Trans. Nonferrous Met. Soc. China 26(2016) 1985-1994

Integration system research and development for three-dimensional laser scanning information visualization in goaf

Zhou-quan LUO, Jun-jie HUANG, Zhen-yan LUO, Wei WANG, Ya-guang QIN

School of Resources and Safety Engineering, Central South University, Changsha 410083, China

Received 14 January 2016; accepted 6 June 2016

Abstract:

An integration processing system of three-dimensional laser scanning information visualization in goaf was developed. It is provided with multiple functions, such as laser scanning information management for goaf, cloud data de-noising optimization, construction, display and operation of three-dimensional model, model editing, profile generation, calculation of goaf volume and roof area, Boolean calculation among models and interaction with the third party soft ware. Concerning this system with a concise interface, plentiful data input/output interfaces, it is featured with high integration, simple and convenient operations of applications. According to practice, in addition to being well-adapted, this system is favorably reliable and stable.

Key words:

goaf; laser scanning; visualization; integration system;

1 Introduction

The goaf formed through underground mining of mineral resources is one of the main disaster sources threatening mine safety production [1,2]. Effective implementation of goaf detection and accurate acquisition of its spatial characteristics including the three-dimensional morphology, the spatial position as well as the actual boundary and volume, are important basis to analyze, predict and control disasters caused by goaf. In recent years, three-dimensional laser scanning technology has been effectively applied in goaf detection [3,4]. Large quantities of point cloud data that are acquired for goaf by means of the three-dimensional laser scanning system are processed relying on relevant engineering software to generate a three-dimensional model for goaf. Then, a general modeling analysis and processing instrument are introduced to perform subsequent three-dimensional analysis and calculation [5,6]. Moreover, related development is also carried out in fields such as three-dimensional detection and visualization of hazardous goaf, detection and analysis of unstable failures in goaf, extraction boundary acquisition in stope, visualized computation of damage index, aided design for pillar recovery, and three-dimensional detection analysis and computation for ore pass collapsing; a favorable practical application effectiveness has been achieved finally [7,8].

However, due to the lack of a processing system exclusively used for the laser scanning point cloud data of goaf, multiple third-party software tools have to be adopted in practice in line with actual application demands to perform follow-up scanning point cloud data processing. In this way, file format conversion and data exchange frequently take place among multiple processing soft wares, which is a waste of plenty of time and energies and significantly inconvenient for corresponding practical applications [9]. With the continuous in-depth research and application of three-dimensional laser detection technology for goaf, it is inevitable to develop a visualized integration processing system for three-dimensional laser scanning information of goaf which is specialized in three-dimensional laser scanning information processing of goaf. In addition, such a system is integrated with functions including goaf information management, three- dimensional model construction, profile generation, cavity volume and roof area obtainment and Boolean operation among models. For this purpose, according to years of experiences in researches and practices, the visualized integration processing system research and development is conducted.

2 Algorithm study

In order to fulfill the function goal of such an integration system, multiple algorithms are developed. Some key algorithms can be described as follows.

2.1 Point cloud modeling algorithm for goaf

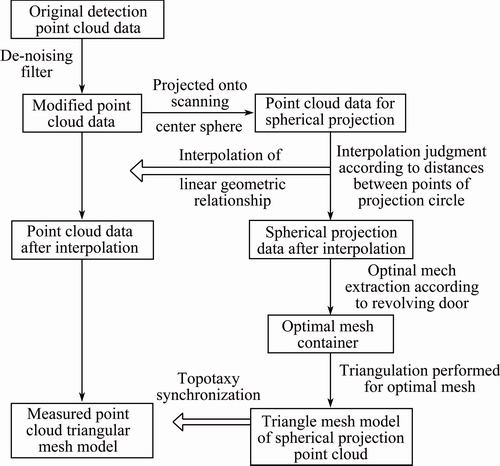

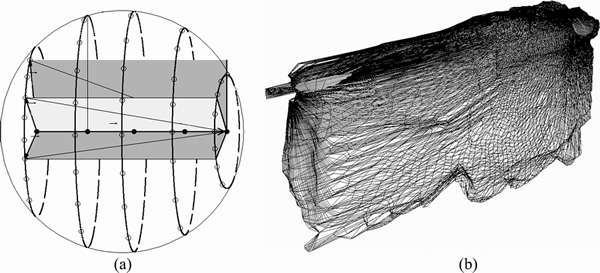

As laser scanning detection conditions under the mine are complicated in goaf, generation of noise points and missing of individual point data are unavoidable, which is able to exert extremely adverse impacts on triangulation of point cloud [10,11]. Aiming at establishing a three-dimensional model for goafs accurately, a grid triangulation modeling algorithm based on rotary surface is developed. Basic procedure of this algorithm is shown in Fig. 1, while Fig. 2 refers to the schematic diagram of this modeling algorithm and its effect picture.

