Deformation twins and twinning at ambient temperature in cryomilled Al-Zn-Mg-Cu alloy powders

CHEN Han-bin(陈汉宾)1, CHENG Jun-sheng(程军胜)2, YANG Bin(杨 滨)1, 3,

ZHANG Ji-shan(张济山)1, TIAN Xiao-feng(田晓风)4, FAN Jian-zhong(樊建中)4

1. State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing,Beijing 100083, China;

2. Institute of Electrical Engineering, Chinese Academy of Sciences, Beijing 100080, China;

3. International Centre for Materials Physics, Chinese Academy of Sciences, Shenyang 110016, China;

4. Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China

Received 25 December 2006; accepted 18 April 2007

Abstract:

The nanocrystalline Al-Zn-Mg-Cu alloy powders were synthesized using cryomilling. Deformation twins and twinning at ambient temperature were observed in Al-Zn-Mg-Cu powders. Experimental results indicate that high strain rate at low temperature during cryomilling induces the formation of deformation twins by the climbing of the restricted dislocations in nano-scale grains, and the cryomilled powders at high energies and nonequilibrium state reduce the grain boundary energies by twinning.

Key words:

cryomilling; Al-Zn-Mg-Cu alloy; twins; mechanism;

1 Introduction

Twins are generally classified into deformation twins and annealing twins. It is known that no deformation twins have been observed in coarse-grained Al and its alloy due to their high stacking fault energies(SFEs). However, based on the study of FCC polycrystal metals, EL-DANAF[1] suggested that the twinning stress instead of the critical value of the SFEs directly influences the production of deformation twins. The analytical model[2] indicates further that the stress of twin growth is much smaller than that for its nucleation. Deformation twins in FCC metal powders produced by cryomilling, such as Inconel 625[3] and Al[4-9], have been observed recently. As for annealing twins, it has been observed in variety of low SFE FCC metals deformed and subsequently annealed at recrystallized temperature. But the microscopic model proposed by MAHAJAN[10] indicated that annealing twins could not form in high stacking fault energy metals because Shockley partial loops are not stable. However, a number of twins were found in Al-Zn-Mg-Cu powder samples prepared by cryomilling for 2 and 10 h and then dwelling in a silica gel desiccator at ambient temperature for nearly two years. The present study was undertaken to elucidate the mechanism of twinning in cryomilling and the microstructural evolvement at ambient temperature.

2 Experimental

Al-Zn-Mg-Cu (10.0 Zn, 3.0 Mg, 1.8 Cu, balance Al, mass fraction, %) alloy powders with a particle size of about 75 ?m were fabricated by cryomilling. Details of processing method can be found in Ref.[11]. The temperature in vial was -140 ℃. The milling was performed in an attritor with a stainless steel vial at a rate of 200 r/min. The stainless steel balls with a diameter of 6.4 mm were used as the grinding media and the ball-to-powder mass ratio was 25?1.

Transmission electron microscopy was performed using a HITACHI H-800 microscope operated at 100 kV. The samples for TEM observations were prepared by carbon grid method. In this approach[12], powders were first immersed in methanol in a small container and agitated using a supersonic instrument for a few minutes. Then, a standard copper grid with a carbon film was used to collect some small fragment of powder particles from the methanol suspension. Finally, after being dried at ambient temperature, the sample was ion-milled at low temperature. The thermal analysis was carried out in a differential scanning calorimeter (NETZSCH STA 449C) employing a heating rate of 10 ℃/min under flowing argon.

