Self-monitoring electrically conductive asphalt-based composite containing carbon fillers

WU Shao-peng(吴少鹏), LIU Xiao-ming(刘小明), YE Qun-shan(叶群山), LI Ning(李 宁)

Key Laboratory for Silicate Materials Science and Engineering of Ministry of Education,

Wuhan University of Technology, Wuhan 430070, China

Received 10 April 2006; accepted 25 April 2006

Abstract:

A new novel function materials, structure self-monitoring asphalt-based composite was introduced. The results show that the output resistance of electrically conductive asphalt-based composites would change under cyclic loading and vehicle loading action. The resistance change of conductive asphalt-based composites was aroused by the variation of its interior structure. When the fatigue failure was studied, the larger cracks cut the continuous electrically conductive path and the electron is difficult to overcome the potential barrier of gap. In the early period, the slight deformation and microcrack may be recovered due to the viscoelasticity character of asphalt, which leads to some cracks close again, the output resistance changes a little. But with the shear process performs continuously, the cracks become larger and larger, which would cut the conductive path and block off the transition of electrons, and if the cracks are large enough, the pitch-matrix composites containing carbon fillers will lose electrically conductive function. When the rutting failure was studied, the flowage of conductive substance results in the decrease of substance due to electrically conducting and conductive path decreasing. The decrease of electron volume contribute to electrically conducting and large stone aggregate prevent the electron from transiting. In a word, the variation of output resistance is aroused by the variation of interior structure completely.

Key words:

asphalt-based composite; self-monitoring; electrically conductive path; resistivity; microcrack;

1 Introduction

A self-monitoring material refers to a structural material that can monitor itself without the need for embedded, attached or remote sensors. This is possible because the self-monitoring material is itself a sensor. Compared with structural material that requires sensor addition in order to diagnose, self-monitoring materials are advantageous in their durability, low cost, large sensing volume and good mechanical properties. Self-monitoring of reversible strain has been previously reported in cement concrete containing short carbon fibers [1]. The structure self-monitoring bituminous composite materials can also monitor its structure health condition according to the related variation ofresistance [2].

The graphite-modified asphalt-based composite material is made up by adding appropriate conductively material (graphite or carbon black) to common asphalt mixture [3]. The electrically conductively performance of asphalt-based composite will increase greatly and the interior structure will convert from insulator to conductor. Research showed [4, 5]. In the system of graphite- modified bituminous composite materials, the electrically conductive medium is the compounds of asphalt and graphite being filled in the interspaces of asphalt mixture. Graphite is dispersed randomly into the asphalt basement. With the content of graphite increasing to certain extent, the single graphite particles get together and form a continuous electrically conductive access, and the contact resistance between graphite particles governed the resistivity. If the interior structure of samples were changed for exterior loading, which would change the contact interface of graphite particles, then consequently affect the electrically conductive network [6]. So it has important significance to building up the correlation between resistance and structure.

In this paper the basic characters of structure self-monitoring asphalt-based material was described. The purposes of the paper is to provide a new novel function material that has the ability to sense its own fatigue damage, deformation and other failure.

2 Experimental

Asphalt was heavy-duty AH-70 produced by Koch Asphalt Co. Ltd (Hubei Province, China), with a penetration of 55 (0.1 mm at 25 ℃, 100 g & 5 s), ductility 25.3 cm (at 5 ℃) and softening point 47.5 ℃. Aggregate was basalt mineral, with a density of 2.93 g/cm3 and the maximal size 16 mm. Limestone powders were applied as mineral filler, with a density of 2.83 g/cm3, major chemical compounds: CaO 51.5% and SiO2 1.76%. The passed percentage on sieve is 100%, 97.3% and 83.7 % for the sieve openings 0.30, 0.150 and 0.075 mm, respectively. Graphite powders was obtained from Xingtai Graphite Ore Factory (Hebei Province, China), with maximum particle size 150 μm, carbon 98.9%, ash 0.2%,iron 0.03%, the conductivity 105 S/cm. In this study, the superpave12.5 composition was 8.0%-8.5% for asphalt,87% for basalt aggregates and 5% fillers (included limestone powder and graphite powder).

