文章编号:1004-0609(2014)06-1562-16

烧结NdFeB永磁体的晶界微细结构及性能研究进展

王 静1,梁 乐1,武梦艳1,陈诗豪1,祝隐峰1,曲冠雄1,郑博瀚1,张澜庭1, 2

(1. 上海交通大学 材料科学与工程学院,上海 200240;

2. 上海交通大学 平野材料创新研究所,上海 200240)

摘 要:

基于新能源汽车/风力发电对高性能动力电机的需求与稀土资源危机的考虑,迫使人们重新审视烧结NdFeB永磁体发展的新趋势。烧结NdFeB永磁体具有的优异性能与其晶界微观结构、化学结构/组分特征以及基体相的内禀性能密切相关。近期利用3DAP、NBED、EELS和STEM等纳米级尺度的解析手段,揭示了界面微区的微观结构与化学结构/组分特征,对深入理解微磁学理论起到了推动作用,并衍生了许多改善磁体性能的新技术。本文作者综述磁体晶界微观结构的最新进展、磁体制备的新技术与其微观机制,并总结分析了近期在第一性原理计算研究和Nd2Fe14B单晶实验研究方面的一些新动态。

关键词:

NdFeB永磁体;稀土;晶界;单晶体;新能源;第一性原理计算;

中图分类号:TG132.272 文献标志码:A

Research progress on grain boundary fine microstructure and magnetic properties of sintered NdFeB magnet

WANG Jing1, LIANG Le1, WU Meng-yan1, CHEN Shi-hao1, ZHU Yin-feng1, QU Guan-xiong1,

ZHENG Bo-han1, ZHANG Lan-ting1, 2

(1. School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China;

2. Hirano Institute for Materials Innovation, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: Due to a recent demand on new energy systems, such as hybrid/electrical vehicles and wind turbines for electricity generation etc., and considering the “rare earth crisis”, there has been a revived interest in sintered NdFeB permanent magnets because of their outstanding comprehensive properties. The microstructure and chemical structure/ composition characteristic of the grain boundary, as well as the intrinsic properties of Nd2Fe14B matrix phase, are closely related to the magnetic properties of sintered NdFeB magnets. Recent nanoscale characterization studies using 3DAP, NBED, EELS and STEM have revealed the microstructure and chemical characteristics of the interface between grain boundary phase and matrix phase, which have made a substantial contribution towards understanding the micromagnetism and induced new technologies for improving the properties of the magnets. In this work, new developments and understandings on the microstructure evolution of the grain boundary were reviewed, as well as the new technologies for magnet processing and their corresponding micromechanism. First-principles calculations and the experimental investigation of Nd2Fe14B single crystals were also discussed.

Key words: NdFeB permanent magnet; rare earth; grain boundary; single crystal; new energy; first-principles calculations

NdFeB稀土永磁材料目前占据了超过60%的永磁材料市场份额,随着混合动力汽车(HEV)、纯电动汽车(EV)和风力发电等新能源体系的发展,在永磁材料中具有最高磁能积的烧结NdFeB永磁材料,是实现电机小型化、轻量化以及大功率化的关键[1]。具有实用价值的永磁材料,除了要求其具有高剩余饱和磁化强度以产生高磁感应强度外,还要求其具有高矫顽力以抵抗退磁和高居里温度以防止热退磁。新能源汽车使用电机的工作温度普遍在180~200 ℃之间,而NdFeB永磁体的居里温度为312 ℃,因此,对NdFeB永磁体的矫顽力提出了较高要求[2]。

合金化Dy和Tb等重稀土元素是目前提高NdFeB永磁体矫顽力的主要方法之一。然而,由于Dy和Tb等重稀土元素的原子磁矩与Nd2Fe14B硬磁相中Fe原子磁矩呈反平行[3],因此,合金化Dy和Tb不可避免地导致磁体剩磁和最大磁能积的下降。实现在不降低剩磁的前提下提高磁体的矫顽力是目前技术上追求的目标。此外,自然界中已知的重稀土储量非常有限,仅能满足下个10年的需要,且主要集中在我国的南方地区[4]。稀土资源的稀缺已经带来了严重的稀土资源危机和环境危机,直接导致稀土价格不断上涨[1, 5]。因此,综合考虑性能、成本和稀土资源,迫切需要发展节约稀土资源的高性能烧结NdFeB永磁材料。

烧结NdFeB磁体的剩磁与Nd2Fe14B相的饱和磁化强度、体积分数、磁体取向度和致密度等因素有关[6-7]。磁体的矫顽力除了与Nd2Fe14B相的各向异性场相关外,是磁体微观结构的敏感参数[7-8]。 等[9]的微磁学理论指出,磁体的矫顽力Hcj与下列因素有关:

等[9]的微磁学理论指出,磁体的矫顽力Hcj与下列因素有关:

(1)

(1)

式中:Ha和Ms分别为Nd2Fe14B基体相的各向异性场和饱和磁化强度; 为磁畴壁宽度;r0为基体相表层晶格畸变层厚度;Neff为有效退磁场因子。烧结NdFeB磁体相的组成主要为Nd2Fe14B基体相、富Nd相和少量富B相等,其中基体相晶粒与晶界上分布的富Nd相构成了烧结NdFeB磁体的基本微观组织特征,而晶界结构和化学结构/组分特征是影响磁体矫顽力的重要微观结构因素。自1983年NdFeB永磁体被发现以来,世界各国的学者即对其微观组织特征进行了比较深入的研究。然而,近期在新的科学目标驱动下,利用3DAP、STEM和NBED等纳米尺度级别的先进微观解析手段,进一步揭示了许多晶界与相界微观结构与化学结构/组分的重要特征,对深入理解式(1)中各参数的物理意义起到了推进作用,并衍生了许多新的磁体处理方法和技术。

为磁畴壁宽度;r0为基体相表层晶格畸变层厚度;Neff为有效退磁场因子。烧结NdFeB磁体相的组成主要为Nd2Fe14B基体相、富Nd相和少量富B相等,其中基体相晶粒与晶界上分布的富Nd相构成了烧结NdFeB磁体的基本微观组织特征,而晶界结构和化学结构/组分特征是影响磁体矫顽力的重要微观结构因素。自1983年NdFeB永磁体被发现以来,世界各国的学者即对其微观组织特征进行了比较深入的研究。然而,近期在新的科学目标驱动下,利用3DAP、STEM和NBED等纳米尺度级别的先进微观解析手段,进一步揭示了许多晶界与相界微观结构与化学结构/组分的重要特征,对深入理解式(1)中各参数的物理意义起到了推进作用,并衍生了许多新的磁体处理方法和技术。

综上所述,目前有关烧结NdFeB永磁材料的大量研究都着重于在不降低磁体剩磁的前提下提高其矫顽力,尤其是减少或取消重稀土元素Dy和Tb的使用量,从综合考虑资源、环境和成本的角度出发,开发微量Dy和无Dy高矫顽力永磁体已基本达成业内共识[10-12]。另一方面,除了聚焦晶界微观结构以外,关注R2Fe14B基体相的基本物理性质,发展低成本的轻稀土掺杂体系,是烧结NdFeB永磁材料未来发展一个可能选择。本文作者综述了近期对烧结NdFeB永磁材料晶界微细结构与化学结构/组分的研究和理解,分析了在磁体制备和磁体改性方法上的一些新趋势,同时概述了近期利用第一性原理计算和单晶实验等手段剖析硬磁相的电子结构与磁性能工作,通过研究R2Fe14B基体相的磁性各向异性起源与决定饱和磁化强度的主导因素,从本源上探索提高NdFeB永磁体矫顽力与剩磁的途径。

1 磁体晶界微观结构的最新研究进展与理解

1.1 晶界相的形貌与结构

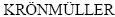

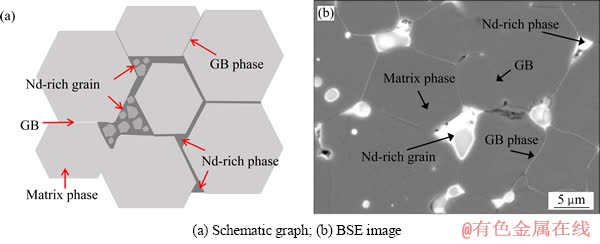

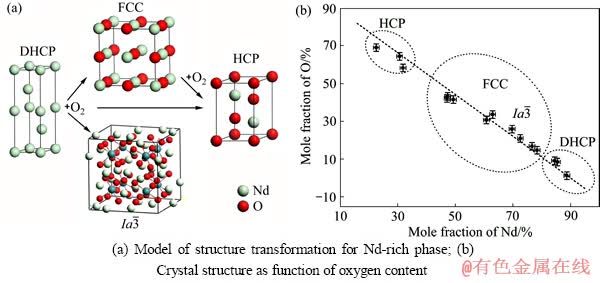

大量研究证实[2, 9, 13-25],烧结NdFeB磁体的磁性能与其微观组织结构有着紧密联系,尤其是晶界处的微观结构与化学结构/组分对磁体矫顽力的提高起着关键作用。早期烧结NdFeB磁体的微观组织研究表 明[9, 14, 23, 26],经最优化热处理后的磁体主要由基体相和富Nd相组成,其中富Nd相根据形貌不同主要分为三叉型富Nd相和细长条型富Nd相两种,且一般将后者称为晶界相。近期细致的研究表明[2, 17, 27],不同富Nd相对磁体矫顽力提高的影响各不相同。以日本物质材料研究机构(NIMS)的HONO研究组为代表的研究者们[2]将富Nd相分成3类:富Nd相晶粒(Nd-rich grains)、富Nd相(Nd-rich phase)和晶界相(Grain boundary phase),如图1所示。其中,富Nd相晶粒通常呈大块状且边界圆润,并含有较高的氧,主要为Nd2O3相,它对矫顽力的提高作用并不明显。此外,大量富Nd相晶粒会明显降低磁体的剩磁,因此,应尽量避免磁体内出现这类富Nd相晶粒。富Nd相主要指晶界交汇处的细小三叉型富Nd相。根据结构不同,这类富Nd相主要分为两类:DHCP型富Nd相和FCC型富Nd相,且后者的氧含量高于前者。FUKAGAWA等[28-29]通过在磁体表面镀一层Nd并对其进行热处理,研究证实了FCC型NdOx相的形成与表面矫顽力恢复有关。ZHANG等[27]对富Nd相的结构进行了较为细致和全面的观察,发现烧结NdFeB磁体中存在DHCP、FCC、HCP和 4种晶体结构的富Nd相,且富Nd相的晶体结构主要由氧含量决定,如图2所示。值得注意的是,大部分日本学者[2, 20, 30]在烧结NdFeB磁体内只观察到了DHCP型富Nd相和FCC型富Nd相,这是由于日本磁体制造技术能严格控制磁体内的氧含量。HONO等[2]仅将填充于晶粒之间呈细长条状、厚度仅为几纳米的薄层富Nd相称为晶界相。此类晶界相绝大部分为非晶态,且化学成分特征与富Nd相不同[31]。众学者[2, 17, 19, 25]指出,此类晶界相的存在对磁体矫顽力的提高起关键作用。