3 Results

3.1 Transmission electron microscopy

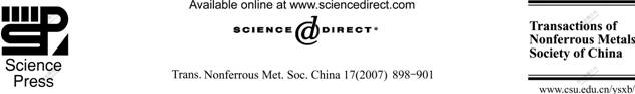

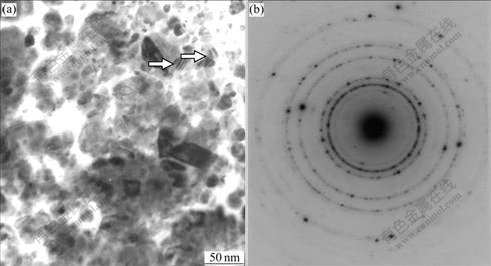

Figs.1 and 2 exhibit the TEM bright field micrographs and selected-area diffraction (SAD) patterns of the samples after being cryomilled for 2 and 10 h respectively. From them, it is obvious that the powders cryomilled for 10 h have a more homogeneous particle size distribution than those milled for 2 h. Additionally, the lamellae twins can be observed in both samples, as white arrows shown in Fig.1(a) and Fig.2(a). More lamellae twins can be found in Fig.2(a), indicating that under the limitation of the attritor’s maximum allowable velocity, extending cryomilling time contributes to the formation of deformation twins.

Fig.1 TEM image (a) and SAED pattern (b) of Al-Zn-Mg-Cu alloy powders cryomilled for 2 h

Fig.2 TEM image (a) and SAED patterns (b) of Al-Zn-Mg-Cu alloy powders cryomilled for 10 h

By comparing Fig.1(b) with Fig.2(b), it can be found that both SAD patterns of the samples consist of rings. However, the continuity of rings in Fig.2(b) is better than that in Fig.1(b). It is known that more continuous the rings, the smaller the grain size within the selected field of the view and the more homogeneous the distribution of grains. These results demonstrate that the grain size of Al-Zn-Mg-Cu alloy powders can be reduced markedly with increasing cryomilling time. It should be noted that the obvious spots on the SAD pattern of Fig.1(b) spread along rings, indicating that some coarse grains are formed in the samples.

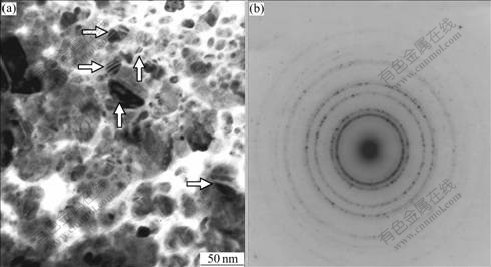

Figs.3(a) and (b) show typical TEM micrographs of the samples cryomilled for 2 and 10 h and then dwelled in silica gel desiccator at ambient temperature for nearly two years. One can see that many twins are formed in the samples and the twins run through the grains by means of lamellae with the thickness of about 10 nm. The grain boundaries are sharp and the distributions of grain size are observably different in Figs.3(a) and (b). The distribution of grain size in Fig.3(a) is inhomogeneous, and a random distribution of equiaxed grains in Fig.3(b) can be found. The presence of many twins indicates that the high grain boundary energy of cryomilled aluminum may be decreased by forming twins at ambient temperature for long time.

Fig.3 TEM images of cryomilled Al-Zn-Mg-Cu alloy powders cryomilled for 2 h (a) and 10 h (b), then dwelled at ambient temperature for about 2 a

3.2 DSC measurement

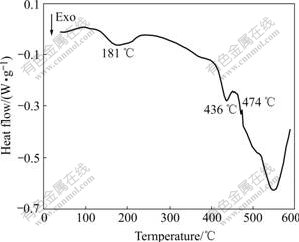

The thermal property of the powder sample cryomilled for 10 h was examined using DSC immediately after synthesis, and the result is shown in Fig.4. The DSC curve indicates two distinct exothermic peaks prior to the dropping of the thermal stability (around 450 ℃). The lower temperature (around 181 ℃) and higher temperature (around 436 ℃) exothermic peaks are considered to be recovery and recrystallization, respectively.

