文章编号:1004-0609(2011)12-3115-05

稀土改性Fe-Ni基涂层的高温性能

张丽民1,刘邦武2,刘淑凤1,夏 雯1,王书明1

(1. 北京有色金属研究总院 国家有色金属及电子材料分析测试中心,北京 100088;

2. 中国科学院 微电子研究所,北京 100029)

摘 要:

为提高Fe-Ni基涂层的高温性能,在Fe-Ni基合金粉末中添加La2O3和Ce2O3的混合物,对涂层的高温氧化行为和高温耐磨损性能进行研究。结果表明:稀土改性Fe-Ni基涂层组织细密、晶粒细小、形成稀土化合物LaNi4Si、Ce2Ni22C3以及硬质相Cr3Si;稀土改性Fe-Ni基涂层具有良好的高温抗氧化性能,在氧化初期,涂层质量迅速增加,氧化动力学曲线符合抛物线规律,在氧化后期,氧化动力学曲线符合直线规律,质量增加缓慢。高温抗氧化性能的提高和Cr3Si硬质相的弥散分布使涂层的高温耐磨性能得到显著的提高。

关键词:

中图分类号:TG156.99

High-temperature properties of Fe-Ni based coating doped with RE

ZHANG Li-min1, LIU Bang-wu2, LIU Shu-feng1, XIA Wen1, WANG Shu-ming1

(1. National Center of Analysis and Testing for Non-ferrous Metals and Electronic Material,

General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Institute of Microelectronics, Chinese Academy of Sciences, Beijing 100029, China)

Abstract: The La2O3 and Ce2O3 oxides were doped into the Fe-Ni based alloy powder in order to improve the high-temperature properties of Fe-Ni based coating, and the high-temperature oxidation behavior and high-temperature wear-resistant property of the Fe-Ni based coating were also studied. The results show that the microstructure is fine and the RE compounds LaNi4Si, Ce2Ni22C3 and hard phase Cr3Si form in the coating. The coating has good high-temperature oxidation-resistant performance. At the initial stage of the oxidation test, the oxidation kinetics line basically follows the parabolic rate law and the mass gain is rapid. At the later period, the oxidation kinetics line becomes straight line and the mass gain is slow. Both the increase of high-temperature oxidation resistant property and the dispersion distribution of the hard phase Cr3Si improve the high-temperature wear-resistant performance of the Fe-Ni based coating remarkably.

Key words: Fe-Ni based coating; rare earth; high-temperature oxidation; high-temperature wear

稀土由于其独特的原子结构而具有良好的物理和化学性能,现在已成功应用到多个领域,如冶金、电子和化学工程等[1]。稀土应用的另一重要领域是对工程零部件的表面性能进行改性处理,如化学热处理、火焰喷涂和电镀等[2-3]。近几年来,稀土被越来越多地应用到表面涂层技术中,LIU等[4]在NiCr-Cr3C2粉末中加入La2O3,制备了激光熔覆γ/Cr7C3/TiC涂层,研究表明,加入适量的La2O3可使涂层组织细小、稀释率降低、显微硬度升高。SHARMA等[5]在Ni基火焰喷涂涂层中添加La2O3,得到了相同的研究结果。ZHAO等[6]研究了CeO2掺杂Ni/WC激光熔覆涂层组织的演化过程,结果表明:CeO2可以促进WC颗粒的分解,因此,可使未分解的WC颗粒更加圆滑,CeO2也可以促进共晶体的球化。WU等[7]将稀土氧化物添加到Fe基合金涂层中,发现稀土氧化物可以降低Fe基涂层的开裂敏感性,促进非均匀形核,易于形成强化相,提高涂层的性能。总之,通过对金属基材料或陶瓷材料进行稀土改性,在保持低成本的情况下,可以有效改善涂层组织结构和性能。

