DOI: 10.11817/j.ysxb.1004.0609.2020-37608

球形TC4合金粉末的制备、表征及雾化机理

冯 凯,李丹明,张凯锋,郑 军,何成旦,周 晖

(兰州空间技术物理研究所 真空技术与物理重点实验室,兰州 730000)

摘 要:

采用真空气体雾化法制备了TC4合金粉末,并采用激光粒度分析仪、扫描电子显微镜和霍尔流速计等对制备的粉末粒度分布、组织形貌、松装密度、流动性等进行了测试分析。结果表明:真空气体雾化法制备的TC4合金粉末粒度呈正态分布,尺寸集中分布在32.52~182.50 μm左右,粉末中值粒径d50为92.70 μm,粉末球形度高,氧含量低(0.14%);粉末具有较低的松装密度和良好的流动性,粒径在38~106 μm的粉末其流动性为25~50 s/(50 g),松装密度为2.52~2.56 g/cm3。TC4合金粉末中粒径较大的颗粒表面呈发达的近似等轴的胞状枝晶组织,而颗粒粒径越小,其表面越光滑。少部分小颗粒粘附在大颗粒表面上,出现连体的“卫星”状。

关键词:

文章编号:1004-0609(2020)-07-1594-08 中图分类号:TF123;TG146.2 文献标志码:A

钛及钛合金具有高强度、良好的耐腐蚀性和耐热性等特点,是航空航天、武器装备等高端制造领域重要的结构材料[1-4]。近年来,以粉末冶金和3D打印/增材制造等技术为代表的近净成形技术是低成本加工制造钛材产品的新技术,在航空航天等众多领域具有广阔的市场前景,市场需求量巨大[5-7]。而这些近净成形技术所需的高品质钛材粉末原材料大多还是依靠进口,国内的制粉企业规模和产品质量与国外先进水平有一定差距,主要原因是国产钛合金粉末的氧含量、球形度等重要参数还不能完全达到应用技术指标,如氧含量偏高、粒度较大且分布范围宽、球形度较差、不同批次粉末质量不稳定等问题,难以满足关键部件3D打印要求,仅有几家航空级钛合金粉末生产厂家也未能完全实现产业化生产,粉末原材料的制备和产业化在一定程度上制约了我国3D打印技术的发展与应用[8-11]。因此,如何制备满足3D打印应用需求的高品质球形粉末原材料是一个重要的研究方向,尤其是围绕满足3D打印的钛合金粉末的研究方法和成果也逐渐增多[12-13]。

气体雾化法、等离子旋转电极法和等离子体球化法均可制备高品质的球形钛合金粉末,但等离子旋转电极法和等离子体球化法制粉设备和工艺较气雾化成本更高、更复杂[14-17]。气体雾化法是金属熔体在雾化喷嘴产生高速、高压气流冲击和破碎的作用下,熔体液流形成细小的液滴在较高的冷却速率下瞬间经过球化、冷却和凝固而得到粉末的方法。该工艺制备的粉末具有粒度细小、成分均匀、球形度高、氧含量低且易于实现规模化生产等优点,在微细、球形金属及合金粉末制备领域得到了广泛的应用[13, 15]。由于钛合金具有极易氧化和吸氢等特点,因此需采用真空气体雾化法制备氧含量低和球形度高的高品质钛合金粉体材料。本文将采用真空气体雾化法制备TC4合金球形粉末,重点解决粉末的氧含量、球形度和尺寸等关键指标问题,通过对粉末粒度分布、形貌特征进行表征,分析粉末雾化影响因素和形成机理,为3D打印用高品质钛合金粉末制备和产业化应用提供技术支撑和理论指导。

1 实验

雾化原材料为d 40 mm×600 mm的TC4合金棒材,成分如表1所示。采用中南大学自主研制的无坩埚真空气体雾化制粉系统制备球形粉末,真空系统真空度达到1×10-3 Pa,其中,采用感应线圈加热钛合金棒材,加热温度高于熔点100~300 ℃使其熔化,雾化制粉时采用氩气气氛保护,雾化气体的压力约为3.0~3.5 MPa。采用振动筛分法对所制备的粉末进行粒度分级,并将其真空包装封存。

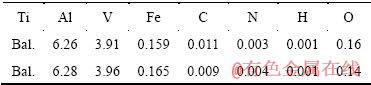

表1 钛合金棒材和粉末成分表

Table 1 Components of TC4 bars and powder (mass fraction, %)

