文章编号:1004-0609(2010)09-1680-06

Mg-Al-Nd/Sr耐热镁合金的组织结构与蠕变性能

吴玉锋1, 2, 杜文博2, 左铁镛1, 2

(1. 北京工业大学 循环经济研究院,北京 100124;

2. 北京工业大学 材料科学与工程学院,北京 100124)

摘 要:

以Mg-6Al合金为基体,分别单一添加稀土Nd、Sr和复合添加稀土Nd和碱土Sr元素,采用水冷模工艺制备Mg-6Al-6Nd,Mg-6Al-2Sr和Mg-6Al-2Sr-2Nd耐热镁合金,并比较研究单一添加Nd或Sr和复合添加稀土Nd和碱土Sr对合金组织结构和蠕变性能的影响。结果表明:复合添加稀土Nd和碱土Sr后,合金中除了析出第二相Al2Nd、Al11Nd3和Al4Sr外,还析出Sr和Nd相互取代的Al4(Sr,Nd)和Al11(Nd,Sr)3复合相;在Mg-6Al-2Sr基础上添加2%Nd,不仅细化合金枝晶间距,还显著地提高第二相的分布密度,增强合金蠕变过程中位错与第二相交互作用,提高合金的蠕变性能。

关键词:

中图分类号:TG 146 文献标志码:A

Microstructures and creep properties of

heat-resistant Mg-Al-Nd/Sr alloys

WU Yu-feng1, 2, DU Wen-bo2, ZUO Tie-yong1, 2

(1. Institute of Recycling Economy, Beijing University of Technology, Beijing 100124 , China;

2. College of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China)

Abstract: By single addition of Nd or Sr, and combined addition of Nd and Sr into Mg-6Al matrix alloys, heat-resistant Mg-6Al-6Nd, Mg-6Al-2Sr and Mg-6Al-2Sr-2Nd were obtained by water cooled technology, respectively. The microstructures and creep properties of water-cooled Mg-6Al-2Sr-2Nd alloys were analyzed and compared to reveal the effects of addition means. The results show that when the Nd and Sr elements are added into the Mg-6Al matrix alloy together, there occur the complicated compound named Al4(Sr,Nd) with part Sr substituted by Nd and the complicated compound named Al11(Nd,Sr)3 with part Nd substituted by Sr precipitate besides the compound Al11Nd3 and Al2Nd formed in the Mg-6Al-6Nd alloy and Al4Sr formed in the Mg-6Al-2Sr alloy. In the Mg-6Al-2Sr alloy, the addition of 2%Nd not only refines its grains and dendrite spacing but also improves the distribution density of all precipitates, which leads to the stronger interaction between the dislocation and precipitates in the creep process and improves its creep properties.

Key words: magnesium alloy; heat-resistant magnesium; alkaline earth; rare earth; heat-resistance; creep property

