DOI:10.19476/j.ysxb.1004.0609.2019.04.07

石墨烯增强镁合金钨极氩弧焊接接头性能

谢 雄,沈 骏,胡右典,张 涛,谢福幸

(重庆大学 材料科学与工程学院,机械传动国家重点实验室,重庆 40044)

摘 要:

通过活性钨极氩弧焊接将石墨烯纳米片溶入AZ31镁合金中,制得石墨烯/AZ31镁合金复合焊接接头。研究石墨烯加入量对复合焊接接头组织和性能的影响。结果表明:石墨烯纳米片在Marangoni逆流的运载和电磁力的搅拌作用下,均匀分布在AZ31镁合金基体中。均匀分散的石墨烯纳米片有效地细化镁合金的晶粒组织,并显著提高其接头的力学性能。所有试样中,4#石墨烯/AZ31镁合金复合接头的晶粒尺寸最小(约19.8 μm),力学性能最优,其极限拉伸强度和显微硬度为198 MPa和68.9 HV,约为未添加石墨烯纳米片AZ31镁合金接头的190.4%和130%,同时,接头的韧性也达到最佳。因此,石墨烯纳米片的添加量在1.41%左右时,能获得性能最好的石墨烯/AZ31镁合金复合接头。

关键词:

石墨烯纳米片;AZ31镁合金;活性钨极氩弧焊接;微观组织;力学性能;

文章编号:1004-0609(2019)-04-0717-09 中图分类号:TG444 文献标志码:A

近年来,最轻的结构材料 —— 镁及其合金广泛应用于汽车、电子、生物等行业[1-4],然而由于其较差的力学性能,限制了其在一些领域的应用。添加增强相是行之有效的增强镁合金力学性能的优选方案。目前,研究中常用的增强相有纳米颗粒(SiC、Al2O3)、碳纳米管、石墨烯等[5-8]。由于石墨烯的低密度,大比表面积和优秀的力学性能,其作为增强相,极可能获得轻质高强的镁合金复合材料[8-11]。

然而,在传统的铸造工艺中,轻质的石墨烯极易漂浮在熔体表面,而且溶入金属中的石墨烯也极易“团聚“,这些问题严重降低了石墨烯/镁合金复合材料的力学性能[12]。为了解决这些问题,CHEN等[5]基于纳米颗粒的自稳定机理,将纳米SiC颗粒均匀的分散入镁中。KORAYEM等[6]通过搅拌铸造的方法,均匀的将纳米Al2O3颗粒分散入镁中,获得了性能优异的镁基复合材料,此外,徐强等[13]通过钟罩浸块铸造法,将CNTs分散入镁合金中,制备了CNTs/AZ31镁基复合材料。虽然上述方案解决了纳米颗粒溶入金属镁的“团聚”问题,但工艺流程较为复杂。

沈骏等[14]通过将纳米SiC颗粒混入TiO2活性剂中,然后将混合活性剂涂敷在镁合金表面进行活性钨极氩弧焊接,成功地将纳米SiC颗粒分散入AZ31镁合金中,基于此,将上述方案中的纳米SiC颗粒替换为石墨烯纳米片(Graphene nanosheets,简称GNSs),结合镁合金活性钨极氩弧焊接方法[14],系统研究了GNSs的加入量对AZ31镁合金焊接接头的组织和性能的影响。

1 实验

1.1 初始试样制备

待焊件为200 mm×100 mm×5 mm的AZ31镁合金板材,其化学成分(质量分数)为0.8% Mn,0.91% Zn,3.27% Al,剩余是Mg。焊前,用砂纸去除表面氧化物,丙酮清洗去除油污。平均厚度为15 nm的GNSs为增强相,粒径为120 nm的TiO2为活性剂,用酒精将石墨烯和TiO2均匀混合,制成纳米增强活性剂(Nanosheets strengthening activating flux,简称NSA)随后将NSA用毛刷涂敷在待焊件表面。不同试样NSA的配比与涂覆密度如表1所列。NSA的涂覆宽度为10 mm。实验中选用交流TIG焊机(NSA-500-1)完成AZ31镁合金的对接焊试验。焊接电流为80 A,焊接速度为100 mm/min,电极与工件的距离为2 mm,氩气流量为7.5 L/min。实验时,将不开坡口的表面涂覆有纳米增强活性剂的试样放置在铜制垫板上固定,试样之间不留间隙。然后把焊枪放在匀速行进的小车上,以保证在焊接过程中速度和弧长不发生变化,从而保证了焊接工艺过程的稳定性。

