DOI: 10.11817/j.ysxb.1004.0609.2021-41034

基于聚丙烯的介电复合材料研究进展与挑战

谢浩然,罗 行,周科朝,张 斗

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:

介电电容器因具有功率密度高、充放电速度快和循环寿命长等优点,在脉冲功率武器装备、输变电工程和5G通讯等方面具有广阔的应用前景。聚丙烯(PP)具有高抗击穿强度、低介电损耗和良好的可加工性,是目前商业应用最广泛的介电材料之一,但其介电常数低,储能密度难以提高,很大程度上限制其应用。基于PP的复合或者改性可以有效提高其储能密度,因而成为当前的研究热点。本文综述近年来介电复合材料的分类和存在的问题,将填料/聚合物复合材料和全有机复合材料两种合成策略与PP的储能性能提升联系起来,从无机陶瓷填料/PP、导电填料/PP、核-壳结构填料/PP、三元复合材料、交联、共混、多层结构设计等方面重点讨论PP基介电复合材料的研究进展。最后总结开发高性能PP基介电复合材料面临的挑战,对未来研究进行展望。

关键词:

文章编号:1004-0609(2021)-08-2014-15 中图分类号:TB324 文献标志码:A

引文格式:谢浩然, 罗 行, 周科朝, 等. 基于聚丙烯的介电复合材料研究进展与挑战[J]. 中国有色金属学报, 2021, 31(8): 2014-2028. DOI: 10.11817/j.ysxb.1004.0609.2021-41034

XIE Hao-ran, LUO Hang, ZHOU Ke-chao, et al. Research progress and challenges of polypropylene-based dielectric composites[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2014-2028. DOI: 10.11817/j.ysxb.1004.0609.2021-41034

电容器作为高功率的储能器件,在脉冲电力设备、移动电源系统和混合动力汽车等现代电子电气设备中具有广阔的应用前景[1-7]。随着微电子集成与组装技术的快速发展,电子器件日趋小型化、轻量化,这对电容器所用介电材料的储能及加等工性能提出了更高的要求[8-11]。

介电材料储能密度(Ue)的计算方法如式(1)所示:

(1)

(1)

式中:E是外加电场;ε0是真空介电常数;εr是相对介电常数[12]。从式(1)中可以看到,介电常数和抗击穿电场是决定介电材料储能密度的重要参数。目前,商用薄膜电容器中应用最广泛的介电材料是双轴拉伸聚丙烯(BOPP),其具有高抗击穿强度(约640 kV/mm)、低介电损耗(约0.0002),但是聚丙烯(PP)的介电常数仅为2.2左右,大大限制了其储能密度(<2 J/cm3)[13-16]。低的储能密度意味着需要增加电容器的体积和数量才能满足应用要求,这与电子器件的发展趋势是相违背的。因此,大幅提高介电材料的储能密度已迫在眉睫[17-18]。

传统的介电材料主要分为陶瓷和聚合物两类[19-23]。陶瓷材料通常介电常数较高,特别是铁电陶瓷,例如PbZrTiO3(PZT)、BaTiO3(BT)以及BaSrTiO3(BST)等,介电常数通常大于1000,但同时也存在着介电损耗大、抗击穿强度低和加工性差等缺陷[19-22]。聚合物(如PP、PVDF等)则通常具有高抗击穿强度、低损耗和优秀的可加工性,但介电常数普遍较低(<10)[16, 20, 24-26]。由此可见,单一的传统材料很难同时具有高的介电常数和抗击穿强度。

近年来,随着材料复合技术的不断发展,研究者们发现,通过材料多组元间的复合可以有效地提升材料的综合性能,这为实现介电复合材料抗击穿强度和介电常数的协同提升提供了可能[27-30]。目前,有关介电复合材料的研究一般采取两种策略:第一种策略是将高抗击穿强度的聚合物基体与陶瓷、导电填料相结合,通过提高介电常数或者进一步提高抗击穿强度来改善储能性能[20, 31-36];第二种策略是将高抗击穿强度的聚合物与相对较高介电常数的聚合物复合制备全有机介电复合材料,在提升储能性能的同时希望最大限度地保留聚合物高抗击穿强度和优秀加工性能的优势[16, 37-39]。

由此可见,对于介电复合材料的制备而言,聚合物基体的选择非常关键。PP具有高抗击穿强度、低介电损耗和良好的可加工性,是目前应用最广泛的介电材料之一,在电介质储能领域具有巨大潜力。基于PP的介电复合材料制备可以大大加快高储能电容器的开发,从而适应电力系统的快速发 展[27, 40]。本文作者首先对介电复合材料进行了介绍,概述了研究者们从填料/聚合物复合材料和全有机复合材料两个方向进行的尝试,然后总结了近年来PP基介电复合材料的研究进展,最后提出了开发高性能PP基介电复合材料面临的挑战和未来展望。

1 介电复合材料分类

1.1 填料/聚合物介电复合材料

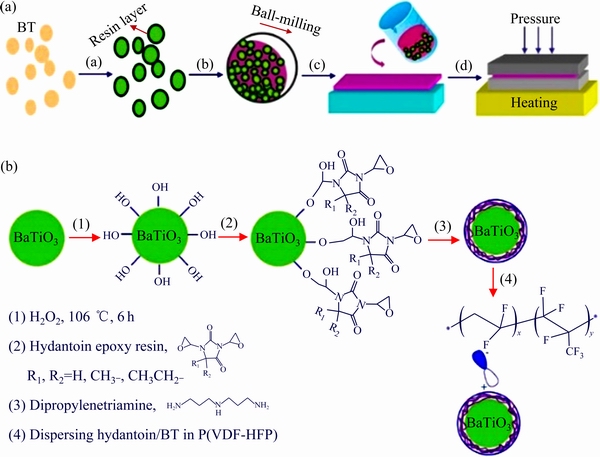

以聚合物为基体与高介电常数的填料进行复合是最常见的策略之一[18, 34-35, 41]。其中,陶瓷/聚合物复合材料是目前研究最广泛的一类介电复合材料,主要是利用陶瓷填料的高介电常数和大量界面引起的界面极化来提高复合材料的介电常数[42-43]。但这类填料往往含量高(>50%,体积分数),尺寸小(一般为纳米级),与聚合物的表面性质存在差异,因而在聚合物基体中极易发生团聚。同时,陶瓷和聚合物介电常数不匹配使得复合材料中电场分布不均匀,容易出现电场局部集中现象。在这种情况下,复合材料介电常数的提高往往是以牺牲抗击穿强度和力学性能为代价[32-34, 44]。为了解决陶瓷填料的分散性、相容性差及与基体介电常数不匹配的问题,研究者们将有机或无机物包覆在陶瓷填料表面制备出核-壳结构填料;一方面可以改变填料的表面性质,降低表面能,使得填料颗粒聚集的情况得到改善;另一方面可以通过在填料表面引入官能团,与聚合物基体形成作用力,提高填料与聚合物基体之间的相容性。同时,壳层的介电常数可控制在填料与基体之间作为过渡层来降低介电常数不匹配的程度[33-34, 36, 45-47]。张斗等[33]使用海因环氧树脂包覆BT作为填料后与P(VDF-HFP)复合,制备流程如图1所示。研究发现,修饰后的BT纳米颗粒在P(VDF-HFP)基体中团聚和相分离的现象得到改善。同时,随着填料含量增加,复合材料介电常数也随之增加且介电损耗一直保持在低水平(低于100 kHz的频率时,介电损耗小于0.065),其中填料含量为20%的复合材料最大能量密度达到了 8.13 J/cm3,约为纯P(VDF-HFP)的两倍。翟继卫等[47]将Al2O3包覆的BT纳米纤维加入到PVDF中,BT纳米纤维表面的Al2O3层可以有效限制载流子迁移,降低空间极化带来的损耗,并且适当的界面区域可以显著提高复合材料的介电常数和抗击穿电场,结果显示,复合材料的放电能量密度达到了12.18 J/cm3,远远高于PVDF的4.8 J/cm3。

