Trans. Nonferrous Met. Soc. China 24(2014) 3459-3464

Effect of ultrasonic degassing on performance of Al-based components

H. PUGA, J. BARBOSA, N. Q. TUAN, F. SILVA

CT2M – Centre for Mechanical and Materials Technologies, University of Minho,  4800-058, Portugal

4800-058, Portugal

Received 28 January 2014; accepted 30 June 2014

Abstract:

The effect of high intensity ultrasound based on the novel multi-frequency multimode modulated technology on the final density, porosity, mechanical and fatigue properties of an AlSi9Cu3(Fe) alloy after different processing time was studied. Reduced pressure test was used to evaluate the density of alloys. The tensile and fatigue tests were used to evaluate the static and dynamic properties for the different time of ultrasonic degassing, respectively. It is found that ultrasonic degassing is effective in reduction porosity as well as to improve the final density of castings. Furthermore, the experimental results suggest that the porosity level does not have a substantial influence on the static properties contrary to what is observed on fatigue properties.

Key words:

casting; ultrasound; degassing; porosity; fatigue;

1 Introduction

In the last years, the demand of cost-effective high strength castings for application in industries where superior specific strength is a crucial factor, such as the automotive and aeronautical industries, has significantly increased. On this context, Al-Si-based alloys are the most widely used aluminium alloys for shape casting due to their high fluidity and castability, easy machinability and weldability, good corrosion resistance and mechanical properties. Caceres et al [1] stated that high mechanical strength is usually achieved by the addition of alloying elements such as copper and magnesium as they make the alloys heat treatable, in spite of having a tendency to decrease ductility.

Ammar et al [2] and Teng et al [3] have shown that traditional casting techniques induce high number of defects like porosities, inclusions and coarse microstructure, each of them being characteristic of a specific casting process, which are highly detrimental to the mechanical and fatigue properties of castings. In addition, TANAKA et al [4] also stated that fatigue is considered the most common failure mechanism of engineering components and it is responsible for almost 90% of all service failures attributed to the mechanical causes. Among casting defects, porosity is considered the key factor controlling the fatigue behavior of Al-based castings since they are preferential sites for crack initiation, independent of the loading conditions and the stress applied.

Gruzleski and CLOSSET [5] and Meidani and HASAN [6] have demonstrated that the main source of gas porosities in aluminium castings is hydrogen, which is the only gas with significant solubility in molten aluminium. For this reason, they stated that the hydrogen content in a molten alloy must be kept as low as possible, especially when dealing with high strength casting alloys for critical applications like aerospace or automobile parts.

Taking the traditional application fields of aluminum alloys into consideration, the porosity and mechanical properties are critical factors in the components performance. Thus, it becomes important to develop techniques for treatment of liquid melt leading to a high sanity and microstructural characteristics that ensure the best possible mechanical performance of components, without environmental impact, more efficient and easier to control than those existing today.

Ultrasonic degassing is a possible way to improve hydrogen removal and thus overtake the drawbacks that occur when traditional methods are applied [7-10]. When a liquid metal is submitted to high intensity ultrasonic vibrations, the alternating pressure above the cavitation threshold creates numerous cavities in the liquid metal which intensifies the mass transfer processes and accelerates the diffusion of hydrogen from the melt to the developed bubbles [11]. As acoustic cavitation progresses with time, adjacent bubbles touch and coalesce, growing to a size sufficient to allow them to rise up through the liquid, against gravity, until reach surface promoting degassing of the liquid [11].

The main advantages of ultrasonic degassing are the high degassing rate and the reduced environmental impact of the process. Moreover, cavitation promotes the removal of non-metallic inclusions from the melt, playing a major contribution to obtain high sanity castings.

In this work, the effect of ultrasonic degassing on the final density and porosity is assessed. Furthermore, the type of pores, area fraction, average size and maximum size are assessed and their influence on mechanical and fatigue properties of the AlSi9Cu3(Fe) alloy is presented, for different degassing time. Moreover, simple prediction equations for the fatigue limit incorporating the effect of the shape and size of casting defects on the fatigue strength of material were used.

