喷射沉积AlFeVSi合金热暴露过程中相转变与沉积态组织特点

肖于德1, 2,钟 掘2,黎文献1,马正青1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 机电工程学院,湖南 长沙,410083)

摘 要:

摘 要:采用喷射沉积工艺制备快速凝固AlFeVSi合金薄片和沉积管坯,通过示差热分析、X射线衍射分析、金相显微组织观察、透射电镜组织观察、硬度测试等检测手段,研究了喷射沉积AlFeVSi合金快凝薄片在高温热暴露过程中的相变和组织演变规律,并分析了喷射沉积AlFeVSi合金坯组织特点。结果表明,喷射沉积AlFeVSi快凝薄片基本上为呈微胞状的过饱和α-Al固溶体。加热温度低于500 ℃时,在高温热暴露过程中微胞状结构发生分解,α-Al过饱和固溶体脱溶,形成α-Al+Al12(Fe,V)3Si (bcc,a≈1.260 nm) 弥散颗粒的分解产物,当温度高于500 ℃时,Al12(Fe,V)3Si颗粒粗化聚集,并以独立形核长大的方式生成θ-Al13Fe4块状相。随着热暴露温度升高,喷射沉积AlFeVSi合金薄片的硬度呈下降趋势。喷射沉积AlFeVSi坯主要由α-Al固溶体和Al12(Fe,V)3Si颗粒组成,但也存在少量含粗大片状或块状相的非快速凝固组织。

关键词:

中图分类号:TG146.2 文献标识码:A 文章编号:1672-7207(2007)05-0795-07

Phase transformation during thermal exposure and microstructural characteristics of spray deposited billets of AlFeVSi aluminum alloy

XIAO Yu-de 1, 2, ZHONG Jue 2, LI Wen-xian 1, MA Zheng-qing 1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: The rapidly solidified flake and pipe blank of spray deposited AlFeVSi aluminum alloy were prepared through the multi-layer spray deposition process in the atomization medium of nitrogen gas. Phase transformation and microstructural evolution of the as-deposited flakes during thermal exposure at high temperature were studied by means of differential thermal analysis (DTA), X-ray diffraction (XRD), optical microscopy (OM), transmission electron microscopy (TEM) and hardness measurement, and microstructures of the spray deposited billet of the Al-8.5Fe-1.3V-1.7Si aluminum alloy were characterized. The results show that the rapidly solidified flakes of AlFeVSi alloy mainly consist of α-Al supersaturated solid solution with microcellular structure. During thermal exposure below 500 ℃, the microcellular structure decomposes, and the α-Al supersaturated solid solution transforms into the mixture of Al12(Fe,V)3Si particles dispersed in α-Al matrix,while above 500 a℃ the Al12(Fe,V)3Si particles coarsen and congregate, and even form lumpish θ-Al13Fe4 phase in an independently nucleating and growing mode. With the increase of exposure temperature, hardness of the rapidly solidified flake of spray deposited AlFeVSi aluminum alloy exhibits obvious reducing trend. The spray deposited billet of the Al-8.5Fe-1.3V-1.7Si aluminum alloy consists on the whole of two phase mixture of α-Al and Al12(Fe,V)3Si (bcc, a≈1.260 nm), which is characterized generally as the fine Al12(Fe,V)3Si particles dispersed uniformly in the α-Al matrix, but there appears a very small amount of non-rapidly solidified microstructures with coarse lumpish particles of θ-Al13Fe4 phase in the condition of near rapid solidification or slowly solidification.

Key words: spray deposition; rapid solidification; aluminum alloy; phase transformation

快速凝固AlFeVSi合金热加工成型后的理想组织可以概述为:晶粒为亚微米量级α-Al过饱和固溶体基体上均匀分布着高达16%~36%(体积分数)的纳米级金属间化合物Al12(Fe,V)3Si[1-3]。事实上,快凝AlFeVSi合金的力学性能、耐热性能和高温服役寿命在很大程度上取决于这种α-Al+Al12(Fe,V)3Si两相组织的粗细、均匀性和热稳定性[1-6]。因此,了解快速凝固AlFeVSi合金在热/力作用下的相变和组织演变规律对其最终成型材料组织性能控制尤为重要。