金属基复合涂层材料由于其高硬度和良好的耐磨损性能引起了广大工程研究者的关注,制备该种材料的技术主要包括热喷涂、激光熔覆和等离子熔覆等。等离子熔覆技术是近些年发展起来并已实现工业应用的表面涂层技术[8-10],其特点是转移弧放电等离子束按照程序轨迹匀速运行的同时,使同步送入的合金粉末和基体表面同时快速熔化,形成瞬间熔池,熔融状态下的合金元素在熔池内发生扩散、反应,并依次快速凝固,形成与基体呈冶金结合的涂层[11-12]。目前关于等离子熔覆技术的研究很多[13-16],但是对于等离子熔覆涂层高温性能方面的研究还鲜见报道,本文作者在Fe-Ni基涂层的基础上添加了CeO2 和 La2O3,对该涂层的高温氧化行为和高温磨损性能进行了系统的研究,为拓展等离子熔覆技术在高温领域的应用奠定基础。

1 实验

基体材料采用普通低碳钢,表面涂层材料为稀土掺杂Fe-Ni基合金粉末,合金粉末成分如表1所列。在前期试验的基础上,设定稀土氧化物CeO2 和 La2O3的添加量为0.5%(质量分数)[17]。试验设备采用山东科技大学研制的等离子熔覆专用设备,优化的熔覆工艺参数如下:等离子炬扫描速度300 mm/min,送粉气0.6 m3/h,离子气0.6 m3/h,保护气1.6 m3/h,等离子束流长度为27 mm,工作电流300 A。

在JSM-7001型场发射扫描电镜上观察等离子熔覆涂层的显微组织、氧化膜形貌和试样的磨损表面形貌,采用TN550型Tracor Northern 能谱仪对氧化膜进行成分分析,采用Philips APD-10 X射线衍射仪对涂层的物相组成进行表征。在高温电阻空气炉中进行高温氧化试验,将涂层加工成30 mm×10 mm×2.5 mm的试样,试样要求厚薄均匀,形状规则,表面磨光,表面粗糙度Ra为0.8 μm,并将所有边棱都打磨圆滑,高温氧化时间为100 h,每隔10 h取出一组试样进行观察并称量,采用AEU-220型电子天平进行称量,其精度为0.000 1 g。在SRV高温摩擦磨损实验机上进行高温磨损试验,试验参数如下:载荷为50 N,频率为30 Hz,冲程为1 mm,时间为10 min,试验温度为500 ℃。

表1 熔覆合金粉末的化学成分

Table 1 Chemical composition of cladding alloy powder (mass fraction, %)

2 结果与讨论

2.1 涂层的组织结构

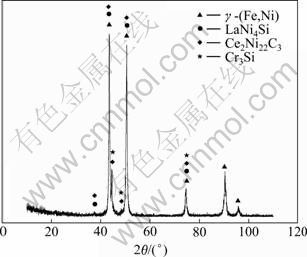

图1所示为涂层的显微形貌,图1(a)所示为未添加稀土的涂层的显微形貌,图1(b)所示为添加0.5%(质量分数)稀土氧化物的涂层显微形貌。由图1可以发现,添加稀土氧化物后,涂层的组织细小,这是由于稀土的添加使涂层中的枝晶臂被打断,细小晶粒析出,显著改善了涂层的组织形貌;涂层的物相组成如图2所示,涂层中除了γ-(Fe,Ni)相外,还形成了稀土化合物LaNi4Si、Ce2Ni22C3以及硬质相Cr3Si,这种铬的硅化物被认为是很有应用前景的高温耐磨材料,可以提高涂层的高温耐磨性能[17]。

图1 涂层的SEM像

Fig.1 SEM images of clad coating: (a) Without RE2O3; (b) With 0.5% RE2O3

图2 涂层的XRD谱

Fig.2 XRD pattern of clad coating

2.2 涂层的高温氧化行为及机理

图3所示为涂层在800 ℃、100 h高温氧化后的氧化膜形貌,为向外生长的针片状富铁氧化物(其化学组成见表2),这是因为在高温氧化过程中,当表面氧化膜形成以后,继续发生氧化只能依靠传质在氧化膜中的扩散来实现。Cr易于在氧化膜/基体界面发生下列反应:

2Cr+Fe2O3=Cr2O3+2Fe (1)

