文章编号:1004-0609(2014)02-0310-07

多向锻造ZK60镁合金组织和性能的均匀性

吴远志1, 3,严红革2,朱素琴2,陈吉华2,刘先兰1,刘安民1, 3

(1. 湖南工学院 机械工程学院,衡阳 421002;

2. 湖南大学 材料科学与工程学院,长沙410082;

3. 湖南工学院 先进制造技术研究所,衡阳 421002)

摘 要:

采用空气锤对ZK60镁合金进行多向锻造变形,研究锻坯的组织演变以及组织和性能均匀性。结果表明,锻锤与锻坯之间摩擦力的作用造成不均匀变形,使锻坯芯部的实际变形量大于边部的。累积应变∑Δε=3.3时,锻坯芯部组织为蜂窝状粗大再结晶组织和岛状细小再结晶组织,而边部组织则由蜂窝状粗大再结晶组织和呈岛状分布的孪晶组成;其抗拉强度从边部到芯部逐渐降低,而伸长率则由边部向芯部逐渐升高。锻坯力学性能存在一定的各向异性,但锻坯各方向抗拉强度在310.6~323.9 MPa之间,伸长率在21.9%~29.7%之间,表明该工艺可以有效地避免强烈的各向异性,是制备高性能变形镁合金的理想工艺。

关键词:

中图分类号:TG146.2 文献标志码:A

Homogeneity of microstructure and mechanical properties of ZK60 magnesium alloys fabricated by high strain rate triaxial-forging

WU Yuan-zhi1, 3, YAN Hong-ge2, ZHU Su-qin2, CHEN Ji-hua2, LIU Xian-lan1, LIU An-min1, 3

(1. Department of Mechanical Engineering, Hunan Institute of Technology, Hengyang 421002, China;

2. School of Materials Science and Engineering, Hunan University, Changsha 410082, China;

3. Institute of Advance Manufacturing Technology, Hunan Institute of Technology, Hengyang 421002, China)

Abstract: Triaxial-forging of ZK60 magnesium alloy was conducted on air hammer, and the microstructure evolution and the homogeneity of microstructures and properties were investigated. The result show that inhomogeneous deformation is detected in the forged specimen due to the friction between the hammer and specimen, and the actual deformation at the central part of the specimen is extensively larger than that at other part. A mixed structure of honeycomb-like coarse dynamic recrystallization (DRX) grains and island-like ultrafine DRX grains are obtained at the central part of the specimen at accumulated strain ∑Δε of 3.3, while the structure at the edge part of the specimen consists of honeycomb-like coarse DRX grains and island-like twins. The ultimate tensile strength (UTS) decreases while the ductility increases from the edge part to centre part of the specimen at ∑Δε of 3.3. Mechanical anisotropy is also detected in the forged specimen at ∑Δε of 3.3. However, the UTS and elongations at different directions range in 310.6-323.9 MPa and 21.9%-29.7%, respectively, which indicates that extensive anisotropy can be avoided by high strain rate triaxial forging technique. High strain rate triaxial forging is therefore identified as a potential technique for producing wrought magnesium with excellent mechanical properties.

Key words: ZK60 magnesium alloy; triaxial-forging; microstructure; mechanical property

镁合金是最轻的金属结构材料,具有高比强度、高比刚度、良好的减振能力、优良的导热性和导电性、良好的尺寸稳定性、电磁屏蔽性和易于回收等特点[1]。随着能源和环境问题的日益突出,镁合金作为新型工程材料迅速崛起,在航空航天、交通运输和电子通讯等领域具有广阔的应用前景[2]。但与钢铁和铝合金等常用的结构材料相比,镁合金强度较低,且塑性成形能力较差,难以满足更高服役条件下的性能需求,极大地限制了镁合金的广泛应用,因此,高性能镁合金的制备已经成为镁合金研究领域的焦点[3-4]。

近年来大塑性变形方法(SPD)作为制备高性能镁合金的有效途径一直广受关注,其代表性的方法包括等径角挤压(ECAE)[5]、累积叠轧(ARB)[6]、往复挤压(CEC)[7]、多向锻造(MF)[8] 和大应变轧制(SR)[9]等。其中多向锻造工艺由于操作简单、成本低廉并且可通过现有的生产装备制备大尺寸材料而得到了较快的发展,该工艺已成功地应用于AZ21[10]、AZ31[11-12]、AZ61[13-14]、AZ80[15]、ZK21[16]和ZK60[17]等合金。但到目前为止,大部分镁合金多向锻造的研究所关注的是其显微组织和力学性能演变以及其晶粒细化机理等,而对锻坯的组织和力学性能均匀性的研究还鲜见报道[18]。由于锻坯的组织和力学性能均匀性对其后续成形具有重要的影响,研究锻坯的组织和力学性能均匀性具有重要实用价值。在此,本文作者以高应变速率多向锻造ZK60合金为研究对象,研究了锻坯不同部位的显微组织和力学性能,并对锻坯不同方向的力学性能进行了分析。