近年来,镁及镁合金以其资源和性能优势,在航天航空、交通工具等领域显现出巨大的应用潜力。但普通牌号的镁合金,如AZ和AM系列合金,由于主要强化相Mg17Al12高温易软化而导致其难以满足中高温零部件的使用要求。稀土Nd和碱土Sr等元素均被认为是有效改善Mg-Al系合金高温力学性能的元素之一,该方面研究受到国内外的重视[1-11]。黄晓锋等[1]研究了Nd对AM50合金组织和性能的影响,认为Nd以A111Nd3相存在,有利于晶粒细化和性能优化。李克杰等[2]研究了Mg-5Al-0.5Nd合金,发现Nd可提高基体合金的抗拉强度,并将其性能的提高归结于细晶强化和Al2Nd粒子的弥散强化。WANG等[3]研究了Mg-4Al-0.4Mn-xNd(x=0,1,2,4)Nd合金,结果表明Nd的添加可改善其拉伸性能,并将合金性能的提高归结于细晶强化和Al11Nd3相阻碍晶界滑动。研究[6-11]表明,添加少量Sr到Mg-Al合金,主要析出相为Al4Sr,可有效提高合金蠕变性能。但同时在Mg-Al合金中添加Nd和Sr两种元素制备耐热镁合金的相关报道并不多见。WU等[12]和杜文博等[13]曾分别研究了元素Nd和Sr对Mg-6Al合金组织结构和力学性能的影响,并对两者的强化效果进行了比较分析,结果表明:将2%~6%的Nd添加到Mg-6Al合金中主要形成Al2Nd、Al11Nd3相,其中后者的析出量明显多于前者的,为主要析出相;添加2%~3%的Sr到Mg-6Al合金中主要形成Al4Sr相。Al11Nd3和Al4Sr主要分布于枝晶界和晶界;在相同铸造条件下,Al11Nd3相的析出温度比Al4Sr相的更高,且比后者更能细化枝晶间距和晶粒度;在相同体积分数下,Al11Nd3对提高合金抗拉强度的效果更为显著,而Al4Sr对提高合金屈服强度和蠕变性能的效果更为显著,但若添加过量的Sr易导致合金抗拉强度较大幅度下降;在相同蠕变温度和时间下,Al11Nd3的热稳定性不及Al4Sr相,且提高合金蠕变性能的效果相对不足。鉴于Nd和Sr对Mg-Al合金力学性能影响效果的不同,且在某些方面具有互补特性,本文作者提出在Mg-6Al合金中复合添加Nd和Sr元素,采用水冷模铸造工艺制备Mg-6Al-2Sr、Mg-6Al-6Nd和Mg-6Al-2Sr-2Nd合金,并分析复合添加后合金的组织结构和蠕变性能的影响。

1 实验

以商业高纯镁、纯铝(>99.99%)为原料,采用熔剂覆盖法在坩锅电阻炉中熔炼合金。电阻炉额定功率为3 kW,炉膛尺寸为d 250 mm×35 mm,石墨坩锅内径为100 mm,深约160 mm。待合金熔体加热到780 ℃时,分别加入Mg-20%Nd中间合金和金属Sr并保温30 min;待Nd和Sr元素完全熔化后,在730 ℃静置5 min后将合金熔体浇注到水冷金属模中。各浇注合金的实际成分由电感耦合等离子发射光谱(ICP)测得,各合金实际成分为Mg-5.7Al-5.9Nd、Mg-5.8Al-1.8Sr和Mg-5.7Al-1.9Sr-2.1Nd,分别记为AJ62、AN66和AJ62-2Nd。蠕变试样采用线切割从铸锭芯部切取。试样为直径5 mm、标距25 mm的标准圆棒。蠕变试验在CSS-3902系列电子蠕变试验机上进行。采用光学显微镜对试验合金进行金相观察。采用XRD、TEM和EDS对合金中各析出相进行分析;采用TEM、SEM和EDS对AJ62-2Nd合金蠕变后的组织进行分析。

2 结果与讨论

各试验合金的金相照片如图1所示。由图1可见,

图1 试验合金的金相照片

Fig.1 Metallographs of experimental alloys: (a) AJ62; (b) AN66; (c) AJ62-2Nd

AJ62合金的枝晶间距为50 μm左右,AN66合金的枝晶间距为10 μm左右。当向AJ62合金中添加2%Nd后,尽管Nd的添加量仅为AN66合金中的1/3,但合金的枝晶间距也被强烈细化,AJ62-2Nd合金的枝晶间距下降到10~15 μm。由于析出相主要析出在枝晶界或晶界上,在AJ62合金基础上添加Nd后,不仅细化了合金的枝晶间距,还显著地提高了第二相的分布密度。