因而在靠近界面的氧化膜中Cr元素聚集,从而使得近基体氧化膜的致密度提高,被置换出来的Fe元素扩散至外表层在空气中被氧化,形成如图3所示的针片状氧化膜。这种针片状氧化膜的各种缺陷密度很高大,为Cr元素由基体向氧化膜/基体界面处扩散提供了快速通道,更有利于Cr元素在氧化膜的富集,提高氧化膜的致密性。总之,涂层中添加稀土氧化物可以促进式(1)中反应的进行,促进Cr元素在表面氧化膜的富集,提高氧化膜的致密度,阻碍氧化反应的发生。

图3 800 ℃时涂层氧化膜的SEM像

Fig.3 SEM images showing oxide film of clad coating at 800 ℃

表2 800 ℃时涂层氧化膜的化学组成

Table 2 Chemical composition of oxide film at 800 ℃ (mass fraction, %)

根据高温氧化过程中涂层质量增加情况作图,采用Wanger氧化经验公式,进行动力学方程线性拟合,微分得

![]() (2)

(2)

式中:w为氧化质量增加;k为氧化速度;t为氧化时间。

将式(2)积分得

![]() (3)

(3)

实践表明,许多金属的氧化曲线均偏离抛物线规律,因此,将式(3)修正成:

![]() (4)

(4)

式中:n为氧化指数。

从![]() 动力学方程出发,利用Origin 7.0软件,对数据进行拟合,可得到最佳的n和k值。拟合后得到的800 ℃时氧化动力学曲线如图4所示,其动力学方程如下:

动力学方程出发,利用Origin 7.0软件,对数据进行拟合,可得到最佳的n和k值。拟合后得到的800 ℃时氧化动力学曲线如图4所示,其动力学方程如下:

![]() (5)

(5)

图4 800 ℃时涂层的氧化动力学曲线

Fig.4 Oxidation kinetics curve of coating at 800 ℃

其氧化指数为0.436 1,Fe-Ni基合金的氧化指数约为0.571 5,说明稀土改性后,涂层的抗氧化性能得到了提高。50 h以前,氧化过程符合抛物线规律,涂层快速氧化,涂层表面形成针片状氧化膜,该过程发生的化学反应如下:

4Fe+3O2=Fe2O3 (6)

4Cr+3O2=2Cr2O3 (7)

2Cr+Fe2O3=Cr2O3+2Fe (8)

50 h以后,氧化动力学曲线接近于平直的直线,涂层质量增加缓慢,此时主要是Cr元素在已经比较一步致密的氧化膜缺陷中向氧化膜外表面扩散,与空气中的氧发生化学反应,使氧化膜更加致密。

稀土元素在改善Fe-Ni基高温耐磨涂层抗氧化方面的作用机理,主要有以下几点。

1) 稀土的微合金化作用。稀土对改性涂层性能的影响,首先应与其微量固溶和合金化有关。理论分析和测试结果证明,“固溶稀土”主要富集于晶界上和其他晶体缺陷(位错、空位等)处,通过与晶体缺陷或其他元素的交互作用,引起晶界的物理、化学环境和界面能量的改变,并影响其他元素的行为和新相的析出,最终导致涂层组织和性能的变化。在含稀土的涂层中,稀土改善了合金氧化过程的扩散动力学,对O2-向内传输起了抑制作用,相对而言促进了Cr3+的向外扩散,改善了氧化膜的形成和生长机理,生成致密并与涂层本体有很强粘附力的保护性氧化膜,从而使涂层的抗氧化能力大大提高。

2) 稀土的活性元素效应。其影响包括如下几个方面:降低氧化膜的生长速度;改善Cr2O3氧化膜的抗剥落性;促进Cr2O3氧化膜的选择性氧化,降低合金形成Cr2O3膜的临界Cr含量。这样如果合金中的Cr含量保持不变,则能延长Cr2O3膜的保护寿命和提高其自愈能力。

