汽车用5182铝合金的温拉深成形性能

王孟君1, 2,周威 1,任杰1,李彩文1,黄电源1,李光耀2

(1. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙 410083;

2. 湖南大学 汽车车身先进设计制造国家重点实验室,湖南 长沙,410082)

摘 要:

摘 要:在变形温度为303~573K,拉深速度为0.1~1.5 mm/s,压边力为2.0~3.5 N/mm2的条件下,采用差温拉深试验,对汽车用5182铝合金板拉深成形性能进行研究。研究结果表明:5182铝合金的极限拉深比LDR并不随着变形温度的升高而单调增加,在523 K时达到最大值2.5,之后随着温度的继续升高,极限拉深比反而下降;当压边力小于3.0 N/mm2时,随着压边力的增加,LDR逐渐增大,但当压边力超过3.0 N/mm2时,LDR迅速减小;5182铝合金板低速拉深时的成形性能(小于0.5 mm/s)比快速拉深的成形性能好。

关键词:

中图分类号:TG146.21 文献标志码:A 文章编号:1672-7207(2010)03-0936-04

Forming properties of 5182 aluminum alloy for automotive body sheet during warm deep drawing processes

WANG Meng-jun1, 2, ZHOU Wei1, REN Jie1, LI Cai-wen1, HUANG Dian-yuan1, LI Guang-yao2

(1. Key Laboratory of Nonferrous Metal Materials Science and Engineering of Ministry of Education,

Central South University, Changsha 410083, China;

2. State Key Laboratory of Advanced Design and Manufacture for Vehicle Body,

Hunan University, Changsha 410082, China)

Abstract: The forming properties of 5182 aluminium alloy sheet for automotive body were studied by warm deep drawing experiment with the drawing speed ranging from 0.1 mm/s to 1.5 mm/s, forming temperature from 303 K to 573 K, blank holder force from 2.0 N/mm2 to 3.5 N/mm2. The results show that the limiting drawing ratio (LDR) does not increase with the forming temperature monotonously and LDR decreases while the forming temperature increases after it gets to the maximum value 2.5 at 523 K. LDR increases with the increase of blank holder force when the blank holder force is below 3.0 N/mm2 and the LDR value decreases rapidly when the blank holder force is higher than 3.0 N/mm2. The forming properties of 5182 aluminium alloy sheet are better when the drawing speed is lower than 0.5 mm/s.

Key words: 5182 aluminum alloy; warm deep drawing; forming property; limiting drawing ratio

随着汽车产业的迅速发展,环境污染和能源短缺两大社会问题日益突出,各国政府均要求汽车制造厂商降低其产品的能耗,提高燃料的经济性,减少污 染[1-2]。当前,使用轻量化材料无疑是改善汽车性能的最佳途径。在众多的汽车轻量化材料中,铝合金由于其密度低、强度高及良好的回收再生性等一系列的优点而受到关注[3-4]。当前,国内外对5182铝合金板在汽车车身覆盖件中的应用研究仍处于起步阶段[5-6]。汽车用铝合金板的成形性能与传统的汽车用钢板相比有很大的差别,主要表现在铝合金板在室温条件下其成形性能较差,总伸长率小,且弹性系数仅为钢板的1/3,成形时易于产生金属流动不均,从而引发裂纹和起皱等缺陷[7]。有关研究表明[8-9]:5182铝合金板在温变形条件下其塑性会有较大提高,这就为工业化生产5000系铝合金车身覆盖件内板创造了条件。为此,本文作者采用差温拉深试验,研究不同变形条件下5182铝合金板的力学特性及成形性能,确定获得最佳成形性能的工艺条件,以期为开发汽车用5000系铝合金板的成形技术提供理论参考。

1 试验材料和方法

1.1 试验材料

本试验采用厚度为1.4 mm的5182铝合金冷轧板,合金化学成分(质量分数)见表1。板材的生产工艺流程为:熔炼→铸造→锯切→铣面→均匀化→热轧→冷轧(板厚1.4 mm)。

