Aging properties and microstructures of Ti-B20 titanium alloy

GE Peng(葛 鹏)1,2, ZHAO Yong-qing(赵永庆)1, ZHOU Lian(周 廉)1

1. Northwest Institute for Non-ferrous Metal Research, Xi’an 710016, China;

2. School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an 710049, China

Received 28 July 2006; accepted 15 September 2006

Abstract:

A new metastable beta titanium alloy of Ti-Al-Mo-V-Cr-Fe-Zr-Sn system was designed and named Ti-B20. In order to investigate the aging properties and microstructures of the new alloy subjected to different solution treatments, the tensile and Vickers hardness tests were carried out and the optical microscope and scanning electron microscope analysis were performed. The results show that the new alloy displays rapid aging response, high age strengthening effect and fine deposition. In addition, beta solution results in ultra high age hardening effect with low tensile ductility, whereas excellent combination of aging strength and ductility can be obtained after solution treated below beta transus temperature.

Key words:

beta titanium alloy; Ti-B20; aging treatment; tensile properties; microstructure;

1 Introduction

Metastable beta titanium alloys can be strengthened over a considerable range by precipitation hardening and they also exhibit excellent hot and cold formability, deep hardening characteristics and superior corrosion resistance. All these advantages make metastable beta titanium alloys become attractive materials for the applications in critical high-stress and corrosive service [1-7]. Molybdenum equivalent is often considered to evaluate the overall beta stability for a beta titanium alloy. In order to retain 100% beta upon quenching from above the beta transus, the molybdenum equivalent value of about 10(according to the experimental formula in Ref.[5]) is required. For some historical reasons, the molybdenum equivalent values of most commercial metastable beta titanium alloys are relatively high, which leads to a series of negative influences on aging response such as slow response rate, low hardening effect and inhomogeneous precipitation[8-9]. Therefore, it is necessary to develop a new metastable beta titanium alloy with relatively low molybdenum equivalent. Ti-B20 is such a kind of titanium alloy with 20%(mass fraction, the same below if not mentioned) alloying elements including Al, Mo, V, Cr, Fe, Zr and Sn. The total amount of beta stabilizer in this alloy is 12% and the nominal molybdenum equivalent is 10.3. This paper presents the tensile properties and microstructures of the new metastable beta titanium alloy.

2 Experimental

The test material used for this study came from a vacuum arc re-melted 25 kg ingot of Ti-B20 alloy, which was forged at 1 050 ℃ then hot-rolled into bars with diameters of 18 mm at 830 ℃. Table 1 shows the chemical composition of the bars. The metallographic observations indicate that the beta transus temperature of this alloy was about 810 ℃. Solution treatment was carried out as heated at different temperatures for 30 min and water quenched. Progress of aging was determined by Vickers hardness measurement (load of 98 N). Tensile testing specimens were machined into cylindrical shape with 25 mm gage length and 5.00 mm diameter and were tested on an Instron 1185 Universal Testing Machine at room temperature (25 ℃). The tests were conducted using a 1 mm/min mean crosshead rate through 0.2% yield, and a 5 mm/min mean crosshead rate thence to failure. Optical microscope (OM), scanning electron microscope (SEM) and X-ray diffraction (XRD) analysis were performed to characterize the alloy.

3 Results and discussion

3.1 Microstructures and properties of Ti-B20 alloy after solution treatment

Solution treatment is necessary for beta titanium alloys so as to improve the homogeneity of microstructure and composition or enhance the cold formability and aging response. Considering the near critical molybdenum equivalent of Ti-B20 alloy, both the above and below beta transus solution treatment were selected. In this study, the solution temperatures 750, 780, 830 and 860 ℃ were chosen, respectively. The XRD analysis confirmed that beta solution treatment results in the single beta structure; however, the beta plus alpha can be observed after solution treatment below beta transus temperature.