2.2 Algorithm for goaf volume and exposed roof area

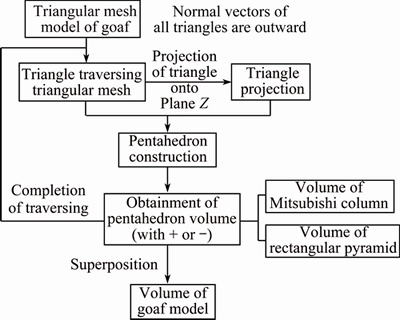

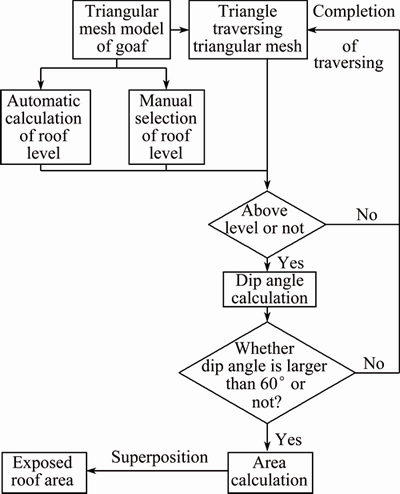

In practice, both the goaf volume and the exposed roof area are not only two essential indicators to evaluate safety characteristics of the goaf, but critical foundations for the implementation of goaf processing [12]. In order to fulfill calculation of them, the computational algorithm is developed for goaf volume and roof area of exposure and their basic procedures are shown in Figs. 3 and 4, respectively.

Fig. 1 Procedure of grid triangulation modeling algorithm based on rotary surface

