Trans. Nonferrous Met. Soc. China 29(2019) 2117-2127

Effect of thermal treatment and ball milling on microstructure and phase transformation of Ni-Mn-Ga-Nb alloys

Jun-song WANG1,2, Bing TIAN1,2, Yun-xiang TONG1,2, Feng CHEN1,2, Li LI1,2

1. Institute of Materials Processing and Intelligent Manufacturing, College of Materials Science and Chemical Engineering, Harbin Engineering University, Harbin 150001, China;

2. Center for Biomedical Materials and Engineering, Harbin Engineering University, Harbin 150001, China

Received 8 January 2019; accepted 2 July 2019

Abstract:

To clarify phase transformation evolution of Nb-doped Ni-Mn-Ga bulk alloys after aging and ball milling, the microstructure and phase transformation of the aged and ball-milled dual-phase Nb-doped Ni-Mn-Ga alloys were investigated by SEM, EDS, XRD, DSC and susceptibility measurements. The as-cast alloys were mainly composed of the second phase with layer-shape and presented a reduced martensitic transformation with increasing the second phase content. The second phase transformed from layer-shape to dense bar-shape and the martensitic transformation was enhanced after being quenched at 1173 K. After aging at 673 and 873 K, the 3% Nb alloy with less second phase exhibited a single-step phase transformation, whereas the 6% Nb and 9% Nb alloys with more second phase exhibited a two-step martensitic transformation and Curie transition. The martensitic transformation and Curie transition of the as-milled dual-phase particles disappeared and were retrieved after annealing at 1073 K due to the recovery of high ordered structure of the matrix.

Key words:

Ni-Mn-Ga-Nb alloy; thermal treatment; ball milling; microstructure; phase transformation;

1 Introduction

Ni-Mn-Ga ferromagnetic shape memory alloys (FSMAs) have been extensively investigated in the past few years since they exhibit a large magnetic field induced strain (MFIS, 6%-10%) [1,2] which is much larger than the strain generated by typical Terfenol-D magnetostrictive material (~0.24%) [3]. Meanwhile, the magnetic-actuated Ni-Mn-Ga alloy has a larger response frequency as compared to the conventional Ni-Ti shape memory alloy controlled by temperature. Therefore, this kind of alloy presents a great potential as actuation material with fast response. The MFIS mainly originates from martensitic variants reorientation by twin boundary motion in a magnetic field. Thus, the martensitic transformation temperature and martensitic structure are critical for the performance of the alloys. In comparison with ternary Ni-Mn-Ga(Sn) alloy, multi- element Ni-Mn-Ga(Sn) based alloys have presented a variety of martensitic transformation behavior [4-7]. It was found that doping elements in this kind of alloy can properly adjust martensitic transformation temperature and meanwhile improve mechanical properties by introducing a second phase [6-11]. However, the phase transformation of multi-element Ni-Mn-Ga based alloys is often sensitive to heat treatment due to the evolution of the second phase. For the dual-phase high temperature Ni-Mn-Ga alloy [12], it has been reported to exhibit a poor thermal stability due to the chemical decomposition or precipitation of Ni-rich second phase after aging treatment. Similarly, for the Cu-doped Ni-Mn-Ga alloy with higher content of Cu, aging decreased the phase transformation stability because of the formation of Cu-rich precipitates [13]. For the Ti-doped Ni-Mn-Ga alloys, the precipitation of Ni3Ti resulted in the change of Ni content of matrix and then altered martensitic transformation temperature [14].

Recently, Zr and Nb have been added into the Ni- Mn-Ga-Cu and Ni-Mn-Ga alloys [15,16], respectively.

It was found that Zr-rich and Nb-rich second phases formed in the Zr- and Nb-doped alloys, respectively, and the amount of second phase increased with increasing content of the doped elements. For the Zr-doped alloys, aging treatment increased martensitic transformation temperature for Ni46Mn33Ga17Cu2Zr2, Ni46Mn33Ga17Zr4 and Ni50Mn25Ga17Zr8 alloys, while decreased martensitic transformation temperature for Ni50Mn25Ga17Cu4Zr4 alloy due to the composition change of matrix. Similarly, for the Nb-doped Ni-Ti shape memory alloys [17,18], it has been reported that aging treatment increased the martensitic transformation temperature due to the change of Nb content in the Ni-Ti matrix. Furthermore, annealing treatment has also been effective to enhance the magnetocaloric effect of Co-doped Ni-Mn-Sn alloy ribbons [19] and improve mechanical properties of Fe-doped Ni-Mn-Ga alloy fibers [20] by increasing atomic order. However, for the Nb-doped Ni-Mn-Ga alloy, the effect of aging treatment on the martensitic transformation was still unknown. In addition, it was found that the mechanical ductility of the dual-phase Nb-doped alloys was low and these alloys were still brittle [16]. To avoid brittleness of the alloys, they were often crushed to particles and then employed to prepare composites or sintered forms [21-23]. Therefore, these alloys were further crushed and milled to particles. The phase transformation evolution of the aged Nb-doped Ni-Mn-Ga alloys should be closely related to the microstructure change of Nb-rich second phase and Ni-Mn-Ga based matrix during aging treatment. And the phase transformation of ball-milled dual-phase particles is critical for the performance of subsequently prepared composites or sintered bulks, which is sensitive to the post-annealing treatment. Thus, in order to clarify the phase transformation evolution of Nb-doped Ni-Mn-Ga alloys after aging and ball milling, in this work, the microstructure and phase transformation of the aged and ball-milled Nb-doped Ni-Mn-Ga alloys were systematically investigated and discussed.