采用Bettersize 2000LD激光粒度分析仪对制备的TC4粉末进行粒度测试分析。采用Leco-600 型氧氮联测仪测定粉末的氧含量,表1对比列出了钛合金原料棒材和雾化后所得粉体的化学组成。从表1可见,雾化所得TC4粉末的成分与棒材的成分相近,尤其是氧含量(质量分数)分别为0.16%和0.14%,棒材和粉末中的Fe、C、N、H等杂质元素含量均在国标之内,制备的TC4粉末氧含量指标满足3D打印要求(0.2%)。

采用JSM-6700型扫描电镜(SEM)对粉末的表面形貌和微区进行观察。将粉末镶嵌,经1000、1500和2000号砂纸预磨后,抛光试样,通过SEM观察粉末颗粒的截面。采用D/MAX2500PC型X射线衍射仪进行物相分析,取少量粉末样品进行测试,选用Cu靶,测试参数为:电流40 mA,扫描步长为0.04°。采用标准漏斗法(霍尔流速计),并按国标GB/T 1482—2010和GB/T 1479—2011测定粉末的流动性和松装密度。

2 结果分析与讨论

2.1 粉末粒度分布

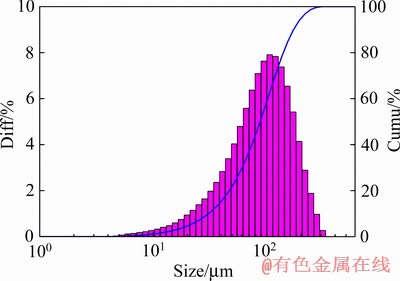

图 1 所示为真空气体雾化法制备的TC4合金粉末粒度分布曲线。由图1 可见,大部分粉末粒度集中在32.52~182.50 μm(累积分布曲线上10%和90%处的粒度分别为32.52 μm 和182.50 μm)范围内,约占80%,其中值粒径d50为92.70 μm,平均粒径为101.40 μm。由粉末的微分分布曲线可以看出,粉末粒度呈单峰分布并且近似于正态分布特征。主要是由于熔滴破碎阶段遵循Weber数准则[18],当We数达到临界值时,初始破碎产生的熔滴会发生二次破碎,形成细小的熔滴,使得粉末粒度呈单峰分布,最终得到的粉末粒度呈正态分布。

图1 TC4合金粉末粒度分布

Fig. 1 Size distribution of TC4 powder

2.2 粉末表面形貌分析

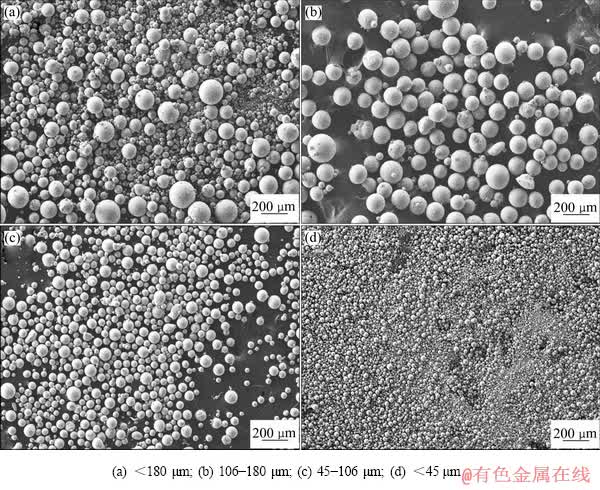

图2所示为真空气体雾化法制备的TC4合金球形粉末的SEM像。由图2可见,粉末颗粒主要呈球形,具有较好的球形度。图2(a)所示为粒径<180 μm的粗筛原始混合粉末SEM像,颗粒大小不均匀。图2(b)、(c)和(d) 所示分别为图2(a)中原始混合粉末过筛后得到的粒径106~180 μm、45~106 μm和<45 μm的粉末SEM像,粒径分布较为均匀,并且随着粉末粒径减小,颗粒的球形度逐渐提高。其中粒径45~106 μm粉末的颗粒粒径分布在50 μm左右,粒径<45 μm粉末的颗粒粒径分布在20~30 μm之间,颗粒球形度较高,氧含量为0.14%(见表1),两种粉末均适合3D打印。气体雾化过程是利用高速气流作用于熔融的金属液流,使气体动能转化为熔体的表面能,形成细小液滴并快速凝固成颗粒。雾化过程可分为两个基本阶段,即熔融液滴的破碎和冷凝[19-21]。破碎导致液滴的形成,同时与熔融液滴的过热度相关,液滴的过热度越大,则黏度越小,在气体的扰动下,容易破碎成小颗粒,则直接影响粉末颗粒的尺寸[22];而冷凝则导致固体颗粒的形成,其中液滴在冷凝过程中的表面张力直接影响颗粒的形貌,表面张力越大,颗粒球形度越高。