1 实验

实验用材料为半连续铸造ZK60镁合金,名义成分为Mg-5.5Zn-0.45Mn(质量分数,%)。样品经330 ℃固溶处理30 h后水淬,其平均晶粒尺寸约为100 μm。将固溶处理后的锭坯加工成尺寸为80 mm×70 mm×70 mm的锻坯,并除去尖锐的棱角,避免由于应力集中引起的开裂。高应变速率锻造实验在C41-750空气锤上进行,空气锤的锻打次数为105 次/min,锻打速度约为9 m/s。锻造前将样品置于300 ℃的电阻炉中保温10 min,所有试样均采用一次加热成形,即道次间不进行加热。多向锻造时锻造方向按样品长宽高的方向依次循环变化,每锻一个方向计作一道次,每道次变形量为20%,即道次应变Δε=0.22。锻造完成后对试样进行水淬以保留高温变形组织,锻坯表面良好没有明显裂纹。取垂直于最终锻造方向的平面进行组织观察,按图1(a)所示方法进行取样以研究锻坯各部位的组织演变及组织均匀性。对累积应变∑Δε=3.3的锻坯(15道次)进行力学性能均匀性分析,取样方式如图1(b)和(c)所示,片状拉伸试样的标距尺寸为10 mm×3 mm×2.5 mm;并将锻坯各截面分别标记为A面(垂直于取样前锻造方向的平面)、B面(垂直于下一锻造方向的平面)和C面;室温拉伸在WDW-E200万能试验机上进行,拉伸速度为0.5 mm/min。

2 结果与分析

2.1 合金的显微组织

图2所示为ZK60合金芯部组织演变(M3)。累积应变∑Δε=0.66时,初始晶界附近形成了蜂窝状再结晶组织,其平均晶粒尺寸约为10 μm,初始晶粒内有大量的孪晶,这些孪晶被蜂窝状再结晶组织分割呈岛状分布,如图2(a)所示。累积应变增加到∑Δε=1.32时,蜂窝状粗大再结晶组织基本维持不变,初始晶粒内的孪晶密度明显提高,如图2(b)所示。继续增大累积应变,累积应变∑Δε=1.98时,初始晶界附近的粗大再结晶组织继续维持不变,但孪晶区域的形貌则发生了较大变化,如图2(c)所示,根据文献[17]中所述,此时孪晶区域已经开始形成细小的孪生再结晶晶粒。进一步增大累积应变到∑Δε=2.64和3.3时,合金组织与累积应变∑Δε=1.98时基本相似,由蜂窝状粗大再结晶组织和岛状的细小再结晶组织构成,如图2(d)~(e)所示。

图1 锻坯取样示意图

Fig. 1 Schematic diagrams of specimens extracted from forged alloys

图2 ZK60锻坯芯部显微组织演变(M3)

Fig. 2 Microstructures for core of forged alloy (M3) at different accumulated strains

图3所示为ZK60合金边部组织演变(M1)。累积应变∑Δε=0.66时,初始晶粒内出现少量的孪晶,同时在初始晶界上也有少量的再结晶晶粒,如图3(a)所示。累积应变增加到∑Δε=1.32时,初始晶界上的再结晶程度明显增加,并形成了连续的蜂窝状粗大再结晶组织,其晶粒尺寸约为10 μm,同时初始晶粒内的孪晶密度也有较大幅度的提高,如图3(b)所示。继续增大累积应变,累积应变∑Δε=1.98时,蜂窝状的再结晶组织基本保持不变,初始晶粒内的孪晶密度进一步提高,如图3(c)所示。进一步增大变形量,累积应变初∑Δε=2.64和3.3时,蜂窝状再结晶组织继续维持不变,初始晶粒内的孪晶密度有所升高,但孪晶仍然清晰可见,如图3(d)和(e)所示。