2 Experimental

The (Ni49.8Mn28.5Ga21.7)100-xNbx (x=1, 3, 6, 9 at.%) polycrystalline ingots were fabricated by arc-melting under an argon atmosphere using high purity elements of Ni (99.99%), Mn (99.7%), Ga (99.99%) and Nb (99.95%), during which the ingots were flip smelted six times. Following Ref. [16], for simplicity, the alloys for x=1, 3, 6, and 9 were denoted as Nb1, Nb3, Nb6 and Nb9 hereafter, respectively. The as-cast ingots were sealed in vacuum quartz tubes and heat-treated at 1173 K for 12 h followed by water-quenching. Then, the quenched Nb3, Nb6 and Nb9 dual-phase alloys were sealed in vacuum quartz tubes and aged at 673 and 873 K for 10 h, respectively. The quenched alloys were also further ball-milled for 20 min in a QM-3A vibration ball mill (milling speed: 1400 r/min) with hardened steel balls and acetone as milling medium at a ball-to-powder mass ratio of 10:1 [24] to obtain fine particles and then the particles were annealed in vacuum at 1073 K for 2 h. The microstructure was observed using a FEI Quanta 200 scanning electron microscope (SEM) equipped with an energy dispersive spectrometry (EDS) analyzer. The EDS measurement was performed by a qualitative measurement process (semi-quantitative analysis). X-ray diffraction (XRD) was performed for phase identification at room temperature using a Panalytical X-pert PRO diffractometer with Cu Kα radiation. Martensitic transformation and Curie transition were measured by recording the temperature dependence of low field AC-susceptibility with a heating/cooling rate of ~10 K/min using a multi-parameter magnetic measurement system (manufactured by Institute of Physics, Chinese Academy of Sciences). The phase transformation was also detected using a Perkin-Elmer diamond differential scanning calorimeter (DSC) with a heating/cooling rate of 20 K/min.

3 Results and discussion

3.1 Microstructure and phase transformation before and after quenching treatment

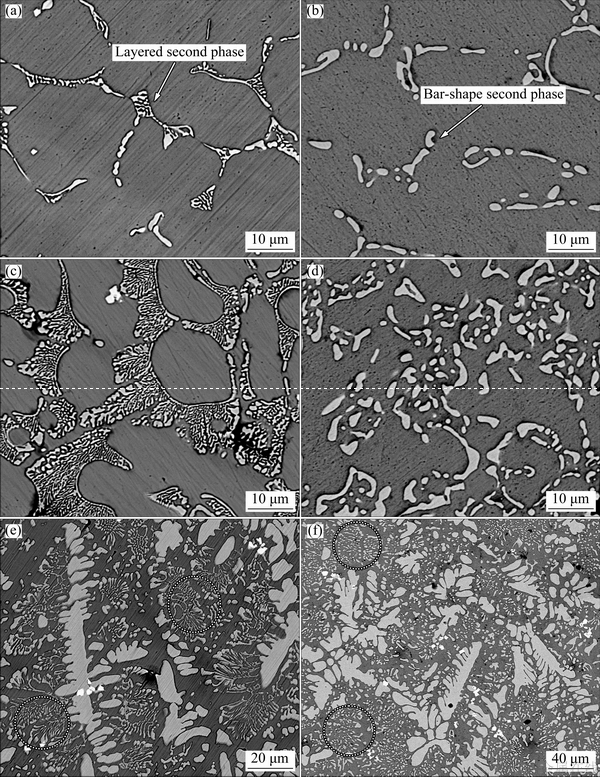

Figure 1 shows SEM images of the as-cast and as-quenched Nb3, Nb6 and Nb9 alloys. It can be seen that the light-color second phase is widely distributed in the dark-color matrix for both as-cast and as-quenched alloys. The main difference of microstructure between the two alloys is the morphology of the second phase. The typical laminated eutectic structure is shown in the as-cast alloy and the second phase exhibits layer-shape, as indicated by arrow in Fig. 1(a) for Nb3 alloy, similar to the result obtained in the Nb-doped Ti-Ni-Cu alloy [25]. In contrast, after quenching, the eutectic structure disappears and the second phase demonstrates a dense bar-shape, as indicated in Fig. 1(b). With increasing Nb content to 6 at.%, the volume fractions of the second phases for both as-cast and as-quenched alloys increase, as shown in Figs. 1(c) and (d), respectively. With increasing Nb to 9 at.%, it is seen that the as-cast alloy has transformed from a single eutectic structure to a mixture of tiny eutectic structure (dashed circles in Fig. 1(e)) and large dendritic structure. The layer-shape second phase in the tiny eutectic structure transforms to dense bar-shape (dashed circles in Fig. 1(f)) after quenching and the original large dendritic structure remains. This consists well with the results observed in the Nb-doped Ni-Ti alloy [26], in which the eutectic structure transforms to a dense structure after annealing at 1413 K for 2 h. The second phase in the present Ni-Mn-Ga-Nb alloys is Nb-rich containing Ni, Mn and Ga elements [16], therefore the evolution of second phase after quenching could result in the variation of phase transformation of the alloys.

Fig. 1 SEM images of as-cast alloys of Nb3 (a), Nb6 (c) and Nb9 (e), and as-quenched alloys of Nb3 (b), Nb6 (d) and Nb9 (f)