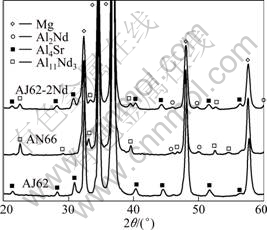

各实验合金的XRD谱如图2所示。由图2可见:在AJ62合金的衍射峰中出现了Al4Sr相;在AN66合金的衍射峰中出现了Al11Nd3相和Al2Nd相,且前者的衍射峰强度较为显著,可认定为主要析出相[10];在AJ62-2Nd合金中出现了Al4Sr、Al11Nd3和Al2Nd 这3种析出相的衍射峰。上述结果均表明Sr和Nd元素添加到Mg-6Al体系中,由于与Al之间具有更强的结合能力,便生成了Al-Sr和Al-Nd析出相,而没有与基体Mg反应[10]。对AJ62-2Nd合金中的析出相进行TEM和EDS 分析,结果表明复合添加Nd和Sr后,不仅形成了Al4Sr、Al11Nd3和Al2Nd相,还形成了Sr和Nd相互取代的复合相。图3和4所示分别为这两种复合析出相的TEM、EDS和电子衍射谱。由图3中的电子衍射谱可认定该相具有Al4Sr结构[14],但EDS分析却表明其成分中含有少量Nd。由图4中的电子衍射谱可认定该相具有Al11Nd3结构[3],但EDS分析却表明其成分中含有少量Sr。为了便于理解这种Nd原子和Sr原子在两种析出相中的相互取代, Al11Nd3和Al4Sr两相的晶胞结构如图5所示。根据它们的晶胞常数,可以发现两者晶胞的a值和c值均非常接近,而Al11Nd3晶胞b值恰为Al4Sr晶胞b值的3倍左右。由图5可见,Al4Sr相晶胞刚好与Al11Nd3相晶胞的1/3相当,尤其是与后者晶胞中间1/3部分结构完全一致。

图2 试验合金的XRD谱

Fig.2 XRD patterns of experimental alloys

另外,Sr原子半径为0.213 nm,Nd的原子半径为0.182 nm,原子半径相差小于15%[15]。以上这些均说明Nd和Sr在Al11Nd3和Al4Sr两种结构完全有可能实现部分相互取代。类似的现象在快速凝固的Al-Ce-Sr合金中也得到证实,发现在Al4Sr析出相中约25%的Sr

图3 AJ62-2Nd合金中析出相的TEM像及能谱分析

Fig.3 TEM image (a), EDP (b) and EDS pattern corresponding to precipitates (c) in AJ62-2Nd alloy

原子被Ce原子取代[15]。本文作者认为,这种取代现象的发生除了析出相结构类似原因之外,还与较快的冷却速率有关。冷却速率加快后可导致合金在凝固过程中溶质元素Al、Nd和Sr向固液界面前沿偏聚加剧[10],3种元素在剩余液相中的浓度迅速上升,造成Nd和Sr分离困难,便与Al反应形成Nd和Sr原子部分相互取代的Al11(Nd,Sr)3和Al4(Sr,Nd)复合相。

图4 AJ62-2Nd合金中析出相的TEM像及能谱分析

Fig.4 TEM image (a), EDP (b) and EDS patterns corresponding to precipitates (c) in AJ62-2Nd alloy

图5 试验合金中部分析出相的晶体结构

Fig.5 Crystal structures of some precipitates in experimental alloys: (a) Al11Nd3; (b) Al4Sr

各实验合金在70 MPa,175 ℃下的蠕变曲线如图6所示。由图6可见,AJ62、AN66和AJ62-2Nd合金在100 h内的总蠕变量分别为0.94%、2.85%和0.12%,AJ62-2Nd合金的总蠕变量分别为单一添加Sr和Nd合金的12.8%和4.2%;3种合金的稳态蠕变速率分别为2.17×10-8、4.2×10-8和1.8×10-9s-1,AJ62-2Nd合金的稳态蠕变速率分别为单一添加Sr和Nd合金的8.3%和4.3%。可见,复合添加Nd和Sr相比单一添加,合金的总蠕变量和稳态蠕变速率均大幅度提高。

图6 在70 MPa,175 ℃下试验合金的蠕变曲线

Fig.6 Creep curves of experimental alloys under applied stress of 70 MPa at 175 ℃

