DOI:10.11817/j.ysxb.1004.0609.2020-39498

焊丝成分对6082-T6铝合金焊接接头组织和性能的影响

靳佳霖1,徐国富1, 2,李 耀1,彭小燕1,梁霄鹏1, 2,邓 英1, 2,尹志民1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:

采用ER5356和ER5087焊丝对12 mm厚6082-T6铝合金进行熔化极惰性气体保护焊(MIG)后,通过显微硬度测试、拉伸力学性能测试、光学显微镜(OM)、扫描电镜(SEM)、电子背散射衍射(EBSD)和透射电镜(TEM)等研究焊丝成分对焊接接头力学性能与显微组织的影响。结果表明:采用ER5087焊丝焊接的6082-T6铝合金焊接接头焊缝区晶粒更细小;抗拉强度、屈服强度、断后伸长率以及焊接系数均高于ER5356焊丝焊接的6082-T6铝合金焊接接头的;两种焊丝焊接的6082-T6铝合金焊接接头的硬度最低区域与拉伸断裂位置均在距离焊缝中心10~15 mm处的热影响区,该区域β″强化相聚集长大、粗化,导致析出相强化作用减弱,成为焊接接头性能最薄弱区域。

关键词:

6082-T6铝合金;MIG焊接;焊丝成分;力学性能;显微组织;

文章编号:1004-0609(2020)-01-0001-08 中图分类号:TG146.2 文献标志码:A

6082铝合金属于中等强度Al-Mg-Si系可热处理强化铝合金,具有良好的力学性能、可焊接性和耐腐蚀性等优点,广泛用于高速列车和城市轨道交通车辆领域,从而实现车辆轻量化[1-3]。焊接作为铝合金连接的主要手段,其焊接接头性能与焊接方法,焊接工艺,以及焊丝成分密切相关。目前,铝合金的焊接方法主要有熔化极气体保护焊、变极性等离子弧焊、激光焊、搅拌摩擦焊、电子束焊等[4-6]。其中,熔化极气体保护焊(MIG)具有保护效果好、热功率高、适于高效焊接中大厚度铝合金结构等优点,目前为铝合金焊接最常用的方法,但由于热输入高,易引起焊接接头软化,导致焊接接头力学性能降低,影响了其适应性[7]。为了提高焊接接头性能,国内外学者在激光-MIG复合焊、等离子-MIG复合焊等复合焊接技术[8-10]以及改善焊接速度、补焊技术、焊后热处理等焊接工艺[11-13]方面做了大量的研究工作。

焊丝成分是影响焊缝性能的关键因素之一,由于大多数金属焊后不再进行热处理,因此在焊丝中添加有利于提高焊接接头性能的元素非常关键。HUANG等[14]采用Al-6.3Mg-0.35Sc-0.1Zr-0.1Cr 焊丝焊接7A52铝合金后,发现钪元素的加入可使熔合区晶粒细化,凝固裂纹倾向降低;YOON等[15]研究了填充焊丝5183A(Al-4%Mg,质量分数),4043A(Al-5%Si)和4047A(Al-12%Si)对6061铝合金激光焊接性能的影响,结果表明4047A焊丝可降低凝固裂纹敏感性,使焊接接头屈服和抗拉强度以及可成形性得到改善;易杰等[16]研究了ER4043焊丝和ER5356焊丝对6061-T6铝合金薄板MIG焊缝组织与性能的影响,发现含Cr元素的ER5356焊丝焊接的接头性能更好;PENG等[17]研究了ER5356焊丝与ER5183(含Zr)焊丝对7020铝合金焊接接头力学性能与腐蚀性能的影响,发现后者焊接接头性能优于前者。

6082-T6铝合金厚板作为高速列车和城市轨道交通车辆的重要结构材料,需采用大量焊接连接,而焊接接头的性能直接影响了车辆的安全性。目前对焊丝成分与6082-T6铝合金厚板的焊接接头组织性能相关性的研究尚少。本文采用ER5356焊丝和ER5087焊丝对12 mm厚6082-T6铝合金进行MIG焊接,研究不同焊丝对焊缝组织与性能的影响规律,为提高6082-T6铝合金MIG焊接接头性能和可靠性提供依据。

1 实验

1.1 实验材料

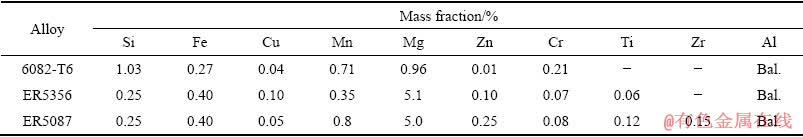

焊接所用基材为12 mm厚6082-T6板材。分别采用ER5356、ER5087焊丝进行MIG焊接,为了描述方便,本实验中,采用ER5356焊丝焊接的6082铝合金焊接接头记为焊接接头1,采用ER5087焊丝焊接的6082铝合金焊接接头记为焊接接头2。实验所用6082-T6铝合金与ER5087、ER5356焊丝化学成分如表1所列。