2 Experimental

2.1 Experimental set-up

The experimental set-up (Fig. 1) used in this work consisted of a novel multi-frequency, multi-mode, modulated technology (MMM) ultrasonic power supply unit, a high power ultrasonic converter (1200 W), acoustic waveguide with 30 mm in diameter and 150 mm in length and the acoustic load which consisted of a Sialon acoustic radiator with 60 mm in diameter and 500 mm in length and the liquid metal.

Degassing tests using ultrasonic frequency of (19.8±0.1) kHz at 60% electric power were carried out for each processing condition: no treatment, time of 1 and 3 min, and melt temperature of (700±5) °C. Before degassing and after each degassing period, 15 cylindrical samples with 14 mm in diameter and 110 mm in length were cast on a metallic mold and used for mechanical and fatigue testing. At the same time, 3 samples for alloy density evaluation, using the reduced pressure test (RPT) and the apparent density measurement method were cast.

2.2 Materials

Melting stocks of AlSi9Cu3(Fe) alloy (Table 1), weighing 6 kg for each ultrasonic treatment were melted in a resistance furnace equipped with a SiC crucible with 210 mm in diameter and 240 mm in height.

2.3 Microstructural and mechanical characterization

Samples for microstructure characterization were taken from each cast sample by sectioning them perpendicularly to its longitudinal axis at half length.

Fig. 1 Laboratory unit for ultrasonic degassing (a) and schematic diagram of experimental apparatus (b)

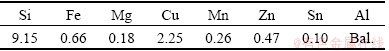

Table 1 Chemical composition of AlSi9Cu3(Fe) alloy (mass fraction, %)

They were ground using 1200 SiC paper and polished up to 1 μm. Those samples used for optical microscopy characterization were etched with Keller’s reagent to reveal the resulting microstructure.

Optical microscopy (OM) and scanning electron microscopy (SEM) with quantitative metallographic analysis capability were used to evaluate the shape and grain size of constituents. Image-ProPlus software was used to quantify the area fraction of porosities and SDAS in fields of 100x.

For tensile testing, specimens were machined from the as-cast samples according to EN 10002-1:tensile testing metallic materials with a gauge length L0 of 50 mm and a cross-sectional diameter d0 of 10 mm. Tensile tests were carried out at room temperature and a strain rate of 0.5 mm/min on a INSTRON testing machine, Model 8874, to obtain yield strength, ultimate tensile strength and strain. At least 12 specimens, with the geometry shown in Fig. 2, were used for fatigue testing under each processing condition. Fatigue tests were performed on a rotating bending machine and life was considered the number of cycles to rupture.

Fig. 2 Schematic diagram of rotating bending fatigue specimen (unit: mm)

3 Results and discussion

3.1 Density and microstructure characteristics

Degassing evaluation was based on the measurement of sample density using the RPT test and the apparent density measurement method, as proposed by Gruzleski and CLOSSET [5]. The degassing efficiency η was calculated from Eq. (2).

(2)

(2)

where d is the theoretical density (2.74 kg/dm3) of alloy, and di and df are density before and after the degassing treatment, respectively.

Figure 3 presents the evolution of the alloy density and porosity with processing time. It is clearly seen an increase in density and a reduction in pore area fraction. It is also clear that the kinetics of ultrasonic degassing is time-dependently changing as hydrogen is removed from the melt, confirming the results of other researchers [7,10]

Fig. 3 Alloy density and area fraction of pores as function of degassing time

The maximum alloy density (2.68 kg/dm3) was obtained after 2 min ultrasonic processing (after 1 min it was already about 97% of the maximum value). In fact, it seems that for the electric power (60%), frequency ((19.8±0.1) kHz) and melt temperature ((700±5) °C) used in this work, 1 min is enough to produce the diffusion of hydrogen from the melt to the developed bubbles and for adjacent bubbles coalesce and grow to a size sufficient to allow them to rise up through the liquid, against gravity, until reaching the surface. For longer degassing time, density remained constant and the difference/balance to the theoretical alloy density is only due to solidification defects. This behavior is due to the mechanism of hydrogen removal from aluminium melts and the effect of acoustic cavitation on that mechanism. In fact, due to the extremely large number of very small bubbles developed in the molten alloy by cavitation, diffusion of hydrogen towards them is very fast.