尽管AN66合金中Nd的添加量为AJ62-2Nd合金中Nd的添加量的3倍,但其对合金蠕变性能的贡献却不及后者,表明第二相的数量只是影响合金蠕变性能的一个方面,后者还与第二相本身的性能、形态、大小以及分布等多种因素有关。在AJ62基础上添加2%的Nd对合金组织结构的影响与仅在Mg-6Al添加2%的Nd也存在明显差别,前者不仅增加了第二相的数量,同时还提高了包括Al4Sr相在内的所有析出相的分布密度,并形成了若干新的复合相。对AJ62-2Nd合金在70 MPa,175 ℃下蠕变100 h后的微观组织进行透射电镜观察,如图7所示。由图7(a)可见,这种类似“U”形密集分布的析出相阻滞了位错的运动,导致其附近位错密度上升。而且由于复合添加后合金中析出相分布密度相比AJ62合金大幅度提高,与位错相互作用的几率也将会上升(见图7(b)),合金中出现大量的位错缠结。对7(a)中析出相进行能谱分析(见图7(c)),表明该析出相成分中同时含有Al、Sr和Nd 3种元素,推测为Nd和Sr相互取代的复合相。由此可见,这些高密度分布的复合相与位错之间强烈的交互作用将是提高合金的蠕变抗力和蠕变性能的重要原因。此外,由少量Sr取代Al11Nd3中部分Nd所形成的复合相Al11(Nd,Sr)3相还提高了前者在蠕变过程中的热稳定性,也有力地促进了合金蠕变性能的优化,这部分研究将作另文讨论。

图7 蠕变过程中AJ62-2Nd合金析出相的TEM像以及ESD分析

Fig.7 TEM images of alloy showing interaction between dislocations (a) and precipitates (b) and high density dislocations (c)

3 结论

1) 在Mg-6Al合金中复合添加Nd和Sr导致合金中除了单一添加该两种元素析出的Al2Nd、Al11Nd3和Al4Sr等第二相外,还析出了Sr与Nd相互取代的Al4(Sr,Nd)和Al11(Nd,Sr)3复合相。

2) 在Mg-6Al-2Sr基础上添加少量Nd,相比单一添加Sr元素,不仅大大细化了合金枝晶间距,还显著地提高了所有第二相的分布密度,增强了合金蠕变过程中位错与第二相交互作用,极大地提高了合金的蠕变性能,同时也避免了单一添加Nd对合金蠕变性能改善有限的弊端。

REFERENCES

[1] 黄晓锋, 付彭怀, 卢 晨, 丁文江. Nd对AM50力学性能及高温性能的影响[J]. 材料研究学报, 2004,18(6): 593-596.

HUANG Xiao-feng, FU Peng-Huai, LU Chen, DING Wen-jiang. Influence of Nd on the mechanical properties and high temperature creep properties of AM50 magnesium alloy[J]. Chinese Journal of Materials Research, 2004,18(6): 593-596.

[2] 李克杰, 李全安, 井晓天, 陈 君, 张兴渊, 李肖丰. Y、Nd对Mg-5Al合金组织和性能的影响[J]. 特种铸造与有色合金, 2009, 29(1): 73-78.

LI Ke-jie, LI Quan-an, JING Xiao-tian, CHEN Jun, ZHANG Xing-yuan, LI Xiao-feng. Effects of Y and Nd on microstructure and properties of Mg-5Al alloy[J]. Special Casting & Nonferrous Alloys, 2009, 29(1): 73-78.

[3] WANG Jian-li, YANG Jie, WU Yao-ming, ZHANG Hong-jie, WANG Li-min. Microstructures and mechanical properties of as-cast Mg-5Al-0.4Mn-xNd (x=0, 1, 2 and 4) alloys[J]. Mater Sci Eng A, 2008, 472(1/2): 332-337.