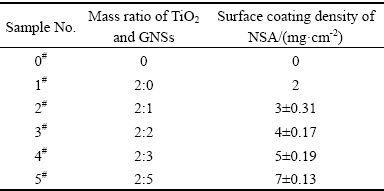

表1 同试样NSA的配比与涂覆密度

Table 1 Mixing ratio and coating density of NSA for different samples

1.2 性能检测

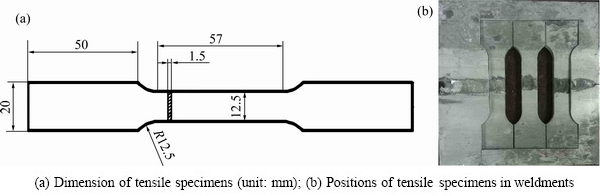

焊后,采用TESCAN VEGA II LMV型扫描电子显微镜进行微观组织和断口形貌分析,用ISIS300型能谱仪和XRF-400型X射线荧光光谱分析焊后接头的元素及成分。采用D/max-2500 PC型X射线衍射仪对试样进行XRD分析,靶材为Cu,扫描速度为4 (°)/min,扫描范围为10°~90°。织构在40 kV和34 mA下分析,{0002}和 极图在旋转角ζ(0°~360°)下完成测试。采用SANS XYA105C型万能试验机对焊后接头在室温下进行抗拉强度测试,拉伸速度为1.5 mm/min。拉伸试样如图1(b)~(d)所示。采用V-1000型显微维氏硬度计对试样进行硬度测试,载荷为0.5 N,加载时间为20 s。

极图在旋转角ζ(0°~360°)下完成测试。采用SANS XYA105C型万能试验机对焊后接头在室温下进行抗拉强度测试,拉伸速度为1.5 mm/min。拉伸试样如图1(b)~(d)所示。采用V-1000型显微维氏硬度计对试样进行硬度测试,载荷为0.5 N,加载时间为20 s。

2 结果与讨论

2.1 加入量对GNSs/AZ31镁合金钨极氩弧焊焊接接头组织的影响

2.1.1 元素成分及含量

图1 钨极氩弧焊焊接接头拉伸试样图

Fig. 1 Tensile test specimens figure of TIG welding joint

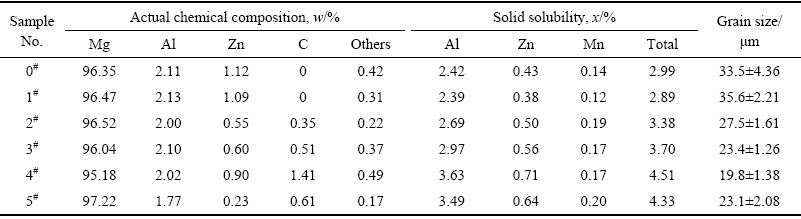

表2 不同GNSs加入量的GNSs/AZ31镁基复合接头的元素成分和固溶度

Table 2 Chemical compositions and solid solubility of all samples in different contents of GNSs

由于待焊试样中不存在C,而且表面涂覆的NSA中除了GNSs外也不包含碳元素,故试样中的碳含量可用来表示焊接接头中的石墨烯含量。表2所列为通过XRF分析的普通TIG、活性TIG和GNSs/AZ31复合接头中的元素含量。由表2可知,随着NSA涂覆量和GNSs在NSA中的密度增大,AZ31镁合金焊接接头中的石墨烯含量逐渐增加。当w(TiO2):w(GNSs)为2:3且NSA涂覆密度约为5 mg/cm2时,即4#接头中的GNSs含量达到最大(约1.41%,质量分数)。然而5#合金虽然NSA的涂覆涂覆密度和GNSs占比虽大。但是过厚的涂覆量在焊接过程中阻碍了GNSs的溶入,故而5#试样中的GNSs含量反而减小[15]。