Table 2 shows the densities obtained by the RPT test, porosity data and secondary dendrite arm spacing (SDAS) values obtained by image analysis of optical micrographs

Table 2 Alloy density, porosity data and microstructural features of cast samples as function of ultrasonic degassing time

According to the experimental results, pore size and density were significantly influenced by the ultrasonic processing time. Two important remarks can be drawn from these results.

1) The number of large pores, considered the most detrimental for fatigue life, drastically decreased with the processing time (Fig. 4) as a consequence of the ultrasonic vibration mechanism of cavitation. These results are according to WU et al [12] who reported that the gas content in melt or slurry of Al-Si alloys decreases with the extension of vibration time. In fact, after 1 min processing, only a small number of hydrogen pores with diameter below 30 μm still remained.

2) Porosity resulting from shrinkage seems also to have been reduced in size (Fig. 4 (c)). In fact, some of the pores observed in materials are shrinkage pores. The microstructures presented in Fig. 4, obtained from polished surfaces, show that shrinkage porosity seems to have almost disappeared after ultrasonic processing and suggest consistent with the results reported by WU et al [12]. When feeding is cut off and the metal continues to solidify, the pressure in the remaining metal pool decreases while segregation causes the gas content to increase. In those places where hot spots occur, porosity is nucleated, but gas must be available for its development. Thus, shrinkage pores start and develop depending on the available dissolved hydrogen.

Fig. 4 Pores characterization as function of degassing time

These remarks are very important for fatigue evaluation since both pores area fraction and their geometrical characteristics are important as fatigue crack risers. In fact, it is well known that mechanical properties of Al-Si alloys depend on several factors, with particular emphasis to size and distribution of porosities [13]. Porosity can be attributed to the inadequate feeding associated to volumetric shrinkage of liquid during solidification and/or to the decrease of hydrogen solubility in Al during cooling. Thus, reducing the content of hydrogen dissolved in the liquid metal (degassing operation) will have a significant impact on the alloy porosity, as well as on their mechanical properties.