除了陶瓷外,以导电材料作为填料来提高介电常数也是一种有效的方法[31, 48-50]。根据逾渗理论,当导电填料含量到达逾渗阈值附近时,介电常数会急剧升高;如果含量继续升高,填料会在复合材料中形成三维连通的网络,引起介电损耗迅速增加[31-32]。因此,针对导电材料/聚合物介电复合材料的设计,一般需要将填料含量控制在逾渗阈值附近,在获得高介电常数的同时避免较大介电损耗的产生。值得注意的是,导电填料的逾渗阈值往往小于20%(体积分数),这意味着使用导电材料作为填料所需的含量远远小于陶瓷,更加容易获得优异的储能性能和力学性能[45, 48-50]。党智敏等[49]通过原位聚合制备的Ag/PI复合薄膜表现出了优异的介电常数,当Ag的含量为12.5%时,复合材料的介电常数达到了400。TJONG等[50]通过溶剂热还原制备了石墨烯片/PVDF复合材料,当石墨烯片含量为0.5%(体积分数)时,复合材料的介电常数从PVDF的7升高至了105。

图1 海因环氧树脂/BT-P(VDF-HFP)复合材料和海因环氧树脂/BT纳米颗粒制备流程示意图[33]

Fig. 1 Schematic diagrams of preparation processes for hydantoin/BT-P(VDF-HFP) nanocomposites(a) and hydantoin/BT nanoparticles(b)[33]

随着对介电复合材料的研究不断深入,研究者们发现单一填料已渐渐无法满足性能要求,例如,陶瓷填料的分散性、相容性差并且需要的含量高,这使得复合材料的力学性能往往较差,而使用导电填料则不可避免地伴随着介电损耗的升高[18]。因此,研究者们尝试同时引入多种陶瓷、导电填料或者辅以分散剂、增容剂等制备三元或多元介电复合材料,期望发挥多元材料的协同效应,实现性能的进一步突破[18, 46, 51-53]。马育红等[52]将BT纳米颗粒固定在石墨烯纳米片表面后作为填料加入到PVDF中,结果表明,与未改性的石墨烯纳米片相比,BT的引入大大改善了填料的分散性,同时还作为连接点加强了填料与基体之间的结合程度。王卓等[53]将纳米级Ba(Fe0.5Nb0.5)O3(BFN)微晶和Ni微晶共同加入到PVDF中,与Ni/PVDF二元复合材料对比发现,BFN可以防止Ni微晶相互接触从而降低介电损耗,同时还可以大大改善复合材料的温度稳定性。当BFN和Ni含量分别为50%和25%时,复合材料在100 Hz频率下获得了475的高介电常数以及0.61的相对较低的介电损耗。

1.2 全有机介电复合材料

近年来,研究者们对全有机介电复合材料越来越感兴趣。聚合物之间相似的表面性质和介电性能,使得复合后可以很好地避免相容性、介电常数不匹配和力学性能下降等问题,研究的重点在于如何提高复合材料的介电常数[54-56]。铁电聚合物,如PVDF基聚合物,由于存在自发极化,具备比大多数聚合物更高的介电常数,但抗击穿强度处于相对较低的水平。以P(VDF-TrFE-CTFE)为例,其介电常数能达到40左右,但抗击穿电场不到400 kV/mm[57-59]。而像上文提到的BOPP则恰恰相反,其介电常数虽然较低(约2.2),但抗击穿电场往往很高(约640 kV/mm)。由此可见,将高介电常数的聚合物和高抗击穿强度的聚合物进行复合是制备高性能介电材料的可行方案。目前,制备全有机介电复合材料的方式主要包括交联、共混和多层结构设计等[55-56, 58-67]。

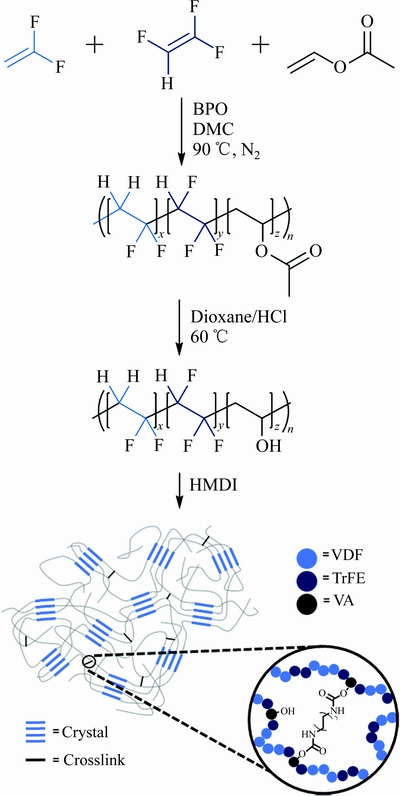

交联聚合物相比常规的介电聚合物,表现出了更大的放电能量密度和更高的放电效率。研究者们发现,交联的分子结构可以有效地充当深陷阱,抑制载流子传输,降低传导损耗,同时,交联网络在放电过程中可以减少偶极子的弛豫时间,降低铁电损耗[60-62]。WANG等[61]在P(VDF-CTFE)中构建了交联网络,发现与熔融拉伸的样品进行对比,交联聚合物的击穿电场、介电损耗和充放电效率得到全面改善。在400 kV/mm电场下,其放电能量密度达到了17 J/cm3,是熔融拉伸样品的两倍以上。LOOS等[63]对P(VDF0.53-ter-TrFE0.37-ter-VA0.10)三元共聚物进行化学交联,合成方法如图2所示,样品在260 kV/mm电场下的剩余极化相比未交联时从1.01 μC/cm2降低至0.15 μC/cm2。

图2 化学交联P(VDF-ter-TrFE-ter-VA)三元共聚物的合成方法[63]

Fig. 2 Synthetic approach towards chemically crosslinked P(VDF-ter-TrFE-ter-VA) terpolymers[63]

共混一般是通过溶液共混或者熔融共混两种方法来实现[55, 64-65]。溶液共混是将两种聚合物在它们的共同溶剂中混合,然后蒸发溶剂成膜,这种方法有利于聚合物的分散。熔融共混则是在高温下将两种聚合物熔融混合后挤出成型,从工业化的角度出发更加简单易行[55, 64-65]。黄兴溢等[64]将P(VDF- TrFE-CFE)与PMMA利用有机溶剂DMF进行共混,复合材料的抗击穿电场从P(VDF-TrFE-CFE)的270 kV/mm提高至了520 kV/mm,放电能量密度从5.4 J/cm3提高至了9.3 J/cm3。BAI等[65]将两种分子量的PVDF(分子量约为180000和441000)高温熔融共混后得到的复合材料的抗击穿电场达到了479 kV/mm,高于两种PVDF原料(412 kV/mm和391 kV/mm)。

多层结构设计是将高介电常数聚合物层与高抗击穿电场聚合物层进行有目的地堆叠,改变材料内部电场分布,增强整体的抗击穿强度。同时,层与层之间的界面还可以有效抑制载流子运动,阻碍电树的传播,从而降低漏电流密度,提高抗击穿强度[58-59, 66-67]。张斗等[58]以高介电常数的P(VDF- TrFE-CTFE)为中间层、高抗击穿电场的PVDF为外层制备了三明治结构复合材料。P(VDF-TrFE-CTFE)含量为25%的样品在660 kV/mm的电场下获得了20.86 J/cm3的放电能量密度。沈洋等[59]将P(VDF-HFP)层和P(VDF-TrFE-CFE)层交替叠层制备了4、8、16层的复合材料。与纯P(VDF-HFP)、P(VDF-TrFE-CFE)对比后发现,通过优化拓扑结 构,可以抑制漏电流以及增强抗击穿强度,复合材料在600 kV/mm的电场下获得了20 J/cm3的放电能量密度。

2 基于聚丙烯的填料/聚合物介电复合材料

2.1 无机陶瓷填料

用于PP的无机陶瓷填料可以分为铁电陶瓷和非铁电陶瓷两类[22, 27]。铁电陶瓷的介电常数与PP差距非常大,以BT为例,其介电常数高达数百甚至数千。如果不对BT纳米颗粒表面进行任何修饰直接作为填料与PP进行复合,容易造成严重的局部电场集中,导致抗击穿电场大幅下降。由此可见,直接使用铁电陶瓷与聚丙烯进行复合反而不利于性能提升[68]。

