J. Cent. South Univ. (2018) 25: 2819-2830

DOI: https://doi.org/10.1007/s11771-018-3955-9

Influence of temperature on swelling deformation characteristic of compacted GMZ bentonite-sand mixtures

CUI Su-li(崔素丽), DU Yan-feng(杜延峰), WANG Xue-pan(王学攀),HUANG Sen(黄森), XIE Wan-li(谢婉丽)

State Key Laboratory of Continental Dynamics, Northwest University, Xi’an 710069, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract:

Laboratory swelling deformation tests were carried out on compacted GMZ bentonite and bentonite-sand mixtures with 30% and 50 % sand contents at 20, 40, 60, 80 and 90 °C with infiltration of distilled water. Influence of temperature, initial dry density, and quartz sand content on the swelling deformation characteristic of compacted bentonite specimens was analyzed. Results indicate that the swelling deformation process is accelerated, and the maximum swelling strain increases with the increase in temperature, while the maximum swelling strain tends to be stable with increasing temperature. In the meantime, the temperature effects depend on both of the sand content and the initial dry density of the specimens, the increases of the maximum swelling strain induced by increasing temperature, are enlarged by increasing sand content or initial dry density. Adding of quartz sand to bentonite not only influences the integrality of bentonite specimen, but also increase the microfissuring in area on quartz sand, which are advantageous to the heat transfer, leading to the increase of swelling deformation capacity of the specimen. The increased dry density relatively increases the bentonite content, so the swelling property is enhanced. However, no change on mineral composition of bentonite was observed when temperature was changed from 20 to 90 °C.

Key words:

GMZ bentonite; swelling strain; temperature; initial dry density; sand content;

Cite this article as:

CUI Su-li, DU Yan-feng, WANG Xue-pan, HUANG Sen, XIE Wan-li. Influence of temperature on swelling deformation characteristic of compacted GMZ bentonite-sand mixtures [J]. Journal of Central South University, 2018, 25(11): 2819–2830.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-018-3955-91 Introduction

Deep geological repository system for high- level radioactive waste is a multi-barrier system including the natural system and engineered barrier systems [1, 2]. The nature barrier system mainly refers to the surrounding rock and the engineered barrier systems include the waste canister and barrier formed by buffer/backfill materials. Compacted bentonite/bentonite-mixtures have been considered the suitable buffer/backfill materials, due to the good sorption properties, low permeability and high swelling capacity of bentonite [3, 4]. Barrier formed by bentonite is has been designed some functions, among which one is swelling to fill the cracks in the grounding rocks caused by tectonic movement, so the possible leakage of the radionuclide from the canister could be stopped.

Therefore, the swelling deformation characteristics of compacted bentonite/bentonite- mixtures need to be investigated seriously, and many researches have been made on this aspect indeed. Results show that swelling property can be influenced by many factors such as density [5], sand proportion [6], pore fluid [7], and temperature [8], among which temperature is one of the important issues for the behaviour of bentonite for there will be heat release during the decay process of nuclear waste, and the temperature of the waste canister will rise due to the heat. Then the temperature of buffer material which is in contact with the canister will also rise. This elevated temperature will impact the properties of bentonite greatly [9–12].

The expansibility of bentonite can be characterized in several forms: volume change behaviour of unsaturated bentonite under different temperature, suction, and stress conditions; swelling pressure under constant volume conditions; swelling strain under one-dimensional free swelling conditions. In the past few years, the influence of heat on the volume change and swelling strain of bentonite and its mixtures under different thermo- mechanical conditions has been investigated in several studies. The volumetric strains of boom clay at different temperatures under different vertical pressure have been investigated. The results show that the swelling deformation of high-density soil at 80 °C is significantly larger than that at 22 °C, especially in the low pressure range [13]. The results of swelling test of compacted FEBEX bentonite show that the maximum swelling strain is increased with the increase in temperature, but the maximum swelling strain will decrease when there was a vertical pressure [14]. Similar results were obtained by LLORET et al [15]. TANG et al [16] observed that MX80 bentonite showed a thermal expansion under 0.1 MPa pressure at suctions of 39 and 110 MPa while presented thermal contraction at a suction of 9 MPa. The same phenomenon was observed for Gaomiaozi (GMZ) bentonite [17]. Influence of temperature on the swelling properties of compacted bentonite was also studied by many researchers. For example, about the influence of heat on swelling pressure of MX-80 bentonite and bentonite-sand mixtures at temperature from 20 to 130 °C [18, 19], FEBEX bentonite at temperatures of 20 and 80 °C [20], Bikaner bentonite and Rourkela local soil at temperatures from 25 to 90 °C [21], compacted MX80 bentonite at 25 and 70 °C [22], and compacted GMZ bentonite at temperatures of 20 and 40 °C [8], some useful results have been obtained.

In China, GMZ bentonite is considered to be the suitable buffer/backfill material for geological disposal of high-level nuclear waste (HLW) [23]. Related researches have been done on many aspects of GMZ bentonite, such as mineral composition, expansive properties, soil–water characteristics, and hydraulic conductivity [24–28]. Some attention has been given to the influence of temperature on the volumetric deformation [29], compression behaviour [30], swelling pressure properties and permeability [8, 31], soil–water characteristics [9], and mineral composition alteration [32] of compacted GMZ bentonite. Dynamic behavior of expersive soil was also studied [33]. However, the knowledge of swelling deformation properties of GMZ bentonite and bentonite-sand mixtures under different heat conditions is limited. To investigate the influence of temperature on the swelling deformation, one-dimensional free swelling tests on compacted GMZ bentonite and bentonite-sand mixtures at temperatures from 20 to 90°C were conducted. Mercury intrusion porosimetry (MIP) tests were performed to determine the change of pore distribution and structure of the bentonite caused by the addition of quartz sand. X-ray diffraction (XRD) tests were also carried out to find out the variation of minerals in the specimen before and after swelling test at different temperatures. Based on the results, influence of temperature, sand contents, and initial dry density on the swelling deformation properties, microstructure, and mineral composition of compacted bentonite specimens was analyzed.

