文章编号:1004-0609(2008)02-0215-06

激光熔覆Ni45 -CaF2-WS2自润滑涂层组织与性能

章小峰,王爱华,张祥林,乔晓勇,黄早文

(华中科技大学 材料成形与模具技术国家重点实验室,武汉 430074)

摘 要:

利用CO2激光器,在45号钢表面熔覆Ni45-CaF2 -WS2粉末制备自润滑复合涂层,研究熔覆涂层微观组织和摩擦磨损性能及其影响规律。结果表明,熔覆过程中,WS2发生部分分解,形成新的润滑相CrxSy和CaWO4,CaF2的存在对熔池的流动性有极大的改善;涂层的室温及400 ℃摩擦性能测试也表明,复合自润滑涂层的摩擦因数显著降低,且Ni45-7.5CaF2-7.5WS2(质量分数,%)涂层的摩擦磨损性能较佳。

关键词:

Ni45-CaF2-WS2;激光熔覆;自润滑涂层;显微组织;摩擦性能;

中图分类号:TF 125.9; TG 174.44 文献标识码:A

Microstructure and tribological properties of laser cladding Ni45 -CaF2-WS2 self-lubrication coating

ZHANG Xiao-feng, WANG Ai-hua, ZHANG Xiang-lin, QIAO Xiao-yong, HUANG Zao-wen

(State Key Laboratory of Material Processing and Die and Mould Technology, Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: Self-lubrication coatings were prepared by CO2 laser cladding of Ni45-CaF2-WS2 compound powders on a medium carbon steel. Microstructure and tribological properties of the laser clad coatings were investigated and analyzed. The results show that, partial WS2 powder decomposes to generate some new lubricants, such as CrxSy and CaWO4. During laser cladding process, the fluidity of laser-generated-pool has been improved by adding CaF2, the friction coefficients of coating reduce remarkably in the tribological properties test at room temperature and 400 ℃, and the laser cladding Ni45-7.5CaF2-7.5WS2 (mass fraction, %) coating presents lower friction coefficient and better wear resistance.

Key words: Ni45-CaF2-WS2; laser cladding; self-lubricating coating; microstructure; tribological properties

WS2、CaF2在不同温度下具有稳定的摩擦性能,是理想的复合涂层润滑材料[1-2]。激光熔覆技术能在材料表面快速熔凝合成非平衡新材料,制备出减摩耐磨合金层,在现代化工业中不断显示强大的经济效益,引起学术界、工业界的极大重视[3-4]。JENG等[5]曾运用激光技术在AISI1020 低碳钢上制备以Ag及BaF2-CaF2共晶粉末为润滑粉末,Cr3C2-(Ni-Al)为耐磨粘结材料的减摩耐磨熔覆涂层,在300~550 ℃时,成分为15%Ag-15%(BaF2-CaF2)(质量分数,%)的涂层获得了最好的摩擦磨损性能[5]。至于对其它各种固体润滑材料,诸如过渡金属硫化物、CaF2、石墨等,以及Al2O3、Si3N4、WC等耐磨材料作为复合材料体系的激光熔覆涂层的研究也越来越广泛[6-9]。铝合金温成形工艺中,常用的液体润滑剂容易被干燥、固化、堆积在模具型腔内,影响模具工作表面精度和生产效率等问题[10-11],若在模具表面制备一层固体自润滑涂层,有望解决铝合金覆盖件和模具间的润滑。本文作者通过激光熔覆Ni45-CaF2-WS2复合粉末,对涂层组织和摩擦性能进行研究,为固体自润滑涂层在温成形模具表面应用提供实验探索。