3.2 Mechanical and fatigue properties

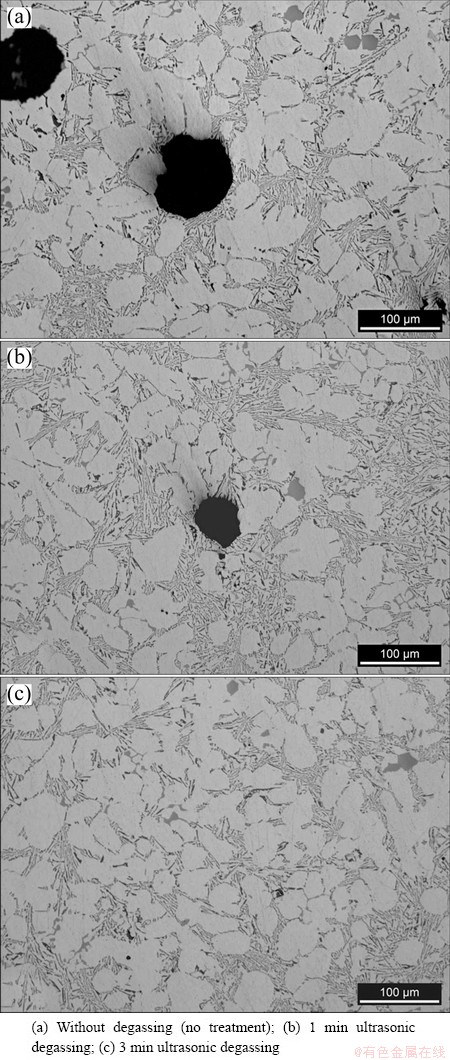

Figure 5 shows the results of tensile tests. It is quite clear that ultrasonic processing has significant effects on the tensile properties. In fact, it has been widely reported that porosity has a small effect on tensile properties, in opposition to what is observed on fatigue properties (Fig. 6). Moreover, only in castings with large pores and high area fraction of porosity, they play a significant role in the mechanical properties. Other metallurgical features, particularly SDAS, which is known to affect the mechanical properties of aluminum alloys, also seem to not be prone to ultrasonic processing, since their values remained almost constant for processing time up to 3 min (Table 2).

Fig. 5 Yield strength, ultimate tensile strength and strain to failure as function of degassing time

The lower elongations measured in the samples are mainly due to the casting defects and the large unmodified eutectic Si particles, with needle-like morphology, characteristic of alloy without process of modifications Si and refinement of grain.

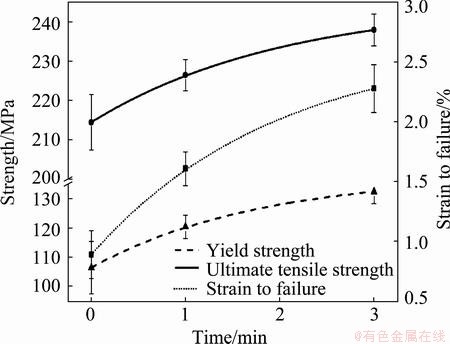

Fig. 6 Stress vs cycle to failure (S-N) curves as function of degassing time

Regarding to Fig. 6, it can be seen that fatigue limit increased by about 30% after 1 min ultrasonic processing and 4% after 3 min processing. The experimental results of the fatigue tests were characterized by medium degree of scatter. As presented in Table 2, the high size and area fraction of the pores on those samples without ultrasonic degassing suggest the most probable cause to the lower limit of fatigue revealed by those samples. To evaluate the experimental data, a set of equations proposed by some authors, which can predict the evolution of fatigue limit with the studied variables, was used. Although typical fatigue limits can be easily seen for iron or titanium- based alloys, in S-N curves of aluminum-based alloys it is not common to reach a plateau. For this reason, a conventional value for fatigue life of 107 cycles was chosen. Moreover, according to Murakami [14], fatigue prediction models based on defects are commonly used for different types of materials.

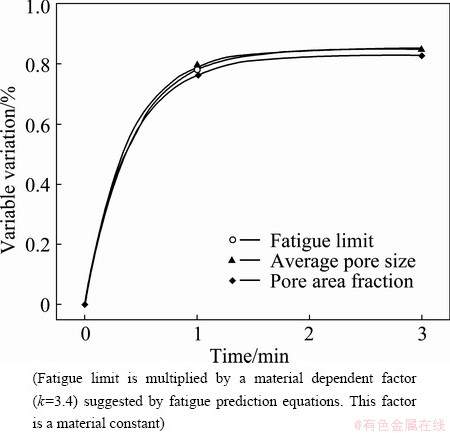

Figure 7 represents properties variation (fatigue limit, average pore size and pores area fraction) as a function of degassing time.

Fig. 7 Properties variation as function of degassing time

Kazinczy [15] proposed an equation allowing to determine the fatigue limit as a function of yield stress (σys) and used a constant representing the defect geometry (k), and the defect size (d). This model is agreement with the experimental results (Fig. 7), since the average defect size decreases with degassing time (Table 2) in the same proportion.

Costa et al [16] developed a model where both volume fraction of defects and their size (diameter) are taken into consideration on fatigue limit. This model is also in line with experimental results since both volume fraction of pores and average size of porosity (Table 2) decrease with degassing time approximately in the same proportion.

Thus, when ultrasonic vibration is applied, the changes in pore geometrical features (average dimension and area fraction) are able to increase fatigue limit of the Al alloy. The increase of fatigue limit is experimentally verified but may also be properly predicted by using most common fatigue limit prediction equations.