2 Materials and methods

2.1 Materials

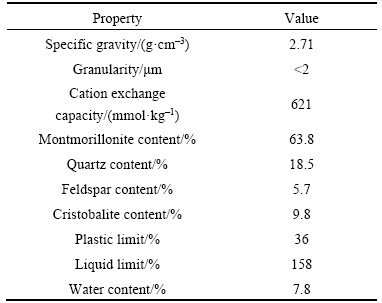

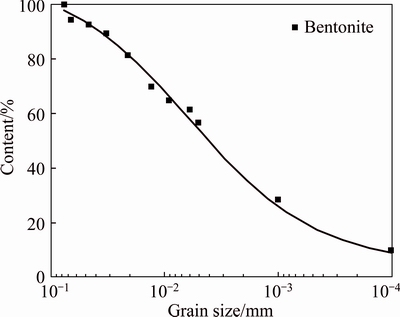

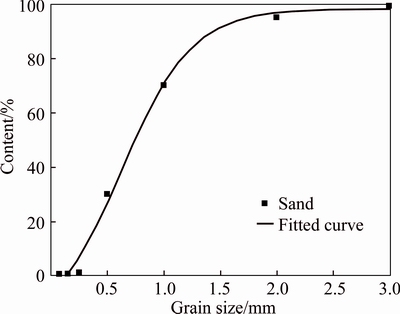

Bentonite used in this paper was mined from a deposit located in Gaomiaozi, in Inner Mongolia, China. It is a light grey Na-bentonite, the montmorillonite mass ratio is 63.8% of which basic physical and chemical properties are presented in Table 1, and the particle size distribution is shown in Figure 1. Quartz sand was obtained from Qinling Mountain in Shanxi Province in China, which contains 99.15% SiO2 and has a specific gravity of 2.67. The particle size distribution is shown in Figure 2. The particle size range used in this study is from 0.5 to 1.0 mm.

Table 1 Physical and chemical properties of GMZ bentonite

Figure 1 Grain size distribution curve for bentonite

Figure 2 Quartz sand particle size distribution

2.2 Sample preparation

Quartz sand was dried at 105 °C and mixed with bentonite powder uniformly to form bentonite- sand mixtures with sand contents, followed by the addition of distilled water. According to the result of heavy compaction tests for bentonite-sand mixtures (Table 2), the values of moisture contents are 19.2%, 14.4% and 11.5% for mixtures with sand contents of 0, 30% and 50%, respectively. Then specimens were statically compacted directly in a specially-designed cylindrical mould (with an inner diameter of 61.8 mm and a height of 60 mm). A compaction load was applied through a piston at a speed of 10 kN/min, step by step, to a final value of 50 kN, and the predetermined height of the specimen was 20 mm, the values of dry density were 1.60, 1.80 and 2.00 g/cm3 for specimens with sand contents of 0, 30% and 50%, respectively, according to Table 2. Specimens were pushed out after the predetermined height was reached and the load was also maintained for 30 min. After that, the specimen was immediately put into the swelling deformation test ring.

Table 2 Compaction property of bentonite-sand mixtures

2.3 Experimental method

The swelling test apparatus under different temperatures is shown in Figure 3. It includes two parts. One is for swelling deformation measurement and another one is for temperature control. The former is a modified swelling deformation apparatus including a specimen ring (Фinner 61.8 mm×H20 mm), one retaining ring, three fixed screws, some porous stones at the bottom, and an organic glass gland with some holes (porous disc) at the top for the infiltration of solutions, and a dial indicator in contact with the porous disc for measuring the vertical deformation. Another part is the thermostat water bath for providing various temperature environments using hot water outside the measuring apparatus. The inner wall of the specimen ring was wiped with Vaseline, in order to reduce the friction between the inner wall of the ring and the specimen. The prepared specimen was pushed into the ring, and then the specimen ring was fixed by screws to the bottom of the apparatus and the retaining ring at the top. The dial gauge was fixed on the bracket and adjusted until the contact was touching the specimen, and the initial digital pointer was usually adjusted to about 10, recorded as s1, then distilled water was injected into the bath and the liquid level was kept 5 mm higher than the upper surface of the specimen throughout the test. The digital of pointer was recorded at regular intervals as si, so the vertical deformation of the specimen could be calculated using the following formula:

(1)

(1)

The swelling strain is defined as:

(2)

(2)

where △H is the current vertical swelling deformation, and H0 is the initial height of the specimen. The test was ended when the digital of pointer had not changed in three days, and the final swelling deformation was recorded as the maximum swelling deformation, and the swelling strain was regarded as the maximum swelling strain, εmax.