图2 不同粒径下TC4合金粉末的低倍SEM像

Fig. 2 Low-magnification SEM images of TC4 powder with different diameters

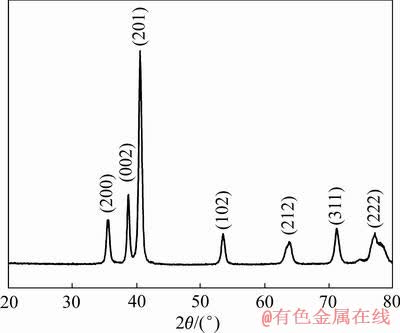

图3 TC4合金粉末XRD谱

Fig. 3 XRD pattern of TC4 powder (45-106 μm in diameter)

图3所示为真空气体雾化法制备的TC4 钛合金粉末筛选的粒径45~106 μm粉末的XRD谱,可见其衍射峰在64°和78°处出现宽化。通过扫描电镜对粒径106~180 μm和45~106 μm两种TC4粉末的表面进行显微形貌分析,结果如图4所示。不同粒径的TC4 合金粉末颗粒均以球形为主,粒径较大的颗粒表面呈发达的近似等轴花瓣状的胞状枝晶组织(见图4(a)和(b));而颗粒粒径越细小,其表面越光滑(见图4(c)和(d))。造成不同粒径颗粒表面形貌差异的原因主要是冷却速率的差异[23-24]。由于颗粒粒径越小,液滴冷却的速率则越高,当冷却速率过高时,结晶过程被抑制,结果形成无结晶组织的光滑表面,与图3中XRD谱的衍射峰宽化的结果一致;相反,尺寸较大的颗粒冷却速率相对较低,因其体积较大,容易造成表面凝固收缩差异,从而大粒径颗粒表面呈现出发达的近似等轴花瓣状的胞状枝晶组织,颗粒表面光滑度相对较差。另外,在雾化过程中,颗粒形状主要取决于金属液滴表面张力促使液滴收缩成球的时间以及金属液滴凝固时间的长短[18, 25-26],当液滴收缩成球的时间小于液滴凝固时间时,金属液滴在凝固前球化时间较充分,颗粒易成球形。从图2(c)、(d)和图4(c)可以看出,粒径较小的颗粒球形度较好,这是由于液体的表面张力特性造成的,雾化液滴体积越小,表面张力的作用越明显,故小液滴更易收缩形成球形。