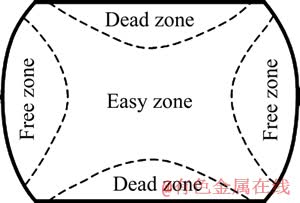

对比图2和图3中合金芯部和边部组织演变,并结合文献[17]中ZK60高应变速率多向锻造组织演变规律可以发现,锻坯边部的组织演变落后于芯部的。单向锻造成形时锻锤与锻坯之间摩擦力的作用会引起锻坯不均匀变形,根据摩擦作用的不同可将锻坯划分为如图4[19]所示的3个变形区。多向锻造可视为3个不同方向单向锻造的叠加,因此,在多向锻造过程中锻坯芯部始终位于易变形区,而锻坯边部则处于难变形区或自由变形区。由于易变形区的金属流动比自由变形区和难变形区更为容易,即在相同的变形量下易变形区金属的实际变形量大于自由变形区和难变形区的,因此,锻坯边部的组织演变落后于芯部的。

图3 ZK60锻坯边部显微组织演变(M1)

Fig. 3 Microstructures for edge of forged alloy (M1) at different accumulated strains

图4 单向锻造工件变形区划分示意图[19]

Fig. 4 Schematic diagram of different deformation zones in uniaxial forged specimen[19]

图5所示为累积应变∑Δε=3.3时ZK60合金锻坯不同部位的显微组织。从图中可以看出,由于摩擦引起的不均匀变形,锻坯不同部位的组织存在一定的差异。其中芯部为蜂窝状粗大再结晶组织和岛状细小再结晶组织,如图5(c)所示;边部(M1和M5)则由蜂窝状粗大再结晶组织和呈岛状分布的孪晶组成,如图5(a)和(e)所示;而介于边部和芯部之间(M2和M4)则由蜂窝状粗大再结晶组织和不完全再结晶组织组成,如图5(b)和(d)所示。

2.2 合金的力学性能

图5 累积应变∑Δε=3.3时ZK60合金不同部位的显微组织

Fig. 5 Microstructures for forged alloy in different positions at ∑Δε of 3.3

图6所示为未变形合金及累积应变∑Δε=3.3时锻坯不同部位的室温拉伸曲线,表1给出了其室温力学性能,包括屈服强度σs、抗拉强度σb和伸长率δ。从图6和表1可以看出,高应变速率多向锻造变形可以大幅提高合金力学性能,锻坯力学性能具有以下特点:1) 锻坯边部和芯部的抗拉强度差别不大,但从边部到芯部有下降的趋势,边部为326 MPa,芯部则为313 MPa;2) 锻坯的伸长率由边部向芯部逐渐增大,合金边部伸长率为20.7%,芯部则增加到27.6%。结合文献[17]所述ZK60锻坯组织与力学性能对应关系和图5中显微组织可知,合金边部和芯部的力学性能的不均匀性是由它们的组织差异造成的。锻坯边部组织由蜂窝状再结晶组织和岛状的孪晶组织构成,由于孪生诱发动态再结晶还未启动,此时孪晶上仍有较多的位错塞积,因此边部强度较高。合金芯部组织由蜂窝状粗大再结晶组织和岛状细小再结晶组织构成,由于孪生诱发动态再结晶的发生,导致位错密度下降,从而使锻坯芯部强度低于边部的;此外,动态再结晶使晶粒尺寸大幅降低,晶界协调变形能力增强,从而使锻坯芯部伸长率高于边部的。

图7所示为累积应变∑Δε=3.3时锻坯不同方向的室温拉伸曲线,表2给出了其室温力学性能。从图7和表2可以看出,两种合金锻坯不同方向上的力学性能特点如下:1) 锻坯各截面上的抗拉强度沿B面、C面、A面呈增大的趋势,其中B面的抗拉强度为310~314 MPa,C面的抗拉强度增加到314~320 MPa,A面的抗拉强度则增加到317~323 MPa;2) 合金各方向的伸长率均达到20%以上,但沿B面、C面、A面呈减小的趋势,其中B面的伸长率为25.4%~32.2%,C面的伸长率为21.9%~29.7%,A面的伸长率则降低至21.9%~26.3%,其中3组平面的最高伸长率均出现在与锻坯的棱边成45°方向。由此可见,锻坯力学性能存在一定的各向异性,但锻坯各方向抗拉强度在310.6~323.9 MPa之间,而伸长率在21.9~29.7%之间。与其他常用的加工方法如挤压和轧制所生产的产品相比[20-21],高应变速率多向锻造生产的产品各向异性较小,表明该工艺可以有效地避免强烈的各向异性,是制备高性能变形镁合金的理想工艺。

图6 未变形合金及累积应变∑Δε=3.3时锻坯不同位置处的室温拉伸曲线

Fig. 6 Tensile curves of undeformed and forged alloy in different positions at ∑Δε of 3.3 and room temperature

表1 未变形合金及累积应变∑Δε=3.3时锻坯不同位置处的室温力学性能

Table 1 Mechanical properties of undeformed and forged alloy in different positions at ∑Δε of 3.3 and room temperature