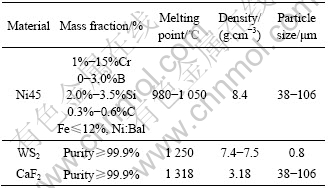

1 实验

激光器为TJ-HL-T5000型5 kW横流CO2激光器(波长λ=10.6 μm)。基材选用45号钢,调质后硬度为HRC42~45,表面粗糙度为0.8 μm。熔覆材料为Ni45自熔性合金粉、WS2、CaF2分析纯。Ni45自熔性合金粉由于具有抗高温氧化性、耐蚀性和激光熔覆工艺性好等优点,加入的WS2、CaF2分别在450 ℃以下和600 ℃以上具有良好的润滑性能,具体化学成分和相关参数见表1。利用BUCHLER Micrometer-Ⅱ型显微硬度计和MMS-1G型销盘高温摩擦磨损实验机分别测定涂层的显微硬度和在不同载荷和速率下的摩擦因数、磨损量。

表1 材料的化学成分和相关参数

Table 1 Chemical component and parameters of materials

将Ni45与WS2、CaF2按一定的质量配比混合均匀,再利用有机粘结剂水溶液将复合粉末预置在基材表面,粉末预置厚度约为1.0 mm。激光工艺参数为:平均功率2.5 kW,扫描光斑直径6.0 mm,扫描速度6 和10 mm/s。

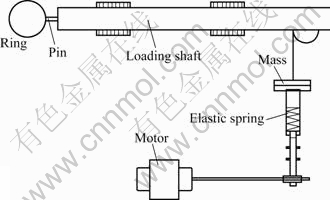

高温摩擦磨损实验采用GCr15材质的对磨盘,试样的工作表面上为不同成分的激光熔覆涂层。在一定温度下,预磨30 s,再调整载荷和速度,由计算机自动采集相关摩擦力矩数据,并转化为摩擦因数—时间曲线,图1所示为MMS-1G型销盘高温摩擦磨损实验机示意图。具体实验条件如下:实验温度为室温、400 ℃;载荷为10、20和40 N;摩擦盘线速度为1、5和10 m/s;涂层摩擦磨损性能用试样质量损失Δm和μ来表征,即:

图1 MMS-1G型销盘高温摩擦磨损实验机示意图

Fig.1 Schematic map of MMS-1G pin-on-ring high temperature tribotester

2 结果与分析

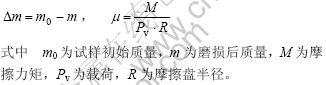

图2所示为各组分的激光熔覆组织宏观表面形貌,Ni45(质量分数,%)的涂层表面呈金属光泽,涂层致密(见图2(a)),而图2(b)~2(f)分别为成分(质量分数,%)为Ni45-0CaF2-15WS2、Ni45-5CaF2-10WS2、Ni45- 7.5CaF2-7.5WS2、Ni45-10CaF2-5WS2、Ni45-15CaF2- 0WS2在相同工艺条件下的涂层表面宏观形貌。可以发现,当CaF2总含量低于7.5%,随着CaF2含量的增加,熔覆层表面越来越光滑;而当CaF2总含量超过7.5%时,涂层表面浮渣逐渐增多,单道涂层不连续。熔覆同组分粉末时,激光扫描速度从6 mm/s提高到10 mm/s,单道熔覆层的宽度下降。并且在成分为Ni45-7.5CaF2-7.5WS2时都达到较宽的单道熔覆涂层,分别为6.99和6.69 mm。

图2 Ni45-CaF2-WS2体系熔覆涂层表面宏观形貌

Fig.2 Macrographs of laser cladding Ni45-CaF2-WS2 composite coatings: (a) 100?0?0; (b) 85?0?15; (c) 85?5?10; (d) 85?7.5?7.5; (e) 85?10?5; (f) 85?15?0