喷射沉积作为一种集快速凝固、半固态加工和近终形加工于一体的新型材料制备技术,近些年来也被用于制备快速凝固耐热铝合金[6-8]。过去的研究工作表明[8-11],高温加热时,快速凝固AlFeVSi合金雾化粉末或平面流铸造薄带中的亚稳组织会朝着平衡化方向转变,主要表现为:过饱和固溶体脱溶,Al12(Fe,V)3Si颗粒粗化、聚集,以及发生向θ-Al13Fe4平衡相转化的有害相变。然而,喷射沉积AlFeVSi合金坯组织状态与雾化粉末或平面流铸造薄带的相比存在差异,这导致在它们后续加热或热加工过程中的相变和组织演变规律也存在差异[12-13]。

本文作者对喷射沉积AlFeVSi合金快凝薄片在高温热暴露过程中的相变和组织演变规律进行研究,同时结合这种演变规律分析喷射沉积坯的显微组织特点,旨在为研制高性能喷射沉积Al-Fe-V-Si合金大规格制品提供有益的参考依据。

1 试验方案与过程

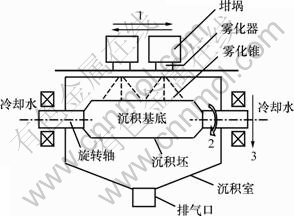

喷射沉积AlFeVSi合金坯在中南大学自制喷射沉积设备上制备,其原理如图1所示。采用高压氮气雾化,调节雾化喷嘴往返平移、沉积基底转动和垂直下降来控制喷嘴和沉积基底的相对距离和运动,制取不同形状和规格的沉积坯[12-13]。沉积旋转轴空心通水,降低沉积温度而提高冷却速率。

1—雾化喷嘴往返平移;2—沉积基底转动;3—垂直下降

图1 喷射沉积Al-Fe-V-Si合金管坯制备原理图

Fig.1 Schematic diagram of preparation of spray deposited tubal blank of Al-Fe-V-Si aluminum alloy

考虑到喷射沉积坯或多或少存在微观组织不均匀性,在冷态接受基底上喷射沉积制备了一些薄薄的沉积物,专门用于相变和组织演变规律研究。选择极薄沉积物(快凝薄片)先在光镜下观察,选用A区多者用于微胞状结构分解规律的研究。同时,制备了实际成分为Al-8.5Fe-1.3V -1.7Si(质量分数,%)的沉积管坯。熔体温度为950 ℃,液流直径为4 mm。雾化气体(N2)压力为0.8 MPa。沉积坯通常需立即进行400 ℃×3 h去应力退火[12-13],但这里用于组织观察的切片直接截取于未退火的沉积坯。快凝薄片的DTA曲线在日本理学示差热分析仪上测定,采用空坩埚作参比物,氩气保护,加热速率为20 ℃/min。热暴露处理在SX-4-10箱式电阻炉中进行,暴露温度为25~700 ℃,时间为0~150 h,暴露后空冷。快凝薄片及其热暴露态试样的硬度在HVA-10A型轻负荷维氏硬度计上测试。金相组织(OM)在Poltar-met立式光学显微镜下观察,抛光样品采用Keller试剂(0.5 mL HF+1.5 mL HCl+2.5 mL HNO3+95.5 mL H2O)浸蚀。X射线衍射(XRD)分析在Siemens D500全自动X射线衍射仪上进行,采用Cu靶辐射,![]() =0.154 056 nm。透射电镜(TEM)组织在JEM-2000EX分析电镜上观察,薄膜样品采用电解双喷制取,电解液为硝酸甲醇(体积比为3?1)混合液,电压为-40 V,液氮冷却。

=0.154 056 nm。透射电镜(TEM)组织在JEM-2000EX分析电镜上观察,薄膜样品采用电解双喷制取,电解液为硝酸甲醇(体积比为3?1)混合液,电压为-40 V,液氮冷却。