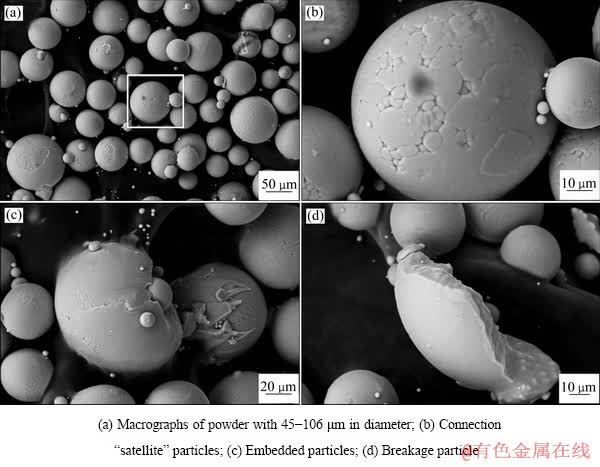

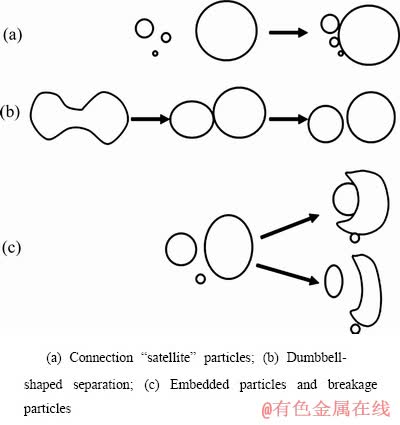

图5和6所示分别为通过SEM观察到的TC4 钛合金粉末几种不同的典型形貌特征和形成示意图。由图5(a)、(b)和图6(a)可见,小颗粒附着在大颗粒表面,造成大颗粒表面粘附“卫星”颗粒的现象;由图5(c)和图6(c)可见,小颗粒镶嵌在未完全凝固的大颗粒中;由图5(d)和图6(c)可见,小颗粒飞行速度较大,动能较大,颗粒之间发生碰撞后造成球形颗粒损坏,变为非球形。同时,还存在一种情况是小颗粒与未完全凝固的大颗粒发生碰撞后可破碎成无数个小液滴,凝固后形成独立微细小的颗粒,如图5(a)和(c)中独立分布的小白点状微型颗粒。雾化得到的“卫星”颗粒主要有两种情况,一是粒径大的熔滴在气雾化过程中因体积大具有的能量高而冷却慢,熔滴在凝固过程中,其飞行速度和轨迹受到重力和气流冲刷的双重作用,容易与已经凝固的小尺寸颗粒发生碰撞,小颗粒在飞行过程中与未完全凝固的较大粒径雾化液滴发生碰撞、焊合,凝固后小颗粒附着在大颗粒表面,造成大颗粒表面粘附“卫星”颗粒的现象,如图5(a)、(b)和图6(a)所示;另一种情况是在液滴处于初级雾化和二次雾化破碎阶段时,不规则的“哑铃型”液滴经二次破碎变形后将形成两个较大的子液滴和连接两个液滴之间的细长型“液桥”联接在一起[20],“液桥”将会在自身表面张力和破碎引起的震动共同作用下形成一个或若干个远小于两个较大子液滴的卫星液滴,有少部分微小的卫星液滴并没有与原始液滴彻底分离,依然粘附并联接于其大颗粒表面,最终同时凝固保留下来,如图6(b)所示。

图4 TC4合金粉末的高倍SEM像

Fig. 4 High-magnification SEM images of TC4 powder

图5 TC4 钛合金粉末的几种典型形貌特征

Fig. 5 Typical morphology characteristics of TC4 powder

图6 几种典型形貌形成示意图

Fig. 6 Schematic diagram of typical morphology of TC4 powder

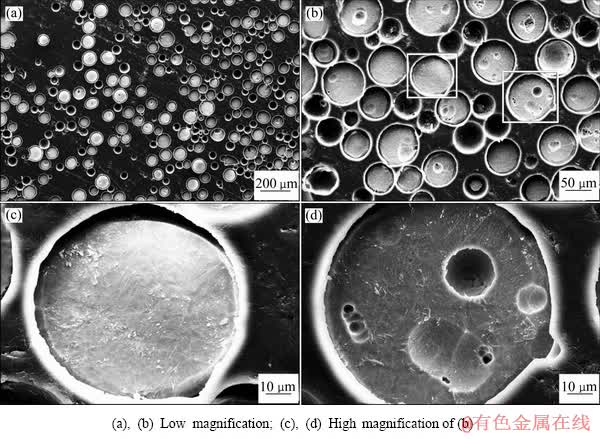

2.3 粉末截面分析

对45~106 μm粉末颗粒的横截面进行SEM观察,如图7所示。大部分球形粉末颗粒内部是实心的,但也有小部分颗粒内部明显存在孔洞,属于空心粉末,如图7(a)和(b)所示。分别对实心和空心粉末的截面微观组织放大观察,实心粉末的内部组织致密,如图7(c)所示;而空心粉末的横截面部分区域则有微小孔洞存在,如图7(d)所示。空心粉末形成过程主要是在雾化过程中熔融液滴的液膜振动和自身表面张力的共同作用下形成。熔融金属液流在高速气流扰动作用下发生震动被吹成较大的液膜,继续在气流的作用下发生剧烈的震动,以至于达到可使液膜自身分裂的能量时,则破碎成细小的液膜[27-29],液膜继续在气体作用力和表面张力的共同作用下局部边缘弯曲变形,从而会包裹住气体,并在表面张力的作用下,液膜会自然收缩成为一个中心带有气体的空心液滴,在极高的冷却速率下,空心液滴的形态在凝固后将被保留下来,即形成空心粉末,因此在对粉末横截面中可观察到有孔洞。

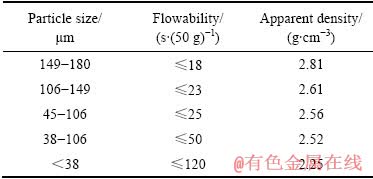

2.4 流动性和松装密度

TC4合金粉末流动性和松装密度的测试结果见表2。随着粉末颗粒粒径增加,粉末的流动时间逐渐减小,而松装密度则逐渐增加,其中粒径在38~106 μm的粉末其流动时间<50 s/50 g,松装密度为2.52~2.56 g/cm3。粉末粒径、粒径分布和表面形貌对其流动性影响较大[30],结合粉末颗粒的SEM观察(见图2和图4)可知,粉末粒径越小,粉末表面则越光滑,有利于粉末的流动,但是随着粉末粒径减小,粉末流动性则变差,主要是由于粉末流动性能还与很多因素有关,如粉末颗粒尺寸、形状和粗糙度、比表面等[31-32]。尺寸较小的粉末颗粒比表面积较大,相互间吸附能力较强,发生粉末间团聚,在流动过程中增加了颗粒间的摩擦,从而会使粉末流动困难,因此随着粉末颗粒尺寸减小,粉体的松装密度逐渐下降,流动性变差。