Fig.4 DSC curve for Al-Zn-Mg-Cu alloy powders cryomilled for 10 h

4 Discussion

4.1 Deformation twinning mechanism during cryomilling

Deformation twinning can occur if a stress exceeds the critical stress for its formation in some materials. Usually, a normal tensile deformation at room temperature can lead to the formation of deformation twins in BCC, HCP or FCC metals with low SFEs. Deformation twinning is usually not an important deformation mechanism for Al and Al alloys due to their high SFEs. Sever plastic deformation or low temperature is conductive to the occurrence of deformation twinning. Coincidentally, cryomilling process has the both favoring factors for deformation twinning[13-14].

Spray-atomized coarse-grained Al-Zn-Mg-Cu alloy powders under strong impact of the milling ball can be severely plastically deformed and produce high density dislocations during the cryomilling. At the beginning of cryomilling, the dislocations in deformed powders entangle together and form “dislocation tangle”. As the plastic deformation intensity increases, the deformation of powder increases. When the dislocation density reaches a certain level, the “dislocation cells” form via dislocation annihilating and rearranging. The high density dislocation concentrated in the surrounding regions of the cells forms the walls of cells. There is a little of misorientation between cells. As the plastic deformation intensity increases gradually, the deformation of powder increases, and the number of “dislocation cell” becomes larger. Subsequently, the grain size turns into smaller. With the multiplication of dislocations, many dislocations are restricted, which cannot slip but only climb along (111) plane, forming stress concentration and inducing deformation twins, which cut the microstructure into lamellae. Furthermore, form Figs.1(a) and 2(a), one can see that the grain sizes of lamellae twins are all less than 50 nm.

4.2 Twinning mechanisms at ambient temperature

As described above, the cryomilled aluminum alloy powders are characterized by its high density dislocation and small grain size. As a result, these powders are in high-energy and nonequilibrium state. The higher energy storage is claimed to be mainly due to high dislocation density. When being annealed at elevated temperatures, they normally revert to a lower energy state by structural evolution, such as recovery and recrystallization. The DSC curve (Fig.4) indicates two distinct exothermic peaks prior to the dropping of the thermal stability (around 450 ℃). The similar DSC curves were obtained in Refs.[7, 15]. ZHOU et al[7] reported that the two peaks were associated with recovery and recrystallization respectively. The low-temperature peak (around 181 ℃) consists with ZHOU’s result. However, the high-temperature peak (around 436 ℃) is higher than ZHOU’s result owing to the precipitated second phases at elevated temperatures. At the threshold of curve, a trend of shaping an exothermic peak is clear. By combining with the microstructures of cryomilled Al-Zn-Mg-Cu alloy powders, it is suggested that the microstructural evolution at ambient temperature even lower temperature occurs to reduce the total energies.

From a thermodynamic point of view, twin formation is kinetically driven, and the nucleation and growth rate of twins are controlled by microstructures and storage energies. The total interfacial energy can be decreased by the formation of twins, because the interfacial energies of coherent twin boundaries are much smaller than those for conventional high angle grain boundaries. Twins prefer to nuclear at grain boundaries(GBs) and triple junctions to reduce the GBs energy. Apparently, the formation of twins is also strongly dependent on the nature of the twin boundaries(TBs) and the ratio of the twin boundary energy to the grain boundary energy (α=γTB/γGB). The smaller the α value is, the easier the twins can be obtained under proper conditions. The TB energy of aluminum is high relatively, so annealing twins cannot be seen in coarse-grained aluminum. But when the grain size is decreased, the grain boundary energies increase and the twining stress may become smaller than the stress for slip. Consequently, the sum of the interfacial energies will be reduced by twinning, which are supposed to appear in cryomilled metals and alloys dwelled at room temperature for long time.

5 Conclusions

1) Severe plastic deformation and cryogenic temperature in cryomilling promote twinning, and the density of twins is increased with increasing cryomilling time.

2) The cryomilling powder samples with high energies reduce the grain boundary energies by twinning at ambient temperature. It is a self-moving process.