2 试验结果与分析

2.1 快凝AlFeVSi合金喷射沉积薄片加热过程的示差热分析和X射线衍射分析

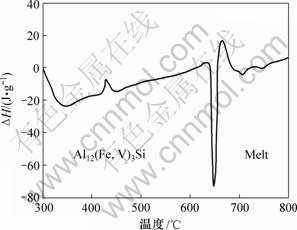

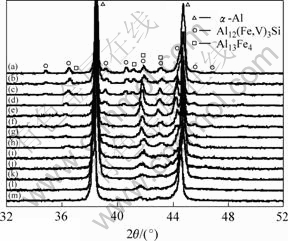

快凝AlFeVSi合金喷射沉积薄片的DTA曲线如图2所示,薄片及其不同温度热暴露(10 h)态试样的X射线衍射图谱如图3所示。可见,薄片中除了存在少量Al12(Fe,V)3Si (bcc,a≈1.260 nm)相外,基本上为α-Al过饱和固溶体。加热后又有更多的Al12(Fe,V)3Si相形成,在DTA曲线上,在400~450 ℃存在1个明显的放热峰,对应于大量Al12(Fe,V)3Si迅速析出。随着温度升高,Al12(Fe,V)3Si量增加;低于500 ℃,加热试样中主要第2相均是Al12(Fe,V)3Si硅化物。θ-Al13Fe4(单斜,a=1.543 nm, b=0.812 nm, c=1.254 nm, β=107.43°)在初生成时量少,X射线衍射图谱上难以清晰显现。只有高于550 ℃,甚至在更高温度下热暴露时,θ-Al13Fe4量明显增加,才可观察到θ-Al13Fe4衍射峰(如图3所示)。高于550 ℃时,Al12(Fe,V)3Si峰有所下降,尤其是高于600 ℃时,θ-Al13Fe4峰更加明显,薄片中可能发生Al12(Fe,V)3Si向θ-Al13Fe4转化的相 变[8-11],且随着温度升高,Al12(Fe,V)3Si量减少,而θ-Al13Fe4增多。

图2 快凝AlFeVSi合金喷射沉积薄片的DTA曲线

Fig.2 DTA curve of as-deposited flakes of rapidly solidified AlFeVSi alloy

温度/℃: (a) 660; (b) 640; (c) 600; (d) 550; (e) 500; (f) 475; (g) 450; (h) 425; (i) 400; (j) 350; (k) 300; (l) 250

图3 快凝AlFeVSi合金喷射沉积薄片及其高温热暴露态试样的X射线衍射谱

Fig.3 Typical XRD patterns of as-deposited flakes of rapidly solidified AlFeVSi alloy and samples exposed at high temperature

2.2 喷射沉积AlFeVSi快凝薄片加热过程中的硬度变化和金相组织变化

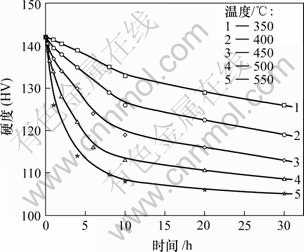

快凝AlFeVSi合金喷射沉积薄片在加热过程中的硬度变化曲线如图4所示,相应的沉积态及其热暴露(10 h)试样的典型金相显微组织(OM)如图5所示。

图4 快凝AlFeVSi合金喷射沉积薄片在不同温度热暴露过程中的硬度变化曲线

Fig.4 Hardness curves of as-deposited flakes of rapidly solidified Al-Fe-V-Si alloy during thermal exposure at various high emperatures

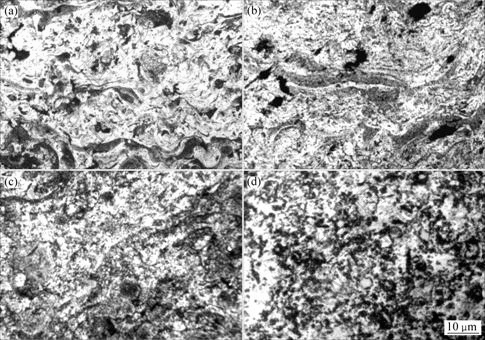

(a) 沉积态; (b) 400 ℃; (c) 500 ℃; (d) 600 ℃

图5 快凝AlFeVSi合金喷射沉积薄片及其在不同温度下热暴露10 h后的金相显微组织

Fig.5 Typical optical microstructures of as-deposited flakes of rapidly solidified AlFeVSi alloy and samples exposed for 10 h at various temperatures