非铁电陶瓷主要包括SiO2、MgO、TiO2、Al2O3、ZnO等[27]。经研究发现,适当地引入这类填料可以明显改善聚合物的绝缘性能,这对于常作为高压电力电容器和电力电缆绝缘材料的PP来说具有重要意义[27, 69]。TAKALA等[70]将5%(质量分数)的纳米SiO2颗粒加入到PP中,发现AC和DC击穿强度分别提升了19.9%和52.3%。RYTOLUOTO等[71]发现SiO2填料含量较低时(约1%),不会发生明显的团聚,可以实现高质量的分散。他们认为SiO2填料的分散是改善复合材料储能性能的前提,良好的分散可以产生散射效应,从而弯曲载流子的传播路径、降低空间电荷的累积,最终提高抗击穿强度[72]。江秀臣等[73]研究了MgO纳米填料对PP直流绝缘性能的影响,发现低浓度纳米填料(0.5%和1%)的引入可以很好地限制空间电荷和电场畸变,显著改善MgO/PP复合材料的绝缘性能。如果填料浓度过高(3%和6%),则会发生团聚,降低对空间电荷和电场畸变的抑制效果,使得直流击穿强度下降。查俊伟等[74]在PP/SEBS混合物中添加了0.5 phr (每百克份数)的纳米MgO。他们认为加入纳米MgO可以形成一定数量的深陷阱,这些陷阱可以直接捕获空间电荷,表现出优异的空间电荷抑制效果,从而提高抗击穿强度。除了填料浓度外,查俊伟等[75]还研究了填料微观结构对复合材料性能的影响。他们在PP中分别添加了ZnO纳米颗粒、纳米线以及针状晶须,对比了不同结构ZnO填料对复合材料空间电荷、抗击穿强度和导电电流的影响,发现加入ZnO纳米线可以明显改善材料的绝缘性能,而针状晶须结构则更容易积累空间电荷、形成三维导电网络,引起抗击穿强度的下降。

2.2 导电填料

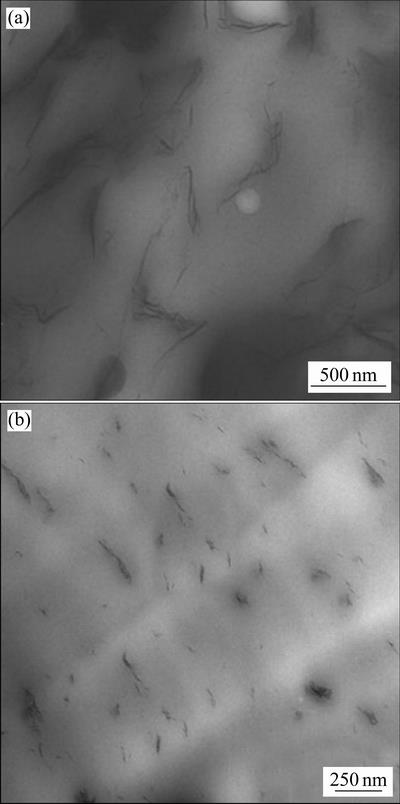

目前常见的导电填料包括金属纳米颗粒、有机导电材料等,复合材料的性能取决于导电填料的浓度、性质以及在聚合物基体中的分散状态[76-77]。PRASHANTHA等[77]探究了不同浓度多壁碳纳米管(MWCNTs)对PP基体性能的影响。他们发现复合材料的介电常数随着MWCNTs含量(质量分数)的增加而加强(低频下超过110),同时,含量超过2%后,介电常数会突然升高,到3%时再趋于稳定,这与逾渗理论是相符的。SHEVCHENKO等[78]通过原位聚合法制备了石墨烯纳米片(GNP)和等规聚丙烯(IPP)的复合材料,复合材料TEM像如图3所示。结果表明,与添加相近浓度MWCNTs的复合材料相比,GNP/IPP的介电常数值要高得多。另外,填料的分散程度会影响到聚集体的长径比,从而影响复合材料性能。党智敏等[79]将PP乳胶与氧化石墨烯混合,然后原位化学还原氧化石墨烯得到了一种渗透阈值仅为0.033%(体积分数)的还原氧化石墨烯/聚丙烯(rGO/PP)复合材料。导电rGO纳米片在复合材料中形成了许多微型电容器,促进rGO/PP界面上的载流子累积产生界面极化,从而提高介电常数。

图3 不同GNP含量复合材料的TEM像[78]

Fig. 3 TEM images of composites with 1.1% pristine GNP(a) and 0.9% sonicated GNP(b)[78]

2.3 核-壳结构填料

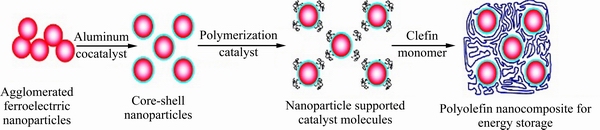

MARKS等[80]使用甲基铝氧烷(MAO)分别对ZrO2、BT、TiO2纳米颗粒以及TiO2纳米棒进行表面处理得到了Al2O3包覆层。Al2O3层可以作为填料与PP基体之间的介电缓冲层,缓解局部电场集中现象,改善储能性能,合成过程如图4所示。复合材料的抗击穿强度保持在590 kV/mm,同时介电常数提高到6.1,最终能量密度达到9.4J/cm3。此外,MARKS等[81]还利用MAO逐层涂覆制备了Al2O3壳层厚度可控的BT和ZrO2纳米颗粒。随着壳层厚度的增加,复合材料的介电损耗明显下降,漏电流也得到抑制。另外,MARKS等[82]还对比了不同厚度Al2O3包覆的BT、ZrO2、MgO、SrTiO3和Ba0.5Sr0.5TiO3纳米颗粒作为填料对性能的影响。结果表明,复合材料的介电损耗随着内部纳米颗粒表面积的增大而增大,通过增加Al2O3壳层厚度可以抑制高电场下的损耗。ZHU等[83]将BT纳米颗粒用TiO2包覆后加入到PP基体中,与未包覆的BT对比发现,介电损耗大大降低。他们认为,介电损耗主要来源于空间电荷在BT纳米颗粒内部以及填料、基体界面处的传导损耗,TiO2包覆层可以有效降低界面处的传导损耗。党智敏等[84]用EPDM包覆BT纳米颗粒后制备了EPDM@BT/PP复合材料,储能密度达到3.06 J/cm3。他们对比了EPDM壳层厚度、拉伸工艺对材料性能的影响,发现适当的壳层厚度除了可以提高BT纳米颗粒在基体中的相容性、分散性外,还可以改善材料的拉伸性能。党智敏等[68]还研究了PMMA包覆的BT颗粒,将其与PP复合后,复合材料的储能密度从1.40 J/cm3提高到了3.86 J/cm3,且保持了94.1%的高放电效率。而未进行包覆的BT纳米颗粒加入到PP基体中后,性能相比于原始PP反而是下降的,储能密度仅为0.83 J/cm3。这也从进一步说明了分散性、相容性的改善对于复合材料储能性能提升的重要性。李琦等[85]希望能改善PP在高温下的储能特性,他们使用与PP基体相容性良好的马来酸酐接枝聚丙烯(PP-g-mah)对MgO纳米颗粒进行包覆。PP-g-mah作为壳层除了可以提供深陷阱抑制载流子运动外,本身的极性分子也有益于介电常数的提高,最终复合材料在120 ℃下的储能密度达到了1.66 J/cm3,是PP的6.15倍,放电效率也保持在90%以上。

对于以导电填料为核、绝缘材料为壳的核-壳纳米填料,绝缘壳层除了改善分散性和相容性外,还起到抑制导电网络形成的作用。MARKS等[86]在Al表面原位包覆了Al2O3壳层,希望通过引入Al2O3绝缘层,在保证Al纳米粒子提升复合材料介电常数的同时,使样品保持低的介电损耗。最终,Al2O3@Al/PP复合材料的介电常数提高至15.4,其中Al含量10.4%的样品获得了14.4 J/cm3的储能密度,同时填料含量低于逾渗阈值的样品都表现出了低的介电损耗(在100 Hz~1 MHz范围内小于0.1)。丁运生等[87]使用离子液体将MWCNTs进行表面处理后与PP复合,发现相比于未处理的MWCNTs,前者可以大大提高复合材料的储能性能。这一现象可以归因于MWCNTs经过表面处理后增加了绝缘壳层,绝缘壳层可以阻碍空间电荷移动,抑制导电网络的形成,从而降低漏电流、减少介电损耗,同时可以增强MWCNTs在PP基体中的分散性和相容性。

