文章编号:1004-0609(2008)11-2020-05

Sm(CoFeCuZr)12快淬薄带的晶体织构与磁性能各向异性

潘 晶,刘新才,郭鹏举,肖 军,徐 峰

(宁波大学 材料科学与化学工程学院,省部共建国家重点实验室培育基地,宁波315211)

摘 要:

摘 要:在辊表面速度为15~35 m/s的条件下制备Sm(Co0.68Fe0.20Cu0.08Zr0.04)12合金快淬薄带,对薄带的微观组织、晶体织构和磁性能各向异进行研究。结果表明:薄带的微观组织由成束的Th2Ni17型结构的2?17相取向柱晶在薄带平面内交织排列而成,每一束柱晶内各个柱晶之间互相平行,而各束柱晶的取向随机分布;随着辊速从15 m/s增加到35 m/s,柱晶宽度显著细化,在35 m/s时达到285 nm;当辊表面速度分别为15、25和35 m/s时,薄带自由面的衍射谱中衍射峰强度比(I(200) /I(111))分别为3.0、3.6和4.5,表明快淬薄带自由面存在(200)晶体织构并且随着辊速的增大而增强,2?17相柱状晶的易磁化方向[001]晶向则处于薄带平面内;平行于薄带平面方向的饱和磁化强度和剩磁比垂直于薄带平面方向的分别高出0.21~0.37 T和0.04~0.10 T;随着辊速从15 m/s增大到35 m/s,薄带的饱和磁化强度、剩余磁化强度和矫顽力都相应提高。

关键词:

中图分类号:TM 273 文献标识码:A

Crystalline texture and magnetic anisotropy of

Sm(CoFeCuZr)12 melt-spun ribbons

PAN Jing, LIU Xin-cai, GUO Peng-ju, XIAO Jun, XU Feng

(State Key Base Laboratory of Novel Functional Materials and Preparation Science,

Faculty of Materials Science and Chemical Engineering, Ningbo University, Ningbo 315211, China)

Abstract: Sm(Co0.68Fe0.20Cu0.08Zr0.04)12 melt-spun ribbons were prepared at wheel surface speed of 15?35 m/s. The microstructures, crystalline texture and magnetic anisotropy were studied. The results show that the microstructures of the melt-spun ribbons are composed of many binds of oriented columnar of 2?17 phase with Th2Ni17–type structure. Within a bind, many columns parallel to each other. And the directions of the binds are distributed randomly in the ribbon plane. With the wheel surface speed increasing from 15m/s to 35m/s, the average widths of the columnar sharply decrease, and it is 285 nm at 35 m/s. The intensity ratios of I(200) to I(111) in the XRD patterns on the ribbon plane which are melted at the wheel surface speed of 15, 25 and 35 m/s are 3.0, 3.6 and 4.5, respectively. This exhibits the existence of (200) texture in the ribbon plane and it is intensified with increasing wheel surface speed. Thus, the easy magnetization axes [001] of 2?17H columnar are in the ribbon plane. The saturation magnetization and residual magnetization of the ribbons measured along the length direction in the ribbon plane are 0.21?0.37 T and 0.04?0.10 T higher than those measured along the direction perpendicular to the ribbons. As the wheel surface speed increases from 15 m/s to 35 m/s, the intrinsic coercive is enhanced, and so are the saturation magnetization and the residual magnetization.

Key words: Sm-Co alloys; melt spun ribbons; crystalline texture; magnetic anisotropy