The aggregates were a mixture of 23% crushed stone (4.75-9.5 mm) in mass, 72% fine crushed stone (<2.36 mm) and 5% fillers (<0.075 mm) in mass. Graphite powders in the amount of 30%-40% of asphalt in mass were used. Three specimens of each composition were prepared by gyrate compactor (EP-31111 Model, America) at the temperature of (155±1)℃. Gyrate number is Nini=9, Ndes=125, and Nmax=205. The size of the specimen is d 150 mm×(130±5) mm. Two wire-mesh (70 mm×70 mm, 5 mm×5 mm sieve) electrodes were pre-imbedded on both sides of samples during feeding mixture into the mold. The preparation method of asphalt-based composites can be found in Ref.[7].

Testing was performed at 15℃ under cyclic indirect tensile testing (IDT).The maximum stress of cyclic loading equaled to 8 400 N and minimum stress was 300 N. A hydraulic mechanical testing system (MTS Model 810) was used until the specimens were destructed totally. During mechanical testing, the longitudinal strain was measured by using a strain gage. Simultaneously with mechanical testing, the electrical resistance measurements were made by a Keithley 2700 multimeter (USA). The reading frequency of resistance was equal to that of loading (10 Hz). The longitudinal strain and resistance were measured simultaneously for each specimen. Technical details can be found inRef.[8]. Three specimens of each composition were tested to ascertain reproducibility of the trends here.

3 Results and discussion

3.1 Fatigue damage self-diagnosing upon cyclic loading

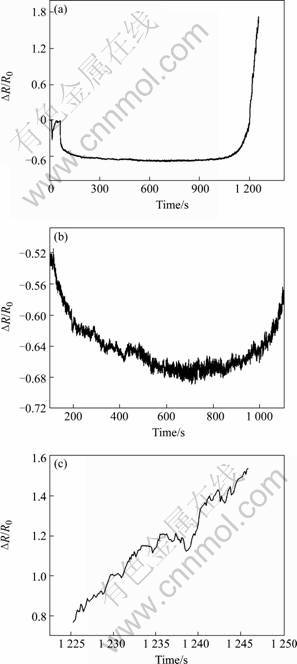

Fig.1 gives the fractional resistance variation(ΔR/R0) during cyclic indirect tensile test. The initial resistance of specimen is 328.12 Ω.

Fig.1 (a) shows thatΔR/R0 decreases as cycling progresses. This decrease occurs in 400 s, after 400 s the curve becomes flat. The flat line persists up to 800 s.

Fig.1 Change of fractional resistance increase (ΔR/R0) during cyclic indirect tensile loading at initial resistance 328.12 Ω: (a) Start to fatigue failure at 1 850 s; (b) 100-1 000 s; (c) Last 20 s before fatigue failure

As shown in Fig.1 (b), the line shows a slight variation at about 400 s (about from 0.45 to 0.60). As shown inFig.1 (c), the variation of resistance ?R/R0 abruptly and greatly increases in fracture period, ?R/R0 changes from 0.54 to 0.59.

Fig.2 shows results similar to Fig.1, except that Fig.2 was obtained from specimen whose initial resistance is 1 118.32 Ω. As shown in Fig.2 (a), the flat section is longer than that in Fig.1 (a). In Fig.2 (b), the variation of ?R/R0 is from 0.52 to 0.68; As in Fig.2 (c), the variation amplitude of ?R/R0, is more than that in

Fig.2 Change of fractional resistance increase (?R/R0) during cyclic indirect tensile loading at initial resistance 1 118.32 Ω: (a) Start to fatigue failure at 1 850 s; (b) 100-1 000 s; (c) Last 20 s before failure

Fig.1 (c), increases from 0.75 to 1.55 in fracture period.

The ?R/R0 curve monotonically decreases upon cyclic loading from start up to around 600 s. This decrease is attributed to the further compacting function caused by cyclic loading, which makes adjacent graphite particles or isolated graphite particles contacted more close. This compacting function enhances the chance for graphite particles to touch each other and forming more electrically conductive networks, thereby causing the?R/R0 curve to decrease. It occurrs only in the early fatigue life. Although the ?R/R0 decrease is clear and monotonic, it is not linear with repeated cycles. Nevertheless, it provides an indication of the extent of compacting function in the interior structure of asphalt-based composite.