1.2 实验方法

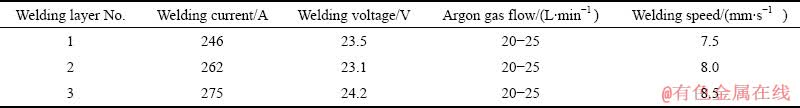

MIG焊接采用机械焊接,保护气体为氩气,试样采用V形对接接头,分3道次进行焊接。焊接工艺参数如表2所列,焊接方向垂直于轧制方向。

室温拉伸力学性能测试在Instron3369型试验机上进行,拉伸速度为2 mm/min,拉伸方向垂直于焊缝轴线方向,且焊缝的轴线位于试样平行段的中间;显微硬度测试在HVS-1000型维氏硬度计上完成,加载载荷为0.981 N,加载时间为15 s,由焊缝中心向两侧基材方向每隔1 mm取点测试。

焊接接头金相显微组织采用Leica DMIL LED倒置显微镜观察,试样采用Keller试剂进行腐蚀。TEM观察在Tecnai G2-20型透射电子显微镜上进行,试样经机械减薄后,再双喷减薄,双喷腐蚀液HNO3与CH3OH体积比为3:7,温度为-25~-30 ℃。采用配有能谱仪(EDS)和电子背散射衍射(EBSD)探头的SIRION200扫描电镜观察拉伸断口形貌、对断口第二相粒子成分以及焊缝与基材晶粒结构进行分析。EBSD样品经打磨、机械抛光后,采用EP06型电解抛光腐蚀仪进行电解抛光,腐蚀液中HCLO4与CH3OH体积比为1:9。

2 结果与分析

2.1 焊接接头硬度分布

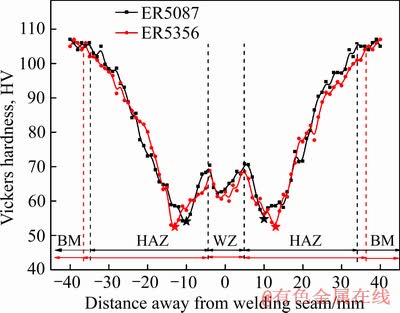

两种焊丝焊接后的焊接接头显微硬度分布如图1所示。从图中可以看出两种焊接接头的硬度分布曲线变化趋势基本一致,均以焊缝(WZ)中心为对称轴,近似对称分布。ER5356、ER5087焊丝焊接接头均在焊缝中心出现第一个硬度低值,分别约为61HV、63HV;从焊缝中心到熔合线附近,硬度值逐渐上升,且在熔合线附近达到一个硬度高值,分别约为69HV、71HV;继续远离焊缝中心,硬度值逐渐降低,进入热影响区(HAZ)。分别在距焊缝中心13 mm、10 mm附近,出现硬度最低值,约为52HV、54HV;之后随着离焊缝中心距离的增大,硬度值逐渐增大,约在36 mm、34 mm处,硬度达到稳定状态,进入基材区(BM),硬度值约为105HV。

由图1可知,在整个焊缝区,焊接接头2的硬度高于焊接接头1的,且焊接接头2热影响区宽度更小。6082-T6铝合金焊接接头热影响区受热循环的影响,在距离焊缝中心10~15 mm处,形成硬度值最低的区域。

表1 6082-T6铝合金与焊丝的化学成分

Table 1 Chemical compositions of 6082-T6 aluminum alloy and welding wires

表2 6082-T6铝合金的MIG焊接工艺参数

Table 2 MIG welding parameters of 6082-T6 aluminum alloy

图1 焊接接头显微硬度分布图

Fig. 1 Microhardness distribution of welded joints

2.2 焊接接头拉伸力学性能

6082-T6铝合金基材和焊接接头的常温拉伸力学性能如表3所列。从表3可以看出:6082铝合金基材的抗拉强度、屈服强度和伸长率分别为324 MPa、304 MPa和17.9%;焊接接头1的抗拉强度、屈服强度分别为201 MPa、143 MPa,伸长率为5.8%,焊接系数为0.62;焊接接头2的抗拉强度、屈服强度分别为206 MPa、155 MPa,伸长率为5.9%,焊接系数为0.64。两种焊接接头的抗拉强度、屈服强度与伸长率均明显低于基材的,且焊接接头2的抗拉强度、屈服强度高于焊接接头1的。