4种晶体结构的富Nd相,且富Nd相的晶体结构主要由氧含量决定,如图2所示。值得注意的是,大部分日本学者[2, 20, 30]在烧结NdFeB磁体内只观察到了DHCP型富Nd相和FCC型富Nd相,这是由于日本磁体制造技术能严格控制磁体内的氧含量。HONO等[2]仅将填充于晶粒之间呈细长条状、厚度仅为几纳米的薄层富Nd相称为晶界相。此类晶界相绝大部分为非晶态,且化学成分特征与富Nd相不同[31]。众学者[2, 17, 19, 25]指出,此类晶界相的存在对磁体矫顽力的提高起关键作用。

理论研究表明[32],富Nd相的晶体结构影响富Nd相/Nd2Fe14B界面处的Nd2Fe14B晶格损伤厚度,此厚度对应于式(1)中的参数r0,且相邻于FCC型富Nd相的Nd2Fe14B晶格损伤厚度与相邻于HCP型富Nd相相比较小。此外,FUKAGAWA等[29]和ZHANG等[33]利用纳米衍射技术(NBED)研究了富Nd相/Nd2Fe14B界面处的晶格完整性,同样证实了不同富Nd相/ Nd2Fe14B界面处的Nd2Fe14B晶格完整性不同,且晶格完整性越高,则相应的磁体矫顽力越高。电子背散射衍射(EBSD)研究[34]证实,各向异性烧结NdFeB磁体中发现富Nd相无明显的择优织构,这可能与富Nd相在热处理过程中先熔化再冷却凝固形成有关,这也解释了世界各国研究者报道在透射电镜(TEM)观察中发现不同富Nd相与Nd2Fe14B相具有不同位向关系的原因。在所有报道的各种位向关系中,以下低指数位向关系具有较小的两相错配度,且计算衍射斑点得到了两相错配度为4.2%[35]:

(2)

(2)

WOODCOCK等[17]指出,需要注意富Nd相/ Nd2Fe14B界面错配引起的应变对矫顽力的影响,但目前还未见与此相关的系统性研究报道。

图1 烧结NdFeB磁体的微观结构

Fig. 1 Microstructure of sintered NdFeB magnets

图2 三元NdFeB磁体中富Nd相的晶体结构的演变[27]

Fig. 2 Evolution of crystal structure in ternary NdFeB magnet[27]

1.2 晶界与相界微区的化学成分特征

根据性能要求不同,商业用烧结NdFeB磁体主要分为两类:高磁能积磁体和高矫顽力磁体。其中,前者添加的合金元素相对固定。日本学者报道[10]的50 MGOe磁能积级别磁体的主要成分为Nd-Pr-B-Cu- Al-Co-Fe,其中Cu和Al含量(摩尔分数)分别控制在0.1%和0.6%左右。而后者的成分则是在前者的基础上,用近30%~40%的重稀土元素Dy取代Nd,使磁体室温矫顽力从约为9.6×105提高到2.4×106 A/m以上[21]。烧结NdFeB磁体的矫顽力主要决定于反磁化畴形核场的大小,而形核又主要发生在富Nd相/ Nd2Fe14B界面处的Nd2Fe14B晶粒表面[2]。因此,了解富Nd相/Nd2Fe14B界面处的微区结构与化学结构/组分对探讨磁体矫顽力的影响规律有着重要作用。近期3DAP、EELS和NBED等纳米尺度级别分析技术的运用对了解晶界与相界微区的化学结构与组成起到了至关重要的作用[36-37]。

早在1991年就有报道指出[38]:磁体中少量Cu的添加可以提高晶界相润湿性,使磁体矫顽力在烧结后的回火过程中有显著提高。3DAP的研究[21]证实在烧结后的回火过程中,发生了Cu元素向晶界偏聚的现象,表明回火后Nd2Fe14B晶粒被一层富Cu层所包裹。相反,在烧结态样品晶界处只发现发生了轻微的稀土元素偏聚。根据Nd-Fe-B三元相图,富Fe侧三元低熔点共晶温度为635 ℃。但是,在添加Cu等合金元素的磁体中,用差示扫描量热分析(DSC)研究发现[39],在三元共晶温度以下有更低熔点的转变出现,具体的温度点与磁体的合金元素及其添加量有关。根据Nd-Cu二元相图,Nd-Cu二元共晶的最低温度为520 ℃,说明Cu在晶界的偏聚降低了晶界相的熔点。最近的研究[30]表明,磁体经最佳回火温度以下回火后的矫顽力低于其烧结态的矫顽力。微观观察发现,前者晶界上有裂纹产生,这可能与回火温度偏低,使晶界相不能充分熔化浸润晶界有关。

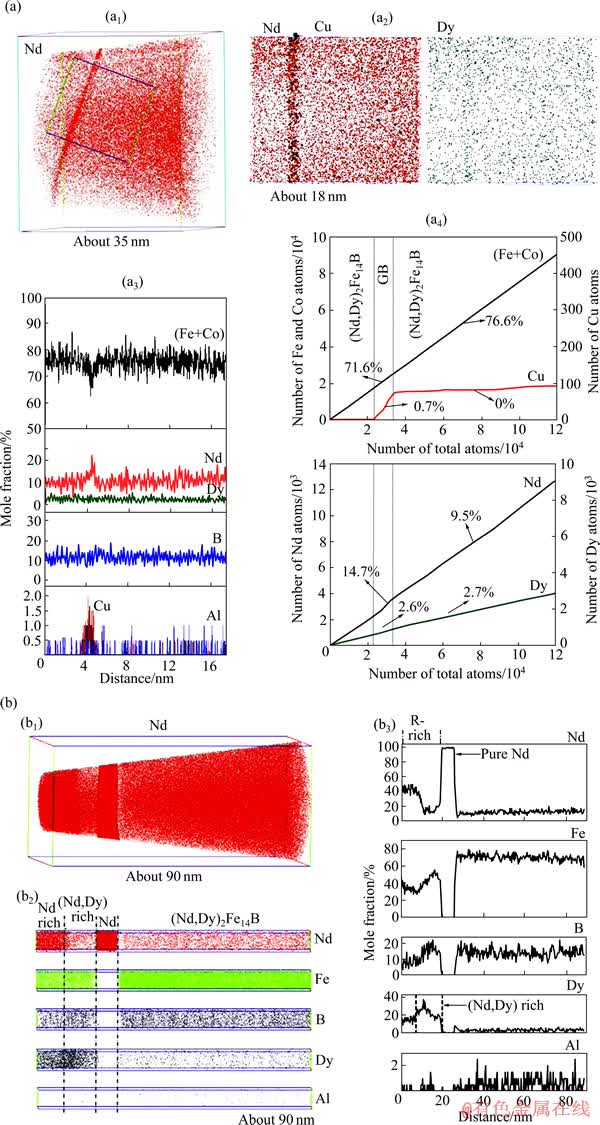

在含Dy磁体中,一般认为Dy原子置换了Nd2Fe14B相中的Nd原子,形成各向异性场更高的(Nd,Dy)2Fe14B相,从而提高磁体的矫顽力[40]。最近,LI等[21]利用电子探针波谱(EPMA)面扫描研究了一种含3.2% Dy(摩尔分数)的烧结NdFeB磁体,证实Dy的分布存在不均匀现象。其中,在基体相中存在富Dy区和贫Dy区,前者对应的含量为3.3% Dy和8.5% Nd,后者对应的含量为2.5% Dy和9.2% Nd(摩尔分数)。3DAP进一步证实,与不含Dy磁体类似,回火后含Dy磁体的薄层晶界相中存在Cu元素的富集,但未观察到Dy在此富集,如图3(a)所示。此外,不同于无Dy磁体,含Dy磁体的FCC和HCP型富Nd相晶粒中存在明显的Dy富集现象,而在DHCP型富Nd相晶粒中未发现Dy富集。这可能是由于Dy与Nd相比具有更强的亲氧性,因此,在氧含量相对较高的FCC和HCP型富Nd相中存在Dy富集,在氧含量较低的DHCP型富Nd相中无Dy富集。特别有趣的是,3DAP研究发现在(Nd,Dy)2Fe14B基体相与富(Nd,Dy)相之间存在一层约几个纳米厚的近纯Nd层,如图3(b)所示,这可能是由于Dy扩散进入基体导致基体中的Nd反向排出形成的。此外,由于金属Nd为非铁磁性相,因此这种近纯Nd层的析出能起到晶粒间的去磁耦合作用,进而提高磁体的矫顽力。综合以上3DAP的最新发现,在烧结NdFeB磁体中添加Dy元素提高矫顽力的主要原因归结于基体相各向异性场的提高和晶界微观结构改善的共同作用。此外,存在于富Nd相晶粒内的Dy元素,无益于提高磁体的矫顽力,因此,若能进一步优化含Dy磁体的微观结构与Dy分布,那么降低磁体中Dy的使用量仍保持相当矫顽力是可能的。

关于晶界处几个纳米厚的非晶态薄层富Nd相的化学成分特征,传统的观点认为[31]此类晶界相是非铁磁性的,存在于晶粒四周,起去磁隔离作用,进而提高磁体矫顽力。最新的3DAP分析[21]表明,此类晶界相成分大都在R30(Fe,Co)66B3Cu1(R代表稀土元素)左右,其中铁磁性元素(Fe和Co)含量高达约72%(摩尔分数)。此外,在超细晶(约为1 mm)高矫顽力烧结NdFeB磁体中也观察到薄层非晶态晶界相内有大量铁磁性元素的富集[20]。类似地,在热变形磁体的晶界相中也观察到约75%(摩尔分数)的铁磁性元素富集[41]。使用溅射方法制备的薄膜研究证明[42],这种富含铁磁性元素的晶界相呈铁磁性,它会与近邻的晶粒发生磁交互耦合,使磁畴可能扩展进入近邻的晶粒。但是,由于这类晶界相的磁晶各向异性场远小于Nd2Fe14B相的各向异性场,所以当磁畴壁迁移越过晶界相进入近邻晶粒时,会受到晶界相的钉扎作用。这一推测可以解释磁体初始磁化曲线呈两个明显阶段的现象,即磁畴在晶粒内迁移时无阻力,初始磁化曲线呈陡峭 状;而当磁畴迁移通过晶界时,晶界相对其有钉扎作用,初始磁化曲线呈平坦状。若能降低这类晶界相内铁磁性元素的含量,削弱其与晶粒间的磁交互耦合作用,使磁体的矫顽力完全由晶界相的反磁化形核场决定,则能进一步提高磁体的矫顽力[20]。

图3 晶界和富Nd相与基体相界面处的三维原子探针分析结果[21]

Fig. 3 3DAP characterizations of grain boundary(a) and interface between Nd-rich and Nd2Fe14B phase(b)[21]