2.1.2 相成分及形态

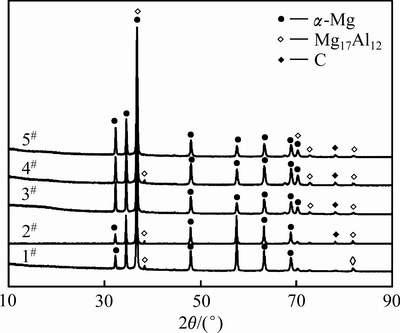

图2 不同GNSs加入量下的GNSs/AZ31镁合金复合接头的XRD谱

Fig. 2 XRD patterns of GNSs/AZ31 magnesium alloy composite joints with different content of GNSs

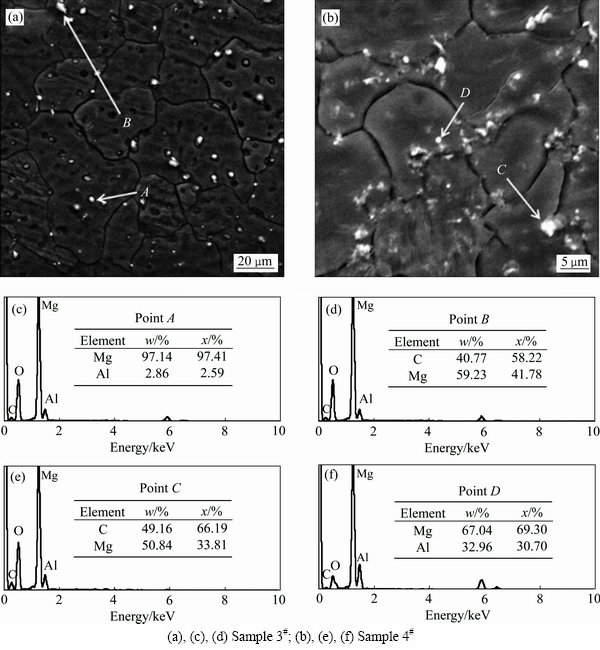

图3 不同GNSs加入量的GNSs/AZ31复合接头的SEM像和EDS分析结果

Fig. 3 SEM images((a), (b)) and EDS spectra((c)-(f)) of GNSs/AZ31 magnesium alloy composite joints with different content of GNSs

图2和3所示为不同GNSs加入量下,GNSs/AZ31镁合金复合接头的XRD和EDS分析结果。GNSs/AZ31镁合金复合接头中包括主相α-Mg,第二相β-Mg17Al12和GNSs。通过EDS分析和文献[16]指出,图3中灰色的晶粒为α-Mg,白色的颗粒为第二相。其中球状且偏小的为β-Mg17Al12(图3中用A和D标出),较大的颗粒为GNSs(图3中用B和C标出)。

2.1.3 显微组织

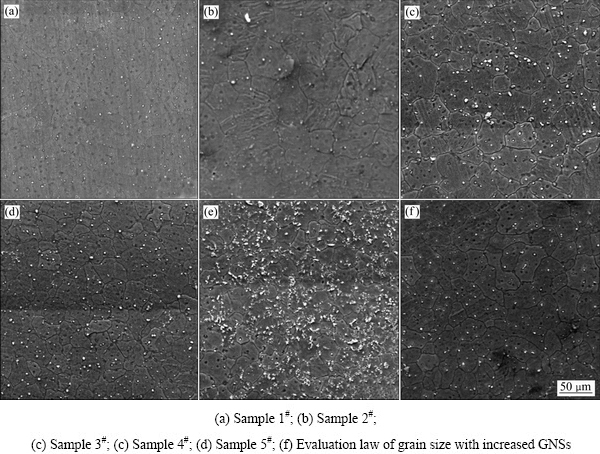

图4所示为普通TIG接头和不同GNSs加入量下,GNSs/AZ31镁合金复合接头的微观组织SEM分析结果。接头中的α-Mg晶粒尺寸列于表2中。从图4和表2可以看出,第二相颗粒均匀分布于接头中。相较于普通TIG焊,活性TIG的α-Mg晶粒较大,但随着GNSs加入量的增加,α-Mg晶粒尺寸逐渐减小,直到GNSs含量为1.41%时,达到19.8 μm的最小值,第二相体积分数逐渐增加。但当GNSs加入量超过1.41%后,α-Mg晶粒尺寸增大,第二相体积分数减小。此外,通过EDS分析统计了各试样中元素的固溶度并列于表1中,结果表明:Al元素的固溶度随着GNSs加入量的增加而增加,故而β-Mg17Al12的体积分数随着GNSs加入量的增加而降低。