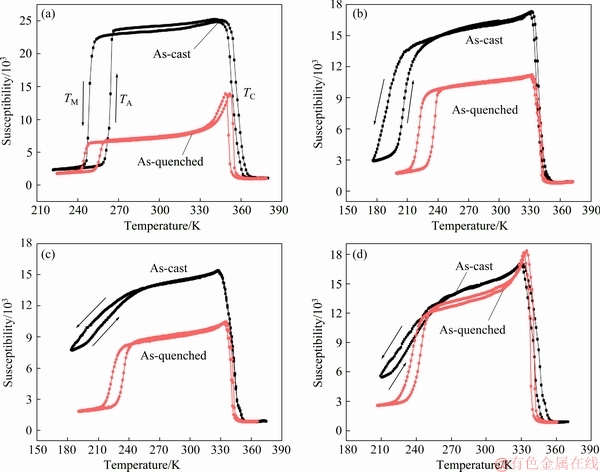

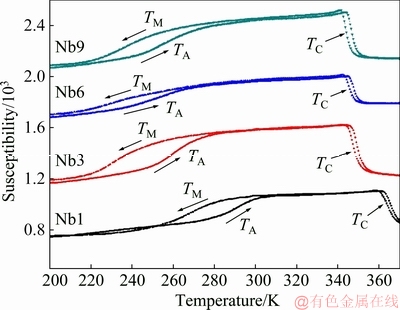

Figure 2 displays the susceptibility-temperature curves of different alloys. As indicated on the curve of as-cast Nb1 alloy, the abrupt susceptibility changes upon cooling and heating at 240-270 K correspond to martensitic transformation and its reverse transformation, respectively. The sudden drop of susceptibility on heating at ~350 K stands for Curie transition. The martensitic transformation temperature (TM), austenitic transformation temperature (TA) and Curie temperature (TC) obtained at the points with the largest slope are indicated on the curve. For the as-cast alloys, Nb1 alloy presents a sharp martensitic transformation and Curie transition, and the martensitic transformation has become blunt gradually from Nb3 to Nb9 alloy with the increase of Nb content. The martensitic transformation exhibits a wide temperature interval for the as-cast Nb6 and Nb9 alloys. However, the Curie transition keeps constantly sharp with increasing the Nb content. The degradation of martensitic transformation with increasing Nb content should be caused by the presence of the second phase. The increase of the second phase results in an increase of composition heterogeneity during casting and thus a wide martensitic transformation. The Curie transition is less sensitive to composition than martensitic transformation, and therefore the Curie transition has no apparent change with the variation of Nb content.

Fig. 2 Susceptibility-temperature curves for as-cast and as-quenched alloys of Nb1 (a), Nb3 (b), Nb6 (c) and Nb9 (d)

For the as-quenched Nb1 alloy, it is seen that the whole susceptibility has decreased in comparison with that of the as-cast alloy, which should be caused by quenching stress that increased the magnetocystalline anisotropy and thus decreased susceptibility [27,28]. The martensitic transformation temperature and Curie temperature of the as-quenched alloy only present a slight change as compared to those of the as-cast alloy, indicating a relatively homogeneous composition of the as-cast Nb1 alloy. For the as-quenched Nb3, Nb6 and Nb9 dual-phase alloys, the susceptibility difference between the as-cast and as-quenched alloys is reduced with increasing Nb content, which means that the quenching stress might be generally reduced with the increase of the second phase content. The martensitic transformation becomes apparently sharp with a narrow transformation range and TM and TA increased, which indicates the improved composition homogenization of the matrix for the as-cast dual-phase alloys after quenching. For Curie temperature, there is almost no change after quenching, which should be due to the less dependence of Curie transition on the composition homogenization. Based on the above results, it is simply thought that post heat treating process for the as-cast dual-phase alloy is more demanding to obtain a homogeneous composition than that for single phase alloy.

3.2 Effect of aging treatment on phase transformation

For the conventional thermally induced Ni-Ti shape memory alloys, aging often changes the content of Ti3Ni4 second phase and then results in a multi-step martensitic transformation [29,30]. For Zr-doped Ni-Mn-Ga dual- phase alloys, it was demonstrated that the martensitic transformation temperature was changed due to the evolution of Zr-rich second phase during aging [15]. Different from Ni-Ti alloy, the Zr-doped Ni-Mn-Ga dual-phase alloys still keep a single-step martensitic transformation after aging. The effect of aging on the transformation behavior of Nb-doped dual-phase alloys was also investigated in the present work.

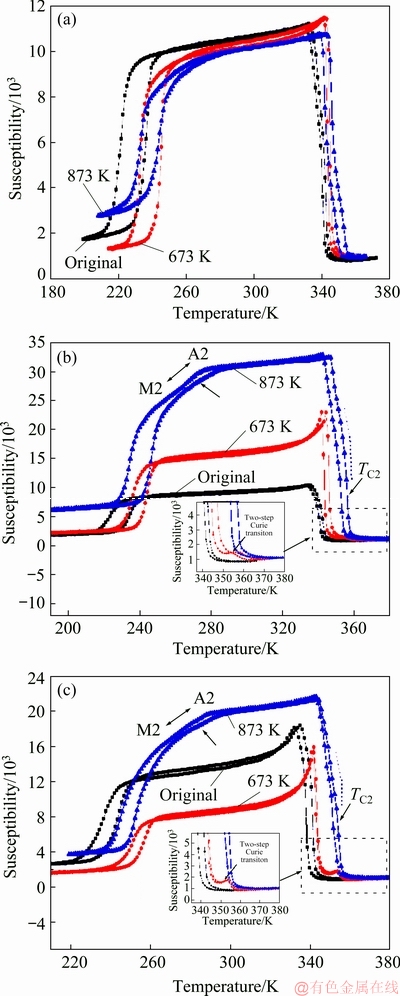

Figure 3 shows the susceptibility-temperature curves of the aged dual-phase Nb3, Nb6 and Nb9 alloys. The Nb3 alloy aged at 673 K exhibits an increased martensitic transformation temperature (by ~10 K) and Curie temperature (by ~5 K) in comparison with those of the quenched one. After increasing aging temperature to 873 K, martensitic transformation temperature and Curie temperature have no apparent change as compared to those of the sample aged at 673 K. For Nb6 alloy (Fig. 3(b)) martensitic transformation and Curie transition become more pronounced with increasing aging temperature, which are quite different from those of Nb3 alloy. Both the martensitic transformation temperature and Curie temperature increased. It is noted that an additional susceptibility change (255-285 K, marked by an arrow) before the susceptibility drop associated with martensitic transformation on cooling has been observed for the 873 K-aged sample, suggesting that an extra martensitic transformation happens, as indicated by M2 A2. In addition, it is interesting to note that a two-step Curie transition is observed for the 673 K-aged sample, as shown in the inset of the figure (an enlarged part of the figure indicated by dashed rectangle). The second step Curie transition curve in 673 K-aged sample seems to overlap with the Curie transition curve (indicated by TC2) of 873 K-aged sample. Therefore, the 873 K-aged sample also contains two-step Curie transition as shown by the intersected red and blue dashed lines. For Nb9 alloy, the evolution of martensitic transformation and Curie transition after aging is similar to that of Nb6 alloy, as shown in Fig. 3(c). Martensitic transformation temperature and Curie temperature increase after aging. The two-step martensitic transformation and two-step Curie transition are also observed on the curves for 873 K-aged sample. Similarly, the second-step Curie transition is also observed in 673 K-aged sample, which agrees well with the Curie transition (TC2) of 873 K-aged sample. It is noted that the second step Curie transition of 873 K-aged sample becomes stronger than that of the 673 K-aged sample, which combines with original Curie transition and exhibits a wide transition temperature range (indicated by the intersected red and blue dashed lines). The enhancement of the second-step Curie transition for the 873 K-aged sample is correlated to the occurrence of the second-step martensitic transformation, both of which should belong to the same composition part in the matrix. The disappearance of the second step martensitic transformation M2