Figure 3 Experimental setup for swelling deformation test with temperature control (1–Modified dilatometer; 2–Dial indicator; 3–Retaining ring; 4–Shipping rod; 5–Porous disc; 6–Cutting ring; 7–Porous stone; 8–Filter paper; 9–Specimen; 10–Thermostatic water bath)

PASTINA et al [34] reported that the maximum temperature caused by decay heat could reach 90 °C. H KMARK et al [35] calculated that the maximum temperature gradient is below 24 °C over the 0.35 m thick buffer material. Based on these studies, the temperatures selected for this study were 20, 40, 60, 80 and 90 °C, supplied by the thermostat water case which surrounded the swelling deformation device. The temperature of the water in the dilatometer compared with that of the water in the thermostat water bath is shown in Figure 4. It can be seen that after about 60 min, the temperature of the water in the dilatometer was almost the same as the temperature of the water in the thermostat water bath, with subsequent temperature fluctuation of less than 2 °C. So, the temperature of the thermostat water was considered to be the temperature of the swelling test. The pH of the water in the dilatometer was 7.1.

KMARK et al [35] calculated that the maximum temperature gradient is below 24 °C over the 0.35 m thick buffer material. Based on these studies, the temperatures selected for this study were 20, 40, 60, 80 and 90 °C, supplied by the thermostat water case which surrounded the swelling deformation device. The temperature of the water in the dilatometer compared with that of the water in the thermostat water bath is shown in Figure 4. It can be seen that after about 60 min, the temperature of the water in the dilatometer was almost the same as the temperature of the water in the thermostat water bath, with subsequent temperature fluctuation of less than 2 °C. So, the temperature of the thermostat water was considered to be the temperature of the swelling test. The pH of the water in the dilatometer was 7.1.

Figure 4 Temperature of water in dilatometer vs time

A mercury intrusion porosimetry (MIP) test and X-ray diffraction (XRD) test were performed. The MIP test was used to determine the pore size distribution of porous materials based on the unique relationship between intrusion pressure and equivalent pore diameter proposed by WASHBURN [36]:

(3)

(3)

in which D is the pore diameter; P is the applied pressure; γ is the surface tension of mercury; θ is the contact angle. The X-ray diffraction (XRD) analysis was performed to analyze the evolution of the contents of clay minerals and the secondary phases formed for bentonite before and after the swelling deformation test at different temperatures. Tests were performed using a XRD-6100 X-ray diffractometer with CuKa radiation (λ=0.1541838 nm). The specimens were scanned for 2θ values ranging between 4° to 90°, with a scanning rate of 10°/min.

3 Experimental results

3.1 Evolution of swelling strains

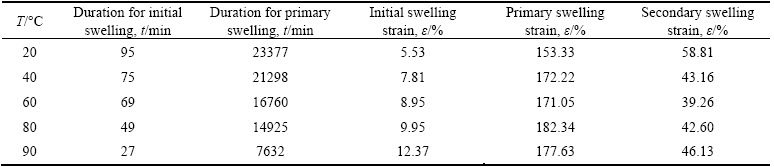

Evolution of swelling strains for compacted GMZ bentonite specimens at 20, 40, 60, 80 and 90 °C is shown in Figure 5. It can be seen that the swelling strain increases with time. The swelling strain–time plots in semi-log coordinates show an “S” shape, and can be divided into three stages: an initial swelling, followed by a rapid primary swelling, and a slow secondary swelling, according to SRIDHARAN et al [37]. Taking a specimen at 90 °C for example, the schematic diagram for the separation of initial, primary, and secondary swelling is shown in Figure 5, and the dividing points between the swelling stages have been marked. The dividing of swelling stages for other specimens is the same as this. During the primary swelling stage, water begins to enter inter-granular pores and bentonite in contact with water expands rapidly. This expansion relates to the rate of matric suction dissipation [38]. Because matric suction changes quickly with water content, this stage lasts a short time. The secondary swelling stage develops very slowly, and is controlled by the transportation of salts and adsorption–desorption reactions [39]. However, the demarcation points of these three stages are different for bentonite specimens at various temperatures. The duration and swelling strain for every stage are calculated and presented in Table 3, showing that the duration of the initial swelling is decreased with increased temperature, while the swelling strain is increased. Similarly, the duration of the primary swelling stage is reduced and the swelling strain is increased with an increase in temperature. These results indicate that elevated temperature accelerates the process of swelling and increases the swelling deformation in these two stages.

Figure 5 Swelling strain vs time for pure bentonite

Figure 5 also shows that the maximum swelling strain is increased with an increase in temperature, and the evolution of the primary swelling stage is different for specimens at different temperatures that it rises smoothly for specimens at low temperatures such as 20 and 40 °C, while the rate of increase varies for specimens at high temperatures such as 60, 80 and 90 °C. The increase in temperature increases the kinetic energy of the water molecules, and tends to accelerate the interaction between water and soil, making the swelling process faster. However, because the thermal conductivity of bentonite is low, the temperature rise is not uniform in the specimen; bentonite which is in direct contact with water will swell quickly, while the rest will swell slowly, making the macroscopic swelling speed of bentonite a phenomenon that it sometimes is fast and sometimes is slow.