表3 6082-T6铝合金基材和焊接接头拉伸力学性能

Table 3 Mechanical properties of 6082 aluminum alloy and its welded joint

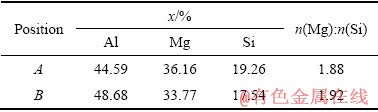

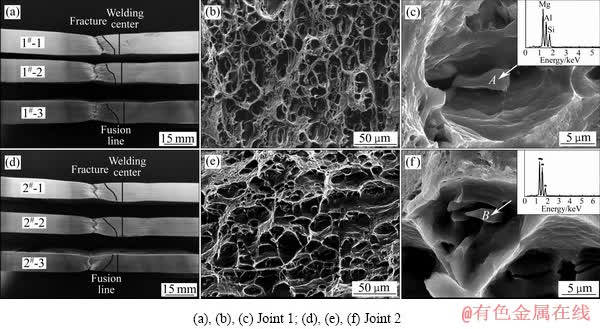

图2所示为焊接试样拉伸断裂后的宏观形貌和断口微观形貌。由图2(a)和(d)可知,焊接试样断裂前均发生明显的颈缩现象,两种焊接接头断裂位置均位于离焊缝中心10~15 mm的热影响区,与图1中该位置表现出最低硬度值相一致,说明该区域为焊接接头力学性能薄弱区域。由图2(b)和(e)可看出,两种焊接接头断口均显示出明显的韧窝,塑性变形充分,属于韧性断裂。焊接接头2的韧窝更大且更深,韧性更好。韧窝处存在长块状粗大第二相粒子,如图2(e)和(f)所示,且EDS分析结果如表4所列,可见这些粒子的Mg、Si摩尔比约为2:1,可以认为该第二相粒子为Mg2Si相。

表4 焊接接头第二相粒子成分组成

Table 4 Second phase particle composition of welded joints

图2 焊接接头拉伸断口宏观与微观形貌

Fig. 2 Macro and micro features of tensile fracture of welded joints

2.3 焊接接头显微组织

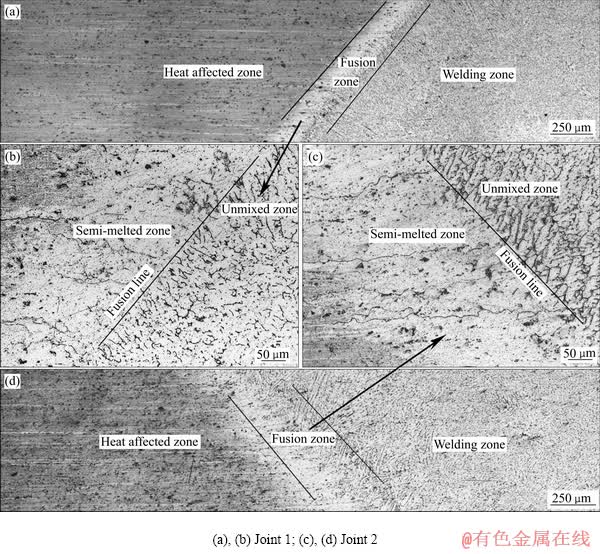

图3所示为采用不同焊丝焊接后焊接接头的金相显微组织。从图3(a)和(d)可以明显看出焊接接头表现为焊缝区(WZ)、熔合区(FZ)与热影响区(HAZ)的典型组织特征。焊缝区呈现出铸造组织特征,为靠近熔合区部分柱状枝晶与焊缝中心的等轴枝晶。图3(b)和(c)所示为焊接接头1、焊接接头2中熔合区的放大图。熔合区可分半熔化区与未混合区:靠近基材一侧,存在已熔化的液相以及未熔化的基材,此区域为明显的亮白色,组织为粗大的胞状枝晶,为半熔化区;靠近焊缝一侧,基材与焊丝已全部熔化,但还未混合,成分与基材基本相同,此区域组织呈柱状晶,为未混合区,两个区域的分界线为熔合线。热影响区的组织均为纤维状组织。