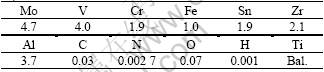

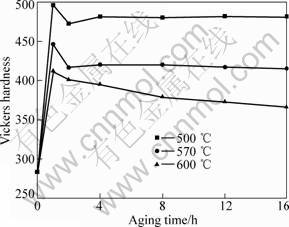

Table 1 Chemical composition of Ti-B20 alloy (mass fraction, %)

Fig.1 shows the optical morphologies of Ti-B20 specimens after water quenching from solution tempera- tures. Figs.1(a) and (b) show that there exist a lot of primary alpha particles in the matrix of Ti-B20 specimens after solution treatment below beta transus temperature and the broken grain boundaries delineated by alpha phase indicate that the grain size is about 20 μm. Solution treatments above the beta transus result in a typical equiaxed beta structure with a grain size of about 100 μm (Figs.1(c) and (d)). It is noticeable that the density of alpha particles in Fig.1(b) is significantly lower than that in Fig.1(a) due to the higher solution temperature.

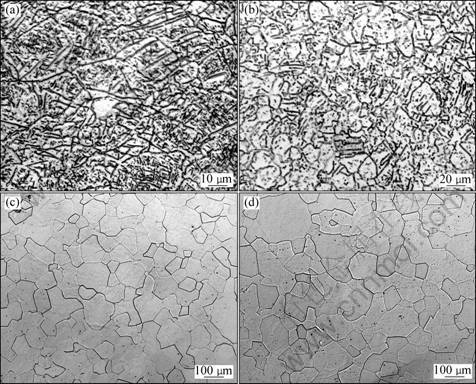

Fig.2 illustrates the tensile properties of Ti-B20 specimens just after solution treatment. The tensile strength decreases with increasing solution temperatures, whereas, the tensile ductility slightly increases. When the solution temperatures exceed the alloy’s beta transus, the change becomes unconspicuous owing to the very similar microstructures. It is notable that the tensile strength of specimens by solution treated at 750 ℃ can achieve 1 000 MPa, which is about 150MPa higher than that after solution treatment above the beta transus (810 ℃). The comparatively high strength could be attributed to the dispersion hardening effect of primary alpha particles and the finer grain size (Fig.1(a)), but the precipitation has also a negative effect on the elongation.

3.2 Aging properties and microstructures of Ti-B20 alloy after beta solution treatment

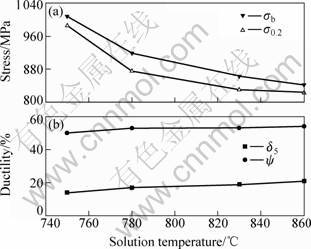

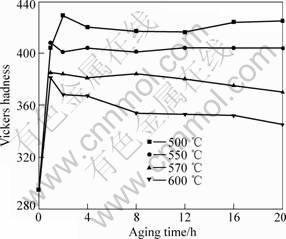

Beta solution plus aging is the most common heat treatment for metastable beta titanium alloys. Fig.3 shows the variation of hardness in Ti-B20 specimens aged at 500, 570 and 600 ℃ after solution treatment at 860 ℃. It is observed that the higher the aging temperature, the lower the hardness. It is about 1 h when the hardness reaches peak values at all testing temperatures. As a comparison, Ti-3Al-8V-6Cr-4Mo-4Zr alloy needs aging at comparatively low aging temperatures and the aging time reaches the peak value usually after 10 h[10]. After 2 h, a stable stage of hardness can be observed for the specimens aged at 500 and 570 ℃. However, the specimens aged at 600 ℃ show a continuous decrease in hardness.

Fig.1 Optical images of Ti-B20 specimens after water quenching at different temperatures: (a) 750 ℃; (b) 780 ℃, (c) 830 ℃, (d) 860 ℃

Fig.2 Tensile properties of Ti-B20 bars after solution treatment

Fig.3 Hardness variation of Ti-B20 specimens after water quenching from 860 ℃

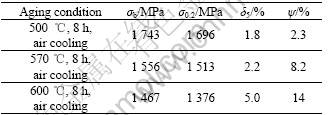

Table 2 lists the tensile properties of Ti-B20 specimens aged at three different temperatures for 8 h after 860 ℃ solution treatment. It can be observed that the aging strength is quite high. The strength achieves 1 700 MPa when the aging temperature is 500 ℃. Even if the aging temperature is 600 ℃, the yield strength is still near 1 400 MPa. In comparison, the yield strength is less than 1 000 MPa for Ti-15V-3Cr-3Sn-3Al alloy aged at 565 ℃ and for Ti-3Al-8V-6Cr-4Zr-4Mo alloy aged at 600 ℃[10]. However, the tensile ductility is too low to fit the practical application of the alloy.