[4] ZHANG Jing-huai, WANG Jun, QIU Xin, ZHANG De-ping, TIAN Zheng, NIU Xiao-dong, TANG Ding-xiang, MENG Jian. Effect of Nd on the microstructure, mechanical properties and corrosion behavior of die-cast Mg-4Al based alloy[J]. J Alloys Compd, 2008, 46: 556-564.

[5] ZHENG Xing-wei, WANG Li-dong, WANG Jian-li, WU Yao-ming, NING Zhi-liang, SUN Jian-fei, WANG Li-min. Microstructure and mechanical properties of Mg-4Al-4Nd-0.5Zn-0.3Mn alloy[J]. Mater Sci Eng A, 2009, 515: 98-101.

[6] GUAN Shao-kang, ZHU Shi-jie, WANG Li-guo, YANG Qing, CAO Wen-bo. Microstructures and mechanical properties of double hot-extruded AZ80+xSr wrought alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1143-1151.

[7] YANG Ming-bo, PAN Fu-sheng, SHEN Jia, BAI Liang. Comparison of Sb and Sr on modification and refinement of Mg2Si phase in AZ61-0.7Si magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 287-292.

[8] PEKGULERYUZ M O, BARIL E. Creep resistant magnesium diecasting alloy based on alkaline earth elements[J]. Mater Trans, 2001, 42(7): 1258-1267.

[9] ALJARRAH M, PARVEZ M A, JIAN Li, ESSADIQI E, MEDRAJ M. Microstructural characterization of Mg-Al-Sr alloys[J]. Sci Tech Adv Mater, 2007, 8(4): 237-248.

[10] YANG Ming-bo, PAN Fu-sheng, CHENG Ren-ju, TANG Ai-tao. Effects of Al-10Sr master alloys on grain refinement of AZ31 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 52-58.

[11] NIU Jie-xin, CHEN Qiu-rong, XU Nai-xin, WEI Zhong-ling. Effect of combinative addition of strontium and rare earth elements on corrosion resistance of AZ91D magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1058-1064.

[12] WU Yu-feng, DU Wen-bo, YAN Zhen-jie, WANG Zhao-hui, ZUO Tie-yong. Microstructure and strengthening mechanisms of Mg-6Al-6Nd alloy[J]. Rare Metals, 2010, 29(1): 55-61.

[13] 杜文博, 吴玉锋, 王朝辉, 左铁镛. 一种Nd、Sr复合强化耐热镁合金及其制备方法: 中国专利200710177466.9[P]. 2009-08-26.

DU Wen-bo, WU Yu-feng, WANG Zhao-hui, ZUO Tie-yong. A preparation method of one creep-resistant magnesium alloy containing Nd and Sr: CN200710177466.9[P]. 2009-08-26.

[14] PARVEZ M A, MEDRAJ M, ESSADIQI E, MUNTASAR A, DENES G. Experimental study of the ternary magnesium-aluminum-strontium system[J]. J Alloys Compd, 2005, 402: 170-185.

[15] ZHANG Z H, BIAN X F, WANG Y. Solidification microstructure and formation of an Al-Ce-Sr alloy under conventional and rapid solidification conditions[J]. J Alloys Compd, 2002, 346: 134-141.

(编辑 杨 华)

基金项目:国家重点基础研究发展计划资助项目(2007CB613706);北京市重点交叉学科资助项目(033000514203)

收稿日期:2009-11-15;修订日期:2010-02-06

通信作者:杜文博,教授,博士;电话:010-67392917;E-mail:duwb@bjut.edu.cn

[9] ALJARRAH M, PARVEZ M A, JIAN Li, ESSADIQI E, MEDRAJ M.

[J]. Sci Tech Adv Mater, 2007, 8(4): 237-248.

[10] YANG Ming-bo, PAN Fu-sheng, CHENG Ren-ju, TANG Ai-tao.

[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 52-58.

[11] NIU Jie-xin, CHEN Qiu-rong, XU Nai-xin, WEI Zhong-ling.

[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1058-1064.