2.4 三元复合材料

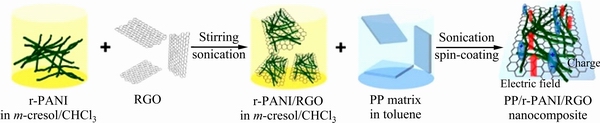

DASARI等[88]在MWNT/PP复合材料的基础上,加入了以钛酸酯偶联剂改性的BT纳米粒子,MWNT的逾渗阈值从3%~5%(质量分数)降低至了2%左右,复合材料在100 Hz下介电常数达到了28,且保持了0.07的低介电损耗。他们认为,较高的聚合物基体黏度通常会导致较高的导电填料渗透阈值,引入BT纳米粒子产生的排斥体积效应以及填料的表面改性都可以明显降低复合材料的熔体黏度,从而降低MWNT的渗透阈值,这对于提升复合材料的介电常数是有利的。JANG等[89]报道了一种应用于高能量密度电容器的聚丙烯/掺杂的聚苯胺/氧化石墨烯(PP/r-PANI/RGO)三元纳米复合材料的制备方法,制备过程如图5所示。具有高电子迁移率和热稳定性的RGO片与r-PANI“面对面”地相互作用可以显著提高r-PANI/RGO填料中载流子的迁移速度,从而在整个PP纳米复合材料中产生更多的电荷陷阱和更高的空间电荷密度,使得复合材料的介电常数提高至51.8,能量密度达到12.6 J/cm3,而介电损耗仅为0.0093。党智敏等[90]以PP-g-mah作为增容剂与功能化石墨烯片(FGS)混合后作为填料与聚丙烯复合,复合材料的渗流阈值在0.535%~0.59%(体积分数)附近,当含量为0.535%时,介电常数达到了15.2。研究结果表明,FGS的表面与增容剂之间存在强相互作用,这大大改善了FGS在基体中的分散性,使得低填料含量下复合材料的力学、热、介电性能获得了显着增强。王东瑞等[91]将四针状氧化锌晶须(T-ZnOw)和BT纳米颗粒加入PP中,发现BT纳米颗粒的加入可以抑制导电网络的形成,降低复合材料的介电损耗,所得的复合材料在1 kHz下介电常数和介电损耗分别为11和0.04。刘文凤等[92]制备了PP-g-mah/ZrO2/PP三元复合材料,研究发现,ZrO2、PP-g-mah都有助于复合材料介电常数的提高,并且PP-g-mah可以改善ZrO2的分散性和相容性从而提升抗击穿强度,相比原始PP,复合材料的储能密度达到1.77 J/cm3,提高了30.2%。

图4 聚烯烃-金属氧化物纳米复合材料的合成示意图[80]

Fig. 4 Schematic illustration of synthesis of polyolefin-metal oxide nanocomposites[80]

3 基于聚丙烯的全有机介电复合材料

3.1 交联

许多研究指出,通过在PP中引入适当的极性官能团,不仅可以提高材料的极化率和结晶度,还可以构建出稳定的交联网络,从而实现复合材料性能的改善[93-96]。CHUNG等[93]对比不同侧基修饰后PP的性能变化,发现OH基团可以增强材料的极化能力,从而提高介电常数,同时PP—OH中偶极子的短弛豫时间保证了高的放电效率,另外,OH基团之间形成的H键可以提供稳定的网络结构改善材料在高电场和高温下的稳定性。最终得到的PP—OH样品能量密度如图6所示,在600 kV/mm的电场下,能量密度达到了7.42 J/cm3。CHUNG等[94]还研究了以丁基苯乙烯(BSt)作为交联剂对PP性能的影响。随着交联密度的升高,复合材料的介电常数、抗击穿电场分别从纯PP的2.27、551.4 kV/mm提升至了2.97、645.1 kV/mm,储能密度超过了5 J/cm3。LANAGAN等[96]将可交联的受阻酚类抗氧化剂基团(HP)通过化学合成引入到PP中,接枝的HP可以限制热分解和载流子传输,从而提高PP的热稳定性、减少介电损耗。

3.2 共混

图5 PP/r-PANI/RGO复合材料制备流程示意图[89]

Fig. 5 Schematic diagram of preparation process of PP/r-PANI/RGO nanocomposite[89]

图6 PP和不同OH含量的PP—OH样品能量密度(其中PP—OH-1、PP—OH-2、PP—OH-3中OH含量分别为0.7%、1.8%、4.2%)[93]

Fig. 6 Energy density of PP and PP—OH with different OH contents (OH contents in PP—OH-1, PP—OH-2 and PP—OH-3 are 0.7%, 1.8% and 4.2%, respectively)[93]

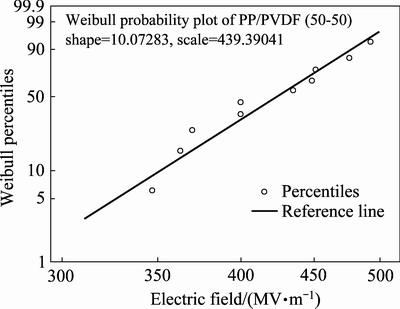

目前工业生产中商业PP膜的主要加工方式是通过高温熔融挤出拉伸,因此在对PP进行改性时许多策略的制定会受到限制。例如,使用填料/聚合物这种策略虽然在一定程度上可以改善性能,但是高含量的填料会在实际工业生产带来像阻塞过滤器、导致生产中断等一系列问题。相比之下,通过聚合物共混改性的方式要更具优势[97-98]。邓元等[99]将PP-g-mah与PP通过简单的溶液共混制备了PP-g-mah含量为0至40%(体积分数)的复合膜。引入的极性酸酐基团可以强化复合材料的极性,同时,由于PP-g-mah与PP之间良好的相容性,介电损耗基本不会随着填料含量的增加而增加。PP-g-mah含量为10%的样品获得了1.96 J/cm3的放电能量密度,放电效率高达96%,其介电常数从纯PP膜的1.72提升至了2.07。BAI等[97]使用含有炭黑填料的PVDF与PP进行共混,复合材料的介电常数随着PVDF含量增加而增加;当PVDF含量为50%(质量分数)时,介电常数达到了4.5,并且介电损耗始终小于0.025。研究者认为炭黑除了可以进一步提高介电常数外,还可以减少共混过程中PVDF与PP分子链之间的摩擦,改善相容性,使得复合材料一直保持低介电损耗。需要注意的是,研究者通过对比实验发现,PP与高分子量PVDF的共混膜质量很差,这是PP和PVDF在熔融拉伸过程中不同的流致结晶行为所致。不同的结晶行为使得凝固过程中出现结晶度不匹配,最终产生相分离和孔隙。考虑到流致结晶很大程度上取决于聚合物的分子量,BAI等[98]使用低分子量的PVDF与PP进行共混,发现相容性果然得到了提高。当PVDF含量为50%时,共混膜的介电常数超过了3.6,介电损耗低至0.0054,击穿强度保持在439 kV/mm,样品抗击穿电场的Weibull分布如图7所示。

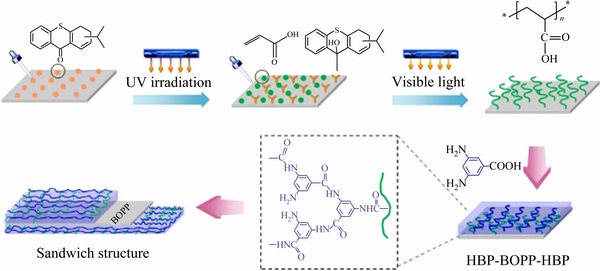

3.3 多层结构设计

图7 PP/PVDF复合材料击穿电场的Weibull分布[98]

Fig. 7 Weibull distribution of breakdown strength for PP/PVDF[98]

图8 三明治结构HBP/BOPP/HBP复合材料的合成示意图[100]

Fig. 8 Schematic illustration of synthesis of sandwich-structured HBP/BOPP/HBP composite[100]

多层结构设计这一策略的出现为解决PP基介电复合材料中高抗击穿电场和高介电常数之间的矛盾提供了新的思路。通过结构设计将PP与具有不同特性的聚合物进行整合,能在提高介电常数的同时保留PP高抗击穿电场、低介电损耗的优势。杨万泰等[100]在BOPP的上下表面接枝超支化芳族聚酰胺(HBP)获得了三明治结构的HBP/BOPP/HBP多层膜,合成过程如图8所示。结果表明,随着HBP层含量的增加,介电常数最高提高至了5.53,而介电损耗仍然保持在0.03之下。研究者认为,介电常数的增加来自于HBP的强极性和HBP/PP界面处的空间电荷极化。需要注意的是,HBP对于复合材料储能特性的改善主要集中于低电场下,外加电场为400 kV/mm时,复合材料的放电能量密度从纯BOPP的1.75 J/cm3提高至了2.32 J/cm3,但在更高的电场下两者几乎没有区别。