A2. In addition, it is interesting to note that a two-step Curie transition is observed for the 673 K-aged sample, as shown in the inset of the figure (an enlarged part of the figure indicated by dashed rectangle). The second step Curie transition curve in 673 K-aged sample seems to overlap with the Curie transition curve (indicated by TC2) of 873 K-aged sample. Therefore, the 873 K-aged sample also contains two-step Curie transition as shown by the intersected red and blue dashed lines. For Nb9 alloy, the evolution of martensitic transformation and Curie transition after aging is similar to that of Nb6 alloy, as shown in Fig. 3(c). Martensitic transformation temperature and Curie temperature increase after aging. The two-step martensitic transformation and two-step Curie transition are also observed on the curves for 873 K-aged sample. Similarly, the second-step Curie transition is also observed in 673 K-aged sample, which agrees well with the Curie transition (TC2) of 873 K-aged sample. It is noted that the second step Curie transition of 873 K-aged sample becomes stronger than that of the 673 K-aged sample, which combines with original Curie transition and exhibits a wide transition temperature range (indicated by the intersected red and blue dashed lines). The enhancement of the second-step Curie transition for the 873 K-aged sample is correlated to the occurrence of the second-step martensitic transformation, both of which should belong to the same composition part in the matrix. The disappearance of the second step martensitic transformation M2 A2 in 673 K-aged sample could be due to the low volume fraction of this composition part. Therefore, it is suggested that the matrices of Nb6 and Nb9 alloys after aging have formed two different composition parts that present different martensitic transformation temperatures and Curie temperatures, which result in the two-step martensitic transformation and Curie transition for the aged Nb6 and Nb9 alloys.

A2 in 673 K-aged sample could be due to the low volume fraction of this composition part. Therefore, it is suggested that the matrices of Nb6 and Nb9 alloys after aging have formed two different composition parts that present different martensitic transformation temperatures and Curie temperatures, which result in the two-step martensitic transformation and Curie transition for the aged Nb6 and Nb9 alloys.

Fig. 3 Susceptibility-temperature curves of originally quenched alloy, 673 K- and 873 K-aged alloys of Nb3 (a), Nb6 (b) and Nb9 (c)

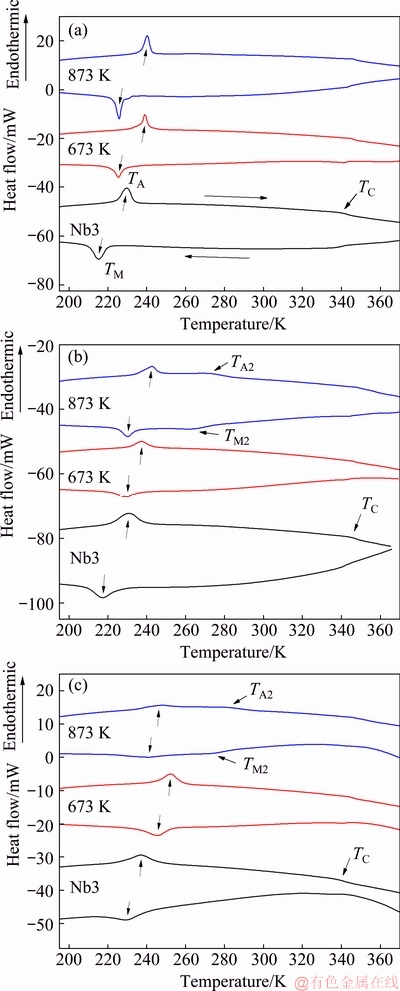

Fig. 4 DSC curves of originally quenched alloy, 673 K- and 873 K-aged alloys of Nb3 (a), Nb6 (b) and Nb9 (c)

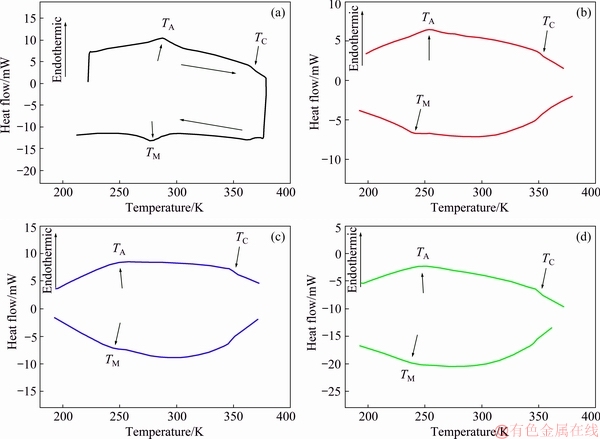

The DSC tests have been performed to characterize phase transformation of the alloys, as shown in Fig. 4. Figure 4(a) shows DSC curves of Nb3 alloy after aging. The transformation peaks at 220-250 K correspond to martensite austenite transformation and the small bend of the curve at ~340 K stands for Curie transition. The martensitic transformation peak temperature (TM) and austenitic transformation peak temperature (TA) indicated by arrows correspond to the transformation temperatures obtained in the susceptibility-temperature curves. It can be seen that the Nb3 alloy mainly exhibits a single-step martensitic transformation and the martensitic transformation temperature increases after aging at 673 and 873 K, being consistent with the results obtained in the susceptibility measurement. In addition, the Curie temperature obtained by DSC is close to that measured by susceptibility-temperature curve. The Nb6 and Nb9 alloys change to a two-step martensitic transformation after aging at 873 K. The second-step martensitic transformation and austenitic transformation peaks have been indicated on the curve by TM2 and TA2, respectively, which are also consistent with the results of susceptibility measurements. However, the two-step Curie transition observed in the susceptibility measurement cannot be found on the DSC curve due to the weak signal of the second order Curie transition reflected by latent heat change.