Fig. 2 Schematic diagram (a) and effect picture (b) of modeling algorithm

Fig. 3 Flow diagram of goaf volume algorithm

Fig. 4 Flow diagram of exposed goaf roof area algorithm

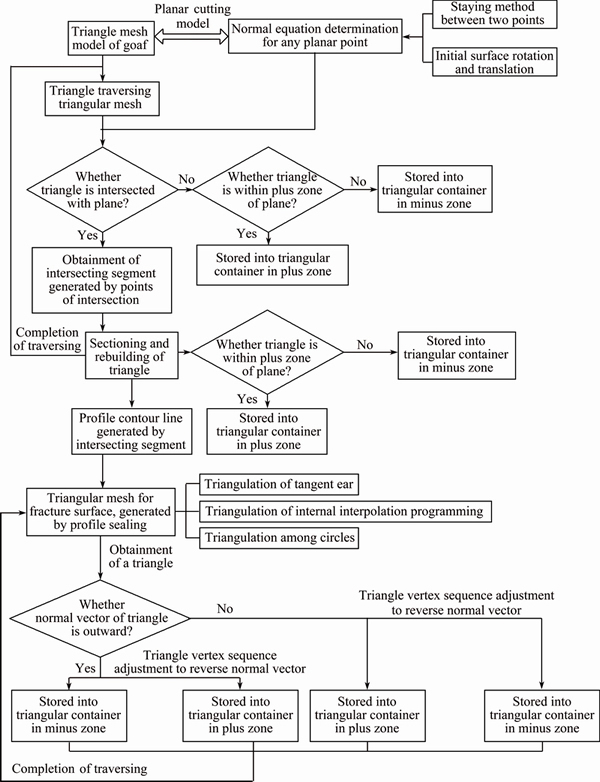

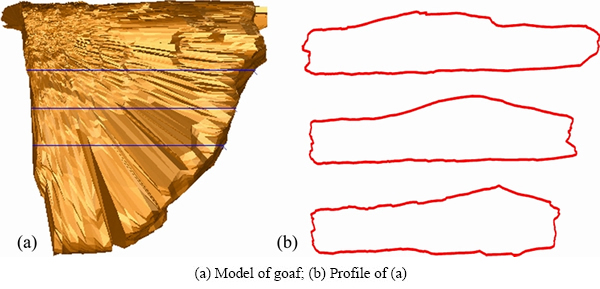

2.3 Algorithm for profile generation in all directions of goaf

Triangulation model for goaf together with its profile is an important representation of its basic morphology and has been widely used in numerous fields such as mining design and goaf safety analysis [13]. Owing to influences of rock joints and fissures, explosion impacts and cavity instability, actual morphologies of goaf are far more complicated and varied. In order to accurately generate its profile contour lines along an arbitrary direction and perform effective sealing for model section, a profile generation algorithm is developed for sophisticated triangulation models in arbitrary directions. Algorithm flow is given in Fig. 5, while Fig. 6 refers to the effect of such an algorithm.

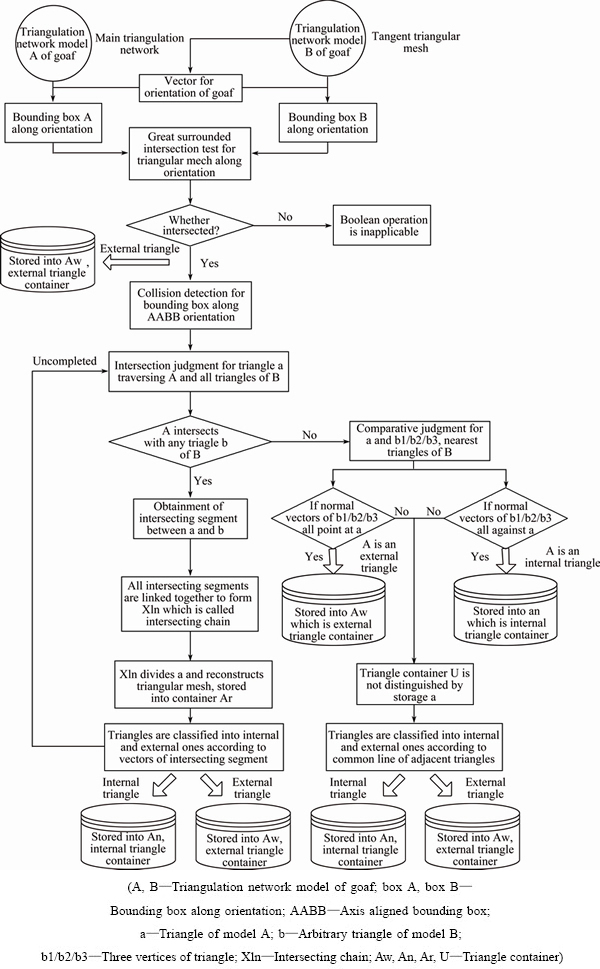

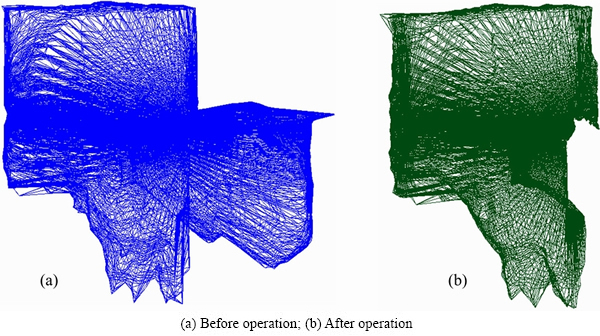

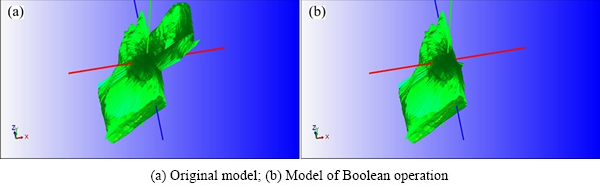

2.4 Boolean operation algorithm among models

The triangular mesh model which is constructed by utilizing goaf point cloud data acquired by laser scanning detection technology has the capability to effectively simulate the sophisticated morphology of goaf. In a practical application, the established goaf model is adopted to carry out back break calculations for ore deposits, goaf instability analysis, model merging and reconstruction as well as comparative analysis of engineering design boundary, moreover, such related work has to be conducted together with Boolean operation among models [14]. Therefore, Boolean operation algorithm is developed for triangular mesh model of goaf so that meet, join and subtraction are implemented among models. The corresponding algorithm flow is shown in Fig. 7, while the algorithm effect can be seen in Fig. 8.