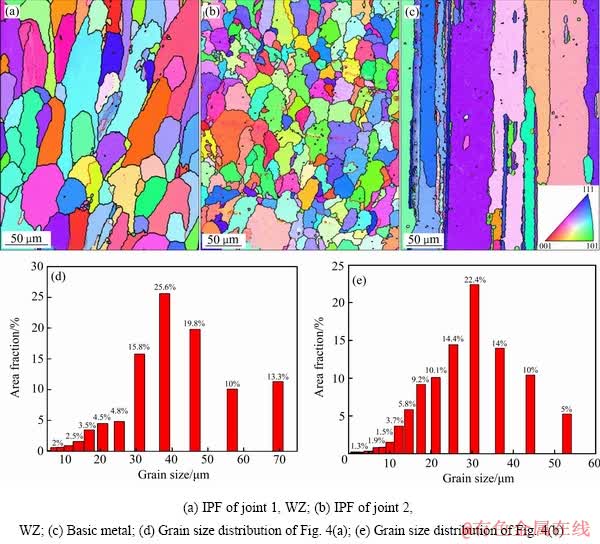

对6082铝合金基材(BM)与两种焊接接头焊缝区(WZ)进行EBSD分析,结果如图4所示。可以看出,焊缝处的晶粒为典型的凝固组织,晶粒形态为等轴晶,基材晶粒呈明显拉长状,为典型的加工态纤维组织。从图4(a)、(b)中可明显看出,焊接接头2焊缝区的晶粒明显较焊接接头1细小,通过对晶粒尺寸统计,如图4(d)和(e)所示,焊接接头2焊缝区的平均晶粒尺寸为28 μm,而焊接接头1焊缝区平均晶粒尺寸为40 μm。

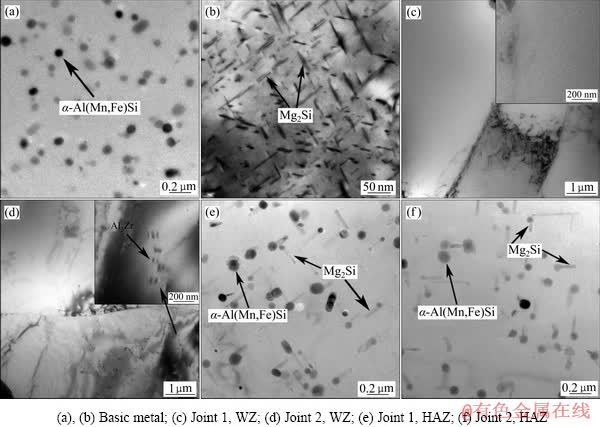

图5所示为不同焊接接头各位置TEM像。从图5(a)中可见,基材中存在颗粒状的第二相,尺寸约为70 nm,为均匀化退火过程中析出的α-Al(Mn,Fe)Si相[18];从图5(b)中可以看出,在基体中沿 还存在尺寸约为5 nm的针状Mg2Si相。图5(c)和(d)所示为焊缝区TEM组织,从图5(c)可见,焊接接头1中焊缝区未观察到明显的析出相,但从图5(d)可见,焊接接头2中焊缝区出现Al3Zr粒子,这是由于ER5087焊丝中含有Zr元素,当Zr含量>0.11%时,Al和Zr之间强的结合力,形成的高熔点Al3Zr粒子会从熔体中优先沉淀[19]。图5(e),(f)可以看出,基材均匀化退火时析出的α-Al(Mn,Fe)Si相,发生粗化,尺寸达到90 nm左右,并且针状Mg2Si相也发生了明显粗化,尺寸达到25 nm。析出相的粗化将导致焊接后热影响区的强度和硬度降低。

还存在尺寸约为5 nm的针状Mg2Si相。图5(c)和(d)所示为焊缝区TEM组织,从图5(c)可见,焊接接头1中焊缝区未观察到明显的析出相,但从图5(d)可见,焊接接头2中焊缝区出现Al3Zr粒子,这是由于ER5087焊丝中含有Zr元素,当Zr含量>0.11%时,Al和Zr之间强的结合力,形成的高熔点Al3Zr粒子会从熔体中优先沉淀[19]。图5(e),(f)可以看出,基材均匀化退火时析出的α-Al(Mn,Fe)Si相,发生粗化,尺寸达到90 nm左右,并且针状Mg2Si相也发生了明显粗化,尺寸达到25 nm。析出相的粗化将导致焊接后热影响区的强度和硬度降低。