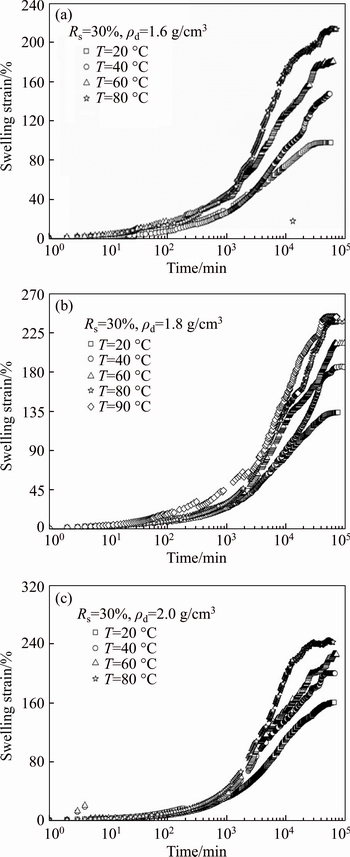

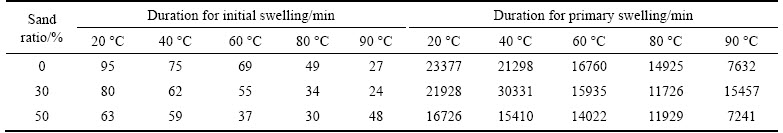

Figures 6 and 7 show the evolutions of swelling strains for compacted GMZ bentonite– sand mixture specimens with 30% and 50% sand content. Similar to Figure 5, there are three swelling stages for the whole swelling process, and the maximum swelling strain increases with the increase in temperature; the process of the primary swelling stage for specimens at low temperatures is smooth while it fluctuates at high temperatures. However, there are also some obvious differences. First, the fluctuation of the swelling process is more obvious with the increased sand content. Second, the growth rate of the maximum swelling strain with increased temperature is enhanced by sand content. Third, the duration of both the primary and secondary swelling stages for bentonite–sand mixtures is shown in Table 4. Because the swelling process is not a typical “S” shape, the dividing points are not very accurate, but they can also give a tendency for the duration of both primary and secondary swelling stage to be shortened with the increase in sand content, showing that the addition of sand can accelerate the influence of the temperature.

Table 3 Duration and swelling strain for bentonite at different temperatures

Figure 6 Swelling strain vs time for bentonite with 30% sand ratio

Figure 7 Swelling strain vs time for bentonite with 50% sand ratio

3.2 Temperature influence on swelling strain

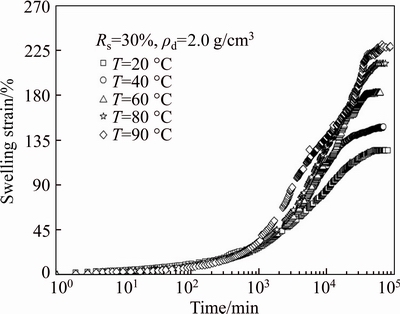

Figure 8 shows the relationship between maximum swelling strain and temperature for compacted specimens with different sand contents and different dry densities for 30% sand content. Figure 8(a) indicates that the maximum swelling strain increases with the temperature rise, but the increase in range is different: the maximum swelling strain increases from 211% (20 °C) to 239% (90 °C) for pure bentonite, while the value increases from 133% (20 °C) to 245% (90 °C) for 30% sand content, and 122% (20 °C) to 229% (90 °C) for 50 % sand content. The increasing rates are 13.27%, 82.70% and 87.70%, respectively, for these three specimens. These results indicate that elevated temperature can improve the maximum swelling strain of bentonite. Meanwhile, the temperature effect on bentonite–sand mixtures is higher than that on pure bentonite, and the effect increases with the increase in sand contents. The maximum swelling strains of 30% compacted bentonite-sand mixture specimen at different temperatures with dry densities of 1.60, 1.80 and 2.00 g/cm3 are presented in Figure 8(b): the maximum swelling strain increases from 97.81% (20 °C) to 214% (80 °C) for the specimen with 1.60 g/cm3, while it increases from 133% (20 °C) to 245% (90 °C) for 1.80 g/cm3, and 160% (20 °C) to 243% (80 °C) for 2.00 g/cm3. It can be calculated that the increasing rates are 118.79%, 84.21% and 51.87%, respectively, for these three specimens, indicating that the growth rate of the maximum swelling strain is reduced with the increase of dry density.

Table 4 Duration of different stages for bentonite–sand mixtures at different temperatures

Figure 8 Relationship between maximum swelling strain and temperature for different sand ratios (a) and different dry densities (b)

Elevated temperature can improve the maximum swelling strain, but the effect is not constant and the growth rate of the maximum swelling strain becomes lower with the increase in temperature for specimens with a certain sand content and initial dry density. And the temperature effect on bentonite-sand mixtures is more obvious than that on pure bentonite (Figure 8(a)).

3.3 Microstructure and mineral composition tests

3.3.1 Mercury intrusion porosimetry (MIP) method

Figure 9 shows the cumulative curves (a) and pore size distribution curves (b) of bentonite–sand mixture specimens before the swelling test. It can be seen from Figure 9(a) that the cumulative pore volume for bentonite–sand mixture specimens decreases with the increase in sand content. This is mainly because quartz sand grain is a completely solid mineral and has no pores, with the increase in sand content, the quantity of bentonite is decreased and the porosity decreases. Figure 9(b) plots the differential pore volume distribution curves. It is observed that the size of the pore population is different for various sand content specimens. One pore population with pore sizes from 0.013 to 0.026 μm exists in all specimens, which belongs to the transition phase from intra-granular pores (d<0.014 μm) to inter-granular pores (0.014–1.8 μm), according to the pore classification [40]. The peak value for this population decreases with the increase in sand content. The peak value for another pore population with pore size of 1.02 μm, which also belongs to inter-granular pores, decreases from 0.581 (0%) to 0.151 (30%), and eventually disappears in specimens with 50% sand content. Meanwhile, two new populations emerge, with sizes about 3.5 and 11 μm, for specimens with 30% and 50% sand content. These pores belong to intra-aggregate pores (1.8–70 μm), and the peak values are increased with sand content. These indicate that adding sand to bentonite could reduce the amount of inter-granular pores, while increase the intra-aggregate pores.