austenite transformation and the small bend of the curve at ~340 K stands for Curie transition. The martensitic transformation peak temperature (TM) and austenitic transformation peak temperature (TA) indicated by arrows correspond to the transformation temperatures obtained in the susceptibility-temperature curves. It can be seen that the Nb3 alloy mainly exhibits a single-step martensitic transformation and the martensitic transformation temperature increases after aging at 673 and 873 K, being consistent with the results obtained in the susceptibility measurement. In addition, the Curie temperature obtained by DSC is close to that measured by susceptibility-temperature curve. The Nb6 and Nb9 alloys change to a two-step martensitic transformation after aging at 873 K. The second-step martensitic transformation and austenitic transformation peaks have been indicated on the curve by TM2 and TA2, respectively, which are also consistent with the results of susceptibility measurements. However, the two-step Curie transition observed in the susceptibility measurement cannot be found on the DSC curve due to the weak signal of the second order Curie transition reflected by latent heat change.

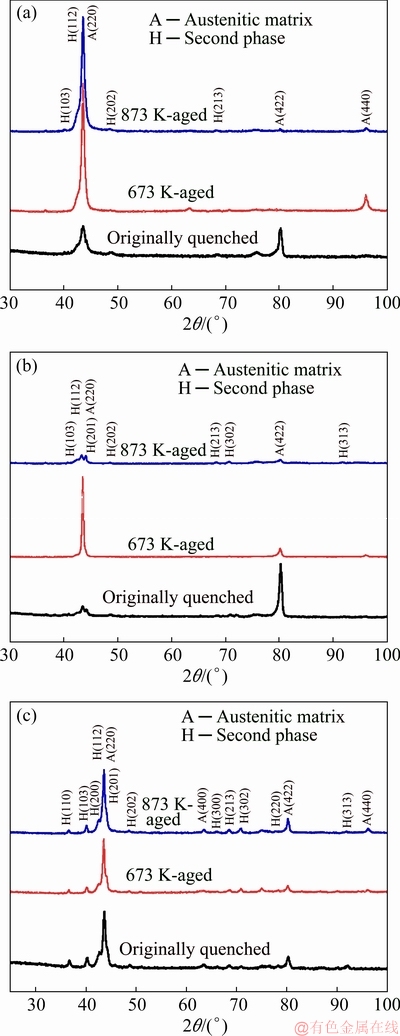

Figure 5 shows XRD patterns for the dual-phase Nb3, Nb6 and Nb9 alloys before and after aging. The original dual-phase alloy is composed of a cubic austenite and hexagonal Nb-rich second phase [16]. The diffraction peaks belonging to austenite and second phases have been indexed and marked by A and H, respectively. It is found that the aged alloys contain similar diffraction peaks to those of the quenched alloys and no other diffraction peaks belonging to a new phase are observed, which means that the change of martensitic transformation and Curie transition is mainly attributed to the evolution of the second phase during aging.

Fig. 5 XRD patterns for originally quenched alloy, 673 K- and 873 K-aged alloys of Nb3 (a), Nb6 (b) and Nb9 (c)

It has been reported that for the Zr-doped Ni-Mn-Ga alloy, further precipitation of Zr-rich second phase after aging resulted in the increase of martensitic transformation temperature [15]. Therefore, it is thought that the increase of the martensitic transformation temperature for these dual-phase alloys should be related to further precipitation of the Nb-rich second phase. The enhancement of whole susceptibility for the aged alloys is attributed to the release of quenching stress. It is known that the precipitation of Ti3Ni4 phase during aging results in a multi-step martensitic transformation for Ni-rich Ni-Ti shape memory alloys due to the inhomogeneous composition distribution caused by the second phase [30]. For the Nb6 and Nb9 alloys, the two-step martensitic transformation and Curie transition are also thought to be related to further precipitation of the second phase. The precipitation of second phase results in composition change of the matrix close to the second phases, and this effect should become more serious and wider with the increase of second phase and aging temperature. Therefore, for the Nb6 and Nb9 alloys with large amount of the second phase, further precipitation of Nb-rich second phase results in the reduction of Nb, Ni, Mn and Ga contents in the matrix around the second phase and a new composition matrix around the second phase forms after aging. This new composition matrix exhibits a higher martensitic transformation temperature (M2 A2) and Curie temperature (TC2) as compared to the matrix away from the second phase, which results in the two-step martensitic transformation and Curie transition in the 873 K-aged Nb6 and Nb9 alloys. Only the second-step Curie transition (without second-step martensitic transformation) is observed in the 673 K-aged sample due to low content of the new composition matrix caused by the lower aging temperature.

A2) and Curie temperature (TC2) as compared to the matrix away from the second phase, which results in the two-step martensitic transformation and Curie transition in the 873 K-aged Nb6 and Nb9 alloys. Only the second-step Curie transition (without second-step martensitic transformation) is observed in the 673 K-aged sample due to low content of the new composition matrix caused by the lower aging temperature.