表1 5182铝合金化学成分

Table 1 Chemical compositions of 5182 aluminium alloy %

1.2 试验方法

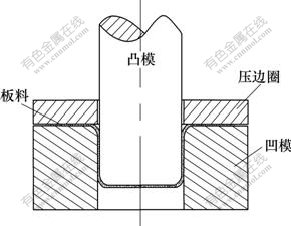

研究表明[10]:温成形时,冲头温度低于板料及凹模温度,进行差温成形,有利于提高成形的变形程度。差温拉深成形实验以Swift杯形件拉深试验[11]为基础。图1所示为拉深试验装置简图。该试验是一种以求极限拉深比LDR作为评定板材拉深性能的试验方法。试验时,采用不同直径的平板毛坯,测算出不发生破裂所能拉深成杯形件的最大毛坯直径Dmax与凸模直径dp之比,此比值称为极限拉深比。

![]()

在实验过程中,将板料涂抹好润滑剂后放置于凹模之上,并用压边圈压紧;板料的加热温度分别为303,373,448,523和573 K;以0.1,0.5和1.5 mm/s 3种不同的拉深速度进行拉深试验[9],并在试验过程中保持拉深速度不变,实验过程的拉深载荷-冲头行程曲线由实验机的绘图机构自动绘制。

图1 拉深试验装置示意图

Fig.1 Schematic diagram of drawing experiment equipment

2.1 温度对成形性能的影响

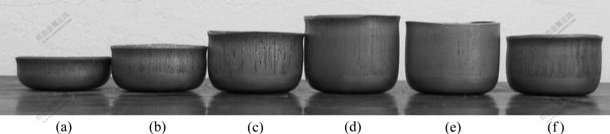

图2和图3所示分别为在拉深速率0.1 mm/s、压边力为3.0 N/mm2的条件下,加热温度为303,373,448,523和573 K时的极限拉深比(LDR)曲线及其对应的拉深杯形件。从图2和图3可知:当加热温度为303~523 K时,随着温度升高,LDR增大,在523 K时LDR达到了最大值,为2.5;随着温度的继续升高,LDR开始下降,当温度为543 K时,LDR为2.45;温度为573 K时LDR则下降到2.3。这说明在不同温度下,5182铝合金板的拉深特征为:极限拉深比并非随着成形温度的上升而单调增大;随着温度的升高,塑性变形能力增强,拉深性能明显改善,但合金的抗拉强度却逐渐降低。若板料的温度过高(超过523 K时),由于凹模圆角处的危险截面抗拉强度降低,而且降低程度超过

图2 5182铝合金极限拉深比随着变形温度的变化

Fig.2 Variations of limiting drawing ratio of 5182 aluminium alloy with forming temperatures

变形温度/K: (a) 303; (b) 373; (c) 448; (d) 523; (e) 543; (f) 573

图3 不同变形温度下5182铝合金拉深杯形件

Fig.3 Drawing cup of 5182 aluminium alloy at various forming temperatures

2.2 压边力对成形性能的影响

压边力是板料成形中的重要工艺参数。若压边力过小,则无法有效地控制材料的流动,板料容易起 皱;若压边力过大,虽可避免起皱,但会导致拉裂趋势明显增加,同时模具和材料表面受损的可能性也相应增大,这会降低模具的寿命和拉深成形制品的质 量[14-16]。本实验中采用恒定压边力的设置方式(将压边力设置为抑制板料起皱的临界值并在拉深过程中保持不变)对5182铝合金板材进行拉深。实验中,压边力分别设定为2.0,2.3,2.5,2.8,3.0,3.3和3.5 N/mm2,成形温度为523 K,拉深速度为0.1 mm/s。