到目前为止,为提高2?17型Sm-Co合金快淬薄带的磁性能,研究者通过以下3条途径进行了研究:1) 添加合金元素如B、C和Nb等,以细化晶粒直至得到纳米晶组织[1?3];2) 进行合适的退火处理,并进一步简化退火工艺,得到理想的微观结构[4?6];3) 通过合金成分和快淬工艺的综合作用在薄带中形成晶体织构,以获取各向异性快淬薄带[7?9]。当过渡金属与稀土金属的摩尔比Z(过渡族元素与稀土元素摩尔比)在7.14~8.10范围内变化时,LIU等[10]对Sm(Co, Fe, Cu, Zr)Z快淬薄带高温性能进行了研究。以往的研究都集中于Z=7.0~8.5之内的Sm(Co, Fe, Cu, Zr)Z合金快淬薄带。但近年来随着对热变形各向异性纳米复合Sm-Co磁体研究的开展,对Z≥10.0的Sm(Co, Fe, Cu, Zr)Z合金快淬薄带的研究已受到重视。GOPALAN等[11]研究了Sm(Co0.56Fe0.31Cu0.04Zr0.05- B0.04)Z合金中Z值分别为8、10和12的的快淬薄带。结果显示:Z=8,10的快淬薄带由1?7相组成,而Z值提高至12的快淬薄带主要由2?17相组成;Z=8的合金快淬薄带的矫顽力最高,达到880 kA/m。而Z=12的快淬薄带的剩磁较高,但因其组织较粗,矫顽力损失较多。HUANG等[12]研究了添加Zr、Nb和Cu对Z=10的Sm(Co, Fe, Cu, Zr)Z快淬薄带的影响。结果显示:Zr、Nb能抑制晶粒长大,而Cu能改善退磁曲线的方形度。上述两项研究都没有涉及快淬薄带的晶体织构和磁性能各向异性问题。

本文作者研究Sm(Co0.68Fe0.20Cu0.08Zr0.04)12合金在辊轮表面速度15~35 m/s条件下快淬薄带的微观组织、晶体织构,分析晶体织构与易磁化轴取向的关系,对比平行于薄带平面和垂直于薄带平面两个方向上的磁性能。

1 实验

在真空电弧炉中熔炼并浇铸Sm(Co0.68Fe0.20Cu0.08- Zr0.04)12合金的钮扣状铸锭。将铸锭在LAK-12A真空快淬炉中甩制成快淬薄带,其中铜辊表面的线速度分别为15、25和35 m/s。采用D/Max-RB型X射线衍射仪(Cu Kα射线)分析合金的相组成、晶体织构;采用Philips XL FEG场致扫描电镜分析微观组织形貌。采用Lake Shore 7410振动样品磁强计(最大磁场强度2.5 T)测量试样室温磁性能。

2 结果与分析

2.1 快淬薄带的微观组织

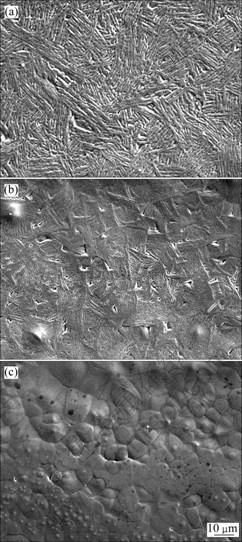

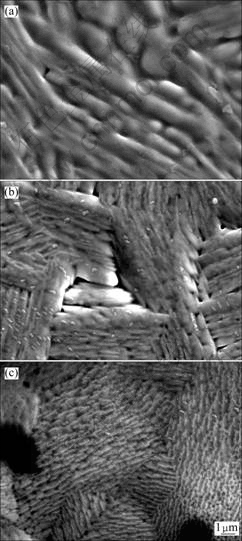

当辊轮表面速度分别为15、25和35 m/s时,制备得到Sm(Co0.68Fe0.20Cu0.08Zr0.04)12快淬薄带,薄带的厚度分别为55、30和20 μm。图1所示为不同快淬速度下制备的Sm(Co0.68Fe0.20Cu0.08Zr0.04)12的SEM像。由图可知,提高辊轮表面速度对组织细化的作用十分明显。从图1(a)可见,呈束状取向生长的柱晶在薄带平面内交织排列,每一束胞柱晶内的各个柱晶之间相互平行,而各束柱晶的取向随机分布。当辊速提高到35 m/s时,薄带组织细化,得到似乎与前者不同的组织形态。但将与图1对应薄带的形貌进一步放大发现,随着辊速提高,柱晶组织显著细化,而排列形态并未发生改变,结果如图2所示。由定向凝固理论可知,对于具有晶体学择优生长方向的晶体,在单向热流条件下及一定的生长速度范围内可以实现定向柱晶凝固。所以,薄带的柱晶组织是合金定向凝固的结果。并且在实验所采用的快淬速度范围内,快淬速度的变化并没有改变晶体在薄带平面内择优定向生长的内在动力。与此同时,束状柱晶在薄带平面内交织排列的形态说明,在薄带平面内各个方向上的散热条件相同[13]。