图7 粒径45~106 μm 的TC4合金粉末截面形貌

Fig. 7 Cross-section morphologies of TC4 powder with 45-106 μm in diameter

表2 TC4合金粉末流动性和松装密度

Table 2 Flowability and apparent density of TC4 powder

3 结论

1) 采用真空气体雾化法制备的TC4合金粉末粒度呈正态分布,粒径集中分布在32.52~182.50 μm,d50为92.7 μm。通过筛选,45~106 μm粉末粒径主要分布在50 μm左右,<45 μm的粉末粒径则主要是在20~30 μm之间,粉末球形度较高,氧含量为0.14%,两种粉末均适合3D打印。

2) 制备的TC4合金粉末具有较低的松装密度和良好的流动性,随着粉末颗粒粒径增大,粉末的流动时间逐渐减小,而松装密度则逐渐增加,其中粒径在38~106 μm的粉末其流动时间<50 s/(50 g),松装密度为2.52~2.56 g/cm3。

3) 粒径较大的粉末表面呈发达的近似等轴胞状枝晶组织,而粒径越小,其表面越光滑。制备的TC4粉末中存在部分小颗粒粘附在大颗粒表面上,出现连体的“卫星”状。

REFERENCES

[1] SUN Xiao-yan, YUAN Li, WANG Lei-long, CHENG Li-yan. Study on the formability of 3D printed TC4 alloy powder by EIGA[J]. Materials Science and Engineering, 2019, 493: 1-5.

[2] 黄伯云, 韦伟峰, 李松林, 张 立, 李丽娅, 刘 锋, 李瑞迪. 现代粉末冶金材料与技术进展[J]. 中国有色金属学报, 2019, 29(9): 1917-1933.

HUANG Bai-yun, WEI Wei-feng, LI Song-lin, ZHANG Li, LI Li-ya, LIU Feng, LI Rui-di. Development of modern powder metallurgy materials and technology[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 1917-1933.

[3] 黄 旭, 李臻熙, 高 帆, 王 浩. 航空发动机用新型高温钛合金研究进展[J]. 先进高温材料, 2014(7): 70-75.

HUANG Xu, LI Zhen-xi, GAO Fan, WANG Hao. Recent development of high-temperature titanium alloys for aeroengine[J]. Advanced High-temperature Material, 2014(7): 70-75.

[4] 张绪虎, 单 群, 陈永来, 杜志惠. 钛合金在航天飞行器上的应用和发展[J]. 中国材料进展, 2011, 30(6): 28-32.

ZHANG Xu-hu, SHAN Qun, CHEN Yong-lai, DU Zhi-hui. Application and development of titanium alloys for aircrafts[J]. Materials China, 2011, 30(6): 28-32.

[5] GIBSON I, ROSEN D W, STRUCKER B. Additive manufacturing technologies: Rapid prototyping to direct digital manufacturing[M]. New York: Springer-Verlag, 2010: 498.

[6] 袁建鹏. 3D打印用特种粉体材料产业发展现状与趋势[J]. 新材料产业, 2013(12): 19-23.

YUAN Jian-peng. Development status and trend of 3D printing special powder materials industry[J]. New Material Industry, 2013(12): 19-23.

[7] 王延庆, 沈竞兴, 吴海全. 3D打印材料应用和研究现状[J]. 航空材料学报, 2016, 36(4): 89-98.

WANG Yan-qing, SHEN Jing-xing, WU Hai-quan. Application and research status of alternative materials for 3D-printing technology[J]. Journal of Aeronautical Materials, 2016, 36 (4): 89-98.

[8] TANG H P, QIAN M, LIU N, ZHANG X Z, YANG G Y, WANG J. Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting[J]. Journal of the Minerals, Metals & Materials Society, 2015, 67: 555-563.

[9] GU D D, MEINERS W, WISSENBACH K, POPRAWE R. Laser additive manufacturing of metallic components: materials, processes and mechanisms[J]. International Materials Reviews, 2012, 57: 133-164.

[10] CHEN G, ZHAO S Y, TAN P, WANG J, XIANG C S, TANG H P. A comparative study of Ti-6Al-4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization[J]. Powder Technology, 2018, 333: 38-46.