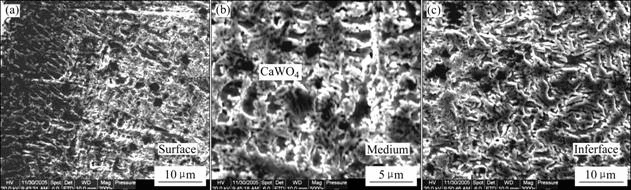

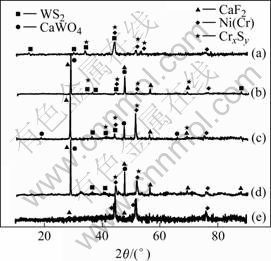

激光熔覆涂层断面组织由表及里依次为熔覆区、过渡区、热影响区、基材,不同成分和熔覆工艺对最终涂层组织形态有极大的影响。图3所示为成分为Ni45-5CaF2-10WS2的涂层断面组织,其形态比较均匀,据其EDX显示,涂层表面(熔覆区)的Cr元素含量相对中间(过渡区)、界面(热影响区)的要高,说明该区有Cr的化合物富聚。随着CaF2含量的增加,熔覆区的疏松组织很明显,过渡区和热影响区组织致密,见图4,EDX显示该区富聚大量钨、钙、氧元素。XRD分析结果表明,Ni45-CaF2-WS2体系粉末经过激光熔覆后有CrxSy及CaWO4生成,见图5。由此可以推断图3表层的絮状物可能为CrxSy,黑色小颗粒为WS2所在,并且WS2在涂层中分布比较均匀;图4过渡区下可能是新的物相CaWO4。

图3 Ni45-5CaF2-10WS2熔覆组织断面的SEM形貌

Fig.3 SEM morphologies of cross-sections of laser cladding Ni45-5CaF2-10WS2 coating

图4 Ni45-7.5CaF2-7.5WS2熔覆组织断面的SEM形貌

Fig.4 SEM morphologies of cross-sections of laser cladding Ni45-7.5CaF2-7.5WS2 coating

图5 Ni45-CaF2-WS2体系的激光熔覆组织的XRD谱

Fig.5 XRD patterns of laser cladding Ni45-CaF2-WS2 composite coatings: (a) 85?0?15; (b) 85?5?10; (c) 85?7.5?7.5; (d) 85?10?5; (e) 85?15?0

从图6可知,Ni45-CaF2-WS2体系粉末各组分熔覆组织断面的显微硬度测试结果表明,涂层硬度由表及里几乎呈递减趋势,涂层表面硬度最高,基体由于稀释度较大,硬度最低,这与粉末本身及生成物理化特性、分布状态有关,也与激光熔覆熔池的形成和快速冷凝过程有关。当扫描速度为6 mm/s时,100%Ni45粉末形成的涂层整体硬度最低,涂层表面由于冷凝过快,过冷度较大,硬度较高。加入CaF2、WS2后,由于CaF2质硬且脆[12],涂层硬度普遍较100%Ni45的要高。

图6 Ni45(100%)及Ni45(85%)体系激光熔覆层显微硬度

Fig.6 Microhardness of laser cladding composite coatings

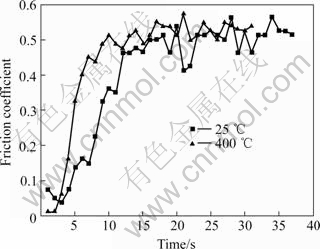

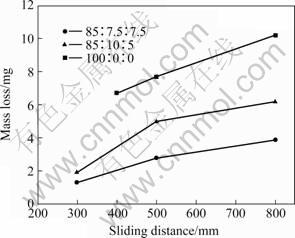

图7显示了激光熔覆各成分涂层在载荷为10 N,摩擦副线速度为1 m/s时的摩擦曲线。成分Ni45- 5CaF2-10WS2、Ni45-7.5CaF2-7.5WS2、Ni45-10CaF2- 5WS2涂层的摩擦因数分别在0.4~0.44、0.28~0.36、0.46~0.56之间波动,而对Ni45-10CaF2-5WS2涂层的室温及400 ℃摩擦测试表明,400 ℃时摩擦因数略高,温度对该涂层摩擦因数的影响较小,见图8。磨损测试结果表明成分为Ni45-7.5CaF2-7.5WS2的涂层在相同摩擦距离条件下,涂层损失量最少,见图9。

图7 Ni45(85%)激光熔覆层室温摩擦因数

Fig.7 Friction coefficients of laser cladding Ni45(85%) composite coatings at room temperature

图8 Ni45-10CaF2-5WS2涂层在不同温度的摩擦因数

Fig.8 Friction coefficients of laser cladding Ni45-10CaF2- 5WS2 composite coating at different temperatures