3 Integration system development

3.1 Platform instrument and system interface

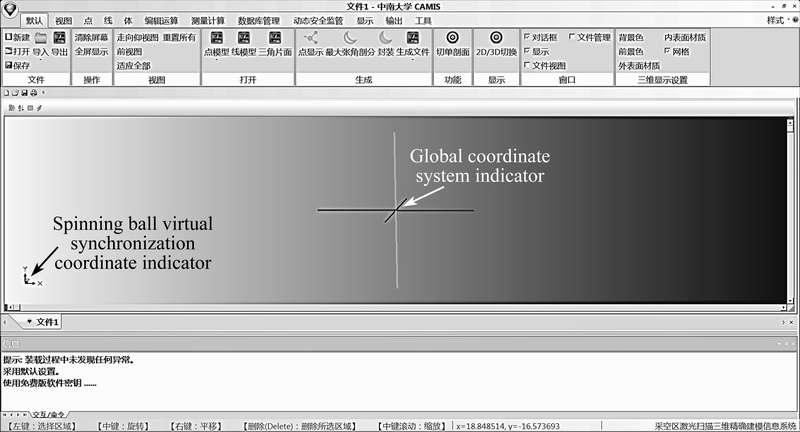

System development platform is Windows 7, and it is developed by employing a powerful Visual C++ development environment and OpenGL which is an open interface [15]. “NW Corner”, a Windows Office interface style of the latest class, is adopted by such a system. Regarding its interface with shorter shortcut bars, color effects become brighter. High compatibility of C++ and OpenGL interface makes the development process simpler, more convenient and more efficient. The interface of this integration system is given in Fig. 9.

According to specific object organization functions such as File Import/Open & Export contained in the default menu, interface menu is used to clear screen, display full screen, restore original data and open tools including the point model, the line model, the triangular plate face as well as 2D & 3D switch. With regard to the tool bar which is a set of icons relevant with functions, users are able to find common functions directly based on it without seeking them from menus. File management shares resemblances with Windows Resource Server; files and directories are managed by virtue of tools such as open, clip, copy, paste and file and folder removing. All sub-files which can be recognized in the working directory are displayed by work field. On work surface of layer, data from various layers are managed to realize the centralized management of multiple layers.

A majority of system operations are carried out in graphic workspace which is a three-dimensional working region. In addition, any file that has been uploaded into this graphics area is provided with coordinates X, Y and Z. Information bar automatically displays some information of objects in the working region, such as the total number of model’s triangular plate faces, model volume and exposed roof area of model. In the status bar, coordinate positions of mouse cursor and function prompts of mouse’s keys are displayed. File type, file path and contents of the information bar of a workspace object are shown in the property panel.

Fig. 5 Flow chart of generation algorithm for goaf triangulation models in arbitrary directions

Fig. 6 Effects of generation algorithm for goaf triangulation models in arbitrary directions

Fig. 7 Flow chart of Boolean operation algorithm among models

Fig. 8 Subtraction algorithm effect among models

Fig. 9 User interface of cvis integration system

3.2 System function and application

The development of such an integration system is on the basis of algorithm study. Main functions of it include the automatic operation of de-noising algorithm when the original detection point cloud data are loaded into system and the de-noising optimization implementation of three-dimensional modeling point cloud data. In the case that the automatic de-noising fails to filter noise points completely, they can be removed manually as supported by the system after those noise points have been confirmed in conformity with engineering experience. After de-noising and the completion of point cloud optimization, a three-dimensional model can be constructed for goaf in this system; besides, both the goaf volume and the roof area can be figured out. In addition to implementing operations of zooming in and zooming out, translation and rotation, etc., for the goaf model, multimode display of such a three-dimensional model under the support of system is convenient for multi-dimensional observations and analysis of the goaf morphology. Sectioning, clipping and Boolean operation among models can also be performed directly at this model. Model measurement which can be performed by two approaches is also supported. To be specific, the distance between two arbitrary points can be measured directly by a mouse after the model is displayed as a front view; or, it can be implemented by means of intuitive grid measurement. Furthermore, multiple management functions incorporating the information database management for users and goaf are also realized for the system.