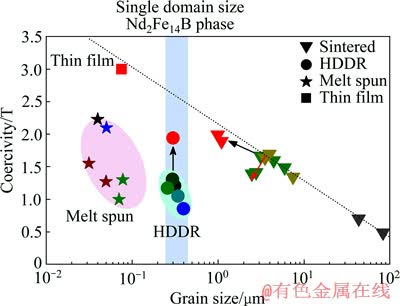

1.3 晶粒尺寸

除了合金化方法,晶粒细化也是提高矫顽力的一条有效途径,而且理论上不损害剩磁。近期,HONO等[2]总结了烧结磁体、HDDR粉末及快淬片的矫顽力Hcj与晶粒尺寸D的关系,如图4所示。当4.5 μm≤D≤7.5 μm时,矫顽力Hcj与晶粒尺寸D存在类似于强度与晶粒尺寸的Hall-Petch关系[43]:

(3)

(3)

这与RAMESH等[44-45]提出的理论一致,即随着晶粒尺寸D减小,磁体矫顽力Hcj增大。但是,当晶粒尺寸D继续减小(<4.5mm)时,磁体矫顽力出现了降低现象[43]。为了获得晶粒尺寸细小的烧结体,则需相应降低初始粉末颗粒尺寸。细致的分析表明,初始粉末颗粒的分布不均匀直接影响烧结时晶界处均匀薄层富Nd相的形成,从而导致磁体矫顽力下降。最近,SAGAWA等[46]将气流磨气氛由N2改为He,用控氧无压烧结工艺(PLP)成功制备了晶粒尺寸仅为1 mm的无Dy烧结NdFeB磁体,其磁能积为(398 kJ/m3,矫顽力高达1512 kA/m。相应的微观结构观察表明[43],大量存在于烧结态磁体中的DHCP型富Nd相保证了回火后形成连续的薄层晶界相。因此,通过磁体制备工艺地不断改进,尤其是氧含量的严格控制与晶界微区成分的精准控制,完全有可能成功制备出超细晶高矫顽力烧结NdFeB磁体,以彻底摆脱重稀土元素Dy的使用。

溅射、HDDR和快淬的方法均可获得纳米级晶粒的NdFeB材料[2]。使用溅射方法可以获得微观组织接近优化、具有高取向度、厚度仅为1 mm的薄膜,并由此获得极高的磁能积和矫顽力[42](如图4所示)。此外,这种薄膜经常被作为模型体系展示与研究[42]。相比于传统的粉末颗粒,HDDR粉末具有非常细小的颗粒尺寸(30~500 mm),在合适的HDDR工艺条件下,单颗粉末颗粒中的晶粒间可能形成一层类似于烧结NdFeB磁体中的晶界薄层相,从而使单颗HDDR粉末具有一定的矫顽力[47-49]。而且,与烧结NdFeB磁体相比,其晶粒细化所带来的矫顽力提高具有较大潜力。若能继续优化HDDR粉末颗粒的微观组织结构,则由HDDR粉末颗粒制备的磁体矫顽力将进一步提高[2]。传统的快淬条带主要用于制备各向同性的粘接NdFeB磁体[50-51],近期利用快淬条带制备烧结/热变形磁体的工作已开始见诸报道[52-54]。通过冷却条件的控制,能获得具有纳米级晶粒尺度的快淬条带,然而相比于烧结NdFeB磁体,其晶粒间不存在薄层晶界相。无论是HDDR粉末还是快淬条带,由于其具有纳米级晶粒结构,因此,由此制备的磁体具有获得高矫顽力的巨大潜力[2]。但是,在保持其纳米晶结构的前提下,用当前的制备技术和方法实现具有理想烧结NdFeB磁体微观结构的各向异性的块体永磁材料制备,尚存在较大的挑战。

图4 NdFeB磁体矫顽力与晶粒尺寸的关系[2]

Fig. 4 Grain size dependence of coercivity of various NdFeB magnets[2]

2 磁体制备改性的新方法、新工艺及其微观机制

调控晶界的微观结构与成分分布是提高磁体矫顽力的有效手段。在商业生产中,磁体成分的调配、氧含量的控制及烧结、回火条件的控制,是优化晶界微观结构的有效手段。氧含量不仅影响烧结磁体中富Nd相的晶体结构,而且还影响富Nd相的晶格常数,通过降低氧含量能有效减小富Nd相/Nd2Fe14B界面处的晶格错配度,进而提高磁体矫顽力[27-28, 31, 35]。烟台正海磁性材料股份有限公司研发的正海无氧工艺技术(ZHOFP)[55],能将磁体的氧含量控制在100×10-6~400×10-6范围内,使生产的烧结NdFeB磁体性能提高了一个等级,进而降低了稀土元素的用量达28%~29%,尤其是减少了重稀土元素Dy和Tb的用量。此外,通过晶界相改性以及致力于获得纳米晶结构的各向异性烧结NdFeB磁体,衍生了一些新的磁体改性和制备方法。

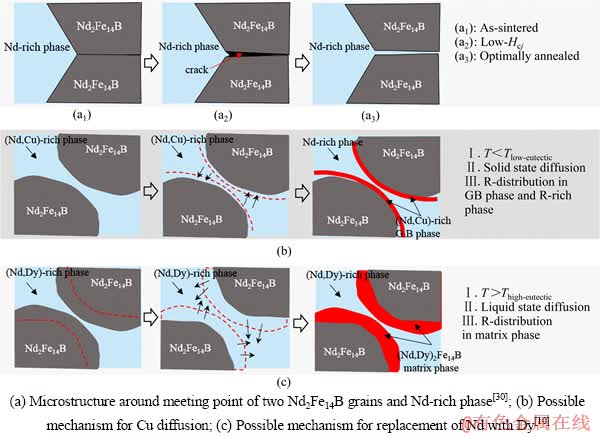

2.1 回火温度的精准控制

由Nd-Fe-B三元相图可知,与烧结后回火相关的低熔点共晶温度在665 ℃左右。在实际商业烧结NdFeB磁体中,大量合金元素的添加使低熔点共晶温度与纯三元体系相差较大,且转变更加复杂。早在1993年,ECKERT等[56]报道利用热分析手段研究了烧结NdFeB磁体中的相变点,且测得的相变点能与制定的回火方案相对应,进而解释了不同回火温度对磁性能影响不同的内在原因。但是,实践中商业磁体的最佳回火方案制定仍通常采用经验-尝试法,这可能与稀土磁体在加热过程中容易氧化,因此,难以测得清晰转变点有关。近期,VIALA等[39]结合差示扫描量热分析(DSC)手段测得的烧结磁体的低温相变点,探讨了磁体矫顽力与回火温度的关系,并通过晶界微观结构观察证实了在特定温度下回火矫顽力的提高与形成薄层富Nd晶界相相关。本文作者所在研究小组在一种N38SH级别的磁体研究中发现,仅当回火温度高于DSC检测的最低转变温度时,经回火处理后磁体的矫顽力才高于烧结态磁体的矫顽力。AKIYA等[30]研究一种平均晶粒尺寸仅为1.6 mm的烧结磁体发现,当回火温度小于最佳回火温度区间时,回火后磁体的矫顽力低于其烧结态时的矫顽力,且随着回火时间的延长继续下降直至稳定。这是晶界相与基体相的热膨胀系数不同导致在晶界处形成裂纹,且无液态晶界相填充,如图5(a)所示,从而增加了晶粒表面的杂散场,使式(1)中的有效退磁场因子Neff增大,最终导致矫顽力的降低。将式(1)简化:

(4)

(4)

式中: 为显微结构因子,

为显微结构因子, 。进一步分析最佳回火处理样品和非最佳回火处理样品的矫顽力与温度关系,AKIYA等[30]指出回火处理仅改变有效退磁场因子Neff,而不改变显微结构因子

。进一步分析最佳回火处理样品和非最佳回火处理样品的矫顽力与温度关系,AKIYA等[30]指出回火处理仅改变有效退磁场因子Neff,而不改变显微结构因子 。这一结论与ECKERT等[56]提出的回火处理改善显微结构因子

。这一结论与ECKERT等[56]提出的回火处理改善显微结构因子 而提高矫顽力的观点不同。ECKERT等[56]研究的磁体中不含Cu元素,最佳回火温度较高(约为750 ℃),晶粒表层随富Nd相一起熔化发生重排,修复了晶粒表层晶格缺陷,提高了显微结构因子

而提高矫顽力的观点不同。ECKERT等[56]研究的磁体中不含Cu元素,最佳回火温度较高(约为750 ℃),晶粒表层随富Nd相一起熔化发生重排,修复了晶粒表层晶格缺陷,提高了显微结构因子 而提高磁体矫顽力。AKIYA等[30]研究的磁体中含微量Cu,最佳回火温度较低(约为500 ℃),晶粒表层不随富Nd相熔化,因此,回火后仅改善了晶界微观结构与化学结构/组分,仅降低了有效退磁场因子Neff,而提高磁体矫顽力。

而提高磁体矫顽力。AKIYA等[30]研究的磁体中含微量Cu,最佳回火温度较低(约为500 ℃),晶粒表层不随富Nd相熔化,因此,回火后仅改善了晶界微观结构与化学结构/组分,仅降低了有效退磁场因子Neff,而提高磁体矫顽力。

图5 回火处理改善Nd2Fe14B晶粒与富Nd相界面微观结构与化学成分的机理示意图[10, 30]

Fig. 5 Schematic illustrations of mechanisms to improve microstructure and chemistry of interface between Nd2Fe14B grains and Nd-rich phases during annealing

合金元素的添加使烧结NdFeB磁体具有多个低熔点转变温度。对于含Cu磁体,晶界相主要为低温Nd-Cu共晶相(475~530 ℃)和高温R-Fe-B共晶相(>640 ℃),相应的回火处理方案可主要分为3类:1) 低于低温共晶点(T<Tlow-eutectic)进行回火处理。此时合金元素在晶界处以固态扩散方式进行重新分布,几乎不进入基体相,如图5(b)所示。其优势在于回火处理温度较低,可以有效避免回火过程中晶粒的长大,从而在不降低剩磁的前提下提高磁体的矫顽力;2) 高于高温共晶点(T>Thigh-eutectic)进行回火处理,当磁体内含有Dy、Ni和Al等合金元素时,相邻于晶界相的基体相亦发生熔化,参与合金元素的重新分布,形成新的(Nd,Dy)2Fe14B相[10],如图5(c)所示,采用此回火处理方案将不可避免地导致磁体剩磁下降,但能有效提高磁体的矫顽力;3) 在低温共晶点和高温共晶点温度之间(Tlow-eutectic<T<Thigh-eutectic)进行回火处理。此时,Nd-Cu等二元低温共晶相以液态方式扩散,在晶界处重新分布,形成薄层晶界相。其中,Cu元素偏聚于晶界相/基体相的界面处,不进入基体相。而R-Fe-B等三元高温共晶相以固态方式扩散,受限于扩散速率,通常富集于晶界处和富R相中,仅有少量Dy等稀土元素进入基体相。因此,这种回火处理方案不仅能有效抑制回火过程中晶粒的长大,而且在几乎不降低剩磁的前提下显著提高磁体的矫顽力。