图4 不同GNSs加入量的GNSs/AZ31复合接头的微观结构SEM像

Fig. 4 SEM images of GNSs/AZ31 magnesium alloy composite joints with different amount of GNSs

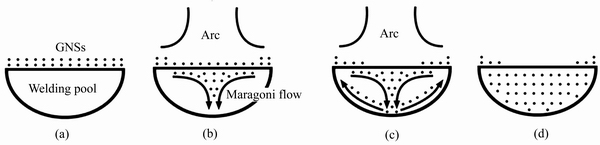

图5 GNSs在活性钨极氩弧焊接前、焊接过程中和核焊后熔池中和的分布规律示意图

Fig. 5 Distribution mechanism of GNSs in welding pool before ((a)), during ((b), (c)) and after ((d)) NSA-TIG

在活性焊接实验中,TiO2活性剂增加了熔池中的热输入,在增加焊缝溶深的同时也促进晶粒的长大。故而活性TIG的晶粒尺寸大于普通TIG的。由于TiO2活性剂改变了熔池中金属液流的流向,从而GNSs容易被引入到AZ31镁合金接头中[14]。图5所示为在活性钨极氩弧焊接过程中GNSs在熔池中的分布及演变规律示意图。由于GNSs的密度小于Mg的,GNSs的沉积速率低于熔池中的金属液流速率,故而GNSs在熔池中容易被金属流驱动,而被带到熔池各处。GNSs进入焊接熔池后,在金属液流的驱动下,从熔池中上方进入,随后,伴随着金属液流逐渐向熔池底部运动。同时,由于焊接电弧中电磁力的搅拌作用,使得GNSs均匀分布于熔池中。GNSs在高温下稳定存在[5],它们作为独立相存在于镁基体中,并起到了细化α-Mg晶粒和抑制第二相β-Mg17Al12析出的作用。主要是由于以下3点原因:1) GNSs作为一种纳米材料,在镁基体中扮演形核剂,促进熔池凝固过程中的α-Mg晶核的均质形核向异质形核转变,细化晶粒。2) GNSs作为一种稳定相,在焊接完成后,GNSs从镁基体中吸收热量,提高冷却速率,缩短晶粒长大的时间,抑制晶粒的长大。而且GNSs从镁基体中吸收热量,也增加了α-Mg的固溶度,抑制了β-Mg17Al12的析出[17]。3) 在α-Mg晶核的长大过程中,由于GNSs的“钉扎”作用,也抑制了晶粒的持续长大。

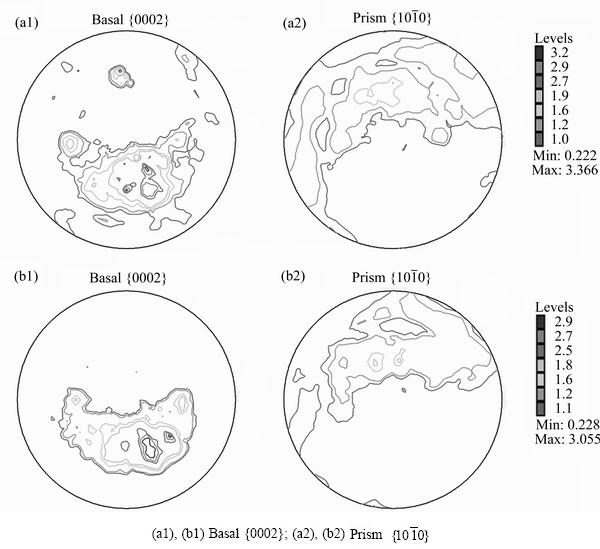

2.1.4 织构分析

图6所示为未加入GNSs和GNSs加入量为1.41%的AZ31镁合金焊接接头的基面{0002}和棱面 的极图。由于焊接过程中发生再结晶退火,焊接接头呈现典型的再结晶织构。由于镁合金滑移系的限制,晶体结构的变化将不可避免地导致镁合金力学性能的变化。如图6所示,GNS的加入削弱了基面{0002}和棱面