3.3 Microstructure and phase transformation of particles

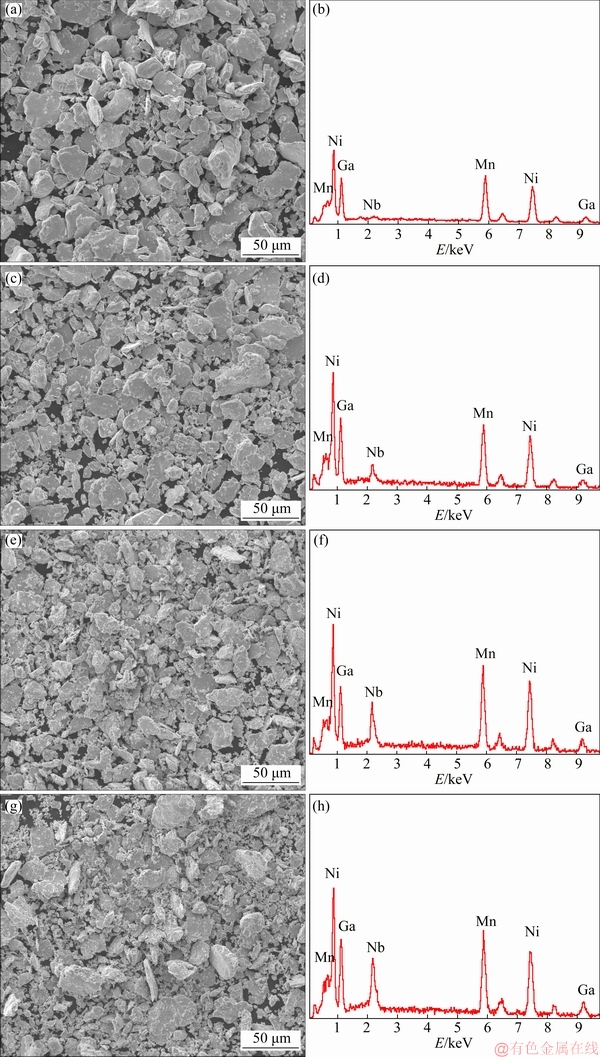

These quenched alloys have been successfully crushed to fine particles by ball milling. Figure 6 shows SEM images and EDS results of the Nb1, Nb3, Nb6 and Nb9 as-milled particles. It can be seen that all the particles exhibit irregular shape after ball milling and the particle surface becomes rougher with increasing Nb content. In addition, the amount of small size particles seems to be increased with increasing Nb content, which should be caused by the volume increase of small size Nb-rich second phase [15]. From the EDS results, it can be seen that the relative intensity of the peak belonging to Nb element is gradually enhanced with increasing Nb content and there are no contaminations from other elements such as Fe or Cr caused by ball milling [31].

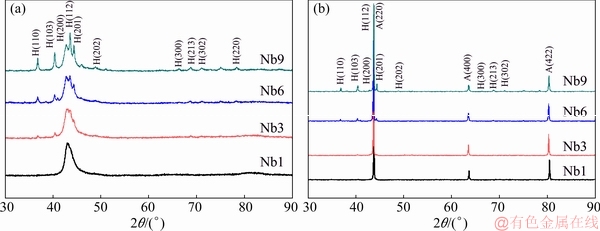

Figure 7(a) shows XRD patterns of the as-milled particles. Different from the single phase Nb1 particles, the dual-phase Nb3, Nb6 and Nb9 particles contain many sharp diffraction peaks that can be indexed as the Nb-rich second phase. This indicates that the second phase is a hard phase and difficult to be deformed, similar to the Zr-rich second phase [15], which further supports the mechanical testing results in the bulk samples [16]. Different from that of the second phase, the structure of the matrix has been completely destructed. Figure 7(b) shows XRD patterns of the as-annealed particles. It can be found that ordered cubic structure of the austenite phase has been restored. The as-annealed Nb1 particle exhibits a pure cubic austenite phase and the annealed Nb3, Nb6 and Nb9 particles are composed of austenitic matrix and Nb-rich second phase, being consistent to that of the corresponding original alloys.

Figure 8 shows DSC results of the as-annealed particles. It can be observed that the martensitic transformation of Nb1 particles has been recovered and the martensitic transformation temperature is 280-290 K and Curie temperature is ~365 K. For Nb3, Nb6 and Nb9 particles, the martensitic transformation peaks are gradually reduced with increasing Nb content and the martensitic transformation of Nb6 and Nb9 particles has become blurry. The Curie transition of all particles can be clearly detected, as indicated by the arrows. In comparison, the martensitic transformation and Curie transition of all the particles measured by susceptibility are more distinct, as shown in Fig. 9. The martensitic transformation temperature and Curie temperature of all the particles measured by susceptibility are close to those measured by DSC. The appearance of martensitic transformation for the annealed particles is in agreement with the XRD results shown in Fig. 7. The blurry martensitic transformation on the DSC curves for the dual-phase Nb6 and Nb9 particles should be caused by the low latent heat of dual-phase particles due to the existence of the second phase particles that do not participate in martensitic transformation. In contrast, the susceptibility is less sensitive to the amount of the matrix particles, leading to the obvious martensitic transformation on the susceptibility measurement curves. In comparison with the bulk alloys, the martensitic transformation temperature and Curie temperature for the annealed particles have been increased, which should be related to the composition change of the matrix caused by ball milling [31].

Fig. 6 SEM images (a, c, e, g) and EDS results (b, d, f, h) of Nb1 (a, b), Nb3 (c, d), Nb6 (e, f) and Nb9 (g, h) as-milled particles

Fig. 7 XRD patterns of as-milled (a) and as-annealed (b) Nb1, Nb3, Nb6 and Nb9 particles

Fig. 8 DSC curves of as-annealed Nb1 (a), Nb3 (b), Nb6 (c) and Nb9 (d) particles

Fig. 9 Susceptibility-temperature curves of as-annealed Nb1, Nb3, Nb6 and Nb9 particles

4 Conclusions

(1) The second phase with layer-shape formed in the as-cast Nb-doped Ni-Mn-Ga alloys and resulted in a reduced martensitic transformation with the increase of second phase. High temperature quenching at 1173 K combined the layer-shape second phase and enhanced the martensitic transformation.