[11] 李俊峰, 魏正英, 卢秉恒. 钛及钛合金激光选区熔化技术的研究进展[J]. 激光与光电子学进展, 2018, 55(1): 1-18.

LI Jun-feng, WEI Zheng-ying, LU Bing-hen. Research progress on technology of selective laser melting of titanium and titanium alloys[J]. Optics Journal, 2018, 55(1): 1-18.

[12] SUN Pei, FANG Z Z, XIA Yang, ZHANG Ying, ZHOU Cheng-shang. A novel method for production of spherical Ti-6Al-4V powder for additive manufacturing[J]. Powder Technology, 2016, 301: 331-335.

[13] YOLTON C F, FROES F H. Conventional titanium powder production[C]//Titanium Powder Metallurgy: Science, Technology and Applications. Elsevier Inc., 2015: 21-32.

[14] 尚青亮, 刘 捷, 方树铭, 周 林. 金属钛粉的制备工艺[J]. 材料导报, 2013, 27(21): 97-100.

SHANG Qing-liang, LIU Jie, FANG Shu-ming, ZHOU Lin. The preparation technology of titanium metal powder[J]. Materials Review, 2013, 27(21): 97-100.

[15] 曾 光, 白保良, 张 鹏, 梁书锦, 韩志宇, 陈小林, 张平祥. 球形钛粉制备技术的研究进展[J]. 钛工业进展, 2015, 32(1): 7-11.

ZENG Guang, BAI Bao-liang, ZHANG Peng, LIANG Shu-jin, HAN Zhi-yu, CHEN Xiao-lin, ZHANG Ping-xiang. Research progress on producing spherical titanium powder[J]. Titanium Industry Progress, 2015, 32(1): 7-11.

[16] 黄 柯, 赵 阳, 张昌松, 王晓明, 常 青, 邱 六, 关雪飞. PREP法制备球形 CuAl10Fe3 铜合金粉末的性能表征[J]. 材料导报, 2019, 33(11): 3783-3788.

HUANG Ke, ZHAO Yang, ZHANG Chang-song, WANG Xiao-ming, CHANG Qing, QIU Liu, GUAN Xue-fei. Properties characterization of spherical CuAl10Fe3 copper alloy powders prepared by plasma rotating electrode processing[J]. Materials Reports, 2019, 33(11): 3783-3788.

[17] 麻西群, 于振涛, 刘汉源, 牛金龙, 余 森, 贺新杰. SPS法制备Ti-3Zr-2Sn-3Mo-25Nb合金的组织与性能[J]. 中国有色金属学报, 2019, 29(1): 74-80.

MA Xi-qun, YU Zhen-tao, LIU Han-yuan, NIU Jin-long, YU Sen, HE Xin-jie. Microstructure and properties of Ti-3Zr-2Sn-3Mo-25Nb alloy prepared by SPS method[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(1): 74-80.

[18] 刘 辛, 骆接文, 谢焕文, 蔡一湘. 惰性气体雾化法制备TiAl3粉末的特性[J]. 中国有色金属学报, 2010, 20(S1): 253-256.

LIU Xin, LUO Jie-wen, XIE Huan-wen, CAI Yi-xiang. Characteristics of TiAl3 powder prepared by inert gas atomization[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 253-256.

[19] 戴 煜. 球形碳化钨粉末的超高温雾化制备技术及机理研究[D]. 长沙: 中南大学, 2008: 24-89.

DAI Yu. Fabricating theory and super high temperature atomizing mechanism for spherical tungsten carbide[D]. Changsha: Central South University, 2008: 24-89.

[20] 赵文军. 喷射沉积气体流场与雾化机制研究[D]. 哈尔滨: 哈尔滨工业大学, 2012: 71-90.

ZHAO Wen-jun. Study on the gas flow field in spray deposition deposition and the breakup mechanism[D]. Harbin: Harbin Institute of Technology, 2012: 71-90.

[21] 金 莹, 刘 平, 史金光, 翁子清, 顾小龙. 雾化压力对电极感应熔炼气雾化 TC4 粉末形貌与性能的影响[J]. 粉末冶金材料科学与工程, 2018, 23(3): 312-317.

JIN Ying, LIU Ping, SHI Jin-guang, WENG Zi-qing, GU Xiao-long. Effects of gas-atomized pressure on morphology and properties of TC4 powder prepared by electrode-induced gas atomization[J]. Materials Science and Engineering of Powder Metallurgy, 2018, 23(3): 312-317.