的极图。由于焊接过程中发生再结晶退火,焊接接头呈现典型的再结晶织构。由于镁合金滑移系的限制,晶体结构的变化将不可避免地导致镁合金力学性能的变化。如图6所示,GNS的加入削弱了基面{0002}和棱面 。这是由于GNSs的加入促进了再结晶过程中α-Mg晶粒的选择性生长。换句话说,平行于挤压板底面的晶面更容易生长[18]。一般认为基面是室温下纯Mg中的一个重要平面,其力学性质与Schmidt因子依赖于结晶取向的基面活动。由于纯镁和其复合材料之间的晶体学结构差异,力学性能发生了改变。试验中,{0002}基面的削弱,增强了材料的屈服强度[19]。

。这是由于GNSs的加入促进了再结晶过程中α-Mg晶粒的选择性生长。换句话说,平行于挤压板底面的晶面更容易生长[18]。一般认为基面是室温下纯Mg中的一个重要平面,其力学性质与Schmidt因子依赖于结晶取向的基面活动。由于纯镁和其复合材料之间的晶体学结构差异,力学性能发生了改变。试验中,{0002}基面的削弱,增强了材料的屈服强度[19]。

2.2 加入量对GNSs/AZ31镁合金钨极氩弧焊接接头力学性能的影响

2.2.1 显微硬度和极限抗拉强度

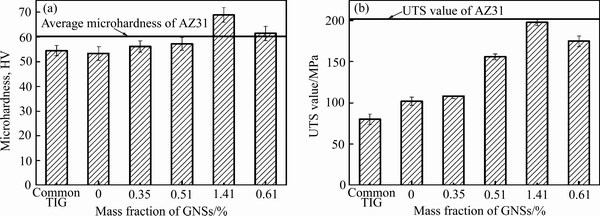

图7所示为各试样接头的显微硬度和极限抗拉强度。普通TIG接头的极限拉伸强度弱于活性TIG的,而显微硬度值强于活性TIG焊的。GNSs加入到AZ31镁合金接头后,明显增强了其力学性能。随着GNSs的增加,接头的显微硬度和极限抗拉强度逐渐增加。

图6 AZ31镁合金接头和1.41% GNSs/Mg合金复合接头的{0002}和{1010}极图

Fig. 6 Pole figures of Mg joints((a1), (a2)) and 1.41% GNSs/Mg composites joints((b1), (b2))

当接头中GNSs含量达到1.41%时,显微硬度值和极限抗拉强度值达到最大,分别为68.9 HV和198 MPa,是未添加GNSs接头的130%和190.4%。

由于实验中采用的焊接参数适用于活性TIG,故而在相同的焊接参数下普通TIG焊缝未焊透,因此,普通TIG接头的极限拉伸强度弱于活性TIG的。此外,普通TIG的α-Mg晶粒尺寸小于活性TIG的,基于细晶强化理论,故而普通TIG的显微硬度高于活性TIG的。GNSs/AZ31镁合金复合接头力学性能的强化机理为细晶强化[20]、固溶强化[21]、奥罗万强化[22]、载荷转移强化[23]和热失配强化[24]。从前面的讨论可知,GNSs加入合金接头后,细化了α-Mg晶粒,增强了主相的固溶度,增加了第二相颗粒的体积分数,故而显著提升了复合接头的力学性能。此外,GNSs和Mg的热失配和载荷在Mg和GNSs间转移也提升了接头的力学性能。故而,随着GNSs加入量的增加,GNSs/AZ31镁合金复合接头的力学性能逐渐增强。

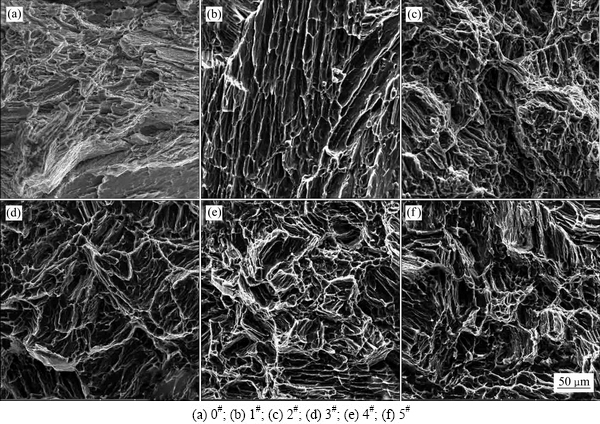

2.2.2 断口形貌

图7 各试样接头的显微硬度和极限抗拉强度值

Fig. 7 Microhardness(a) and UTS values(b) of joints with different mass fractions of GNSs