(2) The alloy with few second phases (Nb3 alloy) exhibited a single-step martensitic transformation and Curie transition after aging; whereas the alloys with large amounts of second phases (Nb6 and Nb9 alloys) demonstrated a two-step martensitic transformation and Curie transition after aging.

(3) The martensitic transformation of the dual-phase particles disappeared after ball milling and was restored by post-annealing at 1073 K due to the recovery of high ordered structure of the austenitic matrix.

References

[1] MURRAY S J, MARIONI M, ALLEN S M, O'HANDLEY R C, LOGRASSO T A. 6% magnetic-field-induced strain by twin- boundary motion in ferromagnetic Ni-Mn-Ga [J]. Applied Physics Letter, 2000, 77: 886-888.

[2] SOZINOV A, LIKHACHEV A A, LANSKA N, ULLAKKO K. Giant magnetic-field-induced strain in NiMnGa seven-layered martensitic phase [J]. Applied Physics Letter, 2002, 80: 1746-1748.

[3] CLARK A E, TETER J P, MCMASTERS O D. Magnetostriction ‘‘jumps’’ in twinned Tb0.3Dy0.7Fe1.9 [J]. Journal of Applied Physics, 1988, 63: 3910-3912.

[4] GUO Shi-hai, ZHANG Yang-huan, QUAN Bai-yun, LI Jian-liang, QI Yan,WANG Xin-lin.The effect of doped elements on the martensitic transformation in NiMnGa magnetic shape memory alloy [J]. Smart Materials and Structure, 2005, 14(S): s236-s238.

[5] SODERBERG O, KOHO K, SAMMI T, LIU X W, SOZINOV A, LANSKA N, LINDROOS V K. Effect of the selected alloying on Ni-Mn-Ga alloys [J]. Materials Science and Engineering A, 2004, 378: 389-393.

[6] XIN Yan, LI Yan. Microstructure and transformation behavior of Ni54Mn25Ga15Al6 high-temperature shape memory alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 126-130.

[7] TAN Chang-long, FENG Zhi-cheng, ZHANG Kun, WU Ming-yang, TIAN Xiao-hua, GUO Er-jun. Microstructure, martensitic transformation and mechanical properties of Ni-Mn-Sn alloys by substituting Fe for Ni [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 2234-2238.

[8] WANG Jing-min, WANG Huan-fang, JIANG Cheng-bao. Microstructure and mechanical properties of a Ni30Cu20Mn41.5Ga8.5 dual-phase shape memory alloy [J]. Materials Science and Engineering A, 2013, 578: 256-259.

[9] TAN Chang-long, ZHANG Kun, TIAN Xiao-hua, CAI Wei. Effect of Gd addition on microstructure, martensitic transformation and mechanical properties of Ni50Mn36Sn14 ferromagnetic shape memory alloy [J]. Journal of Alloys and Compounds, 2017, 692: 288-293.

[10] TAN Chang-long, TAI Zhi-peng, ZHANG Kun, TIAN Xiao-hua, CAI Wei. Simultaneous enhancement of magnetic and mechanical properties in Ni-Mn-Sn alloy by Fe doping [J]. Scientific Reports, 2017, 7: 43387.

[11] MA Yun-qing, LAI San-li, YANG Shui-yuan, LUO Yu, WANG Cui-ping, LIU Xing-jun. Ni56Mn25-xCrxGa19 (x=0, 2, 4, 6) high temperature shape memory alloys [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 96-101.

[12] SANTAMARTA R, CESARI E, MUNTASELL J, FONT J, PONS J, OCHIN P. Thermal and microstructural evolution under ageing of several high-temperature Ni-Mn-Ga alloys [J]. Intermetallics, 2010, 18: 977-983.

[13] SANTAMARTA R, MUNTASELL J, FONT J, CESARI E. Thermal stability and microstructure of Ni-Mn-Ga-Cu high temperature shape memory alloys [J]. Journal of Alloys and Compounds, 2015, 648: 903-911.

[14] DONG G F, GAO Z Y, TAN C L, CAI W, SUI J H. Microstructure and martensitic transformation behavior of a constant-strain aged Ni-Mn-Ga-Ti magnetic shape memory alloy [J]. Journal of Materials Science, 2010, 45: 5490-5494.

[15] TIAN B, TONG Y X, CHEN F, LI L, ZHENG Y F. Effect of ageing and ball milling on the phase transformation of Ni50Mn25Ga17- Cu8-xZrx alloys [J]. Intermetallics, 2015, 58: 56-61.

[16] TIAN B, JI R, TONG Y X, LI L, ZHENG Y F. Microstructure, phase transformation and mechanical property of Nb-doped Ni-Mn-Ga alloys [J]. Intermetallics, 2015, 64: 37-43.

[17] ZHENG Yu-feng, CAI Wei, WANG Yong-qian, LUO Yi-chun, ZHAO Lian-cheng. Effects of heat treatment on the transformation temperature and the microstructure of Ni-Ti-Nb shape memory alloy [J]. Journal of Materials Science and Technology, 1998, 14: 37-40.

[18] SHU X Y, LU S Q, LI G F, LIU J W, PENG P. Nb solution influencing on phase transformation temperature of Ni47Ti44Nb9 alloy [J]. Journal of Alloys and Compounds, 2014, 609: 156-161.

[19] ZHONG Zhen-chen, MA Sheng-can, WANG Dun-hui, DU You-wei. A review on the regulation of magnetic transitions and the related magnetocaloric properties in Ni-Mn-Co-Sn alloys [J]. Journal of Materials Science and Technology, 2012, 28(3): 193-199.

[20] LIU Yan-fen, LIU Xiao-hua, MA Lin, YANG Lü-hua, WEN Ya-xiang, SONG Chao-qun, ZHANG Xue-xi, SUN Jian-fei. Effect of chemical ordering annealing on Ni-Mn-Ga-Fe shape memory microwires [J]. The Chinese Journal of Nonferrous Metals, 2018, 28(4): 749-757.

[21] LIU J, SCHEERBAUM N, KAUFFMANN-WEISS S, GUTFLEISCH O. NiMn-based alloys and composites for magnetically controlled dampers and actuators [J]. Advanced Engineering Materials, 2012, 14: 653-667.