图9 熔覆涂层室温的干摩擦磨损性能

Fig.9 Wear properties of laser cladding coatings at room temperature

当CaF2总含量低于7.5%的Ni45-CaF2-WS2体系粉末激光熔覆时,CaF2因密度小,在快速熔凝过程中,有很大一部分漂浮到涂层表面,增强了熔池的流动性,改善了激光熔体对基材的润湿铺展性能,形成较宽的单道涂层;而当CaF2总含量超过7.5%时,熔池特性发生了改变,大量的CaF2粉末阻碍了Ni45粉末的熔化,冷凝的金属没完全铺展开,形成窄的单道涂层。另外,随着WS2含量增加,部分WS2在高温分解、氧化成WO3了,少量没被氧化成WO3的WS2冷却后保留在涂层中,而WO3进一步与离子化的CaF2化合反应生成Gibbs自由能更低的CaWO4,因其密度大而富聚在涂层的过渡区以下,减少了CaF2上浮到熔池表面,改善了熔池的流动性。但当WS2含量增大到15%时,熔池中没有CaF2,涂层与基体的润湿性变差。

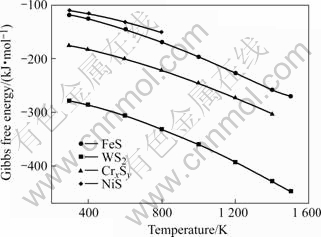

Ni45自熔性合金粉中Cr元素一定程度上促进了WS2的分解,因为按照Ni、Cr、W、Fe等与S形成化合物的Gibbs自由能可知,WS2、CrxSy、FeS、NiS等的Gibbs自由能依次增加,见图10。尽管形成WS2所需要的能量最少,但WS2在5l0 ℃开始分解,导致S出现,因涂层中W含量远小于Cr含量,大量S与Cr发生反应生成低密度的CrxSy富聚在涂层表面;另外,部分Cr也会向Ni/WS2界面扩散而反应产生CrxSy,并浮起在涂层的表面和中间富聚。至于涂层中没FeS、NiS的原因,一是形成FeS、NiS的自由能较CrxSy高,二是涂层粉末中Fe含量较少的缘故。

图10 Fe、W、Cr和Ni各自硫化物的Gibbs自由能曲线

Fig.10 Curves of Gibbs free energy of sulfides of Fe, W, Cr and Ni

至于涂层的摩擦性能,因WS2是层状结构,质软,低温润滑性能好,而CaF2在500 ℃时,才由脆性向塑性转变,润滑性能逐渐增强[13],故低温时增加CaF2的含量,对改善涂层摩擦性能并无多大帮助,但过多的WS2使熔池的流动性能变差,WS2分解量变多。当成分为Ni45-7.5CaF2-7.5WS2时,涂层中生成CaWO4相及CrxSy相较其它组分的要多(可由图5的峰值得知),而CaWO4及CrxSy均有较好的摩擦性能[14],导致涂层的润滑性能、耐磨性能较好。

3 结论

1) 激光熔覆Ni45-CaF2-WS2体系粉末,制备了组织均匀、摩擦性能良好的自润滑涂层。

2) 在相同的激光熔覆条件下,Ni45-CaF2-WS2体系粉末均获得了含有CaWO4相及CrxSy相的涂层,且成分为Ni45-7.5CaF2-7.5WS2的涂层具有较小的磨损量,摩擦因数为0.28~0.36,而 Ni45-10CaF2-5WS2涂层400 ℃较室温时摩擦因数略高,温度对该涂层摩擦因数的影响较小。

3) CaF2含量低于7.5%时,熔池的流动性有很好的改善,涂层润湿性较好,涂层表面光滑,且在成分为Ni45-7.5CaF2-7.5WS2时形成较宽的单道熔覆涂层,而当CaF2含量高于7.5%时,熔池特性发生了改变,单道熔覆涂层宽度随CaF2含量增加而变窄。

REFERENCES

[1] COHEN S R, RAPOPORT L, PONOMAREV E A, COHEN H, TSIRLINA T, TENNE R, LEVY-CLEMENT C. The tribological behavior of type Ⅱ textured MX2 (M=Mo, W; X=S, Se) films[J]. Thin Solid Films, 1998, 324: 190-197.