Figure 9 Cumulative curves (a) and pore size distribution curves (b) of bentonite–sand mixtures specimen before swelling test

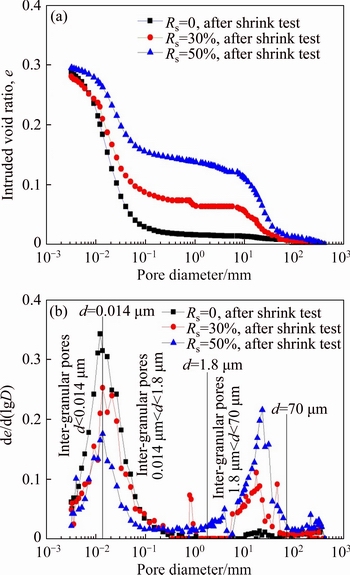

The cumulative curves (a) and pore size distribution curves (b) of bentonite–sand mixture specimens after the shrink test are shown in Figure 10. It is important to point out that, ‘after the shrink test’ refers to specimens that have finished the swelling test, then lost water and shrunk to a stable size. It can be observed from Figure 10(a) that the total porosity of specimens after the shrink test is almost the same for these three specimens. Compared with Figure 9(a), it can be seen that the total porosity is much lower than that of the specimens before the swelling test, indicating that bentonite can shrink to a denser state than that before swelling test. Furthermore, this can be confirmed from Figure 10(b) by comparing with Figure 9(b). For these three specimens, the quantity of pores with sizes from 0.013 to 0.026 μm increases and the size decreases, while the pore population with pore size of 1.02 μm disappears for the 0% specimen, and both the quantity and the size of intra-aggregate pores increase for 30% and 50%. These results show that adding sand to bentonite makes the number of intra-aggregate pores increase, and leads to an enhanced total porosity after the swelling test, and then shrunk to a stable point. In addition, a higher sand content will lead to larger pore size and porosity. This can be confirmed from Figures 9(a) and 10(a) that the total porosities of the 30% and 50% specimens are far below that of the 0% specimen before swelling test, while the value of the 30% specimen is a little lower than the 0% specimen, and that of the 50% specimen is a little higher.

These results suggest that a bentonite specimen which has undergone the swelling test and then shrunk to a stable state, has a smaller pore size and greater compactness, and that the sand content has an obvious effect on the pore distribution of specimens after the test. These are interesting results, and may be useful to the function of bentonite placed in dry–wet alternate environments in high level radioactive waste repositories.

Figure 10 Cumulative curves (a) and pore size distribution curves (b) of bentonite–sand mixture specimen after shrink test

3.3.2 X-ray diffraction (XRD) measurement

In order to make it clear whether temperature will change the mineral composition, X-ray diffraction (XRD) experiments were carried out on bentonite specimens before and after swelling tests at 20, 60 and 90 °C.

It can be seen clearly from Figure 11 that the peak value and the differences are essentially the same for these three specimens, that is, the composition of smectite mineral in these specimens is almost the same, and there is no mineral composition change phenomenon, meaning that smectite mineral cannot be transformed into other minerals such as illite at temperatures lower than 90 °C.

Figure 11 XRD patterns of bentonite specimens before swelling test and after shrink test

4 Discussions

Swelling tests were performed to check the effect of temperature ranging from 20 to 90 °C on the compacted GMZ bentonite–sand mixtures. Results show that the maximum swelling strain of bentonite and its sand mixtures are enhanced with the increase in temperature, and similar results have been obtained by other researchers. ROMERO et al [13] studied the volumetric strains of compacted boom clay with a dry density of 1.67 g/cm3 under various vertical stresses at temperatures of 22 and 80 °C. The volumetric strain was increased from 0.25% (22 °C) to 0.75% (80 °C) for specimens under a vertical pressure of 0.6 MPa, increased from 0.5% to 2.0% (vertical pressure of 0.3 MPa), and increased from 4.0% to 7.0% (vertical pressure of 0.08 MPa). These results mean that the influence of temperature on the swelling behaviour is variable, and swelling deformation of the high-density soil is significantly larger at the higher temperature, especially in the low-stress range. The same conclusion has been obtained from the swelling test of compacted boom clay under vertical pressure of 0.026 MPa [14]. In addition, VILLAR et al [15] performed swelling tests on compacted FEBEX bentonite under different vertical pressure at temperatures from 30 to 80 °C. Results showed that with the increase of temperature, the maximum swelling strain was reduced from 8% to 5% for specimen under a vertical pressure of 3 MPa, reduced from 23% to 19% (vertical pressure of 0.5 MPa) and enhanced from 32% to 37% (vertical pressure of 0.1 MPa), indicating that the maximum swelling strain of a specimen was reduced by elevated temperature under high vertical pressure but enhanced under low vertical pressure. These accord with the results obtained from this study, in which the test was a one-dimensional free swelling test.