[22] 吕海波, 母育锋, 李新军, 陈 芃. 熔体过热度对雾化过程的影响[J]. 中南工业大学学报, 1997, 28(2): 149-151.

Lü Hai-bo, MU Yu-feng, LI Xin-jun, CHEN Peng. The influence of melt superheat on gas atomization process[J]. Journal of Central South University of Technology, 1997, 28(2): 149-151.

[23] ACHELIS L, UHLENWINKEL V. Characterisation of metal powders generated by a pressure-gas-atomiser[J]. Materials Science and Engineering A, 2008, 477(1/2): 15-20.

[24] 赵少阳, 陈 刚, 谈 萍, 王 建, 刘晓青. 球形TC4 粉末的气雾化制备、表征及间隙元素控制[J]. 中国有色金属学报, 2016, 26(5): 980-987.

ZHAO Shao-yang, CHEN Gang, TAN Pin, WANG Jian, LIU Xiao-qing. Characterization of spherical TC4 powders by gas atomization and its interstitial elemental control[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 980-987.

[25] 徐 磊, 李菊英, 田 晓, 崔玉友, 杨 锐. 洁净TiAl基预合金粉末制备和表征[J]. 稀有金属材料与工程, 2008, 37(Suppl.3): 815-817.

XU Lei, LI Ju-ying, TIAN Xiao, CUI Yu-you, YANG Rui. Fabrication and characterization of TiAl based pre-alloyed powder produced by gas atomization[J]. Rare Metal Materials and Engineering, 2008, 37(Suppl.3): 815-817.

[26] 刘文胜, 彭 芬, 马运柱, 崔 鹏, 陈仕奇, 刘有长. 工艺条件对气雾化制备SnAgCu合金粉末特性的影响[J]. 中国有色金属学报, 2009, 19(6): 1074-1079.

LIU Wen-sheng, PENG Fen, MA Yun-zhu, CUI Peng, CHEN Shi-qi, LIU You-chang. Effect of procedure conditions on characteristics of SnAgCu alloyed powder prepared by gas atomization[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1074-1079.

[27] HECK U, FRITSCHING U, BAUCKHAGE K. Gas flow effects on twin-fluid atomization of liquid metals[J]. Atomization and Sprays, 2000, 10(1): 25-46.

[28] MARKUS S, FRITSCHING U, BAUCKHAGE K. Jet break up of liquid metal in twin fluid atomisation[J]. Materials Science and Engineering A, 2002, 326(1): 122-133.

[29] LOZANO A, BARRERAS F, HAUKE G. Longitudinal instabilities in an air blasted liquid sheet[J]. Journal of Fluid Mechanics, 2001, 437: 143-173.

[30] HUANG Yun, LU Dong, WU Wang, ZHONG Bing, LU Xiang-yun. Study on the flowability of TC4 alloy powder for 3D printing[J]. Materials Science and Engineering, 2018, 493: 1-5.

[31] WANG Chang-zhi, WANG Sen, ZHANG Yuan-bin. Study on the flowability of titanium alloy powder[J]. Powder Metallurgy Technology , 2016, 34(5): 330-335.

[32] LETURIA M, BENALI M, LAGARDE S, RONG I, SALEH K. Characterization of flow properties of cohesive powders: A comparative study of traditional and new testing methods[J]. Powder Technology, 2014, 253: 406-423.

Preparation, characterization and atomization mechanism of spherical TC4 alloyed powder

FENG Kai, LI Dan-ming, ZHANG Kai-feng, ZHENG Jun, HE Cheng-dan, ZHOU Hui

(Science and Technology on Vacuum Technology and Physics Laboratory, Lanzhou Institute of Space Technology Physics, Lanzhou 730000, China)

Abstract: Spherical TC4 alloy powder was prepared by vacuum gas atomization. The particle size distribution was analyzed by laser particle size distribution analyzer. The morphology and microstructure were analyzed by scanning electron microscopy. The flowability and apparent density of the powder were analyzed by Hall funnel. The results show that the TC4 powder exhibits normal particle size distribution. The particle size of TC4 alloy spherical powder is in the range from 32.52 μm to 182.50 μm, and the median diameter of the powder is 92.7 μm. The powder has good sphericity and low oxygen content (0.14%, mass fraction). The powder with 38-106 μm in diameter has a low apparent density and a good fluidity, showing a flow time of 25-50 s/(50 g) and a apparent density of 2.52-2.56 g/cm3. In addition, the surfaces of coarse particles exhibit the equiaxial cellular dendritic structure. However, the smooth surfaces and structure refinement appear on the fine powder. Some fine particles adhere on the coarse particles surface, and exhibit the connection “satellite”.