图3 6082-T6铝合金焊接接头金相组织

Fig. 3 Microstructures of welded joints of 6082-T6 aluminum alloy

图4 6082-T6铝合金焊接接头焊缝区与基材EBSD结果

Fig. 4 EBSD maps performed on WZ and BM of welded joints of 6082 aluminum alloy

图5 6082-T6铝合金焊接接头焊接接头TEM像

Fig. 5 TEM images of welded joints of 6082-T6 aluminum alloy

3 讨论

3.1 焊缝区组织与性能

焊缝区由于焊接温度很高,焊丝熔化冷却速度很快,溶质来不及扩散以及均匀化,属于快速结晶组织,具有典型的铸造组织特征。焊缝区成分主要为焊丝成分,ER5356焊丝与ER5087焊丝均属于Al-Mg合金,其中ER5087焊丝中含有微量Zr元素。凝固过程中,Zr元素易与Al结合形成纳米级Al3Zr粒子。Al3Zr粒子晶体结构为四方结构,晶格常数a=b=0.4014 nm,c=1.735 nm,铝基体晶体结构为面心立方,晶格常数a=b=c=0.41169 nm,两者的匹配度高达99.5%,因此Al3Zr粒子可作为Al的有效异质形核核心,促进非均匀形核,从而细化晶粒[20-22],如图4所示,焊接接头2中焊缝区晶粒明显细化。陈和等[23]的研究也表明铝合金焊缝区,Al3Zr作为非均匀形核的中心,形成细小等轴晶,从而细化晶粒。根据Hall-Petch 公式:

(1)

(1)

式中: 与ky为材料相关的常数;d为晶粒尺寸。晶粒尺寸减小,晶界对位错滑移的阻滞效应越明显,导致位错发生塞积,从而提高屈服强度[24]。表3中拉伸力学性能结果表明,焊接接头2的屈服强度比焊接接头1的屈服强度高12 MPa,其抗拉强度也高5 MPa。

与ky为材料相关的常数;d为晶粒尺寸。晶粒尺寸减小,晶界对位错滑移的阻滞效应越明显,导致位错发生塞积,从而提高屈服强度[24]。表3中拉伸力学性能结果表明,焊接接头2的屈服强度比焊接接头1的屈服强度高12 MPa,其抗拉强度也高5 MPa。

3.2 热影响区组织与力学性能

对于6082-T6铝合金基材,沿 析出的针状β″相(Mg2Si)为合金主要强化相,其主要强化方式为位错绕过或切过粒子产生的第二相粒子强化,第二相粒子的大小是影响强化效果的主要因素[25-26]。对于位错切过和绕过机制,使位错继续前进滑移所需的临界切应力为[27]:

析出的针状β″相(Mg2Si)为合金主要强化相,其主要强化方式为位错绕过或切过粒子产生的第二相粒子强化,第二相粒子的大小是影响强化效果的主要因素[25-26]。对于位错切过和绕过机制,使位错继续前进滑移所需的临界切应力为[27]:

(2)

(2)

(3)

(3)

式中: 为位错切过第二相粒子所需临界切应力;

为位错切过第二相粒子所需临界切应力; 为位错绕过第二相粒子所需临界切应力;

为位错绕过第二相粒子所需临界切应力; 为常数;f为粒子体积分数;r为粒子半径。当粒子体积分数一定时,粒子尺寸较小,切过机制起作用,随着粒子半径的增大,强化效果增大;当达到一定尺寸,由于绕过粒子所需的临界切应力比切过粒子所需的低,所以绕过机制起主要作用,即运动的位错在粒子前受阻,迫使位错以弯曲方式继续向前,绕过第二相粒子,留下位错环,实现位错增殖,产生强化,随着粒子半径的增大,强化效果减弱。有研究表明[28],当析出的第二相尺寸大于3~5 nm,位错会绕过第二相粒子(奥罗万机制)产生强化。

为常数;f为粒子体积分数;r为粒子半径。当粒子体积分数一定时,粒子尺寸较小,切过机制起作用,随着粒子半径的增大,强化效果增大;当达到一定尺寸,由于绕过粒子所需的临界切应力比切过粒子所需的低,所以绕过机制起主要作用,即运动的位错在粒子前受阻,迫使位错以弯曲方式继续向前,绕过第二相粒子,留下位错环,实现位错增殖,产生强化,随着粒子半径的增大,强化效果减弱。有研究表明[28],当析出的第二相尺寸大于3~5 nm,位错会绕过第二相粒子(奥罗万机制)产生强化。

在焊接过程中,由于循环热的影响,基材中出现热影响区。从合金热影响区结果可以看出,距离熔合线距离不同,硬度也不同(见图2)。熔合线附近的HAZ,温度高,会有更多的析出相溶解,Mg、Si原子活性高,重新溶回基体,在冷却速度较快情况下,形成含Mg、Si原子的过饱和固溶体,成为热影响区的淬火区。焊接过程完成后,在自然时效过程中,会析出少量与基体共格的强化相β″,硬度值增强;距离熔合线较远处的HAZ,受电弧热影响减弱,只有较少的细小的第二相溶回基体,形成含Mg、Si原子过饱和固溶体不充分,空位浓度低,在自然时效过程中只有少部分析出,大部分第二相不发生回溶,有更大的空间聚集长大,发生粗化,导致硬度降低。在距离焊缝10~15 mm处,极少存在第二相回溶,大部分第二相发生长大,由于温度相对较高,粗化的驱动力充足,β″相(Mg2Si)发生粗化最为严重(见图5(e)和(f)),平均粒径达到25 nm,由位错绕过机制可知,随着粒径增大,强化效果作用减弱,强度、硬度最低,形成热影响区的软化区;继续远离焊缝中心,温度影响越来越低,粗化程度逐渐减弱,硬度逐渐升高,直到达到基材区,硬度趋于平稳。