The swelling of bentonite mainly depended on the type and amount of bentonite, type of exchangeable cation, and the microstructural water placed in the interlayer. So, specimens with higher dry density have higher swelling strain due to their higher montmorillonite content (Figure 8(b)). Elevated temperature also has an obvious influence on the maximum swelling strain (Figure 8(a)). With the increase of temperature, the osmotic pressure is increased, and then the double-layer repulsion of adjacent stacks will be increased. This would require a raise in applied pressure to maintain constant volume for a specimen with low dry density in a constant volume swelling test, which presents as an increasing swelling pressure [19]. While a one-dimensional free swelling test is used in this study, the increased double-layer repulsion of adjacent stacks would make the distance between adjacent stacks increase, leading to an increased swelling deformation. In addition, with the increase of temperature the additional water molecules are embedded into the soil matrix, especially into the inter layers of expansive minerals, also causing an increase of swelling deformation [41].

It also can be seen from Figure 8(a) that adding sand to bentonite will improve the influence of temperature on swelling strain conspicuously. It is generally acknowledged that sand has no expansibility, so adding sand to bentonite makes its swelling properties decrease, due to the reduction of the amount of bentonite. However, the results obtained from Figure 8(a) show that the effect of temperature is higher for the higher sand content, which suggests that the effect of temperature is improved as the sand content is higher. This phenomenon can be explained by the observed results of MIP experiments from Figure 9 (b), which shows that the peak values of smaller size pore populations are reduced, or even disappear, with the increase of sand content, while larger size pores appeared in bentonite-sand mixtures. These results suggest that adding sand to bentonite not only breaks the integrity of the specimen but also changes the structure of the area without sand. Larger pores increase gradually with the increase of sand content, causing the specimens to have microcracks, then the conduction of heat and water in the specimen is improved. XU et al [42] also reported that the increase in sand content could improve both the thermal conductivity and hydraulic conductivity of bentonite–sand mixtures significantly. So, the growth rate of the maximum swelling strain due to temperature is raised as the sand content ratio increases, so the effect of temperature on the swelling deformation of bentonite-sand specimens is more prominent than that on pure bentonite.

The result of XRD proves that there is no change in mineral composition in this study. Indeed, smectite can be subjected to illitization, kaolinitization, saponitization, etc., through the processes of dissolution, cementation, and precipitation. However, these processes depend on the environmental conditions. According to several experimental studies, illitization of smectite could occur above 120 °C even 250 °C [43]. The mineralogical composition also could be changed due to the pore solutions of high pH and high salinity at an elevated temperature lower than 100 °C [44]. In this study, the pore solution is distilled water and the pH was 7.1, and the temperature was lower than 90 °C, so no mineralogical composition exchange occurred during the swelling test, and the influence of temperature on the swelling deformation characteristic was only reflected in an increase in the diffuse layer thickness, reducing the surface potential and dielectric constant of pore fluid.

5 Conclusions

1) The evolution curve of the swelling stage for bentonite-sand mixtures is smooth at low temperatures and fluctuant at high temperatures. The fluctuation is more obvious with the increase of sand content. The durations for both the initial swelling and primary swelling stages are shorted with the increase of temperature and sand content.

2) The maximum swelling strain is increased with the increase of temperature for specimens with the same sand content, but the growth rate gradually reduces with increasing temperature. The influence is enhanced by increasing sand content or initial dry densities.

3) The cumulative pore volume for bentonite– sand mixture specimens decreases with the increase of sand content. The quantity of smaller pore populations reduces, while that of larger pore populations increases in bentonite–sand mixtures compared with pure bentonite specimens. After the shrink test, the total porosity of pure bentonite specimens is much lower than that before the swelling test, but the porosity of bentonite-sand mixtures is just reduced a little due to its production of more intra-aggregate pores during the shrinking process.

4) No mineralogical composition change was detected for specimens during the swelling test under temperature from of 20 to 90 °C in this study with infiltration of distilled water at pH=7.1.

References

[1] RADHAKRISHNA H S, CHAN H T, CRAWFORD A M, LAU K C. Thermal and physical properties of candidate buffer-backfill materials for a nuclear fuel waste disposal vault [J]. Canadian Geotechnical Journal, 1989, 26: 629–639.

[2] CHAPMAN N, HOOPER A. The disposal of radioactive wastes underground [J]. Proceedings of the Geologists’ Association, 2012, 123(1): 46–63.

[3] VILLAR MV. Investigation of the behaviour of bentonite by means of suction controlled oedometer tests [J]. Engineering Geology, 1999, 54 (1, 2): 67–73.

[4] YE W M, CHEN Y G, CHEN B, WANG Q, WANG J. Advances on the knowledge of the buffer/backfill properties of heavily-compacted GMZ bentonite [J]. Engineering Geology, 2010, 116(1): 12–20.

[5] KAUFHOLD S, BAILLE W, SCHANZ T, DOHRMANN R. About differences of swelling pressure-dry density relations of compacted bentonites [J]. Applied Clay Science, 2015, 107: 52–61.

[6] CUI S L, ZHANG H Y, ZHANG M. Swelling characteristics of compacted GMZ bentonite–sand mixtures as a buffer/ backfill material in China [J]. Engineering Geology, 2012, 141–142: 65–73.

[7] YE W M, ZHU C M, CHEN Y G, CHEN B, CUI Y J, WANG J. Influence of salt solutions on the swelling behaviour of the compacted GMZ01 bentonite [J]. Environmental Earth Sciences, 2015, 74: 793–802.