图8 各试样断口形貌的SEM像

Fig. 8 SEM images of tensile fracture surfaces of GNSs/AZ31 magnesium composite materials enchanced by different mass fractions of GNSs

图8所示为普通TIG接头和GNSs/AZ31复合接头进拉伸测试后断口的SEM像。普通TIG接头断口呈现典型的解理断裂特征。这是由于铸态AZ31镁合金有限的滑移系造成的。而GNSs/AZ31镁合金复合接头的断口为典型的韧性断裂形貌,其断口形貌由韧窝与纤维状结构构成。且4#合金的韧窝数量最多,表明4#合金的韧性最优。

3 结论

1) 通过纳米增强活性钨极氩弧焊的方法,将石墨烯纳米片加入AZ31镁合金焊接接头中。GNSs在熔池中由金属液流驱动和电磁力搅拌共同作用下,最终均匀分散于熔池中。分散于接头中的GNSs细化了α-Mg晶粒,增加了α-Mg固溶度和减小了β-Mg17Al12析出,削弱了基面{0002}和棱面 。

。

2) 随着GNSs加入量的增加,合金中的α-Mg细化越明显,且β-Mg17Al12相更多地固溶于基体之中。

3) 由于细晶强化、固溶强化、奥罗万强化、热失配强化和载荷转移强化的共同作用,4#GNSs/AZ31复合接头的力学性能(硬度、强度和韧性),达到本组实验中的最大值。因此,石墨烯纳米片的质量分数约为1.41%时,可获得性能最好的石墨烯/AZ31镁合金复合接头。

REFERENCES

[1] LUO A A. Materials comparison and potential applications of magnesium in automobiles[J]. Essential Readings in Magnesium Technology, 2000, 2000: 25-34.

[2] 王乃光, 王日初, 彭超群, 冯 艳, 邓 敏, 张俊昌. 镁阳极在海水激活电池中的应用[J]. 中国有色金属学报, 2016, 26(5): 1034-1044.

WANG Nai-guang, WANG Ri-chu, PENG Chao-qun, FENG Yan, DENG Min, ZHANG Jun-chang. Application of magnesium anodes in seawater activated batteries[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 1034-1044.

[3] 袁广银, 章晓波, 牛佳林, 陶海荣, 陈道运, 何耀华, 蒋 垚, 丁文江, 新型可降解生物医用镁合金JDBM的研究进展[J]. 中国有色金属学报, 2011, 21(10): 2476-2488.

YUAN Guang-yin, ZHANG Xiao-bo, NIU Jia-lin, TAO Hai-rong, CHEN Dao-yun, HE Yao-hua, JIANG Yao, DING Wen-jiang. Research progress of new type of degradable biomedical magnesium alloys JDBM[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2476-2488.

[4] ZHU Su-ming, EASTON M A, ABBOTT T B, NIE Jian-feng, DARGUSCH M S, HOTR N, GIBSON M A. Evaluation of magnesium die-casting alloys for elevated temperature applications: microstructure, tensile properties, and creep resistance[J]. Metallurgical and Materials Transactions A, 2015, 46(8): 3543-3554.

[5] CHEN Lian-yi, XU Jia-quan, CHOI H, POZUELO M, MA Xiao-long, BHOWMICK S, YANG Jenn-ming, MATHAUDHU S, LI Xiao-chun. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles[J]. Nature, 2015, 528(7583): 539-543.

[6] HABIBNEJAD-KORAYEM M, MAHMUDI R, POOLE W J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles[J]. Materials Science & Engineering A, 2009, 519(1/2): 198-203.

[7] 杨 华, 潘 强, 孙 姣, 王 譞, 黄周轩, 王 卓, CNTs/AZ91 碳纳米管镁基复合材料的制备及性能研究[J]. 真空与低温, 2018, 24(2): 100-106.

YANG Hua, PAN Qiang, SUN Jiao, WANG Xuan, HUANG Zhou-xuan, WANG Zhuo. Preparation and properties of CNTs/AZ91 carbon nanotubes magnesium matrix composites[J]. Vacuum & Cryogenics, 2018, 24(2): 100-106.

[8] ZHANG Tao, SHEN Jun, LU Lu-qiang, WANG Chun-min, SANG Jia-xin, WU Dong. Effects of graphene nanoplates on microstructures and mechanical properties of NSA-TIG welded AZ31 magnesium alloy joints[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1285-1293.