2.3 涂层的高温强韧化机理

图5所示为涂层磨损后的表面形貌。从图5可看出,涂层的表面上出现了犁沟状磨痕、突起和少量的层片状脱落。涂层中的韧塑相是奥氏体组织,在Si3N4磨球作用下,涂层材料被挤压推移到磨球运动路径的两侧,形成”犁沟”状磨痕,两侧堆积隆起。磨球对涂层的显微切削作用导致涂层形成一些突起。另外,在高温下形成的氧化膜与涂层的结合性比较差,在磨球的犁削作用下被去除,形成小块的层片状脱落,但没有明显的剥落坑,因此,涂层的磨损机理是以磨粒磨损为主导,伴随着氧化物剥落。

图6所示为稀土改性Fe-Ni基高温耐磨涂层摩擦因数与时间的关系曲线,其摩擦因数在0.22上下波动(调质45#钢在同等条件下的摩擦因数约为0.5),并且在试验的后期,其摩擦因数呈降低趋势,这是由于细小的磨屑在涂层磨损面和磨球之间成为摩擦副的润滑剂,起到减磨的作用。

图5 涂层经500 ℃磨损后的表面形貌

Fig.5 Surface pattern of coating after wear test at 500 ℃

图6 500 ℃时涂层摩擦因数与时间的关系曲线

Fig.6 Relationship between friction coefficient of coating and time at 500 ℃

稀土改性提高涂层的高温耐磨性能的主要原因在于:1) 添加稀土氧化物后涂层中生成了具有良好高温性能的Cr3Si硬质点,这些硬质点弥散分布于涂层中,提高了涂层的高温硬度,减小了磨球对涂层的显微切削作用;2) 添加稀土氧化物提高了涂层抗高温氧化性能,使高温磨损过程的氧化物的生成速度减缓,降低了氧化物的剥落。

3 结论

1) 稀土改性Fe-Ni基涂层的组织细小,并且形成有益于提高涂层力学性能的化合物Cr3Si。稀土改性后,涂层的平均硬度明显提高。

2) 稀土改性Fe-Ni基涂层抗氧化性能提高,在氧化初期,涂层质量迅速增加,氧化动力学曲线符合抛物线规律;氧化后期,氧化动力学曲线符合平直的直线规律,质量增加缓慢。稀土促进了Cr向涂层/氧化膜界面的扩散,在表层形成致密的富Cr氧化物,阻止氧化的进一步发生。

3) 稀土改性Fe-Ni基涂层的磨损机理为磨粒磨损,伴随氧化膜的脱落。涂层中的Cr3Si硬质相弥散分布于涂层中,提高了涂层的高温硬度,减小了对磨球对涂层的显微切削,同时提高了涂层抗高温氧化性能,减少了氧化物的剥落,从而提高了涂层的高温耐磨性能。

REFERENCES

[1] BAYANIL H, SAEBOORI E. Effect of rare earth elements addition on thermal fatigue behaviors of AZ91 magnesium alloy[J]. Journal of Rare Earths, 2009, 27(2): 255-258.

[2] YI Wei, ZHENG Chang-qiong, FAN Peng, CHENG Shi-hai. Effect of rare earth on oxidation resistance of iron base fluxing alloy spray-welding coating[J]. Journal of Alloys and Compounds, 2000, 311(1): 65-68.

[3] PLAZA J L, HIDALGO P, MENDEZ B, PIQUERAS J, DIEGUEZ E. Polishing, chemical etching and thermal treatment effects on surface and electrical properties of Er and Nd-doped GaSb substrates[J]. Materials Science and Engineering B, 2000, 71(1/3): 282-287.

[4] LIU Xiu-bo, YU Rong-li. Effects of La2O3 on microstructure and wear properties of laser clad Cr7C3/TiC composite coatings on TiAl intermetallic alloy[J]. Materials Chemistry and Physics, 2007, 101(2/3): 448-454.

[5] SHARMA S P, DWIVEDI D K, JAIN P K. Effect of La2O3 addition on the microstructure, hardness and abrasive wear behavior of flame sprayed Ni based coatings[J]. Wear, 2009, 267(5/8): 853-859.

[6] ZHAO Tao, CAI Xun, WANG Shun-xing, ZHEN Shi-an. Effect of CeO2 on microstructure and corrosive wear behavior of laser-cladded Ni/WC coating[J]. Thin Solid Films, 2000, 379(1/2): 128-132.