Table 2 Aging properties of Ti-B20 specimens after solution treatment at 860 ℃

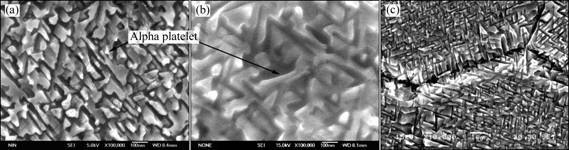

Fig.4 shows a comparison of alpha precipitation for Ti-B20 specimens aged at 500, 570 and 600 ℃ after water quenched from 860 ℃. Here the alpha particles show very fine platelet structure. In Fig.4(a), the thickness of alpha platelet is about 20-30 nm, and in Fig.4(b), the thickness of alpha precipitation is 30-40 nm. Apparently, the higher the aging temperature is, the coarser the size of alpha phase becomes. Hence, the change of strength with aging temperatures can be easily understood. The planar nature of the grain boundary phase as shown in Fig.4(c) and large grain size result in the corresponding long slip path in the beta solution plus aging treated specimens, then high stress concentration and local strain occur at the grain boundaries especially at triple points[11]. In these regions, fracture occurs at low macroscopic strains even though the local strains are not high, which leads to low tensile ductility.

3.3 Aging properties and microstructures of Ti-B20 alloy after solution treated blow beta transus temperature

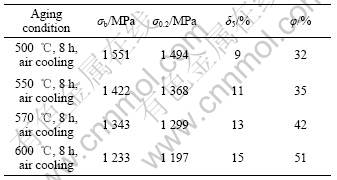

Fig.5 illustrates the hardness variation of Ti-B20 specimens after water quenching from 780 ℃. Compared with Fig.3, the changing tendency of hardness is similar. The difference is that the age hardening effect of Ti-B20 specimens after solution treated at 780 ℃ is significantly lower than that after 860 ℃ solution treatment. Such change can also be displayed by the tensile properties of Ti-B20 specimens listed in Table 3, where the aging strength is about 200 MPa lower than those after water quenching from 860 ℃ at the same aging temperatures. It is noted that the tensile ductility is really good considering the high strength level. Specially, the elongation of specimens is about 9% with the yield strength near 1 500 MPa after aging at 500 ℃. Such combination of high strength and high ductility is quite excellent in metastable beta titanium alloys. Indeed, the tensile ductility of Ti-B20 specimens could be enhance a further by increasing the aging temperatures.

Fig.4 SEM micrographs of alpha precipitation for Ti-B20 specimens aged at different temperatures: (a) 500 ℃; (b) 570 ℃; (c) 600 ℃ for 8 h after water quenching from 860 ℃

Fig.5 Hardness variation of Ti-B20 specimens after water quenching from 780 ℃

Table 3 Aging properties of Ti-B20 specimens after water quenching from 780 ℃

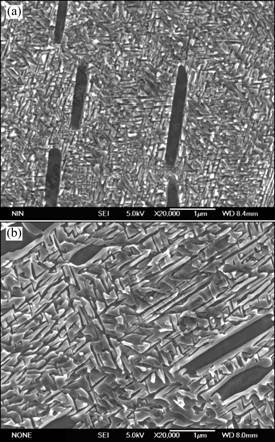

Fig.6 shows the microstructures of Ti-B20 specimens aged at 500 and 570 ℃ after solution treatment at 780 ℃. Obviously, the alpha precipitation aged at 500 ℃ is finer than that aged at 570 ℃. Such change is corresponding to the variation of tensile strength. Additionally, the distribution of primary alpha as showing in Fig.1 is not regular. OKADA, BANERJEE, and WILLIAMS demonstrated that the slip initiates in the beta phase and that parallel alpha plates of the same variant allow dislocations to shear the alpha phase while alpha plates with different orientations promote homogeneous slip[11]. Such kind of aging microstructure in Ti-B20 specimens after solution treatment below beta transus is beneficial to the tensile ductility.