4 结论

1) 采用ER5087焊丝焊接的6082-T6铝合金焊接接头的抗拉强度、屈服强度、断后伸长率以及焊接系数分别达到206MPa 、155 MPa、5.9%、0.64,均高于ER5356焊丝焊接的6082-T6铝合金焊接接头。

2) 采用含Zr元素的ER5087焊丝焊接后,由于Al3Zr粒子的非均匀形核作用,焊接接头焊缝区晶粒更细小。

3) 采用ER5356和ER5087焊丝焊接的6082-T6铝合金焊接接头硬度最低点及拉伸断裂位置均在距离焊缝中心10~15 mm处的热影响区。在循环热的作用下,该区域的β″强化相聚集长大、粗化,导致强化作用减弱,形成热影响区的软化区。

REFERENCES

[1] PANAGOPOULO C N, GEORGIOU E P, GAVRAS A G. Corrosion and wear of 6082 aluminum alloy[J]. Tribology International, 2009, 42(6): 886-889.

[2] LIU Fang, YU Fu-xiao, ZHAO Da-zhi, ZUO Liang. Microstructure and mechanical properties of an Al-12.7Si-0.7Mg alloy processed by extrusion and heat treatment[J]. Materials Science and Engineering A, 2011, 528(10): 3786-3790.

[3] WANG Jian-min, ZHANG Yan. A study on weldability of aluminum alloy-aluminum-steel transition joints[J]. Advanced Materials Research, 2013, 631/632: 713-716.

[4] 杨得帅. 6061铝合金激光焊接接头组织及力学性能研究[D]. 济南: 山东大学, 2014.

YANG De-shuai. Study on microstructure and mechanical properties of 6061 aluminum alloy laser welded joints[D]. Ji’nan: Shandong University, 2014.

[5] WAN Long, HUANG Yong-xian, Lü Zong-liang, Lü Shi-xiong, FENG Ji-cai. Effect of self-support friction stir welding on microstructure and microhardness of 6082-T6 aluminum alloy joint[J]. Materials & Design, 2014, 55(6): 197-203.

[6] XU Pian, JIANG Feng, MENG Song, YI Ke-ke, JIANG Jing-yu, CAO Qin-xuan, PENG Yong-yi. Microstructure and mechanical properties of Al-Mg-Sc-Zr alloy variable polarity plasma arc welding joint[J]. Journal of Materials Engineering and Performance, 2018, 27(9): 4783-4790

[7] RODRIGUES D M, MENEZE L F, LOUREIRO A. The influence of the HAZ softening on the mechanical behaviour of welded joints containing cracks in the weld metal[J]. Engineering Fracture Mechanics, 2004, 71(13): 2053-2064.

[8] YAN Shao-hua, CHEN Hui, ZHU Zong-tao, GOU Guo-qing. Hybrid laser-metal inert gas welding of Al-Mg-Si alloy joints: Microstructure and mechanical properties[J]. Materials & Design, 2014, 61(9): 160-167.

[9] ZHANG Da-quan, XIN Ji-na, GAO Li-xin, JOO H G, LEE K Y. Effect of laser-arc hybrid welding on fracture and corrosion behaviour of AA6061-T6 alloy[J]. Materials Science and Engineering A, 2011, 528(6): 2748-2754.

[10] BAI Yan, GAO Hong-ming, WU Lin, MA Zhao-hui, CAO Neng. Influence of plasma-MIG welding parameters on aluminum weld porosity by orthogonal test[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(8): 1392-1396.

[11] ERICSSON M, SANDSTROM R. Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG[J]. International Journal of Fatigue, 2003, 25(12): 1379-1387.

[12] ELDANAF E A, ELRAYES M M. Microstructure and mechanical properties of friction stir welded 6082 AA in as welded and post weld heat treated conditions[J]. Materials & Design, 2013, 46(4): 561-572.

[13] 王恩泽. 6082-T6铝合金MIG焊接头微观组织及力学性能的研究[D]. 长春: 吉林大学, 2013.

WANG En-ze. Study on microstructure and mechanical properties of 6082-T6 aluminum alloy MIG welded joint[D]. Changchun: Jilin University, 2013.

[14] HUANG Ji-wu, YIN Zhi-min, LEI Xue-feng. Microstructure and properties of 7A52 Al alloy welded joint[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 804-808.