图1 不同快淬速度下制得的Sm(Co0.68Fe0.20Cu0.08Zr0.04)12合金薄带的SEM像

Fig.1 SEM images of Sm(Co0.68Fe0.20Cu0.08Zr0.04)12 melt-spun ribbons prepared at different rates: (a) 15 m/s; (b) 25 m/s; (c) 35 m/s

图2 不同快淬速度下制得的Sm(Co0.68Fe0.20Cu0.08Zr0.04)12合金薄带的SEM像

Fig.2 SEM images with higher magnification for Sm(Co0.68- Fe0.20Cu0.08Zr0.04)12 melt-spun ribbons prepared at different rates: (a) 15 m/s; (b) 25 m/s; (c) 35 m/s

显微组织测量结果表明,在辊速为15 m/s时,柱晶的宽度约为1 100 nm,而一束胞柱晶的尺寸约为(10~12) μm×(15~20) μm;在辊速为25 m/s时,柱晶宽度约为360 nm,而一束胞柱晶的尺寸为(5~10) μm×(8~12) μm;在辊速为35 m/s时,柱晶宽度为285 nm,而一束胞柱晶的尺寸为(3~6) μm×(3~10) μm。从这些数据可以看出,快淬速度在15~35 m/s范围内,晶粒随着辊速的增加而细化,但细化的程度逐渐变小。

2.2 凝固织构与各向异性

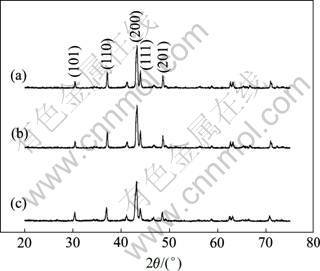

薄带自由面的XRD分析表明,在辊面速度15~ 35 m/s范围内,Sm(Co0.68Fe0.20Cu0.08Zr0.04)12快淬薄带的微观组织都是由Th2Ni17型结构的2?17H相构成,如图3所示。而且,当辊表面速度分别为15、25和35 m/s时,薄带自由面的衍射谱中都出现(200)和(110)衍射峰的相对强度显著增强而(111)衍射峰的相对强度逐步降低的现象,对应的衍射峰强度比I(200) /I(111)分别为3.0、3.6和4.5。这表明,快淬薄带中存在由凝固过程晶体的择优生长而产生的平行于薄带平面的(200)和(110)晶体织构,而且这种晶体织构随淬速的增大而增强。由于2?17H相为六角晶格,由薄带中存在的晶体织构可以判断,2?17相的易磁化方向[001]晶向处于薄带平面内[7, 8, 11, 14]。

图3 不同快淬速度下制得的Sm(Co0.68Fe0.20Cu0.08Zr0.04)12合金薄带的XRD谱

Fig.3 XRD patterns of Sm(Co0.68Fe0.20Cu0.08Zr0.04)12 melt- spun ribbons prepared at different rates: (a) 15 m/s; (b) 25 m/s; (c) 35 m/s

结合薄带中柱状晶组织的生长形态可知,在快淬薄带平面内,每一束柱状晶中各柱晶的[001]晶向是同一取向的,而不同柱状晶束的[001]晶向取向不同。由此可以判断,薄带组织在垂直和平行于薄带的两个方向上是各向异性的,而在薄带平面内的各个方向上是各向同性的[15]。

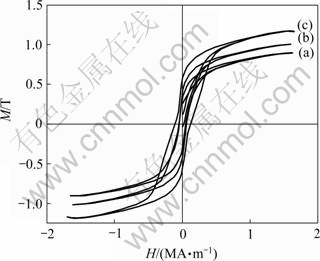

对快淬薄带磁性能测量的结果证实了上述判断。平行于薄带平面带长方向测得的磁滞回线如图4所示。由图4可知,随着辊速的增大,饱和磁化强度、剩磁和矫顽力都增大,这与薄带的凝固组织随着淬速增大而细化直接相关。在淬速35 m/s时,饱和磁化强度为1.19 T,剩余磁化强度为0.57 T,矫顽力为106.98 kA/m。值得注意的是,薄带的Mr /Ms值都小于0.5,说明在薄带平面内是各向同性的。