[9] OVID'KO I A. Mechanical properties of graphene[J]. Reviews on Advanced Materials Science, 2013, 34(1): 1-11.

[10] GONG Shan-shan, NI Hong, JIANG Lei, CHENG Qun-feng. Learning from nature: Constructing high performance graphene-based nanocomposites[J]. Materials Today, 2016, 20(4): 210-219.

[11] PAVITHRA C L P, SARADA B V, RAJULAPATI K V, RAO T N, SUNDARARAJAN G. Process optimization for pulse reverse electrodeposition of graphene-reinforced copper nanocomposites[J]. Materials and Manufacturing Processes, 2016, 31(11): 1439-1446.

[12] Ferguson J B, FARIBA S J, KIM C S, ROHATGI P K, CHO K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs)[J]. Materials Science & Engineering A, 2012, 558: 193-204.

[13] 徐 强, 曾效舒, 周国华. 钟罩浸块铸造法制备的 CNTs/AZ31 镁基复合材料的力学性能[J]. 中国有色金属学报, 2010, 20(2): 189-194.

XU Qiang, ZENG Xiao-shu, ZHOU Guo-hua. Mechanical properties of CNTs/AZ31 composites prepared by adding CNTs block with plunger[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 189-194.

[14] XIE Xiong, SHEN Jun, GONG Fu-bao, LI Yang. Effects of current on nanoparticle reinforced magnesium alloy welding joints[J]. Science & Technology of Welding & Joining, 2015, 20(8): 686-692.

[15] XIE Xiong, SHEN Jun, CHENG Liang, LI Yang, PU Ya-yun. Effects of nano-particles strengthening activating flux on the microstructures and mechanical properties of TIG welded AZ31 magnesium alloy joints[J]. Materials & Design, 2015, 81: 31-38.

[16] LIU Li-min, DONG Chang-fu. Gas tungsten-arc filler welding of AZ31 magnesium alloy[J]. Materials Letters, 2006, 60(17/18): 2194-2197.

[17] ZHANG Shu-yan, JIANG Fu-song, DING Wen-bin. Microstructure and mechanical performance of pulsed current gas tungsten arc surface engineered composite coatings on Mg alloy reinforced by SiCp[J]. Materials Science & Engineering A, 2008, 490(1/2): 208-220.

[18] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[19] 梁书锦, 王 欣, 刘祖岩, 王尔德. AZ31镁合金不同温度挤压后组织性能研究[J]. 稀有金属材料工程, 2009, 38(7): 1276-1279.

LIANG Shu-jin, WANG Xin, LIU Zu-yan, WANG Er-de. Mechanical properties of AZ31 Mg alloy extruded at different die temperatures[J]. Rare Metal Materials and Engineering, 2009, 38(7): 1276-1279.

[20] BOHLEN J, DOBRON P, SWIOSTEK J, LETZIG D, CHMELIK F, LUKAC P, KAINER K U. On the influence of the grain size and solute content on the AE response of magnesium alloys tested in tension and compression[J]. Materials Science & Engineering A, 2007, 462(1/2): 302-306.

[21] XU Yu-lei, ZHANG Kui, LI Xing-gang, LEI Jian, YUAN Hai-bo, LIU Zheng. Effects of on-line solution and off-line heat treatment on microstructure and hardness of die-cast AZ91D alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2652-2658.

[22] HUO Shi-yan, XIE Li-jing, XIANG Jun-feng, PANG Si-qin, HU Fang, UMER Usama. Atomic-level study on mechanical properties and strengthening mechanisms of Al/SiC nano-composites[J], Applied Physics A-Materials Science &Processing, 2018, 124: 209.

[23] ZHOU Ying-hao, LIU Duo, SONG Xiao-guo, LIU Jing-he, SONG Yan-yu, WANG Zhi, FENG Ji-chi, Characterization of carbon/carbon composite/Ti6Al4V joints brazed with graphene nanosheets strengthened AgCuTi filler[J]. Ceramics International2017, 43(18): 16600-16610.

[24] WU Zheng-gang, GAO Yan-fei, BEI Hong-bin. Thermal activation mechanisms and Labusch-type strengthening analysis for a family of high-entropy and equiatomic solid-solution alloys[J]. Acta Materialia, 2016, 120: 108-119.