5182铝合金的极限拉伸比LDR随着压边力的变化曲线如图4所示。由图4可以看出:随着压边力的增大,5182铝合金的极限拉深比逐渐增大,这主要是由于压边力的增大可以加大拉深件的减薄率;当压边力达到3.0 N/mm2左右时,材料的极限拉深比最大;继续增加压边力,则极限拉深比下降。这是由于压边力过大造成5182铝合金拉深件危险断面发生过度减薄,等效应力超过抗拉强度而发生拉裂缺陷。

图4 523 K时5182铝合金极限拉深比随着

压边力的变化

Fig.4 Variations of limiting drawing ratio of 5182 aluminium alloy on different blank holder forces at 523 K

2.3 拉深速度对成形性能的影响

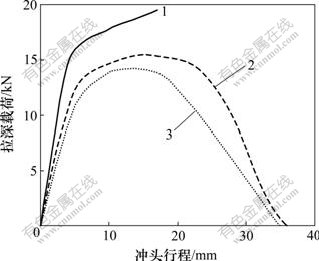

为了确定较佳的拉深速度,在板料温度为523 K、压边力为3.0 N/mm2的条件下,分别采用3种拉深速度0.1,0.5和1.5 mm/s对5182铝合金板料进行拉深试验。不同拉深速度下的拉深载荷-冲头行程曲线如图5所示。从图5可以看出:拉深速度从0.1 mm/s增加到0.5 mm/s时,拉深载荷略有增大;当拉深速度增至1.5 mm/s时,拉深载荷迅速增大,导致板料拉深很浅时就在凸模圆角处被拉断,如图6所示。这是因为拉深速度增加使凸缘的增厚加快,拉深过程继续进行所需的拉深力迅速增大,直至超出凸模圆角处金属材料的承受能力,造成该处金属过早发生局部流动而失稳断裂;另外,在加热条件下拉深成形时,增加变形速度将使5182铝合金的动态回复和动态再结晶受到限制[17],应变硬化得不到充分松弛,使得合金塑性明显下降,拉深变形抗力显著增加,造成材料在凸模圆角处断裂。

拉深速度/(mm?s-1):1—1.5; 2—0.5; 3—0.1

图5 523 K时不同拉深速度下的拉深载荷-冲头行程曲线

Fig.5 Punch stroke-punch load curves at different drawing speeds at 523 K

图6 温度为523 K、拉深速度为1.5 mm/s时的断裂形貌

Fig.6 Fracture morphology at drawing speed of 1.5 mm/s and at 523 K

3 结论

(1) 5182铝合金的极限拉深比LDR并不会随着板料温度的升高而单调增加,在523 K时达到最大值2.5,之后随着温度的继续升高,极限拉深比反而下降。

(2) 当压边力由2.0 N/mm2增加到3.0 N/mm2时,5182铝合金的极限拉深比LDR逐渐增大,并在压边力为3.0 N/mm2时达到最大值2.5;但当压边力超过3.0 N/mm2时,LDR迅速减小。

(3) 当拉深速度低于0.5 mm/s时,可以进行良好的拉深,获得较高的LDR;当拉深速度达到1.5 mm/s,板料在凸模圆角处被拉断。

参考文献:

[1] Miller W S, Zhuang L, Bottema J. Recent development in aluminium alloys for the automotive industry[J]. Materials Science and Engineering A, 2000, 280(1): 37-49.

[2] 王孟君, 黄电源, 姜海涛. 汽车用铝合金的研究进展[J]. 金属热处理, 2006, 31(9): 34-38.

WANG Meng-jun, HUANG Dian-yuan, JIANG Hai-tao. Research progress of aluminium alloys for the automotive industry[J]. Heat Treatment of Metals, 2006, 31(9): 34-38.

[3] Nargess S. Lightening the material[J]. Automotive Engineering, 2003, 31(9): 70.

[4] 肖永清. 铝合金是现代汽车轻量化的首选材料[J]. 铝加工, 2005(5): 36-39.

XIAO Yong-qing. Aluminum alloy-the optimum material for modern light weight automobile[J]. Aluminium Fabrication, 2005(5): 36-39.