图4 在不同淬速下制得的Sm(Co0.68Fe0.20Cu0.08Zr0.04)12合金薄带沿平行于薄带平面带长方向的磁滞回线

Fig.4 Hysteresis curves measured along length direction in Sm(Co0.68Fe0.20Cu0.08Zr0.04)12 ribbon plane prepared at different rates: (a) 15 m/s; (b) 25 m/s; (c) 35 m/s

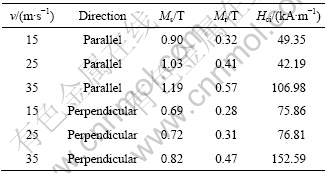

对比表1中列出的平行于薄带平面带长方向和垂直于薄带平面方向测得的磁性能数据发现,后者随辊速的变化规律与前者相同。但是后者的饱和磁化强度和剩磁都小于前者,而矫顽力则大于前者。其中,饱和磁化强度相差0.21~0.37 T,剩磁相差0.04~0.10 T,矫顽力相差26~46 kA/m。这是因为对薄带平面内具有(200)织构的组织而言,当沿着垂直于薄带平面方向测量磁性能时,是沿组织中大多数2?17H相的难磁化方向充、退磁,而当沿着平行于薄带平面方向测量磁性能时,是沿着组织中大多数2?17H相的磁易化方向充、退磁,所以薄带在这两个方向上体现出磁性能各向异性。

表1 Sm(Co0.68Fe0.20Cu0.08Zr0.04)12薄带沿薄带平面带长方向和垂直薄带平面方向的磁性能

Table 1 Magnetic properties of Sm(Co0.68Fe0.20Cu0.08Zr0.04)12 ribbons along length direction in ribbon plane and perpendicular to ribbon plane

3 结论

1) 在辊速15~35 m/s时所得Sm(Co0.68Fe0.20Cu0.08- Zr0.04)12合金快淬薄带的微观组织形貌为束状的取向生长的柱晶在薄带平面内交织排列,每一束胞柱晶内的各个胞柱晶之间相互平行,而各束胞柱晶的取向随机分布。提高辊速对组织细化的作用十分明显,但组织形态未发生改变。

2) Sm(Co0.68Fe0.20Cu0.08Zr0.04)12合金在淬速15、25和35 m/s下所得快淬薄带的微观组织都是由Th2Ni17型结构的2?17相构成的单相组织。其柱状晶的C-轴[001]晶向都在快淬薄带平面内。在快淬薄带平面内,每一束柱状晶中各柱晶的[001]晶向是同一取向的,而不同柱状晶束的[001]晶向取向不同。

3) 随着淬速增大,薄带的饱和磁化强度、剩磁和矫顽力都增大,这与薄带凝固组织随着淬速增大而细化直接相关。薄带组织在垂直和平行于薄带的两个方向上是各向异性的,而在薄带平面内的各个方向上是各向同性的。

致谢:

本实验得到上海交通大学金属基复合材料国家重点实验室和中科院宁波材料技术与工程研究所的支持,在此一并致谢。

[1] DU Xiao-bo, ZHANG Hong-wei, RONG Chuan-bing, ZHANG Jian, ZHANG Shao-ying, SHEN Bao-gen, YAN Yu, JIN Han-min. Magnetic properties and coercivity mechanism of melt-spun Sm(Co1?xFex)6.8Zr0.2C0.06 ribbons with TbCu7 structure[J]. Journal of Magnetism and Magnetic Materials, 2004, 281: 255?260

[2] YAN A, BOLLERO A, GUTFLEISCH O, MULLER K H, SCHULTZ L. Melt-spun precipitation hardened Sm(Co, Fe, Cu, Zr)Z magnets[J]. Mater Sci Eng A, 2004, 375/377: 1169?1172.

[3] GOPALAN R, PING D H, HONO K. Microstructural evolution and the magnetic properties of melt-spun Sm-Co-Cu-B and Sm-Co-Fe-Cu-B ribbons[J]. Journal of Magnetism and Magnetic Materials, 2004, 284: 321?329.