TIG welded joints properties of graphene strengthened magnesium alloy

XIE Xiong, SHEN Jun, HU You-dian, ZHANG Tao, XIE Fu-xing

(State Key Laboratory of Mechanical Transmission, College of Material Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: The graphene nanosheets/AZ31 magnesium alloy composite joints were fabricated by introducing graphene nanosheets into magnesium alloy through activating flux tungsten inert gas welding. The effects of graphene addition amount on microstructure and properties of composite joints were studied. The results show that graphene nanosheets evenly disperse in magnesium alloy matrix due to the combined effect of Marangoni convection and electromagnetic forces. The uniformly dispersed graphene nanosheets refine matrix crystals and enhance mechanical property of the composite joints. The minimum grain size (about 19.8 μm) and optimum of mechanical properties of sample 4# is obtained. The ultra-tensile strength and microhardness of the composite joints reach to 198 MPa and 68.9HV, about 190.4% and 130% of those of the joints without graphene nanosheets, respectively. Simultaneously, the toughness is also the best. Therefore, the grapheme nanosheets/AZ31 magnesium alloy composite joints with the best performance can be obtained when graphene addition amount is about 1.41%.

Key words: graphene nanaosheet; AZ31 magnesium alloy; activating flux tungsten inert gas welding; microstructure; mechanical property

Foundation item: Project(51375511) supported by the National Natural Science Foundation of China; Project (cstc2016jcyjA0167) supported by Chongqing Research Program of Basic Research and Frontier Technology, China; Project(XJ201608) supported by the Key Industry Technology Innovation Fund of Science and Technology Development Board of Xiangcheng District of Suzhou, China; Project(2016-27) supported by the Science and Technology Project of Beibei District of Chongqing, China; Project(SKLMT-22KT-2017M15) supported by the State Key Laboratory of Mechanical Transmission of Chongqing University, China.

Received date: 2018-03-08; Accepted date: 2018-10-16

Corresponding author: SHEN Jun; Tel: +86-13883111150; E-mail: shenjun@cqu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51375511);重庆市基础研究和前沿技术研究资助项目(cstc2016jcyjA0167);苏州相城区科技发展局资助项目(XJ201608);重庆市北碚区科技计划资助项目(2016-27);重庆大学机械传动国家重点实验室基金资助项目(SKLMT-ZZKT-2017M15)

收稿日期:2018-03-08;修订日期:2018-10-16

通信作者:沈 骏,教授,博士;电话:13883111150;E-mail:shenjun@cqu.edu.cn

摘 要:通过活性钨极氩弧焊接将石墨烯纳米片溶入AZ31镁合金中,制得石墨烯/AZ31镁合金复合焊接接头。研究石墨烯加入量对复合焊接接头组织和性能的影响。结果表明:石墨烯纳米片在Marangoni逆流的运载和电磁力的搅拌作用下,均匀分布在AZ31镁合金基体中。均匀分散的石墨烯纳米片有效地细化镁合金的晶粒组织,并显著提高其接头的力学性能。所有试样中,4#石墨烯/AZ31镁合金复合接头的晶粒尺寸最小(约19.8 μm),力学性能最优,其极限拉伸强度和显微硬度为198 MPa和68.9 HV,约为未添加石墨烯纳米片AZ31镁合金接头的190.4%和130%,同时,接头的韧性也达到最佳。因此,石墨烯纳米片的添加量在1.41%左右时,能获得性能最好的石墨烯/AZ31镁合金复合接头。

[2] 王乃光, 王日初, 彭超群, 冯 艳, 邓 敏, 张俊昌. 镁阳极在海水激活电池中的应用[J]. 中国有色金属学报, 2016, 26(5): 1034-1044.

[7] 杨 华, 潘 强, 孙 姣, 王 譞, 黄周轩, 王 卓, CNTs/AZ91 碳纳米管镁基复合材料的制备及性能研究[J]. 真空与低温, 2018, 24(2): 100-106.

[13] 徐 强, 曾效舒, 周国华. 钟罩浸块铸造法制备的 CNTs/AZ31 镁基复合材料的力学性能[J]. 中国有色金属学报, 2010, 20(2): 189-194.

[18] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

[19] 梁书锦, 王 欣, 刘祖岩, 王尔德. AZ31镁合金不同温度挤压后组织性能研究[J]. 稀有金属材料工程, 2009, 38(7): 1276-1279.