3.2.1 Point cloud data de-noising function

De-noising function is automatically operated when the original detection point cloud data are loaded into system. In the case that the automatic de-noising fails to filter noise points completely, they can be removed manually after those noise points have been confirmed in conformity with engineering experiences so that the de-noising optimization implementation comes true for three-dimensional modeling point cloud data.

3.2.2 Three-dimensional model construction and operation function for goaf

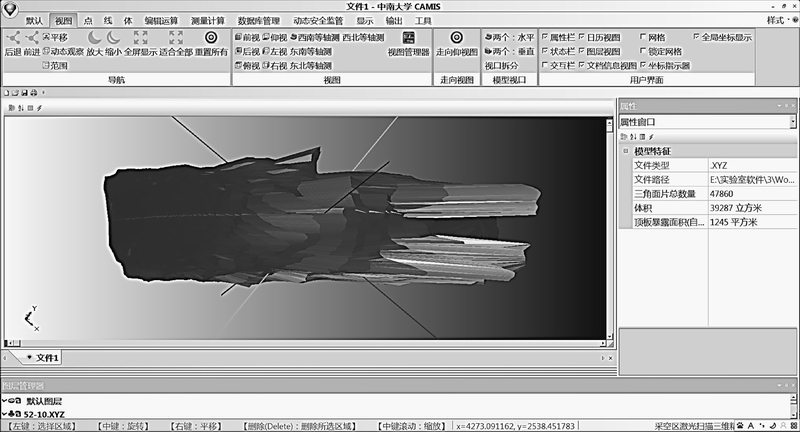

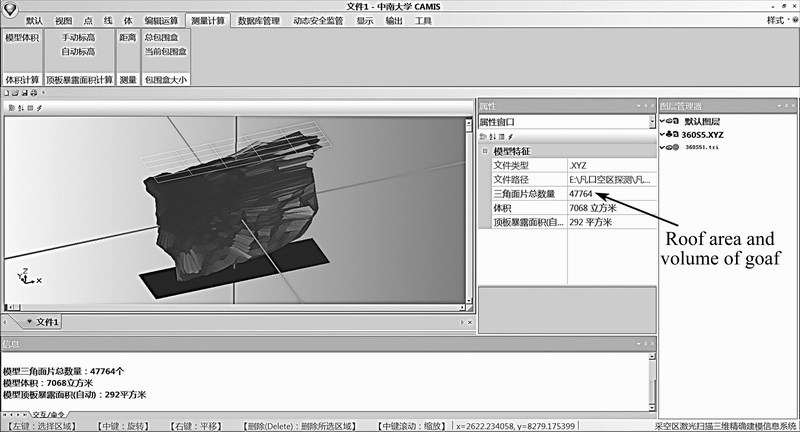

After de-noising and the completion of point cloud optimization, a three-dimensional visualized model can be constructed for goaf in this system; besides, both the goaf volume and the roof area can be figured out (see Fig. 10).

Fig. 10 Interface of goaf’s three-dimensional visualized model constructed in system

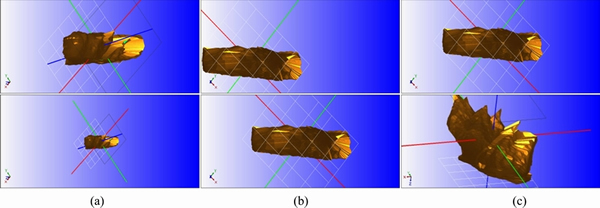

Fig. 11 Model zooming in and out (a), translation (b) and rotation (c) operations

Fig. 12 Model editing function

Fig. 13 Calculation function interface of system

Fig. 14 Boolean operation among models

Fig. 15 Interface of goaf model measurement

Supported by the system, multimode display of the constructed three-dimensional model for goaf includes full-screen display, multi-screen and multi-view display and three-dimensional entity model and point cloud compound display, etc., which is convenient for users to intuitively observe and analyze the morphology of goaf. Operations such as zooming in and zooming out, translation and rotation, can be conducted for the goaf model under the support of system (see Fig. 11).