图7 累积应变∑Δε=3.3时ZK60锻坯不同方向的室温拉伸曲线

Fig. 7 Tensile curves of forged alloy along different directions at ∑Δε of 3.3 and room temperature

表2 累积应变∑Δε=3.3时ZK60锻坯不同方向的室温力学性能

Table 2 Mechanical properties of forged alloy in different directions at ∑Δε of 3.3 and room temperature

3 结论

1) 高应变速率多向锻造变形时,摩擦力的作用造成不均匀变形,锻坯芯部的实际变形量大于边部的。

2) 累积应变∑Δε=3.3时,锻坯芯部为蜂窝状粗大再结晶组织和岛状细小再结晶组织,而边部则由蜂窝状粗大再结晶组织和呈岛状分布的孪晶组成。

3) 累积应变∑Δε=3.3时,锻坯抗拉强度从边部到芯部逐渐降低,其伸长率由边部向芯部逐渐升高。

4) 累积应变∑Δε=3.3时,锻坯力学性能存在一定的各向异性,但锻坯各方向抗拉强度在310.6~323.9 MPa之间,而伸长率在21.9%~29.7%之间,表明该工艺可以有效地避免强烈的各向异性。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium: Properties-applications-potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] AGHION E, BRONFIN B, ELIEZER D. The role of magnesium industry in protecting environment[J]. Journal of Materials Processing Technology, 2001, 117(3): 381-385.

[3] AVEDESIAN M M, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys[M]. Materials Park: ASM International, 1999: 7-8.

[4] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 2-10.

CHEN Zhen-hua. Wrought magnesium alloy[M]. Beijing: Chemical Industry Press, 2005: 2-10.

[5] KIM H K, KIM W J. Microstructural instability and strength of an AZ31 Mg alloy after sever plastic deformation[J]. Materials Science and Engineering A, 2004, 385(1/2): 300-308.

[6] ZHAN M Y, LI Y Y, CHEN W P. Improving mechanical properties of Mg-Al-Zn alloy sheet through accumulative roll-bonding[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 309-314.

[7] CHEN Y J, WANG Q D, ROVEN H J, LIU M P, KARLSEN M, YU Y D, HJELEN J. Network-shaped fine-grained microstructure and high ductility of magnesium alloy fabricated by cyclic extrusion compression[J]. Scripta Materialia, 2008, 58(4): 311-314.

[8] MIURA H, MARUOKA T, YANG X Y, JONAS J J. Microstructure and mechanical properties of multi-directionally forged Mg-Al-Zn alloy[J]. Scripta Materialia, 2012, 66(1): 49-51.

[9] PEREZ-PRADO M T, DEL VALLE J A, RUANO O A. Achieving high strength in commercial Mg cast alloys through large strain rolling[J]. Materials Letters, 2005, 59(26): 3299-3303.

[10] 杨续跃, 孙 欢, 吴新星, 马继军, 秦 佳, 霍庆欢. AZ21镁合金降温多向压缩过程中的组织和微观织构演化[J]. 金属学报, 2012, 48(2): 129-134.

YANG Xue-yue, SUN Huan, WU Xing-xing, MA Ji-jun, QIN Jia, HUO Qing-huan. Evolutions of microstructure and microtexture in AZ21 Mg alloy during multi-directional forging under decreasing temperature conditions[J]. Acta Metallurgica Sinica, 2012, 48(7): 129-134.

[11] YANG X Y, SUN Z Y, XING J, MIURA H, SAKAI T. Grain size and texture changes of magnesium alloy AZ31 during multi-directional forging[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 200-204.

[12] 吴远志, 严红革, 陈吉华, 朱素琴, 薄红伟, 王林伟. AZ31镁合金高应变速率多向锻造组织演变及力学性能[J]. 中国有色金属学报, 2012, 22(11): 3000-3005.

WU Yuan-zhi, YAN Hong-ge, CHEN Ji-hua, ZHU Su-qin, BO Hong-wei, WANG Lin-wei. Microstructure evolution and mechanical properties of AZ31 magnesium alloy fabricated by high strain rate triaxial-forging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3000-3005.

[13] MIURA H, YU G, YANG X, SAKAI T. Microstructure and mechanical properties of AZ61 Mg alloy prepared by multi directional forging[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7): 1294-1298.

[14] MIURA H, YU G, YANG X. Multi-directional forging of AZ61Mg alloy under decreasing temperature conditions and improvement of its mechanical properties[J]. Materials Science and Engineering A, 2011, 528(22/23): 6981-6992.