Wang et al [17] have reported that when porosity size becomes very small, its influence on fatigue limit may become the same level of other microstructural constituents, such as SDAS and eutectic silicon lamellae thickness. In the present study SDAS measurements were performed to verify if other metallurgical constituents, besides porosity, changed with ultrasonic degassing time and could then be responsible for the detected reduction on fatigue limit. Puga et al [7] have reported that when the ultrasonic vibration is used, metallurgical features change with electric power and melt temperature but they are not affected by the degassing time. Thus, a change in SDAS or other metallurgical features other than porosity was not expected really.

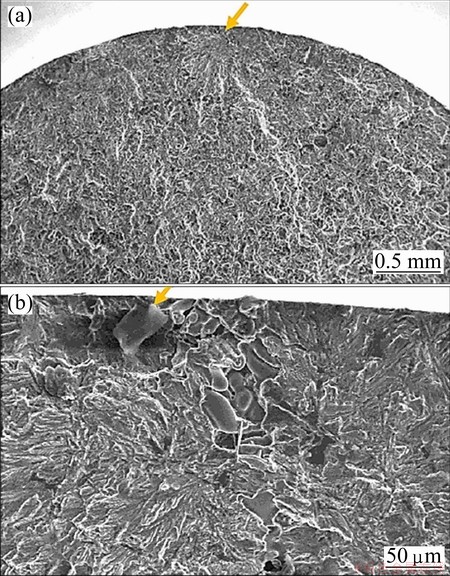

Figure 8 shows the fracture surfaces of the fatigue specimens. The region of crack initiation, steady crack growth and final failure can be characterized. A detailed study of the crack initiation site at 300x of magnification showed that fatigue initiation took place at the porosities and was located closely to the specimen surface. As it was expected, although the porosity level does not have a substantial influence on the static properties, it has a substantial effect on fatigue properties, in particular on fatigue limit.

Fig. 8 SEM images of fatigue specimens with different magnifications

4 Conclusions

1) Ultrasonic degassing seems to be effective in reducing porosity of castings.

2) Ultrasonic degassing seems to act on porosity area fraction as well as on pores size, so that it becomes effective for fatigue improvement.

3) Ultrasonic degassing does not change SDAS spacing.

4) Porosity has a small effect on tensile properties contrary to what is observed on fatigue properties.

Acknowledgements

This research was supported by FEDER/COMPETE funds and by national funds through FCT-Portuguese Foundation for Science and Technology and was developed on the aim of the research project PTDC/EME-TME/119658/2010 and the Post-Doctoral grant SFRH/BPD/76680/2011. Acknowledgements are also to the University of Minho, for the provision of research facilities.

References

[1] CACERES V H, SVENSSON I L, TAYLOR J A. Strength-ductility behaviour of Al-Si-Cu-Mg casting alloys in T6 temper [J]. International Journal of Cast Metals Research, 2003, 15: 531-543.

[2] AMMAR H R, SAMUEL A M, SAMUEL F H. Effect of casting imperfections on the fatigue life of 319-F and A356-T6 Al-Si casting alloys [J]. Materials Science and Engineering A, 2008, 473: 65-75.

[3] TENG X, MAE H, BAY Y, WIERYBICKI T. Pore size and fracture ductility of aluminum pressure die casting [J]. Engineering Fracture Mechanics, 2009, 76: 983-996.

[4] TANAKA K, Nakai Y, Yamashita M. Fatigue growth threshold of small cracks [J]. International Journal of Fracture, 1981, 17(5): 519-533.

[5] Gruzleski J E, Closset B M. The treatment of liquid aluminium-silicon alloys [M]. USA: AFS Publisher, 1990.

[6] Meidani A R N, Hasan M. A study of hydrogen bubble growth during ultrasonic degassing of Al-Cu alloy melts [J]. Journal of Materials Processing Technology, 2004, 147: 311-320.