With the samples became more and more dense gradually upon cyclic loading, the air void would not change again, and the deformation of asphalt mixture was in steadily state. The slight variation in the ΔR/R0 curve at 400-800 s in Fig.1 and 500-900 s (about 60% of compressive fatigue life) in Fig.2 also show that the interior structure of asphalt concrete would variety slightly. After this period, the slight cracks and damage develop quickly. Therefore, the moment of stabilization longer, the structures of asphalt-based composite is steadier. The flat line during a few cycles prior to fracture provides a warning of the impending fracture.

With the increase of number of cycle, more and more damage and crack appear in the interior structure, which increase distance obstacle and cut the existent electrically conductive accesses. As a result, the conductance of the specimens decrease gradually, and ?R/R0 will increase gradually. Finally, ?R/R0 abruptly and greatly increases at fracture period.

The variation in resistance of asphalt-based composite materials produced by compressive stress or strain can be considered in view of three effects as follows.

1) Proximity effect. As the conductive binder deforms under compressive stress, graphite aggregation is contacted or connected more closely, reducing the contact resistance between graphite particles. Moreover, some narrow insulating gaps between graphite particles are decreased to contact together, developing new or additional conductive paths. The combination function of the two proximity effects mentioned above under stress contributes to the resistance reduction.

2) Microcrack. Based on nonlinear visco-elastic correspondence principle, both microdamage and microdamage healing occur during loading cycles [9]. The gap width of microcracks is too large for electrons to transit, so microcracks destroy the conductive network, as a result, the resistance increases.

3) Dislocation of conductive paths. The large vertical deformation originated from the shear stress between interparticle of stone aggregations results in the dislocation of conductive paths at the horizontal direction. Because of the visco-elastic characteristic of asphalt binder, the vertical deformation cannot recover to previous value. Therefore, some horizontal conductive paths dislocated can not regress to original shape.

The variation of resistance can be regarded as the combination function of the above three effects. Just like the analysis mentioned above, the variation of resistance in asphalt-based composite reflects the variation of microstructure. The structural health monitoring and sensing of asphalt-based composite materials is expected to realize based on the relationship of mechanical properties and electrical properties if further research is conducted. For example, because stress-strain relation depends on permanent deformation, similar general changes in their curves have been obtained. It is helpful to monitor the deformation of asphalt pavement through electrical properties. Moreover, the effect of microcracks on the resistance also can be applied as a promising method in monitoring and sensing the produce and development of crack of asphalt pavement instantly and nondestructively.

3.2 Deformation self-monitoring upon wheel loading

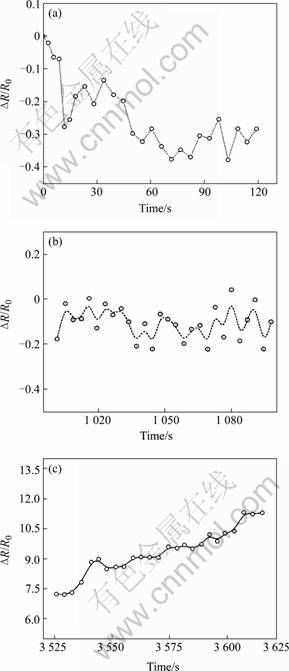

Fig.3 gives the fractional resistance variation (?R/R0) during repeated wheel loading at 0.7 MPa. Fig.3 (a) shows that ?R/R0 decrease as rutting progressed at early 100 s. Fig.3 (b) shows that ?R/R0 in a steady state. As shown in Fig.3 (c), the variation of resistance ?R/R0 abruptly and greatly increases in fracture period.

Fig.3 shows that it has a good real-time corresponding relation between the variation of resistance and the interior structure of specimen. In the early rutting period, the coarse aggregates move away along vertical direction when it is rolled, which forces the asphalt mixture and binder to be compacted. However, the movement of coarse aggregates and asphalt binders leads to the interior structure more compact, and make adjacent conductive fillers (graphite particles or carbon fibers) and isolated conductive fillers contacted more close. This compacting function enhanced the chance for conductive fillers to touch each other and forming more electrically conductive networks, thereby causing ?R/R0 line to decrease. It occurs only in the early rutting process. With the specimens become more and more dense gradually during repeated wheel loading, the air void would not change again, as a result, the resistance are changed very little as shown in Fig.3 (b).

In the later period of rolling, the framework of aggregate becomes unstable. The asphalt and binder flow towards the concentration area because of the lubrication function, and then flow to the free surface of mixture.