喷射沉积快凝薄片主要由呈光学无特征的A类组织构成,但也存在少量的B类组织。400 ℃加热 10 h,微胞状结构分解,α-Al过饱和固溶体脱溶,Al12(Fe,V)3Si颗粒析出,A类组织逐渐消失,转变成为B类组织,同时,B类组织中的Al12(Fe,V)3Si颗粒也聚集粗化,喷射沉积薄片的显微组织整体上逐渐趋于均匀。Al12(Fe,V)3Si具有良好的结构稳定性,500 ℃加热后,薄片中第二相颗粒大多仍为Al12(Fe,V)3Si,但颗粒进一步聚集、粗化,而且似乎有少量细针状θ-Al13Fe4颗粒开始出现,这与文献[13-16]中的结果相吻合。X射线衍射物相分析谱上未显现出来,可能是由于量太少。600℃高温加热,Al12(Fe,V)3Si颗粒强烈聚集粗化,针状Al13Fe4相增多,变粗,而且出现大量的粗大块状Al13Fe4相颗粒,同时,θ-Al13Fe4颗粒周围Al12(Fe,V)3Si硅化物颗粒因溶解而减少。在加热过程中,喷射沉积AlFeVSi快凝薄片硬度随着α-Al固溶体脱溶、Al12(Fe,V)3Si颗粒粗化、针状和块状Al13Fe4相形成而下降。

因此,在喷射沉积的初始阶段雾化熔体液滴撞击冷态沉积基底,在基底上侧流平铺瞬间,其热量迅速输出,冷速较大,因而可获得主要由A类组织构成的喷射沉积AlFeVSi合金薄片。A类组织中α-Al固溶体过饱和度高,脱溶驱动力大,在高温条件下原子活动能力增强,微胞状结构发生分解,析出微细Al12(Fe,V)3Si颗粒。由于Al12(Fe,V)3Si的析出强化难以抵消α-Al固溶体脱溶而产生的固溶强化效应减 弱,另外,随着温度升高,Al12(Fe,V)3Si颗粒粗化聚集,亚稳组织逐渐向热力学更稳定状态演变,因 此,在热暴露过程中喷射沉积AlFeVSi合金薄片的硬度呈下降趋势。