2.2 晶界掺杂和晶界扩散处理

合金化Dy元素是商业烧结NdFeB磁体提高矫顽力的有效途径之一,它是将Dy合金元素通过熔炼过程添加到磁体中,此添加方式不仅导致剩磁的明显下降,而且提高矫顽力的效能非常有限。2006年,HIROTA等[57]证实了将Dy元素置于晶界区域,通过在富Nd相/Nd2Fe14B界面处形成磁硬化区域,降低反磁化畴形核的可能性,从而显著提高了磁体矫顽力,并且几乎不降低剩磁。这种有效添加Dy的方式,可以显著降低磁体内Dy的添加量,并且实现在不降低剩磁的前提下显著提高磁体矫顽力。在此思想指导下,近年来各国研究者报道了大量晶界改性和晶界扩散方面的研究工作,总结如下。

2.2.1 晶界掺杂

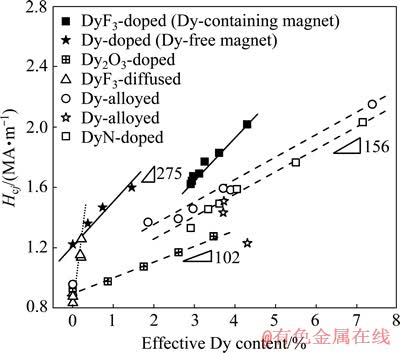

晶界掺杂是指在制粉过程中将NdFeB磁性粉末与晶界添加物混合,压制烧结后经过一定的回火处理提高磁性能。与合金化方法相比,其突出优势在于显著提高磁体矫顽力的同时,几乎不降低磁体的剩磁,而且能显著提高合金元素的利用率。与晶界扩散方法相比,其突出优势在于对磁体尺寸与形状无明显限 制。目前报道的晶界添加物主要有Nd、Pr和Dy等纳米颗粒[58-60],Nd和Dy的氧化物、氟化物[33, 61-62]和氮化物[63]以及其他氧化物[64],Al-Cu[65]和Cu-Zn[66]等共晶合金。晶界掺杂方法主要利用了磁体烧结过程中晶界上有部分液相形成的特点,使添加物与液相迅速反应,富集于Nd2Fe14B基体相的交汇处和晶界处,实现更好的磁隔离效果;或者使Dy元素主要分布于晶界附近的晶粒内,从而提高磁体矫顽力,这主要是以形核场理论为依据加以解释[67]。此外,晶界掺杂Dy元素,使单位有效Dy含量提高矫顽力的效能提高了近1倍[33](见图6)。此外,ZHANG等[62]研究表明,使用不含Dy元素的NdF3晶界掺杂亦可提高烧结磁体矫顽力,其中F元素与富Nd相反应形成一种有序的稀土氟氧化物(Rare-earth oxyfluoride, ROF)。除了有利于形成ROF相外,纳米束衍射(NBED)分析表明F元素能降低富Nd /Nd2Fe14B界面处的Nd2Fe14B晶格畸变层厚度,即减小了式(1)中的参数r0,进而提高了磁体矫顽力。

2.2.2 晶界扩散

2006年,日本信越化学工业株式会社首先报道 了[57]通过晶界扩散提高烧结NdFeB磁体矫顽力的研究。晶界扩散工艺是指在烧结NdFeB磁体表面涂覆一层含稀土元素的化合物,并在富Nd相熔点以上进行回火处理,利用晶界扩散远高于体扩散的特点,在回火处理过程中晶界相部分熔化,加快了与扩散物质的反应,进而改变了晶界附近局域的化学成分和结构特点,实现了磁体矫顽力的提高且不损害剩磁。晶界扩散处理的突出优势与晶界掺杂处理一样,能在不降低磁体剩磁的前提下,显著提高磁体的矫顽力,且效果优于晶界掺杂处理。但是,由于晶界扩散深度的有限,通常只能实现对5 mm厚度以内磁体的改性,这在很大程度上限制了此新技术的广泛应用。目前,各国研究者报道的晶界扩散物质主要有Nd、Pr、Dy和Tb金属及其氧化物、氟化物等[19, 68-69],Nd-Cu二元共晶合金[47]和Dy-Ni-Al三元共晶合金[10, 70]等,且主要以气相沉积和悬浊液沉积两种方式涂覆于磁体表面。本文作者所在研究小组[19]研究了晶界形貌对晶界扩散处理效果的影响。在相同实验条件下,当磁体中的晶界相呈间断分布时,扩散处理磁体的性能以及扩散深度相比于当磁体中的晶界相呈连续分布时均有所下降,这表明晶界及晶界相对这种处理方式的重要性。图6所示为在合金化、晶界掺杂和晶界扩散处理下磁体矫顽力与有效Dy添加量关系的对比[33, 63]。显然,随着有效Dy添加量的提高,磁体的矫顽力也明显增大。更为突出的是,晶界扩散处理工艺明显优于合金化工艺和晶界掺杂工艺,能在添加极少量Dy的条件下,大大提高磁体的矫顽力。

SEPEHRI-AMIN等[71]系统研究了气相Dy晶界扩散处理磁体的晶界微观结构和化学结构/组分,证实了晶界扩散处理后Nd2Fe14B晶粒表面形成了一层富Dy壳层。有关这种壳-核结构以及前面所述的隔离Nd2Fe14B晶粒的晶界相在提高此类磁体矫顽力的贡献机制方面曾一度有所争论。研究者[71]经过细致的研究确认了富Dy的壳-核结构以及晶界上隔离Nd2Fe14B晶粒的晶界相对提高矫顽力具有同等重要的作用。此外,研究还表明[19, 21]Dy沿晶界渗透进入基体,在Nd2Fe14B晶粒表面形成(Nd,Dy)2Fe14B相,同时置换出部分Nd,有利于在晶界上形成连续的起隔离作用的晶界相。

图6 不同工艺处理下有效Dy添加量(质量分数)与磁体矫顽力提高的关系[33, 63]

Fig. 6 Coercivity enhancement as function of effective Dy content under different processing treatments[33, 63]

2.3 亚微米/纳米晶NdFeB磁体的SPS烧结技术

如前所述(如图4),细化晶粒尺寸对矫顽力提高具有较大潜力。无论是采用HDDR方法还是快淬方法都可以获得具有纳米级晶粒的粉末颗粒,且氧含量较低。但是,传统烧结方法的烧结温度在1000 ℃以上,将不可避免地引起晶粒长大。为了获得具有纳米晶结构的各向异性块状烧结磁体,技术上需要解决如何抑制晶粒长大、控制磁体取向以及优化晶界微观结构等主要问题。

放电等离子体烧结(SPS)技术因其低温、快速的优点,广泛应用于陶瓷和金属材料领域。早期研究表明[72-77],将普通磁粉经磁场取向压实后,进行30~50 MPa加压SPS处理,在远低于普通烧结温度的范围内(740~860 ℃),可获得与普通烧结体性能相当或略低的磁体。2006年,YUE等[78]将快淬粉末(MQP-C)进行放电等离子体烧结和热变形处理,制备了一种晶粒尺寸约为200 nm的各向异性NdFeB块体。研究证实热变形后,磁体的取向度明显提高,使磁体剩磁和最大磁能积亦明显提高。但由于磁体的微观组织结构未达到优化,从而导致磁体矫顽力明显下降。类似的研究[53]也证实,SPS烧结后进行热变形能使磁体的剩磁和最大磁能积显著上升,但使磁体矫顽力下降。此外,SURESH等[79]将HDDR粉末用SPS成功制备了晶粒尺寸约300 nm的含有晶界相的块状磁体。GOPALAN等[80]结合SPS技术与原位热变形技术成功制备了剩磁显著提高的磁体。但是,采用SPS技术制备的块体磁体的矫顽力与HDDR粉末的理论性能相比仍有很大差距,这表明SPS烧结磁体的晶界结构与化学结构/组分仍需进一步调整和优化。此外,有必要对烧结亚微米/纳米晶NdFeB磁体的矫顽力机制作更深层次的认识与理解。

3 关于硬磁相和轻稀土元素置换的计算研究和实验研究

为了减少稀贵稀土元素的使用量、降低磁体成本,除了聚焦于烧结NdFeB磁体微观组织结构优化研究外,有关R2Fe14B硬磁相内禀磁性能以及轻稀土元素的置换研究也重新得到了重视。研究证实[2, 10]烧结NdFeB磁体的矫顽力与剩磁呈反比关系。前面提及的晶界掺杂、晶界扩散工艺以及亚微米/纳米晶SPS烧结等磁体改性与制备方法,有望实现在几乎不降低剩磁的前提下提高磁体的矫顽力。但是,除了提高磁体致密度和取向度以外,有关提高烧结NdFeB磁体剩磁的有效途径却鲜有报道。事实上,烧结NdFeB磁体的外禀磁性能本质上由Nd2Fe14B硬磁相的内禀磁性能决定。因此,有必要重新认识与理解R2Fe14B相内禀磁性能的起源与主要影响因素。下文总结了近期第一性原理计算在此方面所取得的进展,回顾并展望了单晶实验研究在此方面所取得的成果与未来的研究方向。

3.1 R2Fe14B硬磁相和稀土元素置换的四元化合物的第一性原理计算研究

R2Fe14B四方相的单胞由68个原子组成(8个稀土原子,56个铁原子和4个硼原子),其中,稀土原子和铁原子分别占据不等价的晶位。稀土元素f电子和过渡金属d电子使整个体系的电子密度分布极不均匀,能量变化梯度较大。处理此类体系的可靠计算方法与计算精度仍在不断改进和提高中。20世纪80年代,早期的计算研究大都是半经验或非自洽的,对于波函数的处理多采用(正交)原子轨道法,而处理交换关联能时虽考虑了稀土元素4f电子的自旋极化,但未考虑4f电子的局域态性质。因此,早期Nd2Fe14B相的计算结果远不足以保证电子结构的计算精度,只能定性地解释一些实验现象[81-83]。自20世纪90年代开始,有关NdFeB永磁材料的第一性原理计算都是自洽的。对于波函数的处理主要采用更为合理的线性Muffin-tin轨道组合法,而处理交换关联能时都采用局域自旋密度近似,即同时考虑了4f电子的自旋极化与局域态性质,并根据Russel-Saunders模型修正4f电子的轨道磁矩[84-87]。与早期的计算结果相比,考虑4f电子的局域态性质后,计算得到的Fe原子磁矩更接近于实验值,但计算得到的稀土原子磁矩仍与实验值存在很大偏差。这是由于4f电子不仅具有局域态性质,而且在巡游电子的作用下,还会与Fe的3d电子发生耦合作用,而在计算中很难同时处理这两种特性。