[15] 郭 强, 严红革, 陈振华, 张 辉. 多向锻造工艺对AZ80镁合金显微组织和力学性能的影响[J]. 金属学报, 2006, 42(7): 739-744.

GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Effect of multiple forging process on microstructure and mechanical properties of magnesium alloy AZ80[J]. Acta Metallurgica Sinica, 2006, 42(7): 739-744.

[16] WU Y Z, YAN H G, CHEN J H, DU Y G, ZHU S Q, SU B. Microstructure and mechanical properties of ZK21 magnesium alloy processed by multiple forging at different strain rate[J]. Materials Science and Engineering A, 2012, 556: 164-169.

[17] WU Y Z, YAN H G, CHEN J H, ZHU S Q, SU B, ZENG P L. Microstructure and mechanical properties of ZK60 alloy fabricated by multiple forging[J]. Material Science and Technology, 2013, 29(1): 54-59.

[18] ZHANG Z R, XING J, YANG X, MIURA H, SAKAI T. Anisotropy of low temperature superplasticity of fine grained magnesium alloy AZ31 processed by multidirectional forging[J]. Materials Science and Technology, 2009, 25(12): 1442-1447.

[19] 黄宏涛, 刘 伟, GODFREY A, 唐瑞鹤, 刘 庆. AZ31镁合金单轴压缩中的孪生行为[J]. 金属学报, 2012, 48(3): 357-362.

HUANG Hong-tao, LIU Wei, GODFREY A, TANG Rui-he, LIU Qing. Study of twin behavior during uniaxial compression of AZ31 magnesium alloy[J]. Acta Metallurgica Sinica, 2012, 48(3): 357-362.

[20] 余 琨, 芮守泰, 王日初, 彭超群, 薛新颖. AZ31镁合金挤压薄板织构及力学各向异性[J]. 中国有色金属学报, 2008, 18(12): 2127-2131.

YU Kun, RUI Shou-tai, WANG Ri-chu, PENG Chao-qun, XUE Xin-ying. Texture and mechanical anisotropy of AZ31 extruded sheets[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2127-2131.

[21] BOHLEN J, NURNBERG M R, SENN J W, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium-zinc- rear earth alloy sheet[J]. Acta Materialia, 2007, 55(6): 2101-2112.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51274092);教育部博士点基金资助项目(20120161110040)

收稿日期:2013-05-20;修订日期:2013-07-28

通信作者:吴远志,讲师,博士;电话:0734-3452089;E-mail: yzwu666@gmail.com

摘 要:采用空气锤对ZK60镁合金进行多向锻造变形,研究锻坯的组织演变以及组织和性能均匀性。结果表明,锻锤与锻坯之间摩擦力的作用造成不均匀变形,使锻坯芯部的实际变形量大于边部的。累积应变∑Δε=3.3时,锻坯芯部组织为蜂窝状粗大再结晶组织和岛状细小再结晶组织,而边部组织则由蜂窝状粗大再结晶组织和呈岛状分布的孪晶组成;其抗拉强度从边部到芯部逐渐降低,而伸长率则由边部向芯部逐渐升高。锻坯力学性能存在一定的各向异性,但锻坯各方向抗拉强度在310.6~323.9 MPa之间,伸长率在21.9%~29.7%之间,表明该工艺可以有效地避免强烈的各向异性,是制备高性能变形镁合金的理想工艺。

[4] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 2-10.

CHEN Zhen-hua. Wrought magnesium alloy[M]. Beijing: Chemical Industry Press, 2005: 2-10.

[10] 杨续跃, 孙 欢, 吴新星, 马继军, 秦 佳, 霍庆欢. AZ21镁合金降温多向压缩过程中的组织和微观织构演化[J]. 金属学报, 2012, 48(2): 129-134.

[12] 吴远志, 严红革, 陈吉华, 朱素琴, 薄红伟, 王林伟. AZ31镁合金高应变速率多向锻造组织演变及力学性能[J]. 中国有色金属学报, 2012, 22(11): 3000-3005.

[15] 郭 强, 严红革, 陈振华, 张 辉. 多向锻造工艺对AZ80镁合金显微组织和力学性能的影响[J]. 金属学报, 2006, 42(7): 739-744.

[19] 黄宏涛, 刘 伟, GODFREY A, 唐瑞鹤, 刘 庆. AZ31镁合金单轴压缩中的孪生行为[J]. 金属学报, 2012, 48(3): 357-362.

[20] 余 琨, 芮守泰, 王日初, 彭超群, 薛新颖. AZ31镁合金挤压薄板织构及力学各向异性[J]. 中国有色金属学报, 2008, 18(12): 2127-2131.