References

[1] EL-DANAF E, KALIDINDI S R, DOHERTY R D. Influence of grain size and stacking-fault energy on deformation twinning in FCC metals [J]. Metal Mater Trans A, 1999, 30: 1223-1233.

[2] ZHU X Y, LIAO X Z, SRINIVASAN S G, ZHAO Y H, BASKES M I. Nucleation and growth of deformation twins in nanocrystalline aluminum [J]. Appl Phys Lett, 2004, 85(21): 5049-5051.

[3] HE J, LAVERNIA E J. Development of nanocrystalline structure during cryomilling of Inconel 625 [J]. J Mater Res, 2001, 16(9): 2724-2731.

[4] LIAO X Z, ZHOU F, LAVERNIA E J, HE D W, ZHU Y T. Deformation twins in nanocrystalline Al [J]. Appl Phys Lett, 2003, 83(24): 5062-5064.

[5] CHEN M, MA E, HEMKER K J, SHENG H, WANG Y, CHENG X. Deformation twinning in nanocrystalline aluminum [J]. Science, 2003, 300: 1275-1277.

[6] HE J, CHUNG K H, LIAO X Z, LIAO X Z, ZHU Y T, LAVERNIA E J. Mechanical milling-induced deformation twinning in FCC materials with high stacking energy [J]. Metal Mater Trans A, 2003, 34: 707-712.

[7] ZHOU F, LIAO X Z, ZHOU Y T, DALLEK S, LAVERNIA E J. Microstructural evolution during recovery and racrystallization of a nanocrystalline Al-Mg alloy prepared by cryogenic ball milling [J]. Acta Mater, 2003, 51: 2777-2791.

[8] LIAO X Z, ZHOU F, LAVERNIA E J, SRINIVASAN S G, BASKES M I, HE D W, ZHU Y T. Deformation mechanism in nanocrystalline Al: Partial dislocation slip [J]. Appl Phys Lett, 2003, 83(4): 632-634.

[9] HAN B Q, LEE Z, NUTT S R, LAVERNIA E J, MOHAMED F A. Mechanical properties of an ultrafine-grained Al-7.5 pct Mg alloy [J]. Metall Mater Trans A, 2003, 34: 603-613.

[10] MAHAJAN S, PANDE C S, IMAM M A, RATH B B. Formation of annealing twins in f.c.c. crystals [J]. Acta Mater, 1997, 45: 2633-2638.

[11] PEREZ R J, HUANG B, LAVERNIA E J. Thermal stability of nanocrystalline Fe-10 wt.% Al produced by cryogenic mechanical alloying [J]. Nanostruct Mater, 1996, 7: 565-572.

[12] HE J, SCHOENUNG J M. Nanostructured coatings [J]. Mater Sci Eng A, 2002, 336: 274-319.

[13] HAN B Q, MATEJCZYK D, ZHOU F, ZHANG Z, BAMPTON C, LAVERNIA E J, MOHAMED F A. Mechanical behavior of a cryomilled nanostructured Al-7.5 pct Mg alloy [J]. Metall Mater Trans A, 2004, 35: 947-949.

[14] YAMAKOV V, WOLF D, PHILLPOT S R, MUKHERJEE A K, GLEITER H. Dislocation processes in the deformation of nanocrystalline aluminum by molecular-dynamics simulation [J]. Nat Mater, 2002, 1: 1-4.

[15] ZHOU F, NUTT S R, BAMPTON C C, LAVERNIA E J. Nanostructure in an Al-Mg-Sc alloy processed by low-energy ball milling at cryogenic temperature [J]. Metal Mater Trans A, 2003, 34: 1985-1992.

Foundation item: Project(2002AA302502) supported by National High-Tech Research and Development Program of China

Corresponding author: YANY Bin; Tel: +86-10-6233351; E-mail: byang@skl.ustb.edu.cn

(Edited by YANG Bing)