Fig.3 Fractional resistance increase (?R/R0) during repeated wheel loading at 0.7 MPa: (a) Start to 100 s; (b) 1 000-1 100 s; (c) Last 100 s

That is to say they all flow from dense area to loose region; the upheaval can be seen at two sides obviously. So the interior structure of specimen is destructed, as a result, the volume output resistance abruptly and greatly increase as shown in Fig.3 (c).

Asphalt pavement top layer will come into being lateral shear flowing under the wheel repeated rolling at high temperature. The flowing is not the flowing on microcosmic level of traditional viscoelastic theory, but is the asphalt mixture structure adjusting constantly on microcosmic level. The character of strain and stress of material itself is the intrinsic factor of rutting, and the lateral distributed rolling is the external factor of microcosmic flowing. Asphalt mixture is the mixing system composed by asphalt binding effect and aggregate skeleton effect. The microstructure strain can overcome the viscous force effect of asphalt film aroused by some grains with weak binding, which cause the mutual moving between some grains. The mutual moving is forced to repeat again and again in the deeper and wider range because of the repeating loading, and then the rutting deform will come into being. The rutting will affect the serving function of roads heavily. Therefore, the rutting damage of asphalt pavement has become an important project which needs to be solved urgently.

It is shown in Fig.4 that the asphalt layer can be divided into two areas under the effect of wheel loading, one is dense flowing area, and the other is loosing flowing area. The section formed by the edge of rutting trace along the thick direction is served as the interface between the two areas. The mixture in dense flowing area flows to the loose flowing area through the interface, which leads to sink of dense flowing area and hump up of the losing area.

Fig.4 Division of deformation area

4 Conclusions

In the service period of asphalt-based composites, it will mostly suffer from two kinds of failure: cracking

And rutting. Experimental results indicate that the resistance change of conductive asphalt-based composites is aroused by the variation of its interior structure. As far as crack is concerned, the larger and larger cracks cut the continuous electrically conductive path and the more difficult the electron is to overcome the potential barrier of gap, so the output resistance is increased with the increment of crack dimension. On the rutting failure side, the decrease of electron volume contributed to electrically conducting and large stone aggregate prevent the electron from transiting, so the output resistance is varied with the flowing of asphalt binder. In a word, the variation of output resistance is aroused by the variation of interior structure completely. Therefore, we can judge the interior structure condition from the variation of output resistance. In other words, the electrically conductive asphalt-based composites have good self-monitoring sense.

References[1] JTJ 073.2-2003, Maintenance Technical Specification for Asphalt Aavement [R]. Beijing: People’s Communication Press, 2003, 8.(in Chinese)

[2] WU S P, MO L T, SHUI Z H. Piezoresistivity of graphite modified asphalt-based composites [J]. Key Engineering Materials, 2003, 249: 391-395.

[3] WU S P, MO L T, SHUI Z H. Percolation model of graphite modified asphalt concrete [J]. J Wuhan Univ of Tech (Mate Sci Ed), 2005, 20(1): 111-113.

[4] JTJ 052-2000. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering[R]. Beijing: People’s Communication Press, 2000. 48-53.

[5] WU S P, MO L T, SHUI Z H, XUAN D X, XUE Y J, YANG W F. Improvement of electrical properties of aspahlt concrete [J]. J Wuhan Univ of Tech(Mate Sci Ed), 2002, 17(4): 69-72.

[6] WEN S H, CHUNG D D L. Effects of carbon black on the thermal, mechanical and electrical properties of pitch-matrix composites [J]. Carbon, 2004, 42(6): 2393-2397.

[7] NAN C W. Physics of in homogeneous inorganic materials [J]. Progress in Mater Sci, 1993, 37: 111-116.

[8] WU S P, MO L T, SHUI Z H, CHEN Z. Investigation of the conductivity of pitch concrete containing conductive fillers [J]. Carbon, 2005, 43(7): 1358-1363.

[9] WU S P, MO L T, LIU X M, SHUI Z H. The conductive mechanism of graphite modified asphalt-based concrete [J]. Progress in Natural Science, 2005, 15(4): 446-451.

Foundation item: Project (2004ABB019) supported by the Outstanding Youth Foundation of Hubei Province, China; project (NCET-05-0656) supported by the New Century Excellent Talents in Wuhan University

Corresponding author: LIU Xiao-ming; Tel: +86-27-87873892; Fax: +86-27-87162595; E-mail: liuxm@mail.whut.edu.cn