[7] WU Chao-feng, MA Ming-xing, LIU Win-jing, ZHONG Min-lin, ZHANG Hong-jun, ZHANG Win-ming. Laser cladding in-situ carbide particle reinforced Fe-based composite coatings with rare earth oxide addition[J]. Journal of Rare Earths, 2009, 27(6): 997-1002.

[8] XU Guo-jian, KUTSUNA M, LIU Zhong-jie, ZHANG Hong. Characteristics of Ni-based coating layer formed by laser and plasma cladding processes[J]. Materials Science and Engineering A, 2006, 417(1/2): 63-72.

[9] LIU Jun-bo, WANG Li-mei, LI Hui-qi. Reactive plasma cladding of TiC/Fe cermet coating using asphalt as a carbonaceous precursor[J]. Applied Surface Science, 2009, 255(9): 4921-4925.

[10] MA Wei, FEI Qun-xing, PAN Wen-xia, WU Cheng-kang. Investigation of laminar plasma remelting/cladding processing[J]. Applied Surface Science, 2006, 252(10): 3541-3546.

[11] LIU Yuan-fu, LIU Xiu-bo, XU Xiang-yang, YANG Si-ze. Microstructure and dry sliding wear behavior of Fe2TiSi/γ-Fe/Ti5Si3 composite coating fabricated by plasma transferred arc cladding process[J].Surface and Coatings Technology, 2010, 205(3): 814-819.

[12] ZHANG Li-min, LIU Bang-wu, YU Hong-ying, SUN Dong-bai. Rapidly solidified non-equilibrium microstructure and phase transformation of plasma cladding Fe-based alloy coating[J]. Surface and Coatings Technology, 2007, 201(12): 5931-5936.

[13] ZHANG Li-min, SUN Dong-bai, YU Hong-ying. Effect of niobium on the microstructure and wear resistance of iron-based alloy coating produced by plasma cladding[J]. Materials Science and Engineering A, 2008, 490(1/2): 57-61.

[14] LU Jin-bin, GONG Jin-xia, LIANG Cun, ZHANG Zhao-jun, ZHANG Rui-jie, LIU Jian-jun. Microstructure and hardness of Fe-based alloy coating reinforced with WC on Q235 steel surface by plasma cladding[J]. Materials for Mechanical Engineering, 2010, 34(9): 31-33.

[15] BI Xiao-qin, YANG Zhong-lei, HU Xiao-li. Microstructure and performance of Ni2Cr cladding formed by plasma surfacing processes[J]. Journal of Material Engineering, 2009(5): 26-29.

[16] XIANG Yong-hua, XU Bin-shi, L? Yao-hui. Study on structures and proper ties of part made by micro plasma arc direct metal formation[J]. Transactions of the China Wedding Institution, 2010, 31(9): 49-52.

[17] ZHANG Li-min, SUN Dong-bai, YU Hong-ying. Characteristics of plasma cladding Fe-based alloy coating with rare earth metal elements[J]. Materials Science and Engineering A, 2007, 452/453: 619-624.

(编辑 龙怀中)

收稿日期:2010-11-30;修订日期:2011-02-20

通信作者:张丽民,工程师,博士;电话:010-82241370;E-mail: zhangliminzlm@163.com

摘 要:为提高Fe-Ni基涂层的高温性能,在Fe-Ni基合金粉末中添加La2O3和Ce2O3的混合物,对涂层的高温氧化行为和高温耐磨损性能进行研究。结果表明:稀土改性Fe-Ni基涂层组织细密、晶粒细小、形成稀土化合物LaNi4Si、Ce2Ni22C3以及硬质相Cr3Si;稀土改性Fe-Ni基涂层具有良好的高温抗氧化性能,在氧化初期,涂层质量迅速增加,氧化动力学曲线符合抛物线规律,在氧化后期,氧化动力学曲线符合直线规律,质量增加缓慢。高温抗氧化性能的提高和Cr3Si硬质相的弥散分布使涂层的高温耐磨性能得到显著的提高。