[2] DONNET C, ERDEMIR A. Solid lubricant coatings: recent developments and future trends[J]. Tribology Letters, 2004, 17(3): 389-397.

[3] 关振中. 激光加工工艺手册[M]. 北京: 中国计量出版社, 1998: 236-337.

GUAN Zhen-zhong. Handbook of laser process technology[M]. Beijing: China Metrology Press, 1998: 236-337.

[4] HIDOUCI A, PELLETIER J M, DUCOIN F, DEZERT D, EL GUERJOUNA R. Microstructural and mechanical characteristics of laser coatings[J]. Surface & Coatings Technology, 2000, 123: 17-23.

[5] JENG M C, SOONG Y L. Wear behaviour of solid lubricants Ag and BaF2-CaF2 obtained by laser surface cladding[J]. Surface & Coatings Technology, 1993, 57: 145-150.

[6] LI Q, SONG G M, ZHANG Y Z, LEI T C, CHEN W Z. Microstructure and dry sliding wear behavior of laser clad Ni-based alloy coating with the addition of SiC[J]. Wear, 2003, 254: 222-229.

[7] 王黎钦, 应丽霞, 张三川, 齐毓霖. 氮化硅/石墨激光合金化涂层的组织结构与性能研究[J]. 中国激光, 2003, 30(9): 855-858.

WANG Li-qin, YING Li-xia, ZHANG San-chuan, QI Yu-lin. Microstructure and performance of laser alloying Si3N4/graphite composite coating[J]. Chinese Journal of Lasers, 2003, 30(9): 855-858.

[8] WANG H M, YU Y L, LI S Q. Microstructure and tribological properties of laser clad CaF2/Al2O3 self-lubrication wear-resistant ceramic matrix composite coatings[J]. Scripta Materialia, 2002, 47: 57-61.

[9] TOBAR M J, ALVAREZ C, AMADO J M, RODRIGUEZ G, YANEZ A. Morphology and characterization of laser clad composite NiCrBSi-WC coatings on stainless steel[J]. Surface & Coatings Technology, 2006, 200: 6313-6317.

[10] ROESCHER A, ALOIS TINNEMANS H A. A new coating for deep drawing with preservation-lubricant- primer properties[J]. Progress in Organic Coatings, 2001, 43: 111-122.

[11] IWAMA T, MORIMOTO Y. Die life and lubrication in warm forging[J]. Journal of Materials Processing Technology, 1997, 71: 43-48.

[12] WANG Li-bo, WANG Bo, WANG Xiao-bo, LIU Wei-min. Tribological investigation of CaF2 nanocrystals as grease additives[J]. Tribology International, 2007, 40: 1179-1185.

[13] 韩杰胜, 王静波, 张树伟, 孟军虎, 吕晋军. Fe-Mo-CaF2高温自润滑材料的摩擦学特性研究[J]. 摩擦学学报, 2003, 23(4): 306-310.

HAN Jie-sheng, WANG Jing-bo, ZHANG Shu-wei, MENG Jun-hu, L? Jin-jun. Study on the tribological properties of Fe-Mo-CaF2 high temperature self-lubricating material[J]. Tribology, 2003, 23(4): 306-310.

[14] 孟军虎, 吕晋军, 王静波, 杨生荣. 两种镍基合金的高温摩擦学性能研究[J]. 摩擦学学报, 2002, 22(3): 184-188.

MENG Jun-hu, L? Jin-jun, WANG Jing-bo, YANG Sheng-rong. Study on friction and wear properties of several Ni-based alloys in sliding against Co-WC at elevated temperature[J]. Tribology, 2002, 22(3): 184-188.

基金项目:国家自然科学基金资助项目(50575081);材料成形及模具技术国家重点实验室资助项目(05-16)

收稿日期:2007-08-30;修订日期:2007-11-19

通讯作者:张祥林,教授,博士;电话:027-87540049; E-mail: hust_zxl@mail.hust.edu.cn