2.3 喷射沉积AlFeVSi快凝薄片加热过程中的TEM组织变化

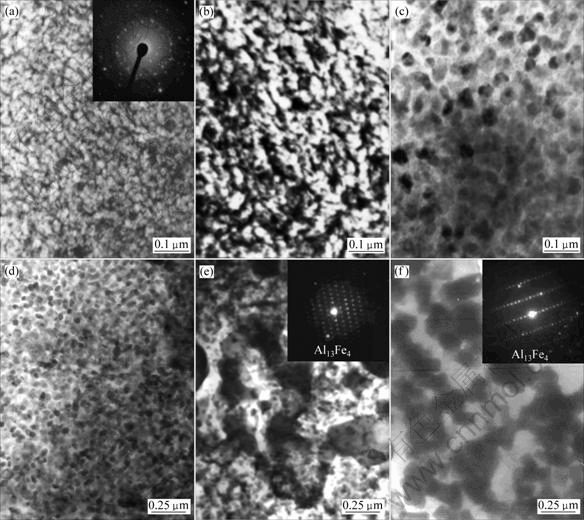

快凝AlFeVSi合金喷射沉积薄片中的A类组织主要由微胞状结构构成。微胞状结构胞内为α-Al过饱和固溶体,胞间或为微小成分偏聚,或为取向自由的Al12(Fe,V)3Si晶体相,或为不规则形微准晶相、非晶相[3, 12-15](如图6(a)所示)。在350 ℃加热时,溶质原子可实现短程晶格扩散和界面扩散,胞间溶质富集加剧,微准晶发生分解和非晶发生晶化,而导致在胞间界上形成不规则形状的Al12(Fe,V)3Si微细颗粒。同时,胞间Al12(Fe,V)3Si相聚集长大,并逐渐球化,胞间界面部分增厚,部分逐渐模糊,溶解,消失,这样,细小胞晶合并长大,胞间界面因部分溶解而呈现出不连续状态,同时胞间相也有向球形颗粒演变的趋势(如图6(b)所示)。在400 ℃加热时,胞间界完全消失,分布在胞间界上的细小Al12(Fe,V)3Si颗粒聚集长大,并球化,同时,α-Al过饱和固溶体脱溶,均匀弥散地析出极其微细的Al12(Fe,V)3Si颗粒,从而形成如图6(c)所示的组织形貌,在α-Al基体上均匀分布已聚集长大的Al12(Fe,V)3Si颗粒,而长大了的Al12(Fe,V)3Si颗粒间的α-Al基体上均匀分布着从过饱和固溶体析出的Al12(Fe,V)3Si微细颗粒。在450 ℃加热时,Al12(Fe,V)3Si相颗粒均匀粗化,仍然保持着其近球形形状,从整体上看,加热后的薄片中Al12(Fe,V)3Si颗粒细小,且分布均匀呈弥散状态(如图6(d)所示),微胞状结构已演变成理想的α-Al加Al12(Fe,V)3Si两相混合组织。当加热温度提高到500 ℃时(如图6(e)所示),Al12(Fe,V)3Si颗粒分布呈现出明显不均匀性,趋于呈不规则网状排列,并在颗粒严重聚集处,这归因于高温下Al12(Fe,V)3Si有沿(亚)晶界析出、聚集、粗化的趋势。另外,局部区域也开始有θ-Al13Fe4块状粗大颗粒出现,且随着块状θ-Al13Fe4长大、增多,其周围的细小Al12(Fe,V)3Si颗粒溶解、减少、或消失。然而,在更高的温度下热暴露后,于550 ℃加热10 h(如图6(f)所示),喷射沉积薄片中出现块状相,形成粗块状颗粒和粗类球状颗粒共存的组织,颗粒多沿晶分布,块状相为θ-Al13Fe4,类球形颗粒仍是Al12(Fe,V)3Si相。

(a) 沉积态; (b) 350 ℃; (c) 400 ℃; (d) 450 ℃; (e) 500 ℃; (f) 550 ℃

图6 快凝AlFeVSi合金喷射沉积薄片的TEM组织及其高温加热(10 h)过程的TEM组织变化

Fig.6 Typical TEM images of as-deposited flakes of rapidly solidified AlFeVSi alloy and samples exposed for 10 h at various high temperatures

因此,快凝薄片在不同温度加热时组织变化主要包括如下过程:a. 胞间溶质富集,亚稳相变,晶体相聚集与球化;b. 胞晶合并长大,胞间界消失;c. 过饱和α-Al固溶体脱溶,Al12(Fe,V)3Si析出;d. Al12(Fe,V)3Si颗粒发生Ostwald粗化、聚集;e. θ-Al13Fe4平衡相颗粒生成与长大。Al12(Fe,V)3Si体心立方相具有良好的结构稳定性,在低于500 ℃热暴露时所发生主要变化是颗粒尺寸与分布状况,而高于500 ℃加热,则有θ-Al13Fe4颗粒以独立形核长大的方式生成,并以周围Al12(Fe,V)3Si颗粒减少为代价而长大。

2.4 喷射沉积AlFeVSi合金坯的微观组织特点与形成原因

喷射沉积是熔滴以不同的状态撞击而沉积于复杂沉积表面的群体行为过程,雾化熔滴粒度呈随机正态分布[16-17]。雾化熔滴大小不同,在喷射沉积过程中凝固历史和冷却速率也不同,故其凝固组织状态也存在差异,这导致喷射沉积AlFeVSi合金坯呈微观组织不均匀[12-13], 出现不同形貌特征的凝固组织。有的是快速凝固条件下形成的,与文献[18-21]中出现的条件相似,有的是在近快速凝固或慢冷条件下形成的,组织粗大。

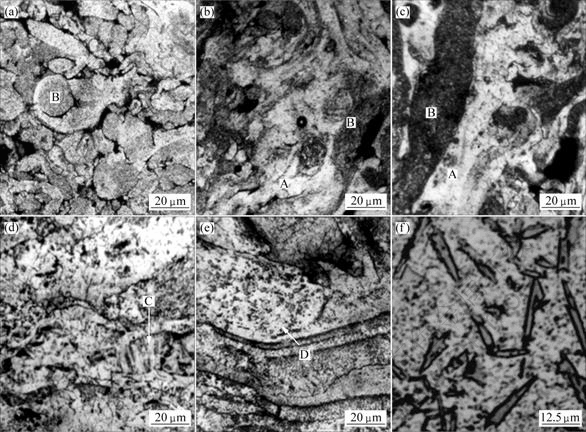

在光镜下(如图7所示),喷射沉积坯显微组织粗略地可分为四类[12-13]:A类、B类、C类和D类。其中:A类呈光学无特征形貌,主要由呈微胞状的α-Al过饱和固溶体构成;B类由α-Al加Al12(Fe,V)3Si的两相构成,颗粒细小,且均匀弥散;C类由粗胞状结构或层片状共晶组织,第二相多呈片状或块状;D类含粗大块状相或针状相的缓冷组织。喷射沉积坯最终组织主要由B类组织构成,而C类和D类组织极少。