Key words: vacuum gas atomization; TC4 alloy; spherical powder; microstructure; atomization mechanism

Received date: 2019-07-26; Accepted date: 2020-06-11

Corresponding author: ZHOU Hui; Tel: +86-931-4585518; E-mail: zhouhuilz510@163.com

(编辑 何学锋)

收稿日期:2019-07-26;修订日期:2020-06-11

通信作者:周 晖,研究员,博士;电话:0931-4585518;E-mail:zhouhuilz510@163.com

摘 要:采用真空气体雾化法制备了TC4合金粉末,并采用激光粒度分析仪、扫描电子显微镜和霍尔流速计等对制备的粉末粒度分布、组织形貌、松装密度、流动性等进行了测试分析。结果表明:真空气体雾化法制备的TC4合金粉末粒度呈正态分布,尺寸集中分布在32.52~182.50 μm左右,粉末中值粒径d50为92.70 μm,粉末球形度高,氧含量低(0.14%);粉末具有较低的松装密度和良好的流动性,粒径在38~106 μm的粉末其流动性为25~50 s/(50 g),松装密度为2.52~2.56 g/cm3。TC4合金粉末中粒径较大的颗粒表面呈发达的近似等轴的胞状枝晶组织,而颗粒粒径越小,其表面越光滑。少部分小颗粒粘附在大颗粒表面上,出现连体的“卫星”状。

[2] 黄伯云, 韦伟峰, 李松林, 张 立, 李丽娅, 刘 锋, 李瑞迪. 现代粉末冶金材料与技术进展[J]. 中国有色金属学报, 2019, 29(9): 1917-1933.

[3] 黄 旭, 李臻熙, 高 帆, 王 浩. 航空发动机用新型高温钛合金研究进展[J]. 先进高温材料, 2014(7): 70-75.

[4] 张绪虎, 单 群, 陈永来, 杜志惠. 钛合金在航天飞行器上的应用和发展[J]. 中国材料进展, 2011, 30(6): 28-32.

[6] 袁建鹏. 3D打印用特种粉体材料产业发展现状与趋势[J]. 新材料产业, 2013(12): 19-23.

[7] 王延庆, 沈竞兴, 吴海全. 3D打印材料应用和研究现状[J]. 航空材料学报, 2016, 36(4): 89-98.

[11] 李俊峰, 魏正英, 卢秉恒. 钛及钛合金激光选区熔化技术的研究进展[J]. 激光与光电子学进展, 2018, 55(1): 1-18.

[14] 尚青亮, 刘 捷, 方树铭, 周 林. 金属钛粉的制备工艺[J]. 材料导报, 2013, 27(21): 97-100.

[15] 曾 光, 白保良, 张 鹏, 梁书锦, 韩志宇, 陈小林, 张平祥. 球形钛粉制备技术的研究进展[J]. 钛工业进展, 2015, 32(1): 7-11.

[18] 刘 辛, 骆接文, 谢焕文, 蔡一湘. 惰性气体雾化法制备TiAl3粉末的特性[J]. 中国有色金属学报, 2010, 20(S1): 253-256.

[19] 戴 煜. 球形碳化钨粉末的超高温雾化制备技术及机理研究[D]. 长沙: 中南大学, 2008: 24-89.

[20] 赵文军. 喷射沉积气体流场与雾化机制研究[D]. 哈尔滨: 哈尔滨工业大学, 2012: 71-90.

[21] 金 莹, 刘 平, 史金光, 翁子清, 顾小龙. 雾化压力对电极感应熔炼气雾化 TC4 粉末形貌与性能的影响[J]. 粉末冶金材料科学与工程, 2018, 23(3): 312-317.

[22] 吕海波, 母育锋, 李新军, 陈 芃. 熔体过热度对雾化过程的影响[J]. 中南工业大学学报, 1997, 28(2): 149-151.

[24] 赵少阳, 陈 刚, 谈 萍, 王 建, 刘晓青. 球形TC4 粉末的气雾化制备、表征及间隙元素控制[J]. 中国有色金属学报, 2016, 26(5): 980-987.

[25] 徐 磊, 李菊英, 田 晓, 崔玉友, 杨 锐. 洁净TiAl基预合金粉末制备和表征[J]. 稀有金属材料与工程, 2008, 37(Suppl.3): 815-817.

[26] 刘文胜, 彭 芬, 马运柱, 崔 鹏, 陈仕奇, 刘有长. 工艺条件对气雾化制备SnAgCu合金粉末特性的影响[J]. 中国有色金属学报, 2009, 19(6): 1074-1079.