4 结论与展望

目前,关于聚丙烯基介电复合材料的研究工作主要集中在填料/聚合物和全有机介电复合材料两方面。引入填料进行性能改善的工艺比较简单,但铁电陶瓷填料对性能的改善往往以牺牲力学性能和抗击穿电场为代价,非铁电陶瓷则对介电常数的提升并不明显;导电填料可以明显提升介电常数,却无法避免高传导损耗;通过建立三元体系或者进行填料表面包覆虽然可以大大改善这些现象,但已知的制备工艺都比较复杂,并不适合工业化生产。全有机介电复合材料相比无机填料/聚合物体系而言拥有更加优秀的力学性能,因此一直是研究的热点,但是也存在着许多的问题。例如采取交联、多层结构设计的策略对性能虽然提升明显,但是工艺复杂、难以大规模生产;共混的工艺相对简单,尤其是高温熔融拉伸这种完全基于BOPP薄膜工业制造的方法,对于最终的工业化应用非常有利,但是目前还没有研究报道过与PP相容性好的高介电常数聚合物,这一问题同时也大大限制了进行多层结构设计时体系的选择。除了复合体系本身存在的缺陷外,更重要的是大多数对于PP基介电复合材料的报道忽略了BOPP与PP的区别,例如,PP经过双轴拉伸变为BOPP的过程中,基体的取向变化会造成填料的取向改变,从而影响复合材料的储能性能。然而,很少有研究者系统研究取向前后性能的变化,甚至很多样品可能根本无法承受住拉伸过程,这与实现工业化的初衷是相互矛盾的。

尽管关于聚丙烯基介电复合材料的研究已经取得了很大的进展,但仍然还无法同时满足高介电常数、高抗击穿电场、高放电效率、优秀的力学性能、热稳定性以及适合工业化生产等要求。为了制备出适合于工业化生产的高性能聚丙烯基介电复合材料,可以考虑开展以下几个方面的研究:1) 探索更为高效的三元复合体系或者核-壳结构模型,在低填料含量下最大限度地提升性能;2) 寻找与PP相容性更好的高介电常数聚合物,简化交联和多层结构复合材料制备过程;3) 加强对复合材料长期稳定性、特殊环境(高温、高电场等)工作可靠性的研究,了解介电材料老化和降解机理;4) 将PP基介电复合材料的研究工作从普通的PP转变为BOPP,这对于工业化应用具有重大的意义。

REFERENCES

[1] MENG N, REN X T, SANTAGIULIANA G, et al. Ultrahigh β-phase content poly(vinylidene fluoride) with relaxor-like ferroelectricity for high energy density capacitors[J]. Nature Communications, 2019, 10(1): 4535.

[2] ZHU Y K, ZHU Y J, HUANG X Y, et al. High energy density polymer dielectrics interlayered by assembled boron nitride nanosheets[J]. Advanced Energy Materials, 2019, 9(36): 1901826.

[3] 沈忠慧, 江彦达, 李宝文, 等. 高储能密度铁电聚合物纳米复合材料研究进展[J]. 物理学报, 2020, 69(21): 105-117.

SHEN Zhong-hui, JIANG Yan-da, LI Bao-wen, et al. Reseach progress of ferroelectric polymer nanocomposites with high energy storage density[J]. Acta PhysicaSinica, 2020, 69(21): 105-117.

[4] 查俊伟, 郑明胜, 党智敏. 铁电聚合物基纳米复合电介质储能材料研究进展[J]. 高电压技术, 2017, 43(7): 2194-2203.

ZHA Jun-wei, ZHENG Ming-sheng, DANG Zhi-min. Research progress of ferroelectric polymer-based composites with high energy density[J]. High Voltage Engineering, 2017, 43(7): 2194-2203.

[5] 蒋婉蓉, 解云川, 张志成. 高储能聚合物基纳米复合电介质[J]. 高电压技术, 2017, 43(7): 2234-2240.

JIANG Wan-rong, XIE Yun-chuan, ZHANG Zhi-cheng. Polymer-based nanocomposite dielectrics with high energy storage capacity[J]. High Voltage Engineering, 2017, 43(7): 2234-2240.

[6] SHEN Y, SHEN D S, ZHANG X, et al. High energy density of polymer nanocomposites at a low electric field induced by modulation of their topological-structure[J]. Journal of Materials Chemistry A, 2016, 4(21): 8359-8365.

[7] 董久锋, 邓星磊, 牛玉娟, 等. 面向高温介电储能应用的聚合物基电介质材料研究进展[J]. 物理学报, 2020, 69(21): 43-58.

DONG Jiu-feng, DENG Xing-lei, NIU Yu-juan, et al. Research progress of polymer based dielectrics for high-temperature capacitor energy storage[J]. Acta Physica Sinica, 2020, 69(21): 43-58.

[8] ZHANG D, LIU W W, GUO R, et al. High discharge energy density at low electric field using an aligned titanium dioxide/lead zirconate titanate nanowire array[J]. Advanced Science, 2018, 5(2): 1700512.

[9] 卢东亮, 陈 龙, 王逸飞. 改性对钛酸钡基陶瓷储能密度的影响[J]. 电源技术, 2017, 41(5): 824-827.

LU Dong-liang, CHEN Long, WANG Yi-fei. Effect of modification on energy storage density of barium titanate based ceramics[J]. Chinese Journal of Power Sources, 2017, 41(5): 824-827.

[10] JIANG J Y, ZHANG X, DAN Z K, et al. Tuning phase composition of polymer nanocomposites towards high energy density and high discharge efficiency by non-equilibrium processing[J]. ACS Applied Materials & Interfaces, 2017, 9(35): 29717-29731.

[11] 欧阳磊, 王晓飞, 臧国忠, 等. Zn2SnO4掺杂对SrTiO3陶瓷烧结温度和储能性能的影响[J]. 功能材料, 2020, 51(2): 2198-2202, 2213.

OU Yang-lei, WANG Xiao-fei, ZANG Guo-zhong, et al. Effect of Zn2SnO4 doping on sintering temperature and energy storage performance of SrTiO3 ceramics[J]. Journal of Functional Materials, 2020, 51(2): 2198-2202, 2213.

[12] GUO M F, JIANG J Y, SHEN Z H, et al. High-energy- density ferroelectric polymer nanocomposites for capacitive energy storage: enhanced breakdown strength and improved discharge efficiency[J]. Materials Today, 2019, 29: 49-67.

[13] WANG Y F, WANG L X, YUAN Q B, et al. Ultrahigh energy density and greatly enhanced discharged efficiency of sandwich-structured polymer nanocomposites with optimized spatial organization[J]. Nano Energy, 2018, 44: 364-370.

[14] 于海生, 王 瑶, 邓 元. 聚丙烯/氮化硼纳米片复合薄膜的制备及介电储能性能研究[J]. 功能材料, 2020, 51(7): 7141-7147.

YU Hai-sheng, WANG Yao, DENG Yuan. Preparation of polypropylene/BNNSs composite films and studies on their dielectric and energy storage properties[J]. Journal of Functional Materials, 2020, 51(7): 7141-7147.

[15] WEN R M, GUO J M, ZHAO C L, et al. Nanocomposite capacitors with significantly enhanced energy density and breakdown strength utilizing a small loading of monolayer titania[J]. Advanced Materials Interfaces, 2017, 5(3): 1701088.

[16] LUO H, ZHOU X F, ELLINGFORD C, et al. Interface design for high energy density polymer nanocomposites[J]. Chemical Society Reviews, 2019, 48(16): 4424-4465.

[17] LAO J P, XIE H A, SHI Z Q, et al. Flexible regenerated cellulose/boron nitride nanosheet high temperature dielectric nanocomposite films with high energy density and breakdown strength[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(5): 7151-7158.

[18] WANG D R, ZHOU T, ZHA J W, et al. Functionalized graphene-BaTiO3/ferroelectric polymer nanodielectric composites with high permittivity, low dielectric loss, and low percolation threshold[J]. Journal of Materials Chemistry A, 2013, 1(20): 6162-6168.

[19] 袁 晰, 王晓宇, 王浩威, 等. 电压特性对压电纤维复合物驱动性能的影响[J]. 中国有色金属学报, 2019, 29(2): 343-349.