[22] TIAN Bing, CHEN Feng, TONG Yun-xiang, LI Li, ZHENG Yu-feng. Magnetic field induced strain and damping behavior of Ni-Mn-Ga particles/epoxy resin composite [J]. Journal of Alloys and Compounds, 2014, 604: 137-141.

[23] TIAN X H, SUI J H, ZHANG X, FENG X, CAI W. Martensitic transformation, mechanical property and magnetic-field-induced strain of Ni-Mn-Ga alloy fabricated by spark plasma sintering [J]. Journal of Alloys and Compounds, 2011, 509: 4081-4083.

[24] TIAN B, CHEN F, TONG Y X, LI L, ZHENG Y F, LIU Y, LI Q Z. Phase transition of Ni-Mn-Ga alloy powders prepared by vibration ball milling [J]. Journal of Alloys and Compounds, 2011, 509: 4563-4568.

[25] JIANG Da-qiang, LIU Yi-nong, YU Cun, LIU Wei-long, YANG Hong, JIANG Xiao-hua, REN Yang, CUI Li-shan. Deformation behavior of Nb nanowires in TiNiCu shape memory alloy matrix [J]. Materials Science and Engineering A, 2015, 646: 52-56.

[26] SHI H, FRENZEL J, MARTINEZ G T, van ROMPAEY S, BAKULIN A, KULKOVA S, van AERT S, SCHRYVERS D. Site occupation of Nb atoms in ternary Ni-Ti-Nb shape memory alloys [J]. Acta Materialia, 2014, 74: 85-95.

[27] TICKLE R, JAMES R D. Magnetic and magnetomechanical properties of Ni2MnGa [J]. Journal of Magnetism and Magnetic Materials, 1999, 195: 627-638.

[28] LIU Z H, CHEN J L, HU H N, ZHANG M, DAI X F, ZHU Z Y, LIU G D, WU G H, MENG F B, LI Y X. The influence of heat treatment on the magnetic and phase transformation properties of quaternary Heusler alloy Ni50Mn8Fe17Ga25ribbons [J]. Scripta Materialia, 2004, 51: 1011-1015.

[29] ZHENG Yu-feng, JIANG Fei, LI Li, YANG Hong, LIU Yi-nong. Effect of ageing treatment on the transformation behavior of Ti-50.9at.%Ni alloy [J]. Acta Materialia, 2008, 56: 736-745.

[30] FAN Gen-lian, CHEN Wei, YANG Sen, ZHU Jin-hua, REN Xiao-bing, OTSUKA K. Origin of abnormal multi-stage martensitic transformation behavior in aged Ni-rich Ti-Ni shape memory alloys [J]. Acta Materialia, 2004, 52: 4351-4362.

[31] TIAN B, CHEN F, TONG Y X, LI L, ZHENG Y F. Phase transformation and magnetic property of Ni-Mn-Ga powders prepared by dry ball milling [J]. Journal of Materials Engineering and Performance, 2012, 21: 2530-2534

热处理和球磨对Ni-Mn-Ga-Nb合金显微组织和相变的影响

王俊淞1,2,田 兵1,2,佟运祥1,2,陈 枫1,2,李 莉1,2

1. 哈尔滨工程大学 材料科学与化学工程学院 材料加工及智能制造研究所,哈尔滨 150001;

2. 哈尔滨工程大学 生物医学材料与工程研究中心,哈尔滨 150001

摘 要:为了揭示时效和球磨后Nb掺杂Ni-Mn-Ga合金的相变演化,采用SEM、EDS、XRD、DSC 和交流磁化率测试等技术研究时效和球磨双相Nb掺杂Ni-Mn-Ga合金的显微组织和相变。铸态合金主要由层状第二相组成,随着第二相含量增加,合金的马氏体相变逐渐减弱。1173 K淬火后第二相从层状转变为致密的棒状,且合金的马氏体相变增强。经673 和873 K时效后,含有较少第二相的3% Nb合金表现为一步相变,而含有较多第二相的6% Nb和9% Nb合金表现为两步马氏体相变和居里转变。球磨双相颗粒的马氏体相变和居里转变消失, 1073 K退火后基体的高有序结构得到恢复,从而导致双相颗粒的马氏体相变和居里转变恢复。

关键词:Ni-Mn-Ga-Nb合金;热处理;球磨;显微组织;相变

(Edited by Wei-ping CHEN)

Foundation item: Project (51201044) supported by the National Natural Science Foundation of China; Project (HEUCFG201836) supported by the Fundamental Research Funds for the Central Universities, China; Project (LBH-Q16046) supported by the Postdoctoral Scientific Research Developmental Fund of Heilongjiang Province, China; Project supported by the Key Laboratory of Superlight Materials & Surface Technology (Harbin Engineering University), Ministry of Education, China

Corresponding author: Bing TIAN; Tel/Fax: +86-451-82518644; E-mail: tianbing@hrbeu.edu.cn

DOI: 10.1016/S1003-6326(19)65118-6

Abstract: To clarify phase transformation evolution of Nb-doped Ni-Mn-Ga bulk alloys after aging and ball milling, the microstructure and phase transformation of the aged and ball-milled dual-phase Nb-doped Ni-Mn-Ga alloys were investigated by SEM, EDS, XRD, DSC and susceptibility measurements. The as-cast alloys were mainly composed of the second phase with layer-shape and presented a reduced martensitic transformation with increasing the second phase content. The second phase transformed from layer-shape to dense bar-shape and the martensitic transformation was enhanced after being quenched at 1173 K. After aging at 673 and 873 K, the 3% Nb alloy with less second phase exhibited a single-step phase transformation, whereas the 6% Nb and 9% Nb alloys with more second phase exhibited a two-step martensitic transformation and Curie transition. The martensitic transformation and Curie transition of the as-milled dual-phase particles disappeared and were retrieved after annealing at 1073 K due to the recovery of high ordered structure of the matrix.