[15] YOON J W, LEE Y S, LEE K D, PARK K Y. Effect of filler wire composition on the Nd:YAG laser weldability of 6061 aluminum alloy[J]. Materials Science Forum, 2005, 475/479: 2591-2594.

[16] 易 杰, 李落星, 刘开勇, 郭鹏程, 曹淑芬. 焊丝成分对6061-T6铝合金双脉冲MIG焊缝组织与性能的影响[J]. 兵器材料科学与工程, 2015, 38(3): 26-30.

YI Jie, LI Luo-xing, LIU Kai-yong, GUO Peng-cheng, CAO Shu-fen. Effect of microstructure and properties of 6061-T6 aluminum alloy double pulse MIG weld[J]. Ordnance Material Science and Engineering, 2015, 38(3): 26-30.

[17] PENG Xiao-yan, CAO Xiao-wu, XU Guo-fu, DENG Ying, TANG Lei, YIN Zhi-min. Mechanical properties, corrosion behavior, and microstructures of a MIG-welded 7020 Al alloy[J]. Journal of Materials Engineering and Performance, 2016, 25(3): 1028-1040.

[18] 潘青林, 李绍禄, 邹景霞, 尹志民. 微量 Mn 对 Al-Mg-Si 合金微观组织与拉伸性能的影响[J]. 中国有色金属学报, 2002, 12(5): 971-975.

PAN Qing-lin, Li Shao-lu, ZOU Jing-xia, YIN Zhi-min. Effects of minor manganese addition on microstructures and tensile properties of Al-Mg-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 971-975.

[19] DANG Jing-zhi, HUANG Yu-feng, CHENG Jun. Effect of Sc and Zr on microstructures and mechanical properties of as-cast Al-Mg-Si-Mn alloys[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 540-544.

[20] 尹志民, 高拥政, 潘青林, 张永红, 尹松波. 微量Sc和Zr对Al-Mg合金铸态组织的晶粒细化作用[J]. 中国有色金属学报, 1997, 7(4): 75-78.

YIN Zhi-min, GAO Yong-zheng, PAN Qing-Lin, ZHANG Yong-hong, YIN Song-bo. Grain refinement of as-cast microstructure of Al-Mg alloy by trace Sc and Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 75-78.

[21] ROKHLIN L L, DOBATKINA T V, BOCHVAR N R, LYSOVA E V. Investigation of phase equilibria in alloys of the Al-Zn-Mg-Cu-Zr-Sc system[J]. Journal of Alloys and Compounds, 2004, 367(1/2): 10-16.

[22] 李 飞, 廖怡君, 王 旭, 朱庆丰, 崔建忠. Zr元素对纯铝细化机理的电子理论研究[J]. 材料导报, 2018, 32(18): 3190-3194.

LI Fei, LIAO Yi-jun, WANG Xu, ZHU Qing-feng, CUI Jian-zhong. Electron theory study of the refinement mechanism of Zr element on pure Al[J]. Material Guide, 2018, 32(18): 3190-3194.

[23] 陈 和. Ti、Zr微合金化焊丝对2A12铝合金焊缝组织及性能的影响[D]. 南昌: 南昌航空大学, 2015.

CHEN He. Effect of Ti, Zr microalloying welding wires on the microstructure and properties of 2A12 aluminum alloy welds[D]. Nanchang: Nanchang Aeronautical University, 2015.

[24] FURYKAWA M, HORITA Z, NEMOTO M, VALIEV R Z, LANGDON T G. Microhardness measurements and the Hall-Petch relationship in an Al-Mg alloy with submicrometer grain size[J]. Acta Materialia, 1996, 44(11): 4619-4629.

[25] MARIOARA C D, ANDERSEN S J, JANSEN J, ZANDBERGEN H W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al-Mg-Si alloy[J]. Acta Materialia, 2003, 51(3): 789-796.

[26] MYHR O R, GRONG  , FJAER H G, MARIOARA C D. Modelling of the microstructure and strength evolution in Al-Mg-Si alloys during multistage thermal processing[J]. Acta Materialia, 2004, 52(17): 4997-5008.

, FJAER H G, MARIOARA C D. Modelling of the microstructure and strength evolution in Al-Mg-Si alloys during multistage thermal processing[J]. Acta Materialia, 2004, 52(17): 4997-5008.

[27] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2013: 497-500.

ZHENG Zi-qiao. Fundamentals of materials science[M]. Changsha: Central South University Press, 2013: 497-500.

[28] MYHR O R, GRONG  , ANDERSEN S J. Modelling of the age hardening behaviour of Al-Mg-Si alloys[J]. Acta Materialia, 2001, 49(1): 65-75.