Fig.6 Alpha precipitation of Ti-B20 specimens aged at 500 ℃(a) and 570 ℃ (b) for 8 h after water quenching from 780 ℃

4 Conclusions

1) After solution treatment, it is about 1 h for the hardness of Ti-B20 alloy to reach peak values during aging treatment, which means that the aging response of this alloy is very rapid.

2) The second alpha precipitates of Ti-B20 alloy after solution and aging treatment exhibit very fine platelet structure. In this work, the thickness of alpha platelet changes from 20 nm to 70 nm based on the heat treatment conditions. Generally, the higher the aging temperature, the coarser the alpha platelet thickness and the lower the strength.

3) For Ti-B20 titanium alloy, beta solution results in ultra high age hardening effect with low tensile ductility, whereas excellent combination of tensile strength and ductility can be obtained after solution treatment below beta transus plus aging treatment.

References

[1] Ivasishin O M, Markovsky P E, Semiatin S L, Ward C H. Aging response of coarse- and fine-grained beta titanium alloys[J]. Mater Sci Eng A, 2005, 405: 296-305.

[2] Doraiswamy D, Ankem S. The effect of grain size and stability on ambient temperature tensile and creep deformation in metastable beta titanium alloys[J]. Acta Mater, 2003, 51(6): 1607-1619.

[3] Kazanjian S M, Starke E A Jr. Effects of microstructural modification on fatigue crack growth resistance of Ti-15V-3Al- 3Sn-3Cr[J]. Int J Fatigue, 1999, 21: S127-S135.

[4] TERLINDE G, FISHER G. Beta titanium alloys[A]. Blenkinsop P A, Evans W J, Flower H M. Titanium’95 Science and Technology[C]. London: The Institute of Materials, 1996: 2177- 2194.

[5] Bania P. Beta titanium alloys and their role in the titanium industry[A]. Eylon D, Boyer R R, Koss D A. Beta Titanium Alloy in the 1990’s[C]. Warrendale, Pennsylvania: TMS, 1993: 3-14.

[6] Makino R, Chikaizumi R, Ngaoka T, Furuhara T, Mkino T. Microstructure development in a thermomechanically processed Ti-15V-3Cr-3Sn-3Al alloy[J]. Mater Sci Eng A, 1996, 213: 51-60.

[7] Karasevskaya O P, Ivasishin O M, Semiatin S L, Matviychuk Yu V. Deformation behavior of beta-titanium alloys[J]. Mater Sci Eng A, 2003, 354: 121-132.

[8] Wagner L, Gregory J K. improvement of mechanical behavior in Ti-3Al-8V-6Cr-4Mo-4Zr by duplex aging[A]. Eylon D, Boyer R R, Koss D A. Beta Titanium Alloy in the 1990’s[C]. Warrendale, Pennsylvania: TMS, 1993: 199-209.

[9] Ferrero J G, Wood J R., Russo P A. Microstructural/ mechanical property relationships in bar products of Beta-C (Ti-3Al-8V-6Cr-4Mo-4Zr)[A]. Eylon D, Boyer R R, Koss D A. Beta Titanium Alloy in the 1990’s[C]. Warrendale, Pennsylvania: TMS, 1993: 211-226.

[10] Boyer R R, Welsch G, Collings E W. Materials Properties Handbook-Titanium Alloy[M]. OH: ASM International, Materials Park, 1994: 826-906.

[11] Porter W J, Eylon D. Effect of HIP and heat treatment on fatigue initiation and tensile failure in Ti-15V-3Cr-3Sn-3Al[A]. Eylon D, Boyer R R, Koss D A. Beta Titanium Alloy in the 1990’s[C]. Warrendale, Pennsylvania: TMS, 1993: 273-281.

(Edited by LONG Huai-zhong)

Corresponding author: GE Peng; Tel: +86-29-86231078; E-mail: gepeng1976@sohu.com