2009年之后,围绕NdFeB磁体矫顽力的原子机制以及磁体合金化的热力学本质,有关R2Fe14B相物理本性的第一性原理计算又出现了新的一波研究热潮,计算结果的准确性和精度都得到了很大的提高。首先,为了进一步提高电子结构的计算精度,波函数的处理方法和选用的势通常分别为线性缀加平面波 和全势能[88-91]。采用这种全势线性缀加平面波方法能显著提高稀土化合物电子结构的准确性与精度,但是其巨大的计算量使计算效率严重降低。因此,有学者[88-89, 92-94]在保证足够的计算精度下尽可能地提高计算效率,而采用投影缀加波(PAW)方法处理波函数,并以牺牲一部分计算精度为代价而采用赝势。PAW赝势方法[95]综合了线性缀加平面波(LAPW)方法和传统赝势方法。相对于LAPW的全电子势,PAW赝势方法将原子核视为刚性不可极化的离子核,这种刚性核可合理地划分成规则网格,避免了庞大的计算量;相对于传统赝势方法,PAW赝势方法提供了对计算效率和精度调节的灵活性,即可通过增加或减少冻核近似的核半径来实现。PAW赝势方法对于Nd 4f电子的处理,部分作芯态处理,部分作价电子处理,前者对应于Nd 4f电子态的局域化特性,后者对应于与Fe 3d电子态的耦合作用特性。与仅将Nd 4f电子作芯态处理或价电子处理相比,其计算得到的Fe原子磁矩更接近于实验值。其次,对于交换关联能的处理,则在局域密度近似(LDA)的基础上,进一步考虑了密度梯度的影响,而采用广义梯度近似(GGA),从而获得更为精准的能量与结构,但是其计算量增大且通常存在过分修正的缺点,因此,迄今为止,LDA和GGA方法仍在并列地广泛使用。此外,为了修正密度泛函理论在处理强关联体系存在的误差,考虑稀土元素4f电子的强关联性,在局域密度近似和广义梯度近似的基础上,加入了一个电子占位库仑排斥项U,即采用(LDA+U)方法[90, 94]和(GGA+U)方法[92]。这类方法中局域的f电子用Hubbard项来描述库仑相互作用,并同时扣除原来LDA或GGA方法中对这部分势和能量的计算。其中,对于Nd 4f电子“+U”处理,通常采用U=6 eV或U=5 eV。“+U”处理的本质是增强4f电子的高度局域化特性,“+U”处理计算得到的Fe原子磁矩增大,且更接近于实验值。另外,KITAGAWA等[91]和ALAM等[94]还考虑了4f电子的自旋-轨道耦合作用(SOI),并指出Fe原子磁矩受自旋-轨道耦合作用而增强。而TANAKA等[88]和TOGA等[93]则在处理交换关联能时引入了自相互作用修正(SIC)。综上所述,Nd2Fe14B硬磁相电子结构精度的提高与计算研究方法的改进紧密相关,其突破口在于如何更好地处理稀土元素4f电子受周围电子的静电屏蔽和交换关联的双重作用。

2000年之前,研究者对R2Fe14B相的能态密度、价电子分布和原子磁矩进行了计算研究,在定性的层次上合理解释了硬磁相磁性的主要来源和不同晶格占位上的原子磁矩等问题。2009年以后发表的文献主要报道了不同晶格占位上Fe原子磁矩、R2Fe14B相表面晶体场参数以及置换稀土元素在2-14-1相中的晶格择优占位等问题。研究表明,采用LDA+U/GGA+U方法,考虑自旋-轨道耦合作用以及引入自相互作用修正所计算得到的Fe原子的磁矩更加接近于实验值。这为进一步计算研究稀土掺杂对(R,R′)2Fe14B硬磁相磁性的影响奠定了可靠基础。R2Fe14B相(001)自由表面的晶体场参数计算研究表明[88, 90],不同于体相内原子,自由表面处的Nd原子和Dy原子均存在面内的各向异性,可以成为反向磁化畴的形核点。这解释了FUKAGAWA等[28-29, 59, 96]实验观察到的磁体“表面矫顽力退化”现象的原因。稀土元素R(R=Dy,Tb,Y和La)在Nd2Fe14B相中的优先占位以及置换后化合物的总能和置换能等的研究[97-98],较成功地解释了合金元素R在NdFeB磁体中的重分布等实验现象以及挖掘了置换掺杂合金元素R的可能性。此外,美国学者[94]对轻稀土置换掺杂体系作了最新研究,主要包括不同价态的稀土元素Ce的优先占位及其对磁性能的影响。

3.2 R2Fe14B硬磁相和掺杂(轻稀土元素)置换四元化合物单晶体的研究

利用单晶体结构完整和晶体学位向可控的特点,在实验上有关R2Fe14B硬磁相的内禀物理性质研究,自发现NdFeB磁体以后就已见诸报道。有关R2Fe14B硬磁相的单晶实验研究主要集中在20世纪80~90年代,研究内容可总结为两个方面:1) R2Fe14B相磁性与各向异性产生的本源问题;2) R2Fe14B相的置换掺杂研究,以寻找性能更佳或成本更低廉的替换元素。

3.2.1 R2Fe14B相磁性与各向异性的起源

1984年,SAGAWA等[99]首次报道了具有Nd15Fe77B8成分的烧结NdFeB磁体具有优异的磁性能,并发现具有四方结构的Nd2Fe14B相是磁体具有优异性能的关键。紧接着HERBST等[100]和GIVORD等[101]几乎同时研究了Nd2Fe14B相内原子的具体占位,及其与磁性能之间的关系。随后的两年内,SINNEMA等[102]和HIROSAWA等[103]分别利用多晶体和单晶体研究了R2Fe14B化合物的内禀物理性质,并获得了大量可靠地实验数据。此外,通过对比分析讨论不同类型R2Fe14B化合物的内禀物理性质,解释了R2Fe14B相的磁性与各向异性的起源等问题。更为重要的是,为后续置换掺杂R2Fe14B相的多元合金体系研究提供了参考依据。

当R为轻稀土(LR)元素时,LR与Fe呈铁磁性耦合,且随着温度升高,所有LR2Fe14B相的饱和磁化强度逐渐降低;而当R为重稀土(HR)元素时,HR与Fe呈反铁磁性耦合。因此,(HR)2Fe14B的饱和磁化强度普遍低于(LR) 2Fe14B的,且当HR为Tm、Er、Ho和Dy时,在特定的温度范围内,出现了正的饱和磁化强度温度系数,这可能是由Fe和R亚点阵间的竞争作用引起的。此外,Nd2Fe14B和Ho2Fe14B都存在类似的自旋再取向现象,这是由稀土原子的4f和4g晶位不同的各向异性竞争引起的。而在Er2Fe14B和Tm2Fe14B中则存在着另一类自旋再取向现象,它是由Fe亚点阵和R亚点阵间的各向异性竞争引起的[103]。

R2Fe14B化合物的各向异性来源于Fe亚点阵和R亚点阵的共同贡献。当R为无磁矩原子时,则R2Fe14B的各向异性仅来自于Fe亚点阵各向异性,且它使易磁化方向平行于c轴。当R具有轨道磁矩时,R2Fe14B化合物中出现了另一类由晶格场作用引起的R亚点阵各向异性。它与Fe亚点阵各向异性间的竞争作用,使R2Fe14B(R=Pr, Nd, Tb, Dy, Ho)的易磁化方向平行于c轴,即具有单轴各向异性;使R2Fe14B(R=Sm, Er, Tm)的易磁化方向垂直于c轴,即具有面内各向异性。对于具有单轴各向异性的R2Fe14B(R=Pr, Tb, Dy),其平均单离子各向异性常数ku1近似等于[MR(T)/MR(0)]3,这与理论预测几乎一致,且存在的微小偏差可能是由R亚点阵中存在两个不等价晶位引起的[103]。此外,SINNEMA等[102]给出了R2Fe14B化合物居里温度的理论表达式,并与实验值进行了对比,发现重稀土型三元化合物吻合很好,但轻稀土型三元化合物则存在一定偏差。

但是,有关R2Fe14B相电子结构的实验解析以及磁性与各向异性更为直接的实验证据却鲜有报道。显然,此方向的研究仍存在着较大的难度,这主要与缺乏先进的仪器设备及高品质大尺寸单晶体有关。

3.2.2 R2Fe14B相轻稀土置换掺杂体系的研究

有关轻稀土的置换掺杂研究,早在NdFeB被发现之前就引起了强烈的兴趣[99]。由于Sm和Co资源的有限,Sm-Co永磁体的应用受到了极大限制。因此,希望用稀土R-Fe型化合物来替换Sm-Co永磁体,尤其是用轻稀土LR-Fe型化合物。此外,若稀土R具有轨道磁矩,则通过晶场作用能使R-Fe型化合物具有很高的磁晶各向异性。但是,R-Fe型化合物并未实现期望,原因如下[99]:1) LR-Fe型化合物的居里点太低;2) LR很少能与Fe形成稳定的金属间化合物;3) R-Fe型化合物并未具有单轴各向异性的。

具有四方结构的Nd2Fe14B相被发现之后,几乎尝试了元素周期表上所有的稀土元素,却未找到任何综合性能优于Nd2Fe14B相的三元稀土化合物。此外,考虑到轻稀土资源的储量相对丰富且价格低廉,轻稀土置换的(R,R′)2Fe14B四元化合物研究再次引起了强烈的兴趣。另一方面,有关部分置换重稀土元素形成(Nd,R)2Fe14B四元化合物与部分置换过渡族元素形成R2(Fe,T)14B四元化合物以提高Nd2Fe14B相某一特定的磁性能研究亦是当时的研究热点。主要报道的合金体系有La2-xCexFe14B[104]、Y2Fe14-xTxB(T=Al, Ni, Co, Mn)[105]、(Nd1-xDyx)2Fe14B[106-107]和Nd2(Fe1-xCox)14B[108]等。

对于稀土元素与过渡族元素置换,保持为四方结构的(R,R′)2Fe14B与R2(Fe,T)14B四元化合物的饱和磁化强度都明显低于Nd2Fe14B化合物,且轻稀土置换的(Nd,LR)2Fe14B化合物的各向异性低于Nd2Fe14B化合物的,而重稀土置换的(Nd,HR)2Fe14B化合物的各向异性优于Nd2Fe14B化合物,尤其是重稀土Dy和Tb。这也是烧结NdFeB磁体中添加Dy和Tb以提高磁体矫顽力的依据。对于过渡族元素置换的R2(Fe,T)14B化合物,其各向异性同样低于R2Fe14B化合物的。但是当过渡族元素为Co时,能明显提高化合物的居里温度[109]。因此,烧结磁体中通常添加一定量的Co以改善热稳定性和提高磁体的矫顽力温度系数。

近期,有关R2Fe14B硬磁相本身和置换掺杂体系的研究以计算为主,有关掺杂单晶体磁性能随掺杂量和温度变化的系统实验研究鲜有报道。但是,考虑到混合动力汽车永磁电机使用的大量需求和重稀土资源的稀缺,有关轻稀土置换掺杂的多元体系的内禀物理性质研究将是未来烧结NdFeB磁体研究的热门方向之一。

4 结语

随着新能源汽车和风力发电等新能源体系的不断发展以及稀土资源危机带来的稀土价格不断上涨,迫使人们不得不重新审视稀土永磁材料发展的新趋势。综合考虑资源、环境和成本的关系,开发微量Dy和无Dy的高矫顽力NdFeB磁体已基本达成业内共识。通过聚焦于烧结NdFeB磁体晶界与相界的微观组织结构与成分优化的研究,近年来发展了一些磁体改性的新方法与新工艺,各向异性的纳米晶/亚微米晶烧结磁体以及低成本轻稀土掺杂体系将是未来烧结NdFeB磁体研究的主要方向。此外,利用第一性原理计算和单晶体实验研究等手段,充分认识磁性相的物理本质,综合考虑其结构、成分、性质和成本间的关系,是发展新型永磁体的关键。

REFERENCES

[1] GUTFLEISCH O, WILLARD M A,  E, CHEN C H, SANKAR S G, LIU J P. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient[J]. Adv Mater, 2011, 23(7): 821-842.