, ANDERSEN S J. Modelling of the age hardening behaviour of Al-Mg-Si alloys[J]. Acta Materialia, 2001, 49(1): 65-75.

Effect of welding wire composition on microstructure and properties of 6082-T6 aluminum alloy welded joints

JIN Jia-lin1, XU Guo-fu1, 2, LI Yao1, PENG Xiao-yan1, LIANG Xiao-peng1, 2, DENG Ying1, 2, YIN Zhi-min1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: 6082-T6 aluminum alloy plates were welded by metal inert welding method (MIG) with ER5356 welding wire and ER5087 welding wire. The effects of welding wire composition on the microstructure and properties of 6082-T6 aluminum alloy welded joints were analyzed by micro hardness and tensile mechanical properties test, optical microscopy (OM), scanning electron microscopy (SEM), electron backscatter diffractometry (EBSD) and transmission electron microscopy (TEM). The results show that the grain size of 6082-T6 aluminum alloy welded joints of ER5087 welding wire is finer than that of welded joints of ER5356 welding wire, and the tensile strength, yield strength, elongation and welding coefficient are better than those of welded joints of ER5356 welding wire. The lowest hardness area and tensile fracture position of the 6082-T6 aluminum alloy welded joints are in the heat affected zone at 10-15 mm away from welding center. The strengthening phase β′′ aggregates and coarsens, and the strengthening effect is weakened, which becomes the weakest area of the welded joints.

Key words: 6082-T6 aluminum alloy; MIG welding; welding wire composition; mechanical properties; microstructure

Foundation item: Project(2016B090931004) supported by the Project Science and Research Plan of Guangdong Province, China; Project(51601229) supported by the National Natural Science Foundation of China; Project (CSUZC201812) supported by the Open Sharing Fund of the Large-scale Instruments and Equipments of Central South University, China

Received date: 2019-05-10; Accepted date: 2019-07-30

Corresponding author: LIANG Xiao-peng; Tel: +86-18684894344; E-mail: mselxp@163.com

(编辑 龙怀中)

基金项目:广东省科学研究计划项目(2016B090931004);国家自然科学基金资助项目(51601229);中南大学贵重精密仪器开放共享基金(CSUZC201812)

收稿日期:2019-05-10;修订日期:2019-07-30

通信作者:梁霄鹏,副教授,博士;电话:18684894344;E-mail:mselxp@163.com

摘 要:采用ER5356和ER5087焊丝对12 mm厚6082-T6铝合金进行熔化极惰性气体保护焊(MIG)后,通过显微硬度测试、拉伸力学性能测试、光学显微镜(OM)、扫描电镜(SEM)、电子背散射衍射(EBSD)和透射电镜(TEM)等研究焊丝成分对焊接接头力学性能与显微组织的影响。结果表明:采用ER5087焊丝焊接的6082-T6铝合金焊接接头焊缝区晶粒更细小;抗拉强度、屈服强度、断后伸长率以及焊接系数均高于ER5356焊丝焊接的6082-T6铝合金焊接接头的;两种焊丝焊接的6082-T6铝合金焊接接头的硬度最低区域与拉伸断裂位置均在距离焊缝中心10~15 mm处的热影响区,该区域β″强化相聚集长大、粗化,导致析出相强化作用减弱,成为焊接接头性能最薄弱区域。

[4] 杨得帅. 6061铝合金激光焊接接头组织及力学性能研究[D]. 济南: 山东大学, 2014.

[13] 王恩泽. 6082-T6铝合金MIG焊接头微观组织及力学性能的研究[D]. 长春: 吉林大学, 2013.

[16] 易 杰, 李落星, 刘开勇, 郭鹏程, 曹淑芬. 焊丝成分对6061-T6铝合金双脉冲MIG焊缝组织与性能的影响[J]. 兵器材料科学与工程, 2015, 38(3): 26-30.

[18] 潘青林, 李绍禄, 邹景霞, 尹志民. 微量 Mn 对 Al-Mg-Si 合金微观组织与拉伸性能的影响[J]. 中国有色金属学报, 2002, 12(5): 971-975.

[20] 尹志民, 高拥政, 潘青林, 张永红, 尹松波. 微量Sc和Zr对Al-Mg合金铸态组织的晶粒细化作用[J]. 中国有色金属学报, 1997, 7(4): 75-78.

[22] 李 飞, 廖怡君, 王 旭, 朱庆丰, 崔建忠. Zr元素对纯铝细化机理的电子理论研究[J]. 材料导报, 2018, 32(18): 3190-3194.

[23] 陈 和. Ti、Zr微合金化焊丝对2A12铝合金焊缝组织及性能的影响[D]. 南昌: 南昌航空大学, 2015.