YUAN Xi, WANG Xiao-yu, WANG Hao-wei, et al. Effect of voltage characteristic to driving property of piezoelectric fiber composites[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(2): 343-349.

[20] DANG Z M, YUAN J K, YAO S H, et al. Flexible nanodielectric materials with high permittivity for power energy storage[J]. Advanced Materials, 2013, 25(44): 6334-6365.

[21] 张少峰, 袁 晰, 闫明洋, 等. 锆钛酸铅压电陶瓷的流延法制备及其性能[J]. 中国有色金属学报, 2020, 30(2): 326-332.

ZHANG Shao-feng, YUAN Xi, YAN Ming-yang, et al. Preparation and properties of lead zirconate titanate piezoelectric ceramics via tape casting[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(2): 326-332.

[22] LIU S H, XUE S X, ZHANG W Q, et al. Significantly enhanced dielectric property in PVDF nanocomposites flexible films through a small loading of surface- hydroxylated Ba0.6Sr0.4TiO3 nanotubes[J]. Journal of Materials Chemistry A, 2014, 2(42): 18040-18046.

[23] ZHU Y K, JIANG P K, HUANG X Y. Enhancing discharged energy density and suppressing dielectric loss of poly (vinylidene fluoride-ter-trifluoroethylene-ter-chlorofluoroethylene) by a sandwiched structure[J]. IET Nanodielectrics, 2018, 1(4): 127-131.

[24] LI H, LIU F H, FAN B Y, et al. Nanostructured ferroelectric-polymer composites for capacitive energy storage[J]. Small Methods, 2018, 2(6): 1700399.

[25] CHENG S, ZHOU Y, HU J, et al. Polyimide films coated by magnetron sputtered boron nitride for high-temperature capacitor dielectrics[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2020, 27(2): 498-503.

[26] WOLAK M A, WAN A S, SHIRK J S, et al. Imaging the effect of dielectric breakdown in a multilayered polymer film[J]. Journal of Applied Polymer Science, 2012, 123(4): 2548-2557.

[27] CHENG L, CHI X H, YAN C Y, et al. Polypropylene nanocomposite for power equipment: A review[J]. IET Nanodielectrics, 2018, 1(2): 92-103.

[28] HU P H, SHEN Y, GUAN Y H, et al. Topological-structure modulated polymer nanocomposites exhibiting highly enhanced dielectric strength and energy density[J]. Advanced Functional Materials, 2014, 24(21): 3172-3178.

[29] CHI Q G, MA T, ZHANG Y, et al. Excellent energy storage of sandwich-structured PVDF-based composite at low electric field by introduced the hybrid CoFe2O4@BZT-BCT nanofibers[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(1): 403-412.

[30] WANG Y F, WANG L X, YUAN Q B, et al. Ultrahigh electric displacement and energy density in gradient layer-structured BaTiO3/PVDF nanocomposites with an interfacial barrier effect[J]. Journal of Materials Chemistry A, 2017, 5(22): 10849-10855.

[31] PRATEEK, THAKUR V K, GUPTA R K. Recent progress on ferroelectric polymer-based nanocomposites for high energy density capacitors: Synthesis, dielectric properties, and future aspects[J]. Chemical Reviews, 2016, 116(7): 4260-4317.

[32] FENG Y, LI M L, LI W L, et al. Polymer/metal multi-layers structured composites: a route to high dielectric constant and suppressed dielectric loss[J]. Applied Physics Letters, 2018, 112(2): 022901.

[33] LUO H, ZHANG D, JIANG C, et al. Improved dielectric properties and energy storage density of poly(vinylidene fluoride-co-hexafluoropropylene) nanocomposite with hydantoin epoxy resin coated BaTiO3[J]. ACS Applied Materials & Interfaces, 2015, 7(15): 8061-8069.

[34] ZHANG Y, ZHANG C H, FENG Y, et al. Excellent energy storage performance and thermal property of polymer-based composite induced by multifunctional one-dimensional nanofibers oriented in-plane direction[J]. Nano Energy, 2019, 56: 138-150.

[35] 钟少龙, 党智敏. 高储能密度低损耗介电高分子功能复合材料的研究进展[J]. 绝缘材料, 2016, 49(12): 13-18, 27.

ZHONG Shao-long, DANG Zhi-min. Progress of dielectric polymer materials with high energy density and low dielectric loss[J]. Insulating Materials, 2016, 49(12): 13-18, 27.

[36] LUO H, MA C, ZHOU X F, et al. Interfacial design in dielectric nanocomposite using liquid crystalline polymers[J]. Macromolecules, 2017, 50(13): 5132-5137.

[37] CARR J M, MACKEY M, FLANDIN L, et al. Effect of biaxial orientation on dielectric and breakdown properties of poly(ethylene terephthalate)/poly(vinylidene fluoride-co- tetrafluoroethylene) multilayer films[J]. Journal of Polymer Science Part B, 2013, 51(11): 882-896.

[38] YIN K Z, ZHOU Z, SCHUELE D E, et al. Effects of interphase modification and biaxial orientation on dielectric properties of poly(ethylene terephthalate)/poly(vinylidene fluoride-co-hexafluoropropylene) multilayer films[J]. ACS Applied Materials & Interfaces, 2016, 8(21): 13555-13566.

[39] ZHOU Z, CARR J, MACKEY M, et al. Interphase/interface modification on the dielectric properties of polycarbonate/ poly(vinylidene fluoride-co-hexafluoropropylene) multilayer films for high-energy density capacitors[J]. Journal of Polymer Science Part B, 2013, 51(12): 978-991.

[40] DANG B, HU J, ZHOU Y, et al. Remarkably improved electrical insulating performances of lightweight polypropylene nanocomposites with fullerene[J]. Journal of Physics D, 2017, 50(45): 455303.

[41] ZHANG Y, ZHANG C H, FENG Y, et al. Energy storage enhancement of P(VDF-TrFE-CFE)-based composites with double-shell structured BZCT nanofibers of parallel and orthogonal configurations[J]. Nano Energy, 2019, 66: 104195.

[42] ZHANG X, SHEN Y, XU B, et al. Giant energy density and improved discharge efficiency of solution-processed polymer nanocomposites for dielectric energy storage[J]. Advanced Materials, 2016, 28(10): 2055-2061.

[43] LUO H, CHEN S, LIU L H, et al. Core-shell nanostructure design in polymer nanocomposite capacitors for energy storage applications[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(3): 3145-3153.

[44] WANG Y F, CUI J, YUAN Q B, et al. Significantly enhanced breakdown strength and energy density in sandwich-structured barium titanate/poly(vinylidene fluoride) nanocomposites[J]. Advanced Materials, 2015, 27(42): 6658-6663.

[45] ZHANG Q L, JIANG Y C, YU E J, et al. Significantly enhanced dielectric properties of P(VDF-HFP) composite films filled with core-shell BaTiO3@PANI nanoparticles[J]. Surface & Coatings Technology, 2019, 358: 293-298.

[46] WANG Y, YAO M G, MA R, et al. Design strategy of barium titanate/polyvinylidene fluoride-based nanocomposite films for high energy storage[J]. Journal of Materials Chemistry A, 2020, 8(3): 884-917.

[47] PAN Z B, YAO L M, ZHAI J W, et al. Excellent energy density of polymer nanocomposites containing BaTiO3@ Al2O3 nanofibers induced by moderate interfacial area[J]. Journal of Materials Chemistry A, 2016, 4(34): 13259-13264.

[48] ZHANG Q P, ZHU W F, LIANG D M, et al. Core-shell structured CaCO3@CNF for enhanced dielectric properties of polymer nanocomposites[J]. Applied Surface Science, 2019, 487: 77-81.

[49] DANG Z M, PENG B, XIE D, et al. High dielectric permittivity silver/polyimide composite films with excellent thermal stability[J]. Applied Physics Letters, 2008, 92(11): 112910.

[50] HE L X, TJONG S C. Low percolation threshold of graphene/polymer composites prepared by solvothermal reduction of graphene oxide in the polymer solution[J]. Nanoscale Research Letters, 2013, 8: 132.

[51] DANG Z M, SHEN Y, NAN C W. Dielectric behavior of three-phase percolative Ni-BaTiO3/polyvinylidene fluoride composites[J]. Applied Physics Letters, 2002, 81(25): 4814-4816.