(a) 沉积粉末中均匀细小组织(A类和B类); (b), (c) 薄沉积片中光学无特征(A类)和均匀弥散(B类)的组织; (d), (e), (f) 在一些粗沉积薄片中与B共存的含块状或针状相的C类和D类组织

图7 喷射沉积AlFeVSi合金坯中存在着形貌和粗细各异的金相显微组织

Fig.7 Typical optical microstructures with different morphologies and dimensions existed in spray deposited billets

在喷射成过程中,喷射沉积坯不可避免地在高温(大于400 ℃)滞留,致使在喷射沉积过程中形成的A类组织可能发生分解,而转变成B类组织。不论是熔体喷射沉积过程中形成的B类组织,还是A类组织的微胞状结构分解和过饱和固溶体脱溶所生成的产物,都由α-Al固溶体+Al12(Fe,V)3Si颗粒组成。B类组织在高温滞留时可能还会发生Al12(Fe,V)3Si颗粒尺寸及分布状态的变化,而C类和D类组织显然是粗大雾化液滴在近快速凝固或慢冷条件下凝固而形成的,而且在固态高温滞留时或冷却过程的中组织形态变化不大,有的甚至完全保留着慢冷凝固组织特点。评估这类粗大组织对材料性能影响,并寻求消除它们的有效措施,尚有待于进一步开展深入细致的工作。

3 结 论

a. 快凝AlFeVSi合金喷射沉积薄片,除了存在少量的Al12(Fe,V)3Si (bcc,a≈1.260 nm)相外,基本上为呈微胞状的过饱和α-Al固溶体。当加热温度低于500 ℃时,在高温热暴露过程中微胞状结构发生分解,α-Al过饱和固溶体脱溶,形成α-Al+Al12(Fe,V)3Si弥散颗粒的分解产物;当加热温度高于500 ℃时,Al12(Fe,V)3Si颗粒粗化聚集,并以独立形核长大的方式生成θ-Al13Fe4块状相。

b. 随着热暴露温度升高,喷射沉积AlFeVSi合金薄片的硬度呈下降趋势。喷射沉积AlFeVSi坯主要由α-Al固溶体+Al12(Fe,V)3Si颗粒组成,但也存在少量含粗大片状或块状相的非快速凝固组织。

参考文献:

[1] Skinner D J, Bye R L, Raybould D, et al. Dispersion strengthened Al-Fe-V-Si alloys[J]. Scripta Metallurgica et Materialia, 1986, 20(6): 867-872.

[2] Sampath K, Baeslack W A. Joining dispersion- strengthened rapidly solidified P/M Al alloys[J]. Journal of Metals, 1994, 6(1): 41-47.

[3] Skinner D J. The physical metallurgy of dispersion strengthened Al-Fe-V-Si Alloys[C]//Kim Y W, Griffith W M. Dispersion strengthened aluminum alloys. Warrendale: The Mineral Metal and Materials Society, 1988: 181-197.

[4] Mitra S. Elevated temperature mechanical properties of a rapidly solidified Al-Fe-V-Si alloy[J]. Scripta Metallurgica et Materialia, 1992, 27(5): 521-526.

[5] Xiao Y D, Li W X, Tan D Q, et al. Influence of processing parameters on microstructures and mechanical properties of rapidly solidified AlFeVSi hot-extruded produce[J]. Trans Nonferrous Soc China, 2003, 13(3): 558-563.

[6] Hariprasad S, Sastry S M L, Jerina K L, et al. Microstructures and mechanical properties of dispersion-strengthened high-temperature Al-8.5Fe-1.2V-1.7Si alloys produced by atomized melt deposition process[J]. Metallurgical Transaction A, 1993, 24(4): 865-873.