E, CHEN C H, SANKAR S G, LIU J P. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient[J]. Adv Mater, 2011, 23(7): 821-842.

[2] HONO K, SEPEHRI-AMIN H. Strategy for high-coercivity Nd-Fe-B magnets[J]. Scripta Mater, 2012, 67(6): 530-535.

[3] ONO K, ARAKI T, YANO M, MIYAMOTO N, SHOJI T, KATO A, MANABE A, NOZAKI H, KANEKO Y, RAABE J. Element-specific magnetic domain imaging of (Nd,Dy)-Fe-B sintered magnets using scanning transmission X-ray microscopy[J]. IEEE Trans Magn, 2011, 47(10): 2672-2675.

[4] 黄小卫, 李红卫, 王彩凤, 王国珍, 薛向欣, 张国成. 我国稀土工业发展现状及进展[J]. 稀有金属, 2007, 31(3): 279-288.

HUANG Xiao-wei, LI Hong-wei, WANG Cai-feng, WANG Guo-zhen, XUE Xiang-xin, ZHANG Guo-cheng. Development status and research progress in rare earth industry in China[J]. Chinese Journal of Rare Metals, 2007, 31(3): 279-288.

[5] 翁兴园. 稀土永磁原料状况与中国稀土永磁产业市场变化分析[J]. 新材料产业, 2012, 5: 52-58.

WEI Xing-yuan. Raw materials status of rare earth permanent magnet and analysis of marketable changes in rare earth perment magnet industry[J]. Advanced Materials Industry, 2012, 5: 52-58.

[6] LI J, LIU Y, GAO S J, LI M, WANG Y Q, TU M J. Effect of process on the magnetic properties of bonded NdFeB magnet[J]. J Magn Magn Mater, 2006, 299(1): 195-204.

[7] 周寿增, 董清飞. 超强永磁体: 稀土铁系永磁材料[M]. 北京: 冶金工业出版社, 2004.

ZHOU Shou-zeng, DONG Qing-fei. Super permanent magnets: Rare earth iron based permanent materials[M]. Beijing: Metallurgical Industry Press, 2004.

[8] HERBST J F. R2Fe14B materials: Intrinsic properties and technological aspects[M]. Rev Mod Phys, 1991, 63(4): 819-898.

[9]  H, SCHREFL T. Interactive and cooperative magnetization process in hard magnetic materials[J]. J Magn Magn Mater, 1994, 129(1): 66-78.

H, SCHREFL T. Interactive and cooperative magnetization process in hard magnetic materials[J]. J Magn Magn Mater, 1994, 129(1): 66-78.

[10] OONO N, SAGAWA M, KASADA R, MATSUI H, KIMURA A. Production of thick high-performance sintered neodymium magnets by grain boundary diffusion treatment with dysprosium- nickel-aluminum alloy[J]. J Magn Magn Mater, 2011, 323(3/4): 297-300.

[11] KOBAYASHI K, URUSHIBATA K, MATSUSHITA T, AKIYA T. The origin of unique initial magnetization curves in Dy- substituted (Nd1-xDyx)2Fe14B (x=0-1) sintered magnets[J]. J Appl Phys, 2012, 111(2): 023907-5.

[12] MATSUURA Y, HOSHIJIMA J, ISHII R. Relation between Nd2Fe14B grain alignment and coercive force decrease ratio in NdFeB sintered magnets[J]. J Magn Magn Mater, 2013, 336: 88-92.

[13] FIDLER J. On the role of the Nd-rich phases in sintered Nd-Fe-B magnets[J]. IEEE Trans Magn, 1987, 23(5): 2106-2108.

[14] SAGAWA M, HIROSAWA S, YAMAMOTO H, FUJIMURA S, MATSUURA Y. Nd-Fe-B Permanent Magnet Materials[J]. Jpn J Appl Phys, 1987, 26(6): 785-800.

[15] SAGAWA M, TENAUD P, VIAL F, HIRAGA K. High coercivity Nd-Fe-B sintered magnetcontaining vanadium with new microstructure[J]. IEEE Trans Magn, 1990, 26(5): 1957-1959.

[16] OLIVER M R, HARRIS I R. A Study of the Effects of Cu-addition on the annealing behaviour and microstructures of Nd-Fe-B type sintered magnets[J]. IEEE Trans Magn, 1993, 29(6): 1993-1995.

[17] WOODCOCK T G, ZHANG Y, HRKAC G, CIUTA G, DEMPSEY N M, SCHREFL T, GUTFLEISCH O, GIVORD D. Understanding the microstructure and coercivity of high performance NdFeB-based magnets[J]. Scripta Mater, 2012, 67(6): 536-541.

[18] JILES D C. Recent advances and future directions in magnetic materials[J]. Acta Mater, 2003, 51(19): 5907-5939.

[19] XU F, WANG J, DONG X P, ZHANG L T, WU J S. Grain boundary microstructure in DyF3-diffusion processed Nd-Fe-B sintered magnets[J]. J Alloys Compd, 2011, 509(30): 7909-7914.

[20] SEPEHRI-AMIN H, UNE Y, OHKUBO T, HONO K, SAGAWA M. Microstructure of fine-grained Nd-Fe-B sintered magnets with high coercivity[J]. Scripta Mater, 2011, 65(5): 396-399.

[21] LI W F, SEPEHRI-AMIN H, OHKUBO T, HASE N, HONO K. Distribution of Dy in high-coercivity (Nd,Dy)-Fe-B sintered magnet[J]. Acta Mater, 2011, 59(8): 3061-3069.

[22] LIU Q Z, ZHANG L T, SHAN A D, WU J S, KOMURO M. Grain boundary modification by Si3N4 additions and the effect on corrosion behaviors in two sintered Nd-Fe-B magnets[J]. Adv Mater Res, 2010, 89/91: 733-738.

[23] 谭春林, 白书欣, 张 虹, 高艳丽, 张家春, 蔡珣. 回火处理对烧结钕铁硼永磁材料组织和磁性能的影响[J]. 中国有色金属学报, 2002, 12(S1): s64-s66.

TAN Chun-lin, BAI Shu-xin, ZHANG Hong, GAO Yan-li, ZHANG Jia-chun, CAI Xun. Effect of tempering on microstructure and magnetic properties of sintered Nd2Fe14B magnets[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): s64-s66.

[24] LI D, SUZUKI S, KAWASAKI T, MACHIDA K. Grain interface modification and magnetic properties of Nd-Fe-B sintered magnets[J]. Jpn J Appl Phys, 2008, 47(10): 7876-7878.

[25] SATO K, MURAKAMI Y, SHINDO D, HIROSAWA S, YASUHARA A. Transmission electron microscopy study on the grain boundaries and magnetic domains in Nd-Fe-B based magnets[J]. Mater Trans, 2010, 51(2): 333-340.

[26] FIDLER J. Analytical microscope studies of sintered Nd-Fe-B magnets[J]. IEEE Trans Magn, 1985, 21(5): 1955-1957.

[27] MO W J, ZHANG L T, LIU Q Z, SHAN A D, WU J S, KOMURO M. Dependence of the crystal structure of the Nd-rich phase on oxygen content in an Nd-Fe-B sintered magnet[J]. Scripta Mater, 2008, 59(2): 179-182.

[28] FUKAGAWA T, HIROSAWA S, OHKUBO T, HONO K. The effect of oxygen on the surface coercivity of Nd-coated Nd-Fe-B sintered magnets[J]. J Appl Phys, 2009, 105(7): 07A724-3.

[29] FUKAGAWA T, OHKUBO T, HIROSAWA S, HONO K. Nano-sized disorders in hard magnetic grains and their influence on magnetization reversal at artificial Nd/Nd2Fe14B interfaces[J]. J Magn Magn Mater, 2010, 322(21): 3346-3350.

[30] AKIYA T, SASAKI T T, OHKUBO T, UNE Y, SAGAWA M, KATO H, HONO K. The origin of the coercivity reduction of Nd-Fe-B sintered magnet annealed below an optimal temperature[J]. J Magn Magn Mater, 2013, 342: 4-10.

[31] SHINBA Y, KONNO T J, ISHIKAWA K, HIRAGA K, SAGAWA M. Transmission electron microscopy study on Nd-rich phase and grain boundary structure of Nd-Fe-B sintered magnets[J]. J Appl Phys, 2005, 97(5): 053504-8.

[32] HRKAC G, WOODCOCK T G, FREEMAN C, GONCHAROV A, DEAN J, SCHREFL T, GUTFLEISCH O. The role of local anisotropy profiles at grain boundaries on the coercivity of Nd2Fe14B magnets[J]. Appl Phys Lett, 2010, 97(23): 232511-3.

[33] XU F, ZHANG L T, DONG X P, LIU Q Z, KOMURO M. Effect of DyF3 additions on the coercivity and grain boundary structure in sintered Nd-Fe-B magnets[J]. Scripta Mater, 2011, 64(12): 1137-1140.

[34] WOODCOCK T G, GUTFLEISCH O. Multi-phase EBSD mapping and local texture analysis in NdFeB sintered magnets[J]. Acta Mater, 2011, 59(3): 1026-1036.

[35] LIU Q Z, XU F, WANG J, DONG X P, ZHANG L T, YANG J Y. An investigation of the microstructure in the grain boundary region of Nd-Fe-B sintered magnet during post-sintering annealing[J]. Scripta Mater, 2013, 68(9): 687-690.

[36] LI W F, OHKUBO T, HONO K. Effect of post-sinter annealing on the coercivity and microstructure of Nd-Fe-B permanent magnets[J]. Acta Mater, 2009, 57(5): 1337-1346.

[37] SEPEHRI-AMIN H, OHKUBO T, SHIMA T, HONO K. Grain boundary and interface chemistry of an Nd-Fe-B-based sintered magnet[J]. Acta Mater, 2012, 60(3): 819-830.

[38] FIDLER J, BERNARDI J. Transmission electron microscope characterization of cast and hot-worked R-Fe-B:Cu(R=Nd,Pr) permanent magnets[J]. J Appl Phys, 1991, 70(10): 6456-6458.

[39] VIAL F, JOLY F, NEVALAINEN E, SAGAWA M, HIRAGA K, PARK K T. Improvement of coercivity of sintered NdFeB permanent magnets by heat treatment[J]. J Magn Magn Mater, 2002, 242/245: 1329-1334.

[40] SAGAWA M, FUJIMURA S, YAMAMOTO H, MATSUURA Y, HIRAGA K. Permanent magnet materials based on the rare earth-iron-boron tetragonal compounds[J]. IEEE Trans Magn, 1984(5): 1584-1589.

[41] WATANABE N, ITAKURA M, NISHIDA M. Microstructure of high coercivity Nd-Fe-Co-Ga-B hot-deformed magnet improved by the Dy diffusion treatment[J]. J Alloys Compd, 2013, 557: 1-4.

[42] CUI W B, TAKAHASHI Y K, HONO K. Microstructure optimization to achieve high coercivity in anisotropic Nd-Fe-B thin films[J]. Acta Mater, 2011, 59(20): 7768-7775.

[43] LI W F, OHKUBO T, HONO K, SAGAWA M. The origin of coercivity decrease in fine grained Nd-Fe-B sintered magnets[J]. J Magn Magn Mater, 2009, 321(8): 1100-1105.

[44] RAMESH R, SRIKRISHNA K. Magnetization reversal in nucleation controlled magnets. Ⅰ: Theory[J]. J Appl Phys, 1988, 64(11): 6406-6415.

[45] RAMESH R, THOMAS G, M. M B. Magnetization reversal in nucleation controlled magnets. Ⅱ: Effect of grain size and size distribution on intrinsic coercivity of Fe-Nd-B magnets[J]. J Appl Phys, 1988, 64(11): 6416-6423.

[46] SAGAWA M. Development and prospect of the Nd-Fe-B sintered magnets[C]// Proceedings of the 21st Workshop on Rare-earth Permanent Magnets and Their Applications. Bled, 2010: 183-186.

[47] SEPEHRI-AMIN H, OHKUBO T, NISHIUCHI T, HIROSAWA S, HONO K. Coercivity enhancement of hydrogenation- disproportionation-desorption-recombination processed Nd-Fe-B powders by the diffusion of Nd-Cu eutectic alloys[J]. Scripta Mater, 2010, 63(11): 1124-1127.

[48] 张深根, 于敦波, 应启明, 姚国庆. 高性能烧结NdFeB生产关键技术研究[J]. 金属功能材料, 2001, 8(2): 12-18.

ZHANG Shen-gen, YU Dun-bo, YING Qi-ming, YAO Guo-qing. Study on the key techniques for producing high performance NdFeB sintered permanent magnets[J]. Metallic Functional Materials, 2001, 8(2): 12-18.

[49] LIU X Y, WANG X, SUN H F, HU L X. MC simulation in microstructure evolution and grain growth during desorption- recombination processing of NdFeB alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S): s412-s416.

[50] 王敬欣, 孙爱芝. 粘结NdFeB磁体制备的研究进展[J]. 稀有金属, 2003, 27(6): 827-831.

WANG Jing-xin, SUN Ai-zhi. Progress of process technology on bonded NdFeB permanent[J]. Chinese Journal of Rare Metals, 2003, 27(6): 827-831.

[51] 刘晓亚, 李玉平, 胡连喜. NdFeB粘结磁体材料研究新进展[J]. 稀有金属材料与工程, 2012, 41(10): 1875-1880.

LIU Xiao-ya, LI Yu-ping, HU Lian-xi. Recent research progress in NdFeB bonded magnet materials[J]. Rare Metal Materials And Engineering, 2012, 41(10): 1875-1880.

[52] SAITO T, TAKEUCHI T, KAGEYAMA H. Structures and magnetic properties of Nd-Fe-B bulk nanocomposite magnets produced by the spark plasma sintering method[J]. J Mater Res, 2011, 19(9): 2730-2737.

[53] LIU Z W, HUANG H Y, GAO X X, YU H Y, ZHONG X C, ZHU J, ZENG D C. Microstructure and property evolution of isotropic and anisotropic NdFeB magnets fabricated from nanocrystalline ribbons by spark plasma sintering and hot deformation[J]. J Phys D: Appl Phys, 2011, 44(2): 025003-10.

[54] MA Y L, LIU Y, LI J, DU H L, GAO J. Anisotropic nanocomposite Nd2Fe14B/a-Fe magnets prepared by spark plasma sintering[J]. IEEE Trans Magn, 2009, 45(6): 2605-2607.

[55] XIE H Z, ZHAO J T, YU Y J. New achievements in NdFeB mass production[C]// Proceedings of 19th International Workshop on Rare Earth Permanent Magnets & Their Applications. Beijing, 2006: 324-330.

[56] ECKERT D,  K H, WOLF M, RODEWALD W, WALL B. Ageing effects in sintered (Nd,Dy)15(Fe,Co,Mo,Al)77B8 permanent magnets[J]. IEEE Trans Magn, 1993, 29(6): 2755-2757.

K H, WOLF M, RODEWALD W, WALL B. Ageing effects in sintered (Nd,Dy)15(Fe,Co,Mo,Al)77B8 permanent magnets[J]. IEEE Trans Magn, 1993, 29(6): 2755-2757.

[57] HIROTA K, NAKAMURA H, MINOWA T, HONSHIMA M. Coercivity enhancement by the grain boundary diffusion process to Nd-Fe-B sintered magnets[J]. IEEE Trans Magn, 2006, 42: 2909-2911.

[58] SUN H, LIU W Q, ZHANG X R, YUE M, ZHANG D T, ZHANG J X. Coercivity enhancement in Nd-Fe-B sintered permanent magnet doped with Pr nanoparticles[J]. J Appl Phys, 2011, 109(7): 07A749-3.

[59] FUKAGAWA T, HIROSAWA S. Coercivity generation of surface Nd2Fe14B grains and mechanism of fcc-phase formation at the Nd/Nd2Fe14B interface in Nd-sputtered Nd-Fe-B sintered magnets[J]. J Appl Phys, 2008, 104(1): 013911-6.

[60] LIU W Q, SUN H, YI X F, LIU X C, ZHANG D T, YUE M, ZHANG J X. Coercivity enhancement in Nd-Fe-B sintered permanent magnet by Dy nanoparticles doping[J]. J Alloys Compd, 2010, 501(1): 67-69.

[61] HAJIME N, KOICHI H, MASANOBU S, TAKEHISA M, MASAKATSU H. Magnetic Properties of Extremely Small NdFeB sintered magnets[J]. IEEE Trans Magn, 2005, 41(10): 3844-3846.

[62] LIU Q Z, ZHANG L T, DONG X P, XU F, KOMURO M. Increased coercivity in sintered Nd-Fe-B magnets with NdF3 additions and the related grain boundary phase[J]. Scripta Mater, 2009, 61(11): 1048-1051.

[63] LIU Q Z, ZHANG L T, XU F, DONG X P, WU J S, KOMURO M. Dysprosium nitride-modified sintered Nd-Fe-B magnets with increased coercivity and resistivity[J]. Jpn J Appl Phys, 2010, 49(9): 093001-5.

[64] 陈 亮, 张澜庭, 莫文剑, 单爱党, 吴建生. 晶界添加氧化物对烧结NdFeB磁性能的影响[J]. 稀有金属, 2007, 31(6): 755-758.

CHEN Liang, ZHANG Lan-ting, MO Wen-jian, SHAN Ai-dang, WU Jian-sheng. Effects of oxides added in grain boundary on magnetic properties of sintered NdFeB[J]. Chinese Journal of Rare Metals, 2007, 31(6): 755-758.

[65] NI J J, MA T Y, CUI X G, WU Y R, YAN M. Improvement of corrosion resistance and magnetic properties of Nd-Fe-B sintered magnets by Al85Cu15 intergranular addition[J]. J Alloys Compd, 2010, 502(2): 346-350.

[66] WU Y R, NI J J, MA T Y, YAN M. Corrosion resistance of Nd-Fe-B sintered magnets with intergranular addition of Cu60Zn40 powders[J]. Physica B, 2010, 405(16): 3303-3307.

[67] SAGAWA M, HIROSAWA S, TOKUHARA K, YAMAMOTO H, FUJIMURA S, TSUBOKAWA Y, SHIMIZU R. Dependence of coercivity on the anisotropy field in the Nd2Fe14B-type sintered magnets[J]. J Appl Phys, 1987, 61(8): 3559-3561.

[68] KOMURO M, SATSU Y, SUZUKI H. Increase of coercivity and composition distribution in fluoride-diffused NdFeB sintered magnets treated by fluoride solutions[J]. IEEE Trans Magn, 2010, 46(11 ): 3831-3833.

[69] SUZUKI H, SATSU Y, KOMURO M. Magnetic properties of a Nd-Fe-B sintered magnet with Dy segregation[J]. J Appl Phys, 2009, 105(7): 07A734-3.

[70] OONO N, SAGAWA M, KASADA R, MATSUI H, KIMURA A. Microstructural evaluation of Dy-Ni-Al grain-boundary- diffusion (GBD) treatment on sintered Nd-Fe-B magnet[J]. Mater Sci Forum, 2010, 654/656: 2919-2922.

[71] SEPEHRI-AMIN H, OHKUBO T, HONO K. Grain boundary structure and chemistry of Dy-diffusion processed Nd-Fe-B sintered magnets[J]. J Appl Phys, 2010, 107(9): 09A745-3.

[72] YUE M, ZHANG J X, LIU W Q, WANG G P. Chemical stability and microstructure of Nd-Fe-B magnet prepared by spark plasma sintering[J]. J Magn Magn Mater, 2004, 271(2/3): 364-368.

[73] YUE M, ZHANG J X, XIAO Y F, WANG G P, LI T. New kind of NdFeB magnet prepared by spark plasma sintering[J]. IEEE Trans Magn, 2003, 39(6): 3551-3553.

[74] MO W J, ZHANG L T, SHAN A D, CAO L J, WU J S, KOMURO M. Microstructure and magnetic properties of NdFeB magnet prepared by spark plasma sintering[J]. Intermetallics, 2007, 15(11): 1483-1488.

[75] LIU Z G, UMEMOTO M. Spark plasma sintering of Nd-Fe-B magnetic alloy[J]. J Mater Res, 1999, 14(6): 2540-2547.

[76] 王公平, 岳 明, 张久兴, 刘卫强. 放电等离子烧结制备高性能NdFeB永磁材料[J]. 中国有色金属学报, 2006, 16(3): 459-463.

WANG Gong-ping, YUE Ming, ZHANG Jiu-xing, LIU Wei-qiang. High performance NdFeB permanent magnetic material prepared by spark plasma sintering[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 459-463.

[77] 莫文剑, 张澜庭, 单爱党, 吴建生. 放电等离子烧结NdFeB永磁材料的显微组织研究[J]. 稀有金属材料与工程, 2007(12): 2140-2143.

MO Wen-jian, ZHANG Lan-ting, SHAN Ai-dang, WU Jian-sheng. Study on microstructure of NdFeB magnet prepared by spark plasma sintering[J]. Rare Metal Materials and Engineering, 2007(12): 2140-2143.

[78] YUE M, TIAN M, ZHANG J X, ZHANG D T, NIU P L, YANG F. Microstructure and magnetic properties of anisotropic Nd-Fe-B magnets produced by spark plasma sintering technique[J]. Mater Sci Eng B, 2006, 131(1/3): 18-21.

[79] SURESH K, OHKUBO T, TAKAHASHI Y K, OH-ISHI K, GOPALAN R, HONO K, NISHIUCHI T, NOZAWA N, HIROSAWA S. Consolidation of hydrogenation-disproportionation- desorption-recombination processed Nd-Fe-B magnets by spark plasma sintering[J]. J Magn Magn Mater, 2009, 321(22): 3681-3686.

[80] GOPALAN R, SEPEHRI-AMIN H, SURESH K, OHKUBO T, HONO K, NISHIUCHI T, NOZAWA N, HIROSAWA S. Anisotropic Nd-Fe-B nanocrystalline magnets processed by spark plasma sintering and in situ hot pressing of hydrogenation- decomposition-desorption-recombination powder[J]. Scripta Mater, 2009, 61(10): 978-981.

[81] ZHONG X F, CHING W Y. First-principles calculation of crystal-field parameters in Nd2Fe14B[J]. Phys Rev B, 1989, 39(16): 12018-12026.

[82] GU Z Q, CHING W Y. Comparative studies of electronic and magnetic structures in Y2Fe14B, Nd2Fe14B, Y2Co14B, and Nd2Co14B[J]. Phys Rev B, 1987, 36(16): 8530-8546.

[83] CHING W Y, GU Z Q. Electronic structure of Nd2Fe14B[J]. J Appl Phys, 1987, 61(8): 3718-3720.

[84] HUMMLER K,  M. Full-potential linear-muffin-tin- orbital calculations of the magnetic properties of rare-earth- transition-metal intermetallics. Ⅱ: Nd2Fe14B[J]. Phys Rev B, 1996, 53(6): 3290-3295.

M. Full-potential linear-muffin-tin- orbital calculations of the magnetic properties of rare-earth- transition-metal intermetallics. Ⅱ: Nd2Fe14B[J]. Phys Rev B, 1996, 53(6): 3290-3295.

[85] NORDSTROM L, JOHANSSON B, BROOKS M S S. Calculation of the electronic structure and the magnetic moments of Nd2Fe14B[J]. J Phys: Condens Matter, 1993, 5(42): 7859-7870.

[86] MIN B I, YANG C J, OLSON C G. Electronic and magnetic structures of the rare-earth permanent magnet Nd2Fe14B[J]. Phys Rev B, 1993, 48(9): 6217-6224.

[87] JASWAL S S. Electronic structure and magnetism of R2Fe14B (R=Y, Nd) compounds[J]. Phys Rev B, 1990, 41(14): 9697-9700.

[88] TANAKA S, MORIYA H, TSUCHIURA H, SAKUMA A,  P. First principles study on the local magnetic anisotropy near surfaces of Dy2Fe14B and Nd2Fe14B magnets[J]. J Appl Phys, 2011, 109(7): 07A702-3.

P. First principles study on the local magnetic anisotropy near surfaces of Dy2Fe14B and Nd2Fe14B magnets[J]. J Appl Phys, 2011, 109(7): 07A702-3.

[89] TANAKA S, MORIYA H, TSUCHIURA H, SAKUMA A,  P. First-principles calculation of crystal field parameters of Dy ions substituted for Nd in Nd-Fe-B magnets[J]. J Phys: Conf Ser, 2011, 266: 012045-5.

P. First-principles calculation of crystal field parameters of Dy ions substituted for Nd in Nd-Fe-B magnets[J]. J Phys: Conf Ser, 2011, 266: 012045-5.

[90] MORIYA H, TSUCHIURA H, SAKUMA A. First principles calculation of crystal field parameter near surfaces of Nd2Fe14B[J]. J Appl Phys, 2009, 105(7): 07A740-3.

[91] KITAGAWA I. Calculation of electronic structures and magnetic moments of Nd2Fe14B and Dy2Fe14B by using linear- combination-of-pseudo-atomic-orbital method[J]. J Appl Phys, 2009, 105(7): 07E502-3.

[92] 郝红飞, 王 静, 孙 锋, 张澜庭. Dy在Nd2Fe14B晶格中的占位及其对Fe原子磁矩影响的第一性原理计算[J]. 物理学报, 2013, 62(11): 117501-6.

HAO Hong-fei, WANG Jing, SUN Feng, ZHANG Lan-ting. First-principles calculation of preferential site occupation of Dy ions in Nd2Fe14B lattice and its effect on local magnetic moments of Fe ions[J]. Acta Phys Sin, 2013, 62(11): 117501-6.

[93] TOGA Y, MORIYA H, TSUCHIURA H, SAKUMA A. First principles study on interfacial electronic structures in exchange-spring magnets[J]. J Phys: Conf Ser, 2011, 266: 012046-5.

[94] ALAM A, KHAN M, MCCALLUM R W, JOHNSON D D. Site-preference and valency for rare-earth sites in (R-Ce)2Fe14B magnets[J]. Appl Phys Lett, 2013, 102(4): 042402-4.

[95]  P E. Projector augmented-wave method[J]. Phys Rev B, 1994, 50(24): 17953-17979.

P E. Projector augmented-wave method[J]. Phys Rev B, 1994, 50(24): 17953-17979.

[96] FUKAGAWA T, HIROSAWA S. Influence of Nd/Nd2Fe14B interface microstructure on the coercivity of surface Nd2Fe14B grains in Nd-sputtered Nd-Fe-B sintered magnets[J]. Scripta Mater, 2008, 59(2): 183-186.

[97] LIU X B, ALTOUNIAN Z, HUANG M, ZHANG Q, LIU J P. The partitioning of La and Y in Nd-Fe-B magnets: A first-principles study[J]. J Alloys Compd, 2013, 549: 366-369.

[98] LIU X B, ALTOUNIAN Z. The partitioning of Dy and Tb in NdFeB magnets: A first-principles study[J]. J Appl Phys, 2012, 111(7): 07A701-3.

[99] SAGAWA M, FUJIMURA S, YAMAMOTO H. New materials for permanent on a base of Nd and Fe[J]. J Appl Phys, 1984, 55: 2083-2087.

[100] HERBST J F, CROAT J J, PINKERON F E. Relationships between crystal structure and magnetic properties in Nd2Fe14B[J]. Phys Rev B, 1984, 29(7): 4176-4178.

[101] GIVORD D, LI H S, MOREAU J M. Magnetic properties and crystal structure of Nd2Fe14B[J]. Solid State Commun, 1984, 50(6): 497-499.

[102] SINNEMA S, RADWANSKI R J, FRANSE J J M, MOOIJ D B D, BUSCHOW K H J. Magnetic properties of ternary rare-earth compounds of the type R2Fe14B[J]. J Magn Magn Mater, 1984, 44(3): 333-341.

[103] HIROSAWA S, MATSUURA Y, YAMAMOTO H, FUJIMURA S, SAGAWA M. Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals[J]. J Appl Phys, 1986, 59(3): 873-879.

[104] FUERST C D, CAPEHART T W, PINKERTON F E, HERBST J F. Preparation and characterization of La2-xCexFe14B compounds[J]. J Magn Magn Mater, 1995, 139: 359-363.

[105] BURZO E, PLUGARU N, POP V, STANCIU L, WALLACE W E. Bulk magnetic properties of the Y2TxFe14-xB compounds[J]. Solid State Commun, 1986, 58(11): 803-805.

[106] KIM M J, KIM Y B, KIM C S, KIM T K. Spin reorientation and magnetocrystalline anisotropy of (Nd1-xDyx)Fe14B[J]. J Magn Magn Mater, 2001, 224(1): 49-54.

[107] LIM D W, KATO H, YAMADA M, KIDO G, NAKAGAWA Y. High-field magnetization process and spin reorientation in (Nd1-xDyx)2Fe14B single crystals[J]. Phys Rev B, 1991, 44(18): 10014-10020.

[108] MATSUURA Y, HIROSAWA S, YAMAMOTO H, FUJIMURA S, SAGAWA M. Magnetic properties of the Nd2(Fe1-xCox)14B system[J]. Appl Phys Lett, 1985, 46(3): 308-310.

[109] SANO Y, ONODERA H, YAMAUCHI H, YAMAMOTO H. Magnetic properties of the 3d sublattice in pseudoternary compounds Y2Fe14-xMxB with M = Co and Mn[J]. J Magn Magn Mater, 1989, 79: 67-75.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51171111)

收稿日期:2013-08-15;修订日期:2013-12-17

通信作者:张澜庭,教授,博士;电话:021-54747471;传真:021-54745197;E-mail: lantingzh@sjtu.edu.cn

摘 要:基于新能源汽车/风力发电对高性能动力电机的需求与稀土资源危机的考虑,迫使人们重新审视烧结NdFeB永磁体发展的新趋势。烧结NdFeB永磁体具有的优异性能与其晶界微观结构、化学结构/组分特征以及基体相的内禀性能密切相关。近期利用3DAP、NBED、EELS和STEM等纳米级尺度的解析手段,揭示了界面微区的微观结构与化学结构/组分特征,对深入理解微磁学理论起到了推动作用,并衍生了许多改善磁体性能的新技术。本文作者综述磁体晶界微观结构的最新进展、磁体制备的新技术与其微观机制,并总结分析了近期在第一性原理计算研究和Nd2Fe14B单晶实验研究方面的一些新动态。

[4] 黄小卫, 李红卫, 王彩凤, 王国珍, 薛向欣, 张国成. 我国稀土工业发展现状及进展[J]. 稀有金属, 2007, 31(3): 279-288.

[5] 翁兴园. 稀土永磁原料状况与中国稀土永磁产业市场变化分析[J]. 新材料产业, 2012, 5: 52-58.

[7] 周寿增, 董清飞. 超强永磁体: 稀土铁系永磁材料[M]. 北京: 冶金工业出版社, 2004.

[23] 谭春林, 白书欣, 张 虹, 高艳丽, 张家春, 蔡珣. 回火处理对烧结钕铁硼永磁材料组织和磁性能的影响[J]. 中国有色金属学报, 2002, 12(S1): s64-s66.

[48] 张深根, 于敦波, 应启明, 姚国庆. 高性能烧结NdFeB生产关键技术研究[J]. 金属功能材料, 2001, 8(2): 12-18.

[50] 王敬欣, 孙爱芝. 粘结NdFeB磁体制备的研究进展[J]. 稀有金属, 2003, 27(6): 827-831.

[51] 刘晓亚, 李玉平, 胡连喜. NdFeB粘结磁体材料研究新进展[J]. 稀有金属材料与工程, 2012, 41(10): 1875-1880.

[64] 陈 亮, 张澜庭, 莫文剑, 单爱党, 吴建生. 晶界添加氧化物对烧结NdFeB磁性能的影响[J]. 稀有金属, 2007, 31(6): 755-758.

[76] 王公平, 岳 明, 张久兴, 刘卫强. 放电等离子烧结制备高性能NdFeB永磁材料[J]. 中国有色金属学报, 2006, 16(3): 459-463.

[77] 莫文剑, 张澜庭, 单爱党, 吴建生. 放电等离子烧结NdFeB永磁材料的显微组织研究[J]. 稀有金属材料与工程, 2007(12): 2140-2143.

[83] CHING W Y, GU Z Q. Electronic structure of Nd2Fe14B[J]. J Appl Phys, 1987, 61(8): 3718-3720.

[92] 郝红飞, 王 静, 孙 锋, 张澜庭. Dy在Nd2Fe14B晶格中的占位及其对Fe原子磁矩影响的第一性原理计算[J]. 物理学报, 2013, 62(11): 117501-6.

[95] P E. Projector augmented-wave method[J]. Phys Rev B, 1994, 50(24): 17953-17979.