[52] ZHANG X H, MA Y H, ZHAO C W, et al. High dielectric performance composites with a hybrid BaTiO3/graphene as filler and poly(vinylidene fluoride) as matrix[J]. ECS Journal of Solid State Science and Technology, 2015, 4(5): N47-N54.

[53] WANG Z, WANG T, FANG M R, et al. Enhancement of dielectric and electrical properties in BFN/Ni/PVDF three- phase composites[J]. Composites Science and Technology, 2017, 146: 139-146.

[54] YANG L Y, LI X Y, ALLAHYAROV E, et al. Novel polymer ferroelectric behavior via crystal isomorphism and the nanoconfinement effect[J]. Polymer, 2013, 54(7): 1709-1728.

[55] ZHANG S H, NEESE B, REN K L, et al. Microstructure and electromechanical responses in semicrystalline ferroelectric relaxor polymer blends[J]. Journal of Applied Physics, 2006, 100(4): 044113.

[56] ZHOU Y J, LIU Q X, CHEN F J, et al. Improving breakdown strength and energy storage efficiency of poly(vinylidene fluoride-co-chlorotrifluoroethylene) and polyurea blend films by double layer structure design[J]. Polymer Testing, 2020, 81: 106261.

[57] CHU B J, ZHOU X, NEESE B, et al. Relaxor ferroelectric poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) terpolymer for high energy density storage capacitors[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2006, 13(5): 1162-1169.

[58] WANG L, LUO H, ZHOU X F, et al. Sandwich-structured all-organic composites with high breakdown strength and high dielectric constant for film capacitor[J]. Composites Part A, 2019, 117: 369-376.

[59] JIANG J Y, SHEN Z H, QIAN J F, DAN Z K, et al. Ultrahigh discharge efficiency in multilayered polymer nanocomposites of high energy density[J]. Energy Storage Materials, 2019, 18: 213-221.

[60] TAN S B, HU X, DING S J, et al. Significantly improving dielectric and energy storage properties via uniaxially stretching crosslinked P(VDF-co-TrFE) films[J]. Journal of Materials Chemistry A, 2013, 1(35): 10353-10361.

[61] KHANCHAITIT P, HAN K, GADINSKI M R, et al. Ferroelectric polymer networks with high energy density and improved discharged efficiency for dielectric energy storage[J]. Nature Communications, 2013, 4: 2845.

[62] LI H, GADINSKI M R, HUANG Y Q, et al. Crosslinked fluoropolymers exhibiting superior high-temperature energy density and charge–discharge efficiency[J]. Energy & Environmental Science, 2020, 13(4): 1279-1286.

[63] MEEREBOER N L, TERZIC I, VAN DER STEEG P, et al. Physical pinning and chemical crosslinking-induced relaxor ferroelectric behavior in P(VDF-ter-TrFE-ter-VA) terpolymers[J]. Journal of Materials Chemistry A, 2019, 7(6): 2795-2803.

[64] ZHU Y K, JIANG P K, HUANG X Y. Poly(vinylidene fluoride) terpolymer and poly(methyl methacrylate) composite films with superior energy storage performance for electrostatic capacitor application[J]. Composites Science and Technology, 2019, 179: 115-124.

[65] FAN B H, XING Z L, BEDOUI F, et al. Improving dielectric strength of polyvinylidene fluoride by blending chains with different molecular weights[J]. Polymer, 2020, 190: 122235.

[66] CHEN C, XING J W, CUI Y, et al. Designing of ferroelectric/linear dielectric bilayer films: an effective way to improve the energy storage performances of polymer- based capacitors[J]. The Journal of Physical Chemistry C, 2020, 124(11): 5920-5927.

[67] CHEN X Y, TSENG J K, TREUFELD I, et al. Enhanced dielectric properties due to space charge-induced interfacial polarization in multilayer polymer films[J]. Journal of Materials Chemistry C, 2017, 5(39): 10417-10426.

[68] LIU B, YANG M H, ZHOU W Y, et al. High energy density and discharge efficiency polypropylene nanocomposites for potential high-power capacitor[J]. Energy Storage Materials, 2020, 27: 443-452.

[69] RAB M A, DHARA R, BASAPPA P. Role of type and content of nanoparticles on certain dielectric characteristics of polypropylene nanocomposites[J]. Journal of Nanophotonics, 2015, 9: 093589.

[70] TAKALA M, RANTA H, NEVALAINEN P, et al. Dielectric properties and partial discharge endurance of polypropylene- silica nanocomposite[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2010, 17(4): 1259-1267.

[71] RYTOLUOTO I, LAHTI K, KARTTUNEN M, et al. Large-area dielectric breakdown performance of polymer films-part Ⅱ: Interdependence of filler content, processing and breakdown performance in polypropylene-silica nanocomposites[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2015, 22(4): 2196-2206.

[72] DANIKAS M G, TANAKA T. Nanocomposites—A review of electrical treeing and breakdown[J]. IEEE Electrical Insulation Magazine, 2009, 25(4): 19-25.

[73] CAO W K, LI Z, SHENG G H, et al. Insulating property of polypropylene nanocomposites filled with nano-MgO of different concentration[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2017, 24(3): 1430-1437.

[74] ZHA J W, WANG Y, LI W K, et al. Electrical properties of polypropylene/styrene-ethylene-butylene-styrene block copolymer/MgO nanocomposites[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2017, 24(3): 1457-1464.

[75] ZHA J W, CHENG Q, YAN H D, et al. Effect of multi-structured zinc oxide on the electrical properties of polypropylene insulating materials[J]. Journal of Physics D: Applied Physics, 2017, 50(30): 305301.

[76] TJONG S C, LIANG G D, BAO S P. Electrical behavior of polypropylene/multiwalled carbon nanotube nanocomposites with low percolation threshold[J]. Scripta Materialia, 2007, 57(6): 461-464.

[77] PRASHANTHA K, SOULESTIN J, LACRAMPE M F, et al. Electrical and dielectric properties of multi-walled carbon nanotube filled polypropylene nanocomposites[J]. Polymers and Polymer Composites, 2010, 18(9): 489-494.

[78] POLSCHIKOV S V, NEDOREZOVA P M, KLYAMKINA A N, et al. Composite materials of graphene nanoplatelets and polypropylene, prepared by in situ polymerization[J]. Journal of Applied Polymer Science, 2012, 127(2): 904-911.

[79] WANG D R, ZHANG X M, ZHA J W, et al. Dielectric properties of reduced graphene oxide/polypropylene composites with ultralow percolation threshold[J]. Polymer, 2013, 54(7): 1916-1922.

[80] GUO N, DIBENEDETTO S A, TEWARI P, et al. Nanoparticle, size, shape, and interfacial effects on leakage current density, permittivity, and breakdown strength of metal oxide-polyolefin nanocomposites: experiment and theory[J]. Chemistry of Materials, 2010, 22(4): 1567-1578.

[81] LI Z, FREDIN L A, TEWARI P, et al. In situ catalytic encapsulation of core-shell nanoparticles having variable shell thickness: Dielectric and energy storage properties of high-permittivity metal oxide nanocomposites[J]. Chemistry of Materials, 2010, 22(18): 5154-5164.

[82] FREDIN L A, LI Z, RATNER M A, et al. Enhanced energy storage and suppressed dielectric loss in oxide core-shell- polyolefin nanocomposites by moderating internal surface area and increasing shell thickness[J]. Advanced Materials, 2012, 24(44): 5946-5953.

[83] ZHANG G Q, BRANNUM D, DONG D X, et al. Interfacial polarization-induced loss mechanisms in polypropylene/ BaTiO3 nanocomposite dielectrics[J]. Chemistry of Materials, 2016, 28(13): 4646-4660.

[84] ZHENG M S, ZHENG Y T, ZHA J W, et al. Improved dielectric, tensile and energy storage properties of surface rubberized BaTiO3/polypropylene nanocomposites[J]. Nano Energy, 2018, 48: 144-151.

[85] ZHOU Y, YUAN C, WANG S J, et al. Interface-modulated nanocomposites based on polypropylene for high- temperature energy storage[J]. Energy Storage Materials, 2020, 28: 255-263.

[86] FREDIN L A, LI Z, LANAGAN M T, et al. Substantial recoverable energy storage in percolative metallic aluminum- polypropylene nanocomposites[J]. Advanced Functional Materials, 2013, 23(28): 3560-3569.