[7] Hariprasad S, Sastry S M L. Processing maps for optimizing gas atomization and spray deposition[J]. Journal of Metals, 1995, 43(11): 56-59.

[8] Srivastava A K, Ojha S N, Ranganathan S. Microstructural features and heat flow of atomized and spray-formed Al-Fe-V-Si alloy[J]. Metallurgical and Materials Transactions A, 1998, 29(11): 2205-2219.

[9] Ramakrishna K N, Mcshane H B, Sheppard T. Extrusion progressing parameter-mechanical property correlations in rapidly solidified Al-6.7Fe-5.9Ce and Al-6.2Fe-5.9Ce-1.63Si (Wt-%) alloy powders[J]. Materials Science and Technology, 1993, 9(1/2): 104-113.

[10] Park W J, Ahn S, Kim N J. Evolution of Microstructure in RS Al-Fe-V-Si alloys[J]. Materials Science and Engineering, 1994, A189(2): 291-299.

[11] Franck L R E, Hawk J A. Effect of very high temperatures on the mechanical properties of Al-Fe-V-Si alloy[J]. Scripta Metallurgica et Materialia, 1989, 23(1): 113-118.

[12] XIAO Yu-de, LI Wen-xian, MA Zheng-qing. Microstructures and mechanical properties of extruded pipe of rapidly solidified Al-Fe-V-Si alloy prepared from multi-layer spray deposited blanks[C]//SONG Jian, YIN Rui-yu. Proceedings of International Conference on Engineering and Technological Sciences 2000 (ICETS2000). Beijing: New Word Press, 2000: 360-364.

[13] 肖于德. 快速凝固AlFeVSi耐热铝合金组织性能及大规格材料制备工艺的研究[D]. 长沙: 中南大学材料科学与工程学院, 2003: 90-128.

XIAO Yu-de. Study on Microstructures and properties of rapidly solidified AlFeVSi heat-resistant aluminum alloy and preparation techniques of its large-size products[D]. Changsha: School of Materials Science and Engineering, Central South University, 2003: 90-128.

[14] Tongsri R, Minay E J, Thackray R P, et al. Microstructures and their stability in rapidly solidified Al-Fe-(V, Si) alloy powders[J]. Journal of Materials Science, 2001, 36(11): 1845-1856.

[15] Hariprasad S, Sastry S M L, Jerina Y L. Under-cooling and super-saturation of alloying elements in rapidly solidified Al-8.5Fe-1.2V-1.7Si alloy[J]. Journal of Materials Science, 1996, 31(6): 921-925.

[16] Grant P S. Spray forming[J]. Progress in Materials Science, 1995, 39(4/5): 497-545.

[17] Mingard K P, Alexander P W, Jangridge S J. Direct measurement of spray form temperatures and the effect of liquid fraction on microstructure[J]. Acta Metallurgical et Materials, 1998, 46(10): 3511-3521.

[18] Koh H J, Park W J, Kim N J. Identification of metastable phases in strip-cast and spray-cast Al-Fe-V-Si alloys[J]. Materials Transactions JIM, 1998, 39(9): 982-988.

[19] Jin T N, Xiao Y D, Li D X. Microstructure characterization of intermetallic phases in a spray-cast Al-8.5Fe-1.3V-1.7Si alloy[J]. Transaction Nonferrous Metals Society of China, 2001, 11(2): 166-172.

[20] Srivastava A K, Ranganathan S. Microstructural characterization of rapidly solidified Al-Fe-Si, Al-V-Si, and Al-Fe-V-Si alloys[J]. Journal of Materials Research, 2001, 16(7): 2103-2117.

[21] Kalkanli A, Oren E E. Variation of phase morphology in gas atomized, spray deposited and melt spun Al-Fe-V-Si alloy[J]. Powder Metallurgy, 2003, 46(4): 324-328.

收稿日期:2006-11-13;修回日期:2007-02-29

基金项目:国家重点基础研究发展规划项目(G1999064900);中国博士后科学基金资助项目(2005038560)

作者简介:肖于德(1969-),男,湖南娄底人,教授,从事快速凝固铝合金研究

通信作者:肖于德,男,博士,教授;电话:0731-8830261;E-mail: xiaoyude@mail.csu.edu.cn