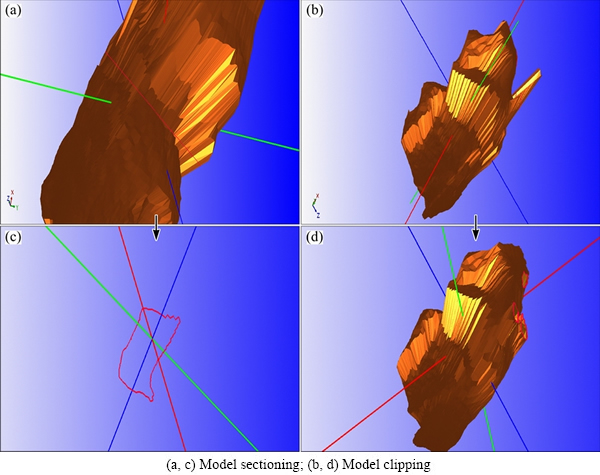

The system is provided with two model editing functions. One is the model sectioning function; the goaf model can be sectioned from an arbitrary direction to generate profiles which can be exported as files in a format of DXF. The other is the model clipping function; clipping of the goaf model can be fulfilled. As for the model editing function, we can refer to Fig. 12.

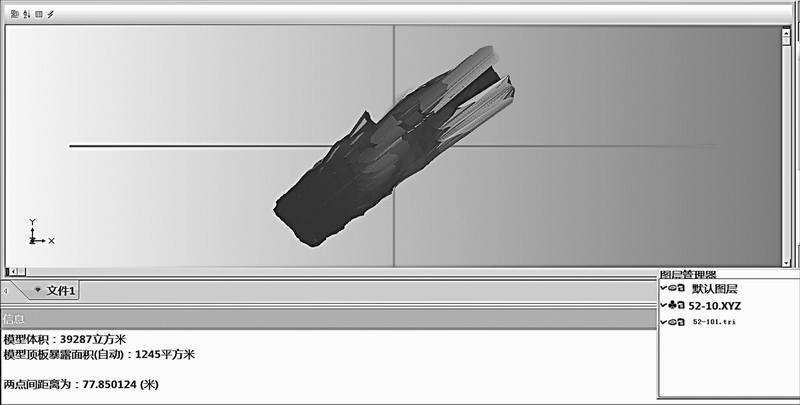

3.2.3 Calculation function of system

The system is equipped with a function that can be utilized to calculate the goaf volume and exposed roof area of goaf (see Fig. 13).

Boolean operation among models can be implemented in the system (see Fig. 14).

After the model is displayed by means of a front view, which is supported by the system, the actual distance between two arbitrary points of the model can be measured by mouse directly so as to figure out relevant information of length, width and height of the model straightly on the screen (see Fig. 15).

3.2.4 System management function and interactive interfaces with other softwares

Based on the system management function, system users and database can be administrated in an effective manner. User management consists of the addition, inquiry, modification and removal of system users as well as user password changes and access control. Then, database management covers the database login and logout, the mine information query, modification and removal, the goaf information query, modification and removal, and the import, export and removal of original cavity detection data.

A variety of interfaces are developed for the system. Not only are three-dimensional software interactions with CAD, Dimine, 3Dmine and Surpac implemented, but docking with other commonly used software is also realized.

4 Conclusions

1) Multiple algorithms including laser scanning point cloud noise point filtering for goaf, three- dimensional modeling for laser scanning point cloud, profile generation in arbitrary directions, calculations of volume and exposed roof area, and Boolean operation among models, etc., are established to form a key technology of visualized goaf modeling and processing based on three-dimensional laser detection scanning.

2) An integration system for three-dimensional laser scanning information visualization of goaf specially used for the processing of three-dimensional laser scanning spatial information of goaf is developed. Practicality of it indicates that the developed well-adapted integration system has favorable stability and reliability and it is able to satisfy actual application demands of information management, three-dimensional visualized representa- tion, computational analysis and profile generation, required by the goaf of mines. Moreover, it also lays a foundation for system upgrading, the further integration with functions such as goaf stability analysis and calculation, goaf treatment scheme generation, and the realization of safety assessment warning and disaster control for goaf.

References

[1] LOU S H, YANG B, LUO Z Q. Three-dimensional information acquisition and visualization application in goaf [J]. Procedia Engineering, 2014, 84(4): 860-867.

