: Projects(50571081; 50671083) supported by the National Natural Science Foundation of China; Project(04G53024) supported by the Aeronautical Foundation of China

Corresponding author: WAN Di-qing; Tel: +86-29-88491484; E-mail: divadwan@tom.com; divadwan@mail.nwpu.edu.cn

Abstract: Applying XRD, DTA, SEM and TEM techniques, an investigation on the solidification microstructure and solidification sequence of Mg-rich Mg-28%Zn-2%Y (mole fraction) alloy was carried out. It is found that, α-Mg dendrites, Mg7Zn3 phase and icosahedral quasicrystal phase coexist in the as-solidified alloy, where the icosahedral quasicrystal, whose structure is indentified to be a face-centered type, originates from a peritectic reaction occurring at 416 ℃. The primary phase of this peritectic reaction has the composition of Mg20Zn66Y14, which is coincident with the H phase reported by TSAI as (Zn, Mg)5Y. Furthermore, the single I-phase grain morphology was observed and its growth evolution was also discussed.