[7] Puga H, Barbosa J, Seabra E, Ribeiro S, Prokic M. The influence of processing parameters on the ultrasonic degassing of molten AlSi9Cu3 aluminium alloy [J]. Materials Letters, 2009, 63: 806-808.

[8] LI Jun-wen, Momono T, FU Ying, ZHENG Jia, TAYU Y. Effect of ultrasonic stirring on temperature distribution and grain refinement in Al-1.65%Si alloy melt [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(4): 691-697.

[9] ZHANG Yu-bo, LU Yi-ping, JIE Jin-chuan, FU Ying, ZHONG De-shui, LI Ting-ju. Overflowing phenomenon during ultrasonic treatment in Al-Si alloys [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3242-3248.

[10] Xu H, Jian X, Meek T, Han Q. Degassing of molten aluminium A356 alloy using ultrasonic vibrations [J]. Materials Letters, 2004, 58: 3669-3673.

[11] ESKIN G I. Ultrasonic treatment of light alloy melt [M]. Amsterdam: Gordon and Breach Science Publishers, 1998.

[12] WU Shu-sen, LIU Long-fei, MA Qian-qian, MAO You-wu, AN Ping. Degassing effect of ultrasonic vibration in molten melt and semi-solid slurry of Al-Si alloys [J]. China Foundry, 2012, 9(3): 201-206.

[13] SAMUEL A M, SAMUEL F H. Effect of melt treatment, solidification conditions and porosity level on the tensile properties of 319.2 Endchill aluminum castings [J]. Journal of Material Science, 1995, 30(19): 4823-4833

[14] MURAKAMI Y. Metal fatigue: Effect of small defects and non metallic inclusions [M]. Oxford: Elsevier Publishers, 2002.

[15] de Kazinczy F. Effect of small defects on the fatigue properties of medium-strength cast steel [J]. Journal of the Iron and Steel Institute, 1970, 208: 851-855.

[16] Costa N, Machado N, Silva F. A new method for prediction of nodular cast iron fatigue limit [J]. International Journal of Fatigue, 2010, 32(7): 987-995.

[17] Wang Q G, Apelian D, Lados D A. Fatigue behavior of A356/357 aluminum cast alloys, Part II—Effect of microstructural constituents [J]. Journal of Light Metals, 2001, 1: 85-97.

超声波脱气对铝基元件性能的影响

H. PUGA, J. BARBOSA, N. Q. TUAN, F. SILVA

CT2M – Centre for Mechanical and Materials Technologies, University of Minho,  4800-058, Portugal

4800-058, Portugal

摘 要:采用基于多频多模调制技术的高强度超声波对AlSi9Cu3(Fe)合金进行处理,并研究超声处理时间对合金的最终密度、孔隙率,力学和疲劳性能的影响。使用减压试验评估合金的密度和样品的孔隙率。在旋转弯曲机上进行拉伸和疲劳试验,以评估样品分别经不同时间超声波脱气后的静态和动态性能。结果表明,超声波脱气可以有效地减少孔隙率并提高铸件的最终密度。此外,实验结果表明,与疲劳性能相反,孔隙率水平对静态性能没有实质性的影响。

关键词:铸造;超声波;脱气;孔隙率;疲劳

(Edited by Xiang-qun LI)

Corresponding author: H. PUGA; Tel: +351-253510220; Fax: +351-253516007; E-mail: puga@dem.uminho.pt

DOI: 10.1016/S1003-6326(14)63489-0

Abstract: The effect of high intensity ultrasound based on the novel multi-frequency multimode modulated technology on the final density, porosity, mechanical and fatigue properties of an AlSi9Cu3(Fe) alloy after different processing time was studied. Reduced pressure test was used to evaluate the density of alloys. The tensile and fatigue tests were used to evaluate the static and dynamic properties for the different time of ultrasonic degassing, respectively. It is found that ultrasonic degassing is effective in reduction porosity as well as to improve the final density of castings. Furthermore, the experimental results suggest that the porosity level does not have a substantial influence on the static properties contrary to what is observed on fatigue properties.