[2] BROWN M, HOBDEN S. Effective goaf gas capture design at Ravensworth underground mine [J]. International Journal of Mining Science & Technology, 2014, 24(3): 379-383.

[3] Optech System Corporation. Cavity monitoring system wireless user manual [M]. Toronto: Optech System Corporation, 2004.

[4] BERALDIN J A, BLAIS F, LOHR U. Three dimensional laser scanning technology [M]. Scotland, UK: CRC Press, 2010.

[5] LUO Z Q, LIU X M, ZHANG B, LU H, LI C. Goaf 3D modeling and correlative techniques based on goaf monitoring [J]. Journal of Central South University of Technology, 2008, 15(5): 639-644.

[6] SLATTERY K T, SLATTERY D K, PETERSON J P. Road construction earthwork volume calculation using three-dimensional laser scanning [J]. Journal of Surveying Engineering, 2012, 138(2): 96-99.

[7] STUTTLE M C. Laser scanning aids underground mine mapping [J]. Mining Engineering, 1999, 51(3): 45-46.

[8] PALAMARA D R, NICHOLSON M, FLENTJE P, BAAFI E, BRASSINGTON G M. An evaluation of airborne laser scan data for coalmine subsidence mapping [J]. International Journal of Remote Sensing, 2007, 28(15): 3181-3203.

[9] LUO Z Q, LIU X M, SU J H, WU Y B, LIU W P. Deposit 3D modeling and application [J]. Journal of Central South University of Technology, 2007, 14(2): 225-229.

[10] WAND M, BERNER A, BOKELOH M, JENKE P, FLECK A. Processing and interactive editing of huge point clouds from 3D scanners [J]. Computers & Graphics, 2008, 32(2): 204-220.

[11] CICI A. Delineating tree crowns from airborne laser scanning point cloud data using Delaunay triangulation [J]. International Journal of Remote Sensing, 2009, 30(14): 3843-3848.

[12] NOMIKOS P P, SOFIANOS A I, TSOUTRELIS C E. Structural response of vertically multi-jointed roof rock beams [J]. International Journal of Rock Mechanics & Mining Sciences, 2002, 39(1): 79-94.

[13] WANG S, NI P. Application of block theory modeling on spatial block topological identification to rock slope stability analysis [J]. International Journal of Computational Methods, 2014, 11(1): 903-914.

[14] ARMESTO J, LORENZO H, ARIAS P. Modeling masonry arches shape using terrestrial laser scanning data and nonparametric methods [J]. Engineering Structures, 2010, 32(2): 607-615.

[15] REINA G, MULLER T, ERIL T. Incorporating modern openGL into computer graphics education [J]. Computer Graphics and Applications, 2014, 34(4): 16-21.

采空区三维激光扫描信息可视化处理集成系统研发

罗周全,黄俊杰,罗贞焱,汪 伟,秦亚光

中南大学 资源与安全工程学院,长沙 410083

摘 要:研发了集采空区激光扫描信息管理、空区激光探测点云数据去噪优化、空区三维模型构建及可视化显示和操作、模型编辑、剖面生成、空区体积及顶板面积计算、模型间布尔运算以及可与第三方软件交互等多种功能于一体的采空区三维激光扫描信息可视化集成处理系统。此系统具有界面简洁、数据导入导出接口丰富、集成度高及应用操作简便等特点。实践表明,该系统具有良好的稳定性和可靠性,且适应性强。

关键词:采空区;激光扫描;可视化;集成系统

(Edited by Xiang-qun LI)

Foundation item: Project (51274250) supported by the National Natural Science Foundation of China; Project (2012BAK09B02-05) supported by the National Key Technology R&D Program during the 12th Five-year Plan of China

Corresponding author: Jun-jie HUANG; Tel: +86-18670901515; E-mail: junjie8466@163.com

DOI: 10.1016/S1003-6326(16)64309-1

Abstract: An integration processing system of three-dimensional laser scanning information visualization in goaf was developed. It is provided with multiple functions, such as laser scanning information management for goaf, cloud data de-noising optimization, construction, display and operation of three-dimensional model, model editing, profile generation, calculation of goaf volume and roof area, Boolean calculation among models and interaction with the third party soft ware. Concerning this system with a concise interface, plentiful data input/output interfaces, it is featured with high integration, simple and convenient operations of applications. According to practice, in addition to being well-adapted, this system is favorably reliable and stable.