[8] YE W M, WAN M, CHEN B, CHEN Y G, CUI Y J, WANG J. Temperature effects on the swelling pressure and saturated hydraulic conductivity of the compacted GMZ01 bentonite [J]. Environmental Earth Sciences, 2013, 68: 281–288.

[9] YE W, WAN M, CHEN B, CHEN YG, CUI YJ, WANG J. Effect of temperature on soil-water characteristics and hysteresis of compacted Gaomiaozi bentonite [J]. Journal of Central South University, 2009, 16(5): 821-826.

[10] RAMAKRISHNA B, AHSAN R. Effect of temperature on swelling pressure and compressibility characteristics of soil [J]. Applied Clay Science, 2017, 136: 1–7.

[11] VILLAR M V, GOMEZ-ESPINA R, LLORET A. Experimental investigation into temperature effect on hydro-mechanical behaviours of bentonite [J]. Journal Rock Mechanics and Geotechnical Engineering, 2010, 2(1): 71– 78.

[12] CHO W J, LEE JO, KANG C H. Influence of temperature elevation on the sealing performance of a potential buffer material for a high-level radioactive waste repository [J]. Annals of Nuclear Energy, 2000, 27: 1271–1284.

[13] ROMERO E, GENS A, LLORET A. Suction effects on a compacted clay under non-isothermal conditions [J]. Géotechnique, 2003, 53(1): 65–81.

[14] ROMERO E, VILLAR M V, LLORET A. Thermo-hydro- mechanical behaviour of two heavily overconsolidated clays [J]. Engineering Geology, 2005, 81: 255–268.

[15] LLORET A, ROMERO E, VILLAR M V. FEBEX II project final report on thermo-hydro-mechanical laboratory tests [R]. Madrid: Publicación Técnica ENRESA 10/04, 2004: 180.

[16] TANG A M, CUI Y J, BARNEL N. Thermo-mechanical behaviour of a compacted swelling clay [J]. Géotechnique, 2008, 58(1): 45–54.

[17] CUI Y J, TANG A M, QIAN L X, YE W M, CHEN B. Thermal-mechanical behaviour of compacted GMZ bentonite [J]. Soils and Foundations, 2011, 51(6): 1065–1074.

[18] PUSCH R. The permeability of highly compacted bentonite [R]. Stockholm: SKB, Swedish Nuclear Fuel and Waste Management Company. 1980.

[19] PUSCH R, KARNLAND O, HOKMARK H. GMM a general microstructural model for qualitative and quantitative studies of smectite clays [R]. Stockholm: SKB, 1990.

[20] VILLAR M V, LLORET A. Influence of temperature on the hydro-mechanical behaviour of a compacted bentonite [J]. Applied Clay Science, 2004, 26: 337–350.

[21] BAG R, RABBANI A. Effect of temperature on swelling pressure and compressibility characteristics of soil [J]. Applied Clay Science, 2017, 136: 1–7.

[22] TRIPATHY S, BAG R, THOMAS H R. Enhanced isothermal effect on swelling pressure of compacted MX80 bentonite [J]. Engineering Geology, 2015, 6: 537–539.

[23] CHEN B, QIAN LX, YE W, CUI Y, WANG J. Soil-water characteristic curves of Gaomiaozi bentonite [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(4): 788–793. (in Chinese)

[24] LUI Y, XU G, LIU S. Study on the basic property of Gaomiaozi bentonite, Inner Mongolia [M]. Beijing: China Nuclear Industry Audio & Visual Publishing House, 2001: 1–20. (in Chinese)

[25] CHEN Y G, YE W M, YANG X M, DENG F Y, HE Y. Effect of contact time, pH, and ionic strength on Cd (II) adsorption from aqueous solution onto bentonite from Gaomiaozi, China [J]. Environmental Earth Sciences, 2011, 64(2): 329–336.

[26] YE W M, CUI Y J, QIAN L X, CHEN B. An experimental study of the water transfer through confined compacted GMZ bentonite [J]. Engineering Geology, 2009, 108(3, 4): 169–176.

[27] CUI S, SI D. Experimental research of swelling behaviors with initial water content and matric suction of bentonite– sand mixtures [J]. Geosystem Engineering, 2014, 17(6): 317–324.

[28] ZHANG H, CUI S, ZHANG M, JIA L. Swelling behaviors of GMZ bentonite-sand mixtures inundated in NaCl-Na2SO4 solution [J]. Nuclear Engineering and Design, 2012, 242: 115–123.

[29] YE W M, ZHANG Y W, CEHN Y G, CHEN, B, CUI Y J. Experimental investigation on the thermal volumetric behaviour of highly compacted GMZ01 Bent [J]. Applied Clay Science, 2013, 83–84: 210–216.

[30] YE W M, ZHANG Y W, CHEN B, CHEN Y G, CUI Y J. Investigation on compressibility of highly compacted GMZ01 bentonite with suction and temperature control [J]. Nuclear Engineering and Design, 2012, 252: 11–18.

[31] YE W M, ZHENG Z J, CHEN B, CHEN Y G, CUI Y J, WANG J. Effects of pH and temperature on the swelling pressure and hydraulic conductivity of compacted GMZ01 bentonite [J]. Applied Clay Sciences, 2014, 101: 192–198.

[32] YE W M, HE Y, CHEN Y G, CHEN B, CUI Y J. Thermo- chemical effects on the smectite alteration of GMZ bentonite for deep geological repository [J]. Environmental Earth Sciences, 2016, 75(10): 1–11.