[4] GOLL D, KLEINSCHROTH I, SIGLE W, KRONMULLER H. Melt-spun precipitation-hardened Sm2(Co, Cu, Fe, Zr)17 magnets with abnormal temperature dependence of coercivity[J]. Applied Physics Letters, 2000, 76: 1054?1056.

[5] YAN A, BOLLERO A, MULLER K H, GUTFLEISCH O. Highly Coercive. Melt-spun Sm(Co, Fe, Cu, Zr)z magnets prepared by simple processing[J]. IEEE Transactions on Magnetics, 2002, 38: 2937?2939.

[6] PANAGIOTOPOULOS I, MATTIAS T, NIARCHOS D, FIDLER J. Melt-spun Sm(Co, Fe, Cu, Zr)Z magnets for high-temperature applications[J]. Journal of Magnetism and Magnetic Materials, 2002, 242/245: 1304?1306.

[7] YAN A-ru, ZHANG Wen-yong, ZHANG Hong-wei, SHEN Bao-gen. Characterization of crystalline texture and magnetic properties of melt-spun Sm(Co0.8Fe0.1Cu0.08Zr0.02)7.4 alloy[J]. Mater Sci Eng B, 2000, 76: 169?171.

[8] YAN A, BOLLERO A, MULLER K H, GUTFLEISCH O. Influence of Fe, Zr, and Cu on the microstructure and crystallographic texture of melt-spun 2?17 Sm-Co ribbons[J]. Applied Physics, 2002, 91: 8825?8827.

[9] YAN A R, SUN Z G, ZHANG W Y, ZHANG H W, SHEN B G. Characterization of crystalline texture and magnetic properties of anisotropic melt-spun Sm(CoZr)7Cy alloy[J]. Appl Phys A, 2000, 311/314: 311?314.

[10] LIU S, POTTS G, DOYLE G, YANG J, KUHL G E, CHEN C, WALMER M S, WALMER M H. Effect of z value on high temperature performance of Sm(Co, Fe, Cu, Zr)z with z= 7.14?8.10[J]. IEEE Transactions on Magnetics, 2000, 36: 3297?3299.

[11] GOPALAN R, PING D H, HONO K. Investigation on structure-magnetic property correlation in melt-spun Sm(Co0.56Fe0.31Cu0.04Zr0.05B0.04)Z ribbons[J]. Journal of Magnetism and Magnetic Materials, 2005, 292: 150?158.

[12] HUANG M Q, TURGUT Z, MA M, CHEN Z M, LEE D, HIGGINS A, CHEN C H, LIU S, CHU S Y, HORWATH J C, FINGERS R T, HUANG M Q, TURGUT Z, MA B M. Effects of Zr, Nb, and Cu substitutions on magnetic properties of melt-spun and hot deformed bulk anisotropic nanocomposite SmCo type magnets[J]. Journal of Applied Physics, 2008, 103: 07E134?1?07E134?3.

[13] 周尧和, 胡壮麒, 介万奇. 凝固技术[M]. 北京: 机械工业出版社, 1998: 30?36.

ZHOU Yao-he, HU Zhuang-qi, JIE Wan-qi. Solidification technology[M]. Beijing: China Machine Industry Press, 1998: 30?36.

[14] 周寿增. 稀土永磁材料及其应用[M]. 北京: 冶金工业出版社, 1990: 84?87.

ZHOU Shou-zeng. Rare-earth permanent magnetic materials and their applications[M]. Beijing: Metallurgical Industry Press, 1990. 84?87.

[15] 刘新才. Sm-Co永磁体定向凝固的研究[D]. 西安: 西北工业大学, 1989: 16?37.

LIU Xin-cai. Study on the directional solidification of Sm-Co permanent magnets[D]. Xi’an: Northwest Polytechnic University, 1989: 16?37.

基金项目:国家重大基础研究发展计划前期专项资助项目(2004CCA04000);国家自然科学基金资助项目(50744014);浙江省自然科学基金资助项目(Y406389);宁波市科技攻关资助项目(2006B100054);宁波大学王宽诚幸福基金资助项目

收稿日期:2008-04-11;修订日期:2008-09-20

通讯作者:潘 晶,教授;电话: 0574-87600392;E-mail: panjing@nbu.edu.cn