[5] Lord J. A materials odyssey[J]. Automotive Industries, 2001, 28(10): 83-89.

[6] 鲁晓楠, 郑德荣. 现代汽车车身冲压成形新技术[J]. 锻压装备与制造技术, 2008(4): 11-13.

LU Xiao-nan, ZHENG De-rong. New stamping techniques for auto body[J]. China Metal Forming Equipment & Manufacturing Technology, 2008(4): 11-13.

[7] 张宝红, 张治民. 温成形杯形件组织性能研究[J]. 材料科学与工艺, 2007, 15(1): 118-120.

ZHANG Bao-hong, ZHANG Zhi-min. Microstructure and property of warm formed cup[J]. Materials Science and Technology, 2007, 15(1): 118-120.

[8] Palumbo G, Tricarico L. Numerical and experimental investigations on the warm deep drawing process of circular aluminum alloy specimens[J]. Journal of Materials Processing Technology, 2007, 184(1/3): 115-123.

[9] 王孟君, 任杰. 汽车用5182铝合金板材的温拉伸流变行为[J]. 中国有色金属学报, 2008, 18(11): 1958-1963.

WANG Meng-jun, REN Jie. Flow behavior of 5182 aluminum alloy for automotive body sheet during warn tensile deformation[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1958-1963.

[10] 李秀华, 张凌云. LY6板材成形性能的试验形究[J]. 沈阳航空工业学院学报, 2002, 19(3): 15-16.

LI Xiu-hua, ZHANG Ling-yun. Experimental investigation of metal sheet forming properties[J]. Journal of Shenyang Institute of Aeronautical Engineering, 2002, 19(3): 15-16.

[11] Naka T, Yoshida F. Deep drawability of type 5083 aluminium- magnesium alloy sheet under various conditions of temperature and forming speed[J]. Journal of Materials Processing Technology, 1999, 89/90: 19-23.

[12] Keigler M, Herbert B. Enhancing the formability of aluminium components via temperature controlled hydroforming[J]. Journal of Materials Processing Technology, 2005, 167(2/3): 363-370.

[13] Naka T, Torikai G. The effects of temperature and forming speed on the forming limit diagram for type 5083 aluminum- magnesium alloy sheet[J]. Journal of Materials Processing Technology, 2001, 113(1/3): 648-653.

[14] Demirci H I, Esner C, Yasar M. Effect of the blank holder force on drawing of aluminum alloy square cup: Theoretical and experimental investigation[J]. Journal of Materials Processing Technology, 2008, 206(1/3): 152-160.

[15] 孙成智, 罗思东. 变压边力对铝合金板冲压成形的影响研究[J]. 塑性工程学报, 2005, 12(3): 41-45.

SUN Cheng-zhi, LUO Si-dong. Mechanism investigation of variable blank-holder forces improving the formability of aluminum alloy sheets during sheet metal forming[J]. Journal of Plasticity Engineering, 2005, 12(3): 41-45.

[16] 刘念聪, 方方. 板料拉深成形中的压边力控制技术分析[J]. 煤矿机械, 2008, 29(10): 87-89.

LIU Nian-cong, FANG Fang. Analysis on blank holding force control technology in drawing of sheet metal[J]. Coal Mine Machinery, 2008, 29(10): 87-89.

[17] 林均品, 程荆卫. Al-2Mg合金的动态再结晶[J]. 中国有色金属学报, 1999, 9(3): 510-514.

LIN Jun-pin, CHENG Jing-wei. Dynamic recrystallization during hot torsion of Al-2Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(3): 510-514.

收稿日期:2009-05-06;修回日期:2009-07-04

基金项目:汽车车身先进设计制造国家重点实验室开放基金资助项目(30815009);中南大学2009年度米塔尔学生创新项目资助(09MX22)

通信作者:王孟君(1965-),男,湖南长沙人,博士,教授,从事有色金属材料成形及模具研究;电话:0731-88836408;E-mail: wmj1965@yahoo.com.cn

(编辑 陈爱华)