[33] QIU Ming-ming, YANG Guo-lin, SHEN Quan, YANG Xiao, WANG Gang, LIN Yu-liang. Dynamic behavior of new cutting subgrade structure of expensive soil under train loads coupling with service environment [J]. Journal of Central South University, 2017, 24(4): 875–890. DOI: 10.1007/ s11771-017-3490-0.

[34] PASTINA B, HELL P. Expected evolution of a spent nuclear fuel repository at Olkiluoto [R]. Olkiluoto: Finland, Posiva Oy, 2006.

P. Expected evolution of a spent nuclear fuel repository at Olkiluoto [R]. Olkiluoto: Finland, Posiva Oy, 2006.

[35] H KMARK H, F

KMARK H, F LTH B. Thermal dimensioning of the deep repository [R]. Svensk: K

LTH B. Thermal dimensioning of the deep repository [R]. Svensk: K rnbr

rnbr nslehantering AB, 2003.

nslehantering AB, 2003.

[36] WASHBURN E W. Note on a method of determining the distribution of pore sizes in a porous material [J]. Proceedings of the National Academy of Sciences of the United States of America, 1921, 7(4): 115–116.

[37] SRIDHARAN A, GURTUG Y. Swelling behaviour of compacted fine-grained soils [J]. Engineering Geology, 2004, 72(1): 9–18.

[38] RAO S M, THYAGARAJ T, THOMAS H R. Swelling of compacted clay under osmotic gradients [J]. Geotechnique, 2006, 56(10): 707–713.

[39] SHACKELFORD C, DANIEL D. Diffusion in saturated soils, Part I [J]. Geotechnical Engineering, 1991, 117: 467–484.

[40] SHEAR M K, COOPER A M, KLERMAN G L, BUSCH F N, SHAPIRO T. A psychodynamic model of panic disorder [J]. American Journal of Psychiatry, 1993, 150: 859–866.

[41] XIE M, WANG W Q, JONGE K. Numerical modelling of swelling pressure in unsaturated expansive elasto-plastic porous media [J]. Transport in Porous Media, 2007, 66: 311–339.

[42] XU L, YE W M, CHEN B, CHEN Y G, CUI Y J. Experimental investigations on thermo-hydro-mechanical properties of compacted GMZ01 bentonite-sand mixture using as buffer materials [J]. Engineering Geology, 2016, 213(1): 46–54.

[43] INOUE A. Formation of clay minerals in hydrothermal environments [J]. Origin and Mineralogy of Clays, 1995: 268–329.

[44] YE W M, HE Y, CHEN Y G, CHEN B, CUI Y J. Thermochemical effects on the smectite alteration of GMZ bentonite for deep geological repository [J]. Environmental Earth Sciences, 2016, 75(10): 1–11.

(Edited by YANG Hua)

中文导读

温度对压实GMZ膨润土-砂混合物膨胀变形特性的影响

摘要:本文对压实GMZ膨润土及掺砂率为30%和50%的膨润土-砂混合物试样在温度分别为20, 40, 60, 80 和 90 °C的条件下进行了膨胀变形试验,试验所用孔隙液为蒸馏水。分析了温度、初始干密度和掺砂率对膨润土-砂混合物压实试样膨胀变形性质的影响。结果表明,随着温度的升高,试样的膨胀变形过程加速,最大膨胀率增大并最终趋于稳定。同时,温度对试样膨胀性的影响会受到掺砂率和初始干密度的影响。因温度的升高而增大的最大膨胀率,随着试样掺砂率或初始干密度的增大而增大。这是因为向膨润土中添加石英砂不仅破坏了试样的整体性,并且使得在没有石英砂区域的微裂隙增多,提高了试样的热传导性和渗透性从而最终导致试样膨胀能力的提高。增大的初始干密度提高了试样中膨润土的相对含量,从而使得试样的膨胀性增大。在本研究的条件下,没有发现膨润土中矿物成分发生改变。

关键词:GMZ 膨润土;膨胀率;温度;初始干密度;掺砂率

Foundation item: Project(41402260) supported by the National Natural Science Foundation of China; Project(20136101120006) supported by the Research Fund for the Doctoral Program of Higher Education, China

Received date: 2017-09-14; Accepted date: 2018-01-21

Corresponding author: CUI Su-li, PhD; Tel: +86-18092677260; E-mail: cuisl@nwu.edu.cn; ORCID: 0000-0001-8220-0126

Abstract: Laboratory swelling deformation tests were carried out on compacted GMZ bentonite and bentonite-sand mixtures with 30% and 50 % sand contents at 20, 40, 60, 80 and 90 °C with infiltration of distilled water. Influence of temperature, initial dry density, and quartz sand content on the swelling deformation characteristic of compacted bentonite specimens was analyzed. Results indicate that the swelling deformation process is accelerated, and the maximum swelling strain increases with the increase in temperature, while the maximum swelling strain tends to be stable with increasing temperature. In the meantime, the temperature effects depend on both of the sand content and the initial dry density of the specimens, the increases of the maximum swelling strain induced by increasing temperature, are enlarged by increasing sand content or initial dry density. Adding of quartz sand to bentonite not only influences the integrality of bentonite specimen, but also increase the microfissuring in area on quartz sand, which are advantageous to the heat transfer, leading to the increase of swelling deformation capacity of the specimen. The increased dry density relatively increases the bentonite content, so the swelling property is enhanced. However, no change on mineral composition of bentonite was observed when temperature was changed from 20 to 90 °C.