[87] XU P, GUI H G, HU Y D, et al. Dielectric properties of polypropylene-based nanocomposites with ionic liquid- functionalized multiwalled carbon nanotubes[J]. Journal of Electronic Materials, 2014, 43(7): 2754-2758.

[88] YU C R, WU D M, LIU Y, et al. Electrical and dielectric properties of polypropylene nanocomposites based on carbon nanotubes and barium titanate nanoparticles[J]. Composites Science and Technology, 2011, 71(15): 1706-1712.

[89] CHO S H, KIM M, LEE J S, et al. Polypropylene/polyaniline nanofiber/reduced graphene oxide nanocomposite with enhanced electrical, dielectric, and ferroelectric properties for a high energy density capacitor[J]. ACS Applied Materials & Interfaces, 2015, 7(40): 22301-22314.

[90] LI C Q, ZHA J W, LONG H Q, et al. Mechanical and dielectric properties of graphene incorporated polypropylene nanocomposites using polypropylene-graft-maleic anhydride as a compatibilizer[J]. Composites Science and Technology, 2017, 153: 111-118.

[91] HU J Z, ZHANG L, DANG Z M, et al. Improved dielectric properties of polypropylene-based nanocomposites via co-filling with zinc oxide and barium titanate[J]. Composites Science and Technology, 2017, 148: 20-26.

[92] CHENG L, LIU W F, LIU C M, et al. Enhanced energy storage properties of polypropylene/maleic anhydride-grafted polypropylene/nano-ZrO2 ternary system[J]. Journal of Applied Polymer Science, 2019, 136(48): 48211.

[93] YUAN X P, MATSUYAMA Y, CHUNG T C M. Synthesis of functionalized isotactic polypropylene dielectrics for electric energy storage applications[J]. Macromolecules, 2010, 43(9): 4011-4015.

[94] YUAN X P, CHUNG T C M. Cross-linking effect on dielectric properties of polypropylene thin films and applications in electric energy storage[J]. Applied Physics Letters, 2011, 98(6): 062901.

[95] ZHANG G, LI H X, ANTENSTEINER M, et al. Synthesis of functional polypropylene containing hindered phenol stabilizers and applications in metallized polymer film capacitors[J]. Macromolecules, 2015, 48(9): 2925-2934.

[96] YUAN M X, ZHANG G, LI B, et al. Thermally-stable low-loss polymer dielectrics enabled by attaching cross-linkable antioxidant to polypropylene[J]. ACS Applied Materials & Interfaces, 2020, 12(12): 14154-14164.

[97] FAN B H, HE D L, LIU Y, et al. Improved dielectric properties achieved by blending PP and PVDF[J]. IET Nanodielectrics, 2019, 2(2): 78-81.

[98] FAN B H, ZHOU M Y, ZHANG C, et al. Improved dielectric properties in polypropylene/poly(vinylidene fluoride) binary blends containing boron nitride nanosheets: toward high-voltage current application[J]. The Journal of Physical Chemistry C, 2019, 123(18): 11993-12000.

[99] CHEN X Q, WANG Y, HE D L, et al. Enhanced dielectric performances of polypropylene films via polarity adjustment by maleic anhydride grafted polypropylene[J]. Journal of Applied Polymer Science, 2017, 134(27): 45029.

[100] HAN CC, ZHANG X H, CHEN D, et al. Enhanced dielectric properties of sandwich-structured biaxially oriented polypropylene by grafting hyper-branched aromatic polyamide as surface layers[J]. Journal of Applied Polymer Science, 2020, 137(34): 48990.

Research progress and challenges of polypropylene-based dielectric composites

XIE Hao-ran, LUO Hang, ZHOU Ke-chao, ZHANG Dou

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Dielectric capacitors have the advantages of high power density, fast charge and discharge speed, and long cycle life. Therefore, they have broad application prospects in pulse power weapon equipment, power transmission and transformation engineering, and 5G communications. Polypropylene (PP) is one of the most widely used dielectric materials in commercial applications at present, which has high breakdown strength, low dielectric loss and good processability. Nevertheless, its dielectric constant is relatively low, which makes it hard to increase the energy storage density. This disadvantage greatly limits the applications of PP. The composite or modification based on PP can effectively enhance the energy storage density, thus becoming a hot research topic. This paper reviews the classification and existing problems of dielectric composites in recent years, linking the two synthesis strategies of filler/polymer composites and all-organic composites with the improvement of the energy storage performance of PP, and focuses on the research progress of PP-based dielectric composites from the aspects of inorganic ceramic fillers/PP, conductive fillers/PP, core-shell structured fillers/PP, ternary composites, cross-linking, blending, design of multilayer structure, etc. Finally, the challenges for developing high-performance PP-based dielectric composites and the prospects for future research directions were summarized.

Key words: polypropylene; energy storage; dielectric composites

Foundation item: Projects(52002404, U19A2087) supported by the National Natural Science Foundation of China; Project(2020GK2062) supported by the Special Funding Support for the Construction of Innovative Provinces in Hunan Province, China

Received date: 2021-01-29; Accepted date: 2021-06-30

Corresponding authors: LUO Hang; Tel: +86-731-88877196; E-mail: hangluo@csu.edu.cn

ZHANG Dou; Tel: +86-731-88877196; E-mail: dzhang@csu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(52002404,U19A2087);湖南创新型省份建设专项(2020GK2062)

收稿日期:2021-01-29;修订日期:2021-06-30

通信作者:罗 行,副教授,博士;电话:0731-88877196;E-mail:hangluo@csu.edu.cn

张 斗,教授,博士;电话:0731-88877196;E-mail:dzhang@csu.edu.cn

摘 要:介电电容器因具有功率密度高、充放电速度快和循环寿命长等优点,在脉冲功率武器装备、输变电工程和5G通讯等方面具有广阔的应用前景。聚丙烯(PP)具有高抗击穿强度、低介电损耗和良好的可加工性,是目前商业应用最广泛的介电材料之一,但其介电常数低,储能密度难以提高,很大程度上限制其应用。基于PP的复合或者改性可以有效提高其储能密度,因而成为当前的研究热点。本文综述近年来介电复合材料的分类和存在的问题,将填料/聚合物复合材料和全有机复合材料两种合成策略与PP的储能性能提升联系起来,从无机陶瓷填料/PP、导电填料/PP、核-壳结构填料/PP、三元复合材料、交联、共混、多层结构设计等方面重点讨论PP基介电复合材料的研究进展。最后总结开发高性能PP基介电复合材料面临的挑战,对未来研究进行展望。

[3] 沈忠慧, 江彦达, 李宝文, 等. 高储能密度铁电聚合物纳米复合材料研究进展[J]. 物理学报, 2020, 69(21): 105-117.

[4] 查俊伟, 郑明胜, 党智敏. 铁电聚合物基纳米复合电介质储能材料研究进展[J]. 高电压技术, 2017, 43(7): 2194-2203.

[5] 蒋婉蓉, 解云川, 张志成. 高储能聚合物基纳米复合电介质[J]. 高电压技术, 2017, 43(7): 2234-2240.

[7] 董久锋, 邓星磊, 牛玉娟, 等. 面向高温介电储能应用的聚合物基电介质材料研究进展[J]. 物理学报, 2020, 69(21): 43-58.

[9] 卢东亮, 陈 龙, 王逸飞. 改性对钛酸钡基陶瓷储能密度的影响[J]. 电源技术, 2017, 41(5): 824-827.

[11] 欧阳磊, 王晓飞, 臧国忠, 等. Zn2SnO4掺杂对SrTiO3陶瓷烧结温度和储能性能的影响[J]. 功能材料, 2020, 51(2): 2198-2202, 2213.

[14] 于海生, 王 瑶, 邓 元. 聚丙烯/氮化硼纳米片复合薄膜的制备及介电储能性能研究[J]. 功能材料, 2020, 51(7): 7141-7147.

[19] 袁 晰, 王晓宇, 王浩威, 等. 电压特性对压电纤维复合物驱动性能的影响[J]. 中国有色金属学报, 2019, 29(2): 343-349.

[21] 张少峰, 袁 晰, 闫明洋, 等. 锆钛酸铅压电陶瓷的流延法制备及其性能[J]. 中国有色金属学报, 2020, 30(2): 326-332.

[35] 钟少龙, 党智敏. 高储能密度低损耗介电高分子功能复合材料的研究进展[J]. 绝缘材料, 2016, 49(12): 13-18, 27.