DOI:10.19476/j.ysxb.1004.0609.2018.04.08

冷加工变形量对Al2O3-弥散强化铜合金组织与性能的影响

张雪辉,李晓闲,刘位江,杨 凯,祝绳健,蒋 苗

(江西理工大学 材料科学与工程学院,赣州 341000)

摘 要:

采用原位反应合成技术制备了Cu-1.12%Al2O3合金(质量分数),通过力学性能、导电率测试及显微组织观察系统研究该合金的冷变形行为。结果表明:对热挤压态合金进行不同变形量的冷拉抜加工处理后,合金的硬度和强度均随变形量的增大而增加,合金加工硬化现象明显,但导电率的变化甚微;冷加工使合金的致密度和位错密度获得进一步的提升,同时由于Al2O3粒子的钉扎位错和阻碍晶界滑移作用,出现位错线缠结和位错塞积,并发展成为变形位错胞组织和亚晶组织。

关键词:

Cu-1.12%Al2O3合金;冷加工行为;力学性能;显微组织;

文章编号:1004-0609(2018)-04-0705-07 中图分类号:TG146.1 文献标志码:A

Cu-Al2O3合金是以高熔点、高硬度、良好热稳定性和化学稳定性的纳米Al2O3颗粒作为增强相,并使其均匀弥散分布在铜基体内,具有高强、高导、高耐热的新型功能材料[1-4],广泛应用于电磁炮导轨材料、大规模集成电路引线框架、电阻焊电极以及国际热核聚变实验堆(ITER)垂直靶材散热片等涵盖先进民用制造业、电子信息业、国防科技工业在内的诸多高新技术领域[5-6]。近年来,国内外对Al2O3-弥散强化铜合金的研究主要集中在制备方法、弥散质点特性以及强化导电机制上[7-13],而对于该类复合材料在加工变形过程中的组织结构和性能演变规律的研究相对较少。国内仅程建奕等[14],郭明星等[15-16],LI等[17]对其冷加工特性进行了相关研究,但其研究对象均为传统真空热压和高温内氧化法制备的Al2O3-弥散强化铜合金,所制备合金中弥散相Al2O3为尖晶石结构,与基体Cu呈非共格关系,强化效果较弱。

本文作者前期通过原位反应合成技术成功制备出增强相为面心立方γ-Al2O3晶型,与基体Cu呈共格相界面关系、综合性能优异的Cu-1.12%Al2O3合金[18-21],但是对该复合材料在冷拉抜变形过程中的微观组织演变及性能变化规律尚未涉及。基于此,本文作者以热挤压态Cu-1.12%Al2O3合金为实验对象,详细研究不同变形量对冷拉抜态合金显微组织和性能的影响,并对其作用机制进行了探讨,旨在为复合材料的热加工工艺制定以及组织性能调控提供数据支撑和理论依据。

1 实验

实验原材料采用前期通过原位反应合成技术制备的Cu-1.12%Al2O3合金[18-21],经真空包套挤压成合金棒材(热挤压温度为1193 K,挤压比为21.6,尺寸为d 14 mm)。为消除内应力,挤压棒材预先经(1173 K、1 h)氢气退火,而后进行变形量分别为0%、25%、50%、75%及95%的冷拉抜加工。冷加工后的合金试样的硬度在HDI-1875洛氏硬度计上进行,载荷98 N,加载时间10 s。合金常温下的导电率在QJ36s直流低电阻测试仪上进行测定,测量结果转化为国际退火铜标准(%IACS)。采用MTS-810万能拉伸试验机对合金试样的拉伸性能进行测量,拉伸速度为2 mm/min。冷加工前后合金的显微组织观察在JSM-7001F场发射扫描电子显微镜和JEM-2000FX透射电子显微镜上进行。

2 结果与分析

2.1 硬度及导电率分析

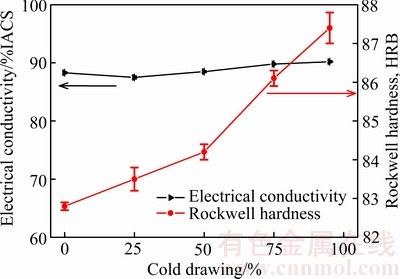

图1所示为热挤压态合金试样其导电率及硬度值随冷拉拔变形量的变化曲线。由图1可知,随着冷拉抜变形量的逐渐增大,合金试样硬度值从原始热挤压态的82.8 HRB增加到95%变形后的87.4 HRB,增幅比较明显。并且当变形量较低时(低于50%),合金的加工硬化速率要低于大变形量加工态,这主要与变形过程中形变胞状组织的形成难易程度有关[21]。只有当变形达到某一程度时,合金内部位错密度增加,交织缠结,变形胞状组织开始形成,加工硬化率才得以明显增大。仔细观察同时发现,合金试样导电率的变化趋势相对硬度来说则显得比较平缓,这主要是因为经过热挤压后的合金,其相对密度已经达到99.2%,基本达到完全致密化,后续的冷拉拔加工对其致密度的影响不大,而材料的导电率是对孔隙、裂纹等缺陷敏感的物理量,对冷拉拔加工相对不敏感[22]。因此,合金的导电率随变形量的增大变化不明显,基本保持在88%~90%IACS之间。

图1 变形量对冷拉抜态Cu-1.12%Al2O3合金硬度和导电率的影响

Fig. 1 Influence of deformation on rockwell hardness and electrical conductivity of cold drawing Cu-1.12%Al2O3 alloy

2.2 拉伸性能分析

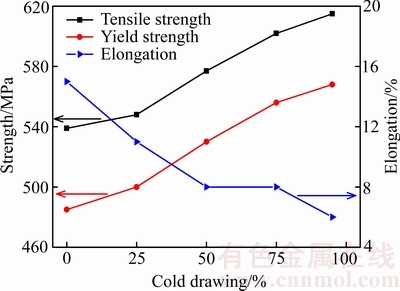

Cu-1.12%Al2O3合金具有良好的冷加工能力,其热挤压棒材可以不需要中间退火而直接经多道次冷拉抜加工至规定尺寸。图2所示为热挤压态合金试样拉伸性能随冷拉抜变形量的变化关系。从图2中可以发现,经冷拉抜变形后,合金试样呈现出明显的加工硬化现象,且随着变形量的不断增大,加工硬化速率逐渐加快。同时可以发现,合金试样的抗拉强度Rm和屈服强度Rp基本呈相对均匀的速率增加,而伸长率则逐渐下降。屈服强度/抗拉强度(屈强比Rp/Rm)是合金材料抗塑性变形能力的重要指标,高的Rp/Rm值表明合金的抗塑性变形能力较强,适宜在高应力环境下使用而不产生变形,因此,对于设计需要在高应力工况下运行的元器件时非常重要[23-24]。通过计算Cu-1.12%Al2O3合金在不同冷加工阶段的屈强比可以得出,该数据维持在90%~93%之间。这也间接说明了Cu-1.12%Al2O3合金具有优异的抗高温软化性能,而不像其他的沉淀强化铜合金(Cu-Cr、Cu-Cr-Zr、Cu-Ni-Si等[25]),在冷加工时也保持较高的屈强比,但经高温退火后会显著下降。

图2 变形量对冷拉抜态Cu-1.12%Al2O3合金拉伸性能的影响

Fig. 2 Influence of deformation on tensile properties of cold drawing Cu-1.12%Al2O3 alloy

2.3 显微组织分析

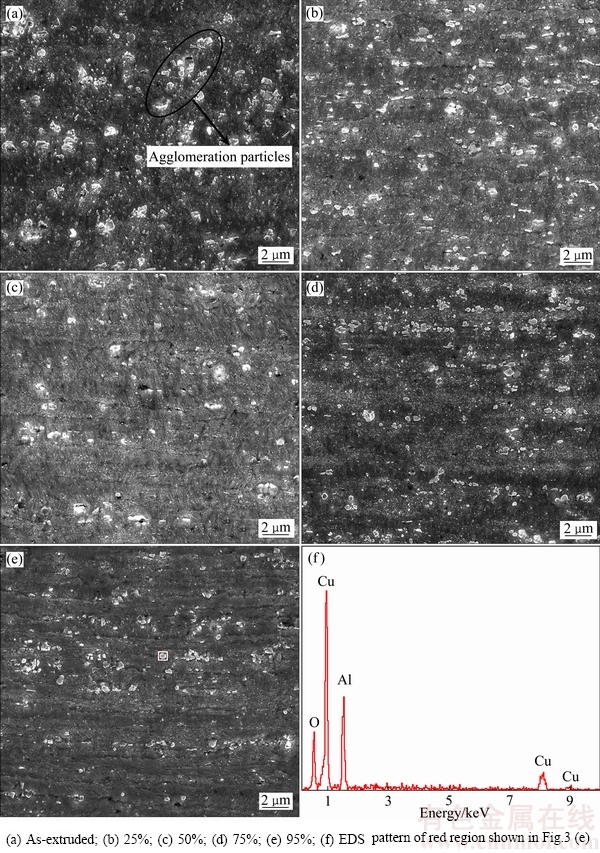

图3所示为不同变形量冷拉抜加工Cu-1.12%Al2O3合金的SEM像。从图3中可以看出,合金经过热挤压和冷拉抜加工后,组织致密,未发现有大的孔洞和显微裂纹等缺陷存在,且合金的致密度在冷拉抜加工后获得了进一步的提升。晶粒内部及晶界之间均匀弥散分布着许多细小的第二相颗粒,对这些亮白色物质进行EDS能谱分析,发现其为原位生成的陶瓷相纳米Al2O3颗粒(见图3(f))。合金粉坯在经过了高温烧结及热挤压后,铜晶粒和弥散相Al2O3晶粒不可避免的发生了轻微的长大和团聚现象(见图3(a)),且这种现象在挤压方向上更为明显,颗粒与颗粒之间的界面也由于弥散相的团聚而变得模糊不清,团聚后的Al2O3颗粒沿变形方向大致呈流线分布。热挤压态合金经冷变形加工后,晶粒变得细小均匀,晶粒与晶粒之间的界面愈发清晰可见,沿着变形方向晶粒被压扁、拉长成纤维状,形成纤维流线组织,且该纤维组织随着变形量的增大逐渐变细,同时变得平直化和宽化,晶粒的长宽比增大。仔细观察还可以发现,界面上呈流线分布的粗大Al2O3颗粒经冷加工后逐渐被破碎、分离,变成细小均匀分布的Al2O3颗粒(见图4),从而有效保证了合金的综合性能。

图3 不同变形量的Cu-1.12%Al2O3合金SEM像

Fig. 3 SEM images of Cu-1.12%Al2O3 alloy under deformation

图4 晶界附近聚集的Al2O3粗颗粒冷变形后被破碎、分离

Fig. 4 Bulk alumina particle gathering near grain boundary crushed and separated after cold deformation

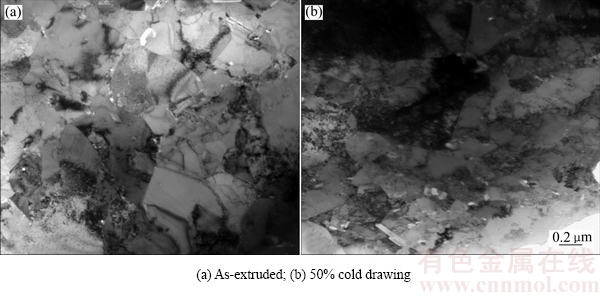

图5~7所示为Cu-1.12%Al2O3合金在不同状态下的TEM像。从图中可以很清楚的看到,热挤压态合金的晶粒细小且比较均匀,平均尺寸约为300 nm,晶界比较平直,部分区域位错密度较高(见图5(a))。在位错的运动路径中,受到高硬度、高熔点、良好热稳定性和化学稳定性的纳米Al2O3颗粒的钉扎,使位错出现缠结现象,形成位错环和位错塞积(见图6)。当热挤压态合金经50%冷拉抜变形后,合金致密度进一步增大,平均晶粒尺寸下降,合金内部随机分布着大量的位错,位错密度较热挤压态合金明显增大,无位错区域较少(见图5(b))。仔细观察还可以发现,在冷加工态合金的内部出现了明显的变形位错胞组织(见图7(a)),该组织是因Al2O3颗粒钉扎位错和阻碍晶界滑移,位错线大量缠结而形成的。位错胞组织沿着变形方向被拉长,胞内异号位错相互抵消,致使胞内位错密度很低。胞尺寸为100~200 nm左右,胞壁清晰可见且较厚,尺寸约为10~20 nm。冷加工引起的变形位错胞组织胞壁还将通过攀移和滑移过程变为低能态的沿滑移面垂直方向排列的位错墙,形成小角度倾侧晶界,并发展成为最初的亚晶晶界,形成亚晶组织,尺寸约为1~2 μm(见图7(b))。因此,Cu-1.12%Al2O3合金的强化机制综合表现为Orowan强化、细晶强化和加工硬化的叠加。

图5 Cu-1.12%Al2O3合金不同状态下的TEM像

Fig. 5 TEM images of Cu-1.12%Al2O3 alloy with different states

图6 热挤压态Cu-1.12%Al2O3合金的TEM像

Fig. 6 TEM images of as-extruded Cu-1.12%Al2O3 alloy

图7 50%冷拉拔加工态Cu-1.12%Al2O3合金的TEM像

Fig. 7 TEM images of Cu-1.12%Al2O3 alloy after 50% cold drawing

3 结论

1) 随冷拉抜变形量的不断增大,Cu-1.12%Al2O3合金的硬度呈逐渐上升趋势,增幅比较明显,但导电率的变化甚微。

2) 冷加工变形使Cu-1.12%Al2O3合金呈现出明显的加工硬化现象,且随着变形量的不断增大,加工硬化速率逐渐加快。

3) 冷加工变形使Cu-1.12%Al2O3合金的致密度和位错密度进一步提升,Al2O3粒子钉扎位错使位错线缠结和位错塞积,并发展成为变形位错胞组织和亚晶。

REFERECES

[1] REN F Z, ZHI A J, ZHANG D W, TIAN B H, VOLINSKY A A, SHEN X N. Preparation of Cu-Al2O3 bulk nano-composites by combining Cu-Al alloy sheets internal oxidation with hot extrusion[J]. Journal of Alloys and Compounds, 2015, 633: 323-328.

[2] 赵郅磊, 李 周, 肖 柱. Cu-3.6%Al2O3铜合金细丝加工过程中组织结构演变规律[J]. 中国有色金属学报, 2017, 27(3): 486-495.

ZHAO Zhi-lei, LI Zhou, XIAO Zhu. Structure evolution of Cu-3.6%Al2O3 alloy fine wire during cold drawing[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 486-495.

[3] 程建奕, 敖学文, 余方新, 谭敦强. Cu-Al合金内氧化工艺参数对性能影响的研究[J]. 材料工程, 2010(7): 29-33.

CHENG Jian-yi, AO Xue-wen, YU Fang-xin, TAN Dun-qiang. Effect of internal oxidation process parameters of Cu-A1 alloy on its properties[J]. Materials Engineering, 2010(7): 29-33.

[4] 陈岁元, 刘义杰, 刘常升, 孙桂芳. 纳米Al2O3颗粒增强新型铜基自润滑复合材料[J]. 复合材料学报, 2009, 26(6): 109-115.

CHEN Sui-yuan, LIU Yi-jie, LIU Chang-sheng, SUN Gui-fang. Nano-Al2O3 particle reinforced Cu-based self-lubrication composites[J]. Acta Materiae Composite Sinica, 2009, 26(6): 109-115.

[5] FATHY A, SHEHATA F, ABDELHAMEED M, ELMAHDY M. Compressive and wear resistance of nanometric alumina reinforced copper matrix composites [J]. Materials and Design, 2012, 36: 100-107.

[6] VISESLAVA R, DUSAN B, MILAN T J. Effects of copper and Al2O3 particles on characteristics of Cu-Al2O3 composites[J]. Materials and Design, 2010, 37: 1962-1970.

[7] 王学亮, 王亚平. Cu-Al2O3复合材料的制备技术及研究现 状[J]. 电工材料, 2014(1): 27-32.

WANG Xue-liang, WANG Ya-ping. Fabrication techniques and research situation of Cu-Al2O3 composites[J]. Electric Material, 2014(1): 27-32.

[8] 李韶林, 宋克兴, 国秀花. SPS法制备Al2O3/Cu复合材料研究[J]. 粉末冶金技术, 2013, 31(3): 43-47.

LI Shao-lin, SONG Ke-xing, GUO Xiu-hua. Study of Al2O3 /Cu composite prepared by SPS[J]. Powder Metallurgy Technology, 2013, 31(3): 43-47.

[9] 丁 飞, 凤 仪, 钱 刚, 王秀娟. 原位合成法制备Cu-Al2O3复合材料及其性能研究[J]. 材料导报, 2014, 28(4): 69-73.

DING Fei, FENG Yi, QIAN Gang, WANG Xiu-juan. Study on in-situ synthesis of Cu-Al2O3 composites and their performance[J]. Materials Review, 2014, 28(4): 69-73.

[10] 刘向兵, 贾成厂, 王富祥, 盖国胜, 陈晓华. 热压与放电等离子体烧结两种工艺制备Al2O3/Cu复合材料[J]. 复合材料学报, 2007, 24(4): 76-81.

LIU Xiang-bing, JIA Cheng-chang, WANG Fu-xiang, GAI Guo-sheng, CHEN Xiao-hua. Al2O3/Cu composite fabricated by hot pressing and spark plasma sintering[J]. Acta Materiae Composite Sinica, 2007, 24(4): 76-81.

[11] 王 松, 谢明, 陈永泰, 张吉明, 王塞北. Al2O3La2O3Y2O3/Cu复合材料的电弧侵蚀特性研究[J]. 有色金属科学与工程, 2014, 5(4): 28-31.

WANG Song, XIE Ming, CHEN Yong-tai, ZHANG Ji-ming, WANG Sai-bei. Arc erosion characteristics of Al2O3La2O3Y2O3/ Cu composite[J]. Nonferrous Metals Science and Engineering, 2014, 5(4): 28-31.

[12] 崔照雯, 李敬仁, 李泽洲, 曾石轩, 颜翃, 蒋立坤, 贾成厂. 粉末冶金法CNTs、Al2O3双增强铜基复合材料性能研究[J]. 机械工程学报, 2013, 49(18): 52-56.

CUI Zhao-wen, LI Jing-ren, LI Ze-zhou, ZENG Shi-xuan, YAN Hong, JIANG Li-kun, JIA Cheng-chang. Performance study of copper matrix composite materials with CNTs, Al2O3 double reinforced by powder metallurgy method[J]. Journal of Mechanical Engineering, 2013, 49(18): 52-56.

[13] RODRIGO H P, AQUILES O S, RODRIGO G E. High- temperature mechanical behavior of Cu-Ti-C, Cu-Al and Cu-Ti-Al-C alloys obtained by reaction milling[J]. Materials Science and Engineering A, 2004, 384: 262-269.

[14] 程建奕, 汪明朴, 李 周, 方善峰, 郭明星, 刘施峰. 纳米Al2O3粒子弥散强化铜合金冷加工及退火行为[J]. 稀有金属材料与工程, 2004, 33(11): 1178-1181.

CHENG Jian-yi, WANG Ming-pu. LI Zhou, FANG Shan-feng, GUO Ming-xin, LIU Shi-feng. Cold drawing and annealing behavior of nano-sized Al2O3 dispersion strengthened copper[J]. Rare Metal Materials and Engineering, 2004, 33(11): 1178-1181.

[15] GUO M X, WANG M P, SHEN K, CAO L F, LEI R S, LI S M. Effect of cold rolling on properties and microstructures of dispersion strengthened copper alloys[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 333-339.

[16] GUO M X, WANG M P, CAO L F, LEI R S. Work softening characterization of alumina dispersion strengthened copper alloys[J]. Materials Characterization, 2007, 58: 928-935.

[17] LI L, LI Z, LEI Q, ZHU X, LIU B, LIU N. Microstructure evolution of alumina dispersion strengthened copper alloy deformed under different conditions[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(12): 3953-3958.

[18] ZHANG X H, LIN C G, CUI S, LI Z D. Microstructure and properties of Al2O3 dispersion strengthened copper fabricated by reactive synthesis process[J]. Rare Metals, 2014, 33(2): 191-195.

[19] ZHANG X H, LI X X. Characteristics of alumina particles in dispersion strengthened copper alloys[J]. International Journal of Minerals, Metallurgy and Materials, 2014, 21(11): 1115-1119.

[20] ZHANG X H, LIN C G, CUI S, LI Z D. Characteristics of nano-alumina particles dispersion strengthened copper fabricated by reaction synthesis[J]. Rare Metals Materials and Engineering, 2016, 45(4): 893-896.

[21] ZHANG X H, LI X X, CHEN H, LI T B, SU W, GUO S D. Investigation on microstructure and properties of Cu-Al2O3 composites fabricated by a novel in-situ reactive synthesis[J]. Materials and Design, 2016, 92: 58-63.

[22] 程建奕. Cu-Al2O3纳米弥散强化铜合金的制备技术及若干基础问题[D]. 长沙: 中南大学, 2004: 79-84.

CHEN Jian-yi. Preparation technology and some basic issue of nano-alumina particles dispersion strengthened copper[D]. Changsha: Central South University, 2004: 79-84.

[23] LI G B, SUN J B, GUO Q M, WANG R. Fabrication of the nanometer Al2O3/Cu composite by internal oxidation[J]. J Mater Process Technol, 2005, 170: 336-340.

[24] SRIVATSAN T S, ANAND S, TROXELL J D. Influence of heat treatment on microstructure and tensile properties of GlidCop dispersion strengthened copper alloy[J]. Materials Letters, 1992, 14(1): 11-16.

[25] MISHNEV R, SHAKHOVA I, BELYAKOV A, KAIBYSHEV R. Deformation microstructure, strengthening mechanisms, and electrical conductivity in a Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2015, 629: 29-40.

Effect of cold deformation on microstructures and properties of Al2O3-dispersion strengthened copper

ZHANG Xue-hui, LI Xiao-xian, LIU Wei-jiang, YANG Kai, ZHU Sheng-jian, JIANG Miao

(School of Materials Science and Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: Cu-1.12%Al2O3 composite was fabricated by in-situ reactive synthesis technology, and its cold deformation behavior was studied by mechanical property measurement, electrical conductivity test and microstructure observation, respectively. The results show that the rockwell hardness and strength increase with increasing the cold deformation of as-extruded Cu-1.12%Al2O3 alloy, and the work hardening phenomenon is obvious, but the change of electrical conductivity is very small. The density and dislocation density of Cu-1.12%Al2O3 alloy further increase after cold deformation. Since the tiny alumina particles can pin dislocation and hinder the grain boundary motion, the dislocation tangle and dislocation pileup generate, and then develop into the dislocation cell or subgrain.

Key words: Cu-1.12%Al2O3 alloy; cold drawing behavior; mechanical property; microstructure

Foundation item: Projects(20161BAB206136, 20161BAB216121, 20151BAB216015, 20161BAB206137, GJJ150638) supported by the National Natural Science Foundation of Jiangxi Province, China; Project(51504104) supported by the National Natural Science Foundation of China

Received date: 2017-02-14; Accepted date: 2017-06-15

Corresponding author: ZHANG Xue-hui; Tel: +86-797-8312422; E-mail: xhzhang@jxust.edu.cn

(编辑 何学锋)

基金项目:江西省自然科学基金资助项目(20161BAB206136,20161BAB216121,20151BAB216015,20161BAB206137);国家自然科学基金资助项目(51504104);江西省教育厅科技计划资助项目(GJJ150638)

收稿日期:2017-02-14;修订日期:2017-06-15

通信作者:张雪辉,副教授,博士;电话:0797-8312422;E-mail: xhzhang@jxust.edu.cn

摘 要:采用原位反应合成技术制备了Cu-1.12%Al2O3合金(质量分数),通过力学性能、导电率测试及显微组织观察系统研究该合金的冷变形行为。结果表明:对热挤压态合金进行不同变形量的冷拉抜加工处理后,合金的硬度和强度均随变形量的增大而增加,合金加工硬化现象明显,但导电率的变化甚微;冷加工使合金的致密度和位错密度获得进一步的提升,同时由于Al2O3粒子的钉扎位错和阻碍晶界滑移作用,出现位错线缠结和位错塞积,并发展成为变形位错胞组织和亚晶组织。

[2] 赵郅磊, 李 周, 肖 柱. Cu-3.6%Al2O3铜合金细丝加工过程中组织结构演变规律[J]. 中国有色金属学报, 2017, 27(3): 486-495.

[3] 程建奕, 敖学文, 余方新, 谭敦强. Cu-Al合金内氧化工艺参数对性能影响的研究[J]. 材料工程, 2010(7): 29-33.

[4] 陈岁元, 刘义杰, 刘常升, 孙桂芳. 纳米Al2O3颗粒增强新型铜基自润滑复合材料[J]. 复合材料学报, 2009, 26(6): 109-115.

[7] 王学亮, 王亚平. Cu-Al2O3复合材料的制备技术及研究现 状[J]. 电工材料, 2014(1): 27-32.

[8] 李韶林, 宋克兴, 国秀花. SPS法制备Al2O3/Cu复合材料研究[J]. 粉末冶金技术, 2013, 31(3): 43-47.

[9] 丁 飞, 凤 仪, 钱 刚, 王秀娟. 原位合成法制备Cu-Al2O3复合材料及其性能研究[J]. 材料导报, 2014, 28(4): 69-73.

[10] 刘向兵, 贾成厂, 王富祥, 盖国胜, 陈晓华. 热压与放电等离子体烧结两种工艺制备Al2O3/Cu复合材料[J]. 复合材料学报, 2007, 24(4): 76-81.

[11] 王 松, 谢明, 陈永泰, 张吉明, 王塞北. Al2O3La2O3Y2O3/Cu复合材料的电弧侵蚀特性研究[J]. 有色金属科学与工程, 2014, 5(4): 28-31.

[12] 崔照雯, 李敬仁, 李泽洲, 曾石轩, 颜翃, 蒋立坤, 贾成厂. 粉末冶金法CNTs、Al2O3双增强铜基复合材料性能研究[J]. 机械工程学报, 2013, 49(18): 52-56.

[14] 程建奕, 汪明朴, 李 周, 方善峰, 郭明星, 刘施峰. 纳米Al2O3粒子弥散强化铜合金冷加工及退火行为[J]. 稀有金属材料与工程, 2004, 33(11): 1178-1181.

[22] 程建奕. Cu-Al2O3纳米弥散强化铜合金的制备技术及若干基础问题[D]. 